|

|

|

Feb 28, 2021 21:49:25 GMT

|

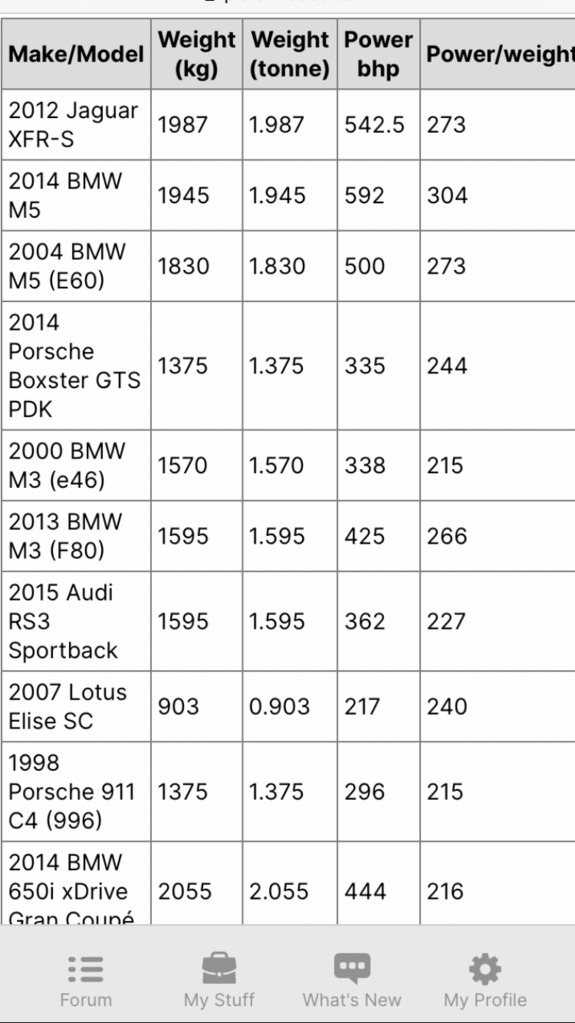

300/tonne put it in serious car territory.  Seriously would need to change a bell of a lot to keep it on the road. But these engines can jump from 200bhp to 300bhp with hardly any mods except a remap. Il already be running a larger than stock intercooler, exhaust, intake and fuel pump. So apart from a map and injectors I could push for 300+ if I really wanted to explode in to hell 🤔 |

| |

|

|

|

|

|

|

|

Any updates on this? Need my fix  |

| |

|

|

|

|

|

Jul 31, 2021 22:51:57 GMT

|

Any updates on this? Need my fix  I am sorry about lack of any progress for the last few months. Had my hands full with work and house renovations but fingers crossed il have some time to get back to the triumph. Engine is sat in with mounts so can start mocking up the inlet and exhaust manifolds when I start back on it. |

| |

|

|

|

|

|

Oct 18, 2021 23:10:34 GMT

|

We have progress. Life has been a bit all over the place recently but with the dark nights diy and landscaping has to wait till next year. Off to the garage I go. So to recap. Engine is pretty much all sat in bar some tiny extra clearancing on the crossmember. Mounts were half made and middle of the night scribbles on bits of paper were in full flow. So tonight the mounts were finished up allowing me to fit the clutch peddle to see if the inlet manifold would fit. It didn’t.  Chop chop and see what we can work out.    I’m thinking 4 x 90* elbows welded to the original inlet then a tube sat along the top and the throttle body flange welded to the end. Not ideal in terms of flow but as I’m not pushing huge power I’m hoping a smoothed out internal wall and a radius on the edges should make it workable. |

| |

|

|

|

|

|

Oct 20, 2021 20:57:00 GMT

|

Got the engine mounts all tidied up and bolted back on tonight.   Ive chopped up the old inlet manifold too. Going to reuse the flange and injector rail and reuse the throttle body flange.  Hopefully I get time tomorrow to nip by my mates so he can pass the milling machine over the top to clean them up and to make sure the edges I’m welding to are true. Just got to order my aluminium 3” tube and the 90* elbows in the morning. |

| |

|

|

|

|

|

Oct 20, 2021 21:36:43 GMT

|

Hell yeah updates  glad to see you're still working on the car inbetween house stuff Must learn to weld aluminium. Makes cutting and re-making inlet manifolds a much easier proposition. Although I suppose you could go for silicone elbows... Engine mounts are looking good too. Nothing like speed holes to make something look more professional  |

| |

|

|

|

|

|

Oct 31, 2021 22:17:02 GMT

|

So the 45mm od 90* elbows are out of stock in the uk depot so are being shipped from German. Not ideal but they are on route. So not to pass up a Sunday afternoon I plodded on with bodywork. Fitted the new bonnet stop rubber cones and dialed in the gaps best I could. Now the shell has had new sills fitted previously which explains why there isn’t any rust on them but after getting the bonnet and door aligned best I could it appears the sills have been fitted to far forward. So either remove the whole sill or cut and alter the bits that don’t quite line up.    This shows how the door fits 90% right but the bottom of the front edge on the door to sill is way off. If I move the bonnet further forward the bonnet to scuttle gap is far to large. So out with the wurly sparky machine.   Bit extreme but didn’t actually take that long.   Put a bit of primer on just to help show the new gap. The bottom of the door corner needs a bit of work but I can shape the edge of the door with the file when I work on the door.   Same approach to the bonnet wheel arch to front edge of the sill area. That’s as far as I got as the little lad needed taking trick or treating. Il get back on that after work one night mid week. |

| |

|

|

|

|

|

|

|

Much improved  how much bodywork do you think there is to do on it? |

| |

|

|

glad to see you're still working on the car inbetween house stuff

glad to see you're still working on the car inbetween house stuff