|

|

|

Dec 11, 2018 14:45:58 GMT

|

I've got a wideband gauge fitted in my three gauge panel, think it's pictured somewhere on the thread, along with a boost gauge. I was thinking of maybe adding a fuel pressure or oil pressure gauge for the third... Does the mx6 have an oil cooler? Because you will be adding quite a lot of heat with the increased power and the turbo. An oil temperature gauge would be my preferred 3rd gauge. Besides that, awesome project, looking forward to seeing it completed! |

| |

|

|

|

|

Kieran

East of England

Posts: 148

|

|

Dec 11, 2018 16:57:35 GMT

|

|

Thanks! No, the MX6 doesn't have an oil cooler as standard, it's a good point about the extra heat that will be produced. I can see that it could well be worth monitoring the oil temp as you suggest, to see if fitting an oil cooler could be necessary.

I've done some restoration work to the standard cooling system by fitting new temp sensors, new thermostat and I've a new radiator to fit as well. Bedsides that I haven't taken an additional steps to improve oil or coolant cooling beyond standard.

I've researched what others have done when turbo charging an MX6 and I've not seen any mention of fitting an oil cooler, that obviously doesn't mean that it definitely wouldn't be required for my car of course, only that there doesn't seem to be a common issue as such. Saying that, it's not a well documented conversion so there's not lots of information out there, it's only guys in the US that I've come across.

|

| |

|

|

|

|

|

Dec 11, 2018 17:52:17 GMT

|

I wouldn't worry too much about the coolant cooling system, most of the time in OEM applications it's capable enough to handle the extra couple of hp. But the oil also cools and lubricates the turbo, which courtesy of the exhaust gases, can get really hot in a really short amount of time. The oil temperature in my Subaru turbo car rises with normal driving almost as fast as the coolant temperature! In reality though, you probably have enough cool oil running around the engine and in the sump that this won't be a problem. In normal driving you actually don't use the turbo that much and EGT will be quite low. This heat cycling will degrade the oil quicker though. If you were to load the engine for prolonged periods (trackdays?) you could run out of cool oil though with all the consequences that this brings. Fitting a gauge allows you to make an fact-based decision whether you need a cooler  |

| |

|

|

|

|

|

Dec 11, 2018 22:28:45 GMT

|

|

It should have a water to oil cooler built in above the filter. All my k series engines do. I don't know how effective it is and I removed it on the Viva as it gave me the filter clearance I needed.

|

| |

|

|

Kieran

East of England

Posts: 148

|

|

Dec 12, 2018 13:12:22 GMT

|

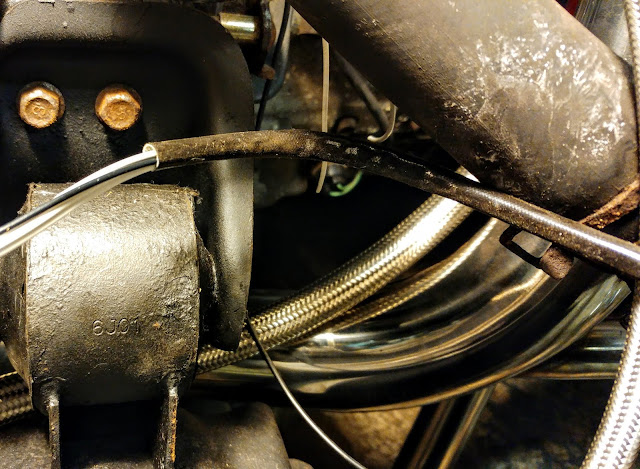

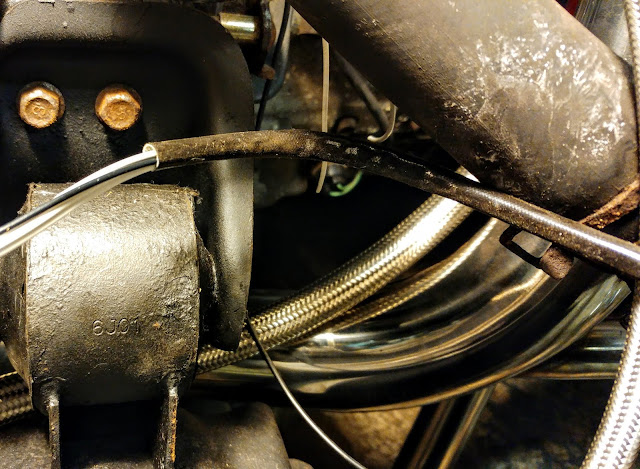

It should have a water to oil cooler built in above the filter. All my k series engines do. I don't know how effective it is and I removed it on the Viva as it gave me the filter clearance I needed. I hadn't thought to mention that but yes it does have that means of oil cooling as you say. I might have posted the pic' already but here are the coolant lines that run into the housing above the oil filter.  Do we think this would be the best position for an oil temp sensor for a gauge measuring such? There are two used ports in the sandwich plates that I could use, the other is obviously for the turbo oil feed line. |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Dec 12, 2018 13:37:48 GMT

|

As good a place as any, and it is already tapped for a sensor or oil pipe  I would be inclined to make a heat shield or get a sleeve over the coolant hose near to the manifold primary though  |

| |

|

|

|

|

|

|

|

Ditto that man ^. O and while you are there I vote you give that block a scrub too  |

| |

|

|

Kieran

East of England

Posts: 148

|

|

Dec 13, 2018 10:43:54 GMT

|

|

Thanks for the comments. I understand what you're saying regarding a heat shield for the hose as the manifold pipes do now run closer, it should look at sleeving it with something as you suggest, seems a sensible move.

Yes the block is very grubby due to the previously leaking valve covers dropping oil over everything (common KL issue), I would like to give it a proper clean. I already feel like things have escalated quite a lot from where I started out! I've been side tracked with various activities like replacing worn parts, painting stuff, so I need to draw a line for now I think. I would have liked to pull the engine out to go over things more thoroughly and get everything properly clean and tidy, redo the wiring harness, etc. but I have been more time limited than I would have liked which is a little frustrating - I do like a bit of a project but I've given myself quite a lot to do...

I can see light at the end of the tunnel though so I have that motivation and excitment to get the turbo conversion built and the engine running again, then I want to revisit various areas to make further improvements and get it all cosmetically up to stratch.

|

| |

Last Edit: Dec 13, 2018 10:45:16 GMT by Kieran

|

|

|

|

|

Dec 13, 2018 19:18:55 GMT

|

|

When I rebuilt one of my engines I fitted a complete new gasket set, as one does. However- the nice new shiny cam cover seals didnt work very well. I refitted the old Mazda ones and they worked better. So as often is the case the OEM products were better in use, even though old.

The moral of this story?...

I'm not sure actually. Try different seals or fit Mazda if in doubt?

I'll leave now and get back to my breakfast..

|

| |

|

|

Kieran

East of England

Posts: 148

|

|

Dec 14, 2018 11:07:47 GMT

|

|

I used generic cam cover seals that were cheap on ebay, but I put quite a bit of RTV silicone sealant both sides as well. I've heard that problems with the PCV valve failing to open can cause pressure to build up inside the crankcase and blow the cam cover seals, so I replaced that we a new one as they are only a couple of quid. It usually connects to the intake but I have it setup to vent to atmosphere now. I may connect it to a catch can when the turbo conversion is complete, depends how bad the blow-by is!

|

| |

|

|

|

|

Kieran

East of England

Posts: 148

|

|

Jan 15, 2019 14:11:02 GMT

|

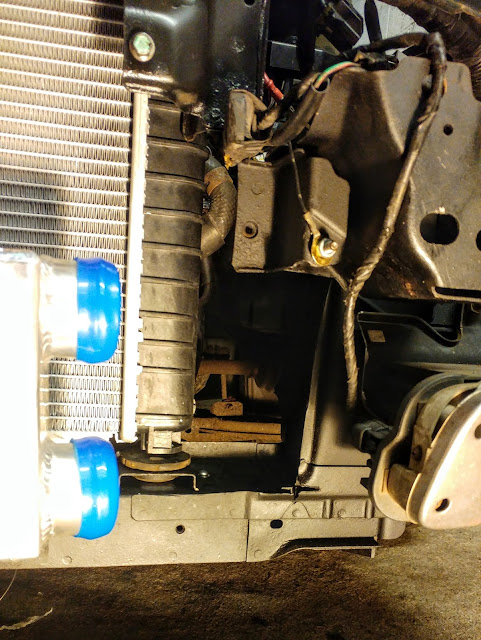

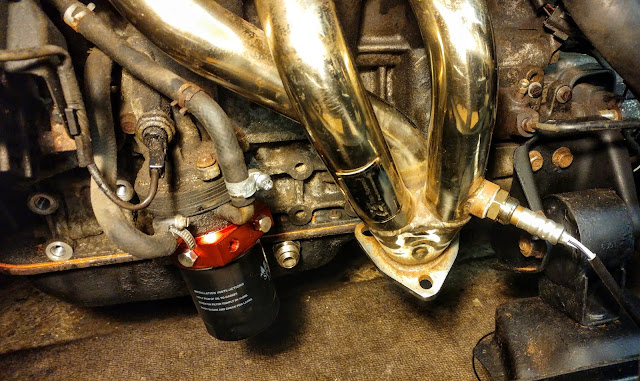

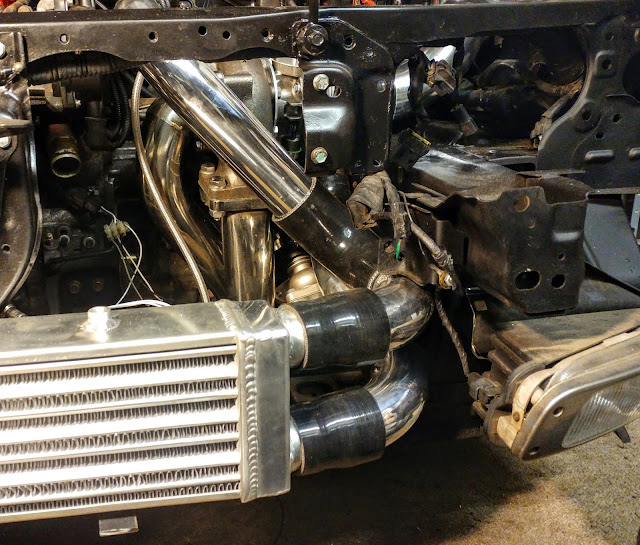

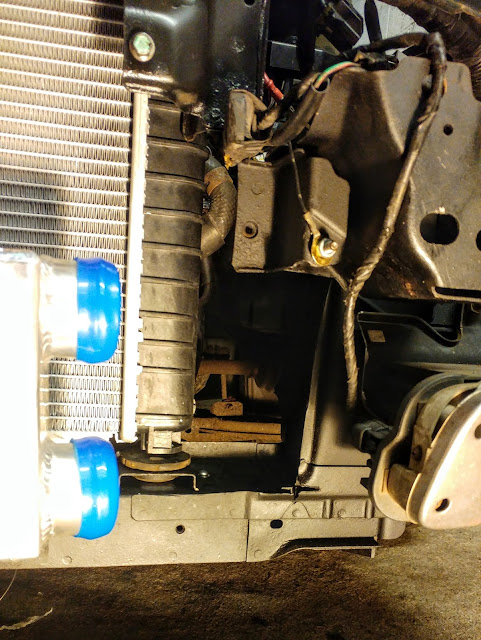

I'm now getting back on the turbo project following the Xmas hiatus, I was abroad for a few weeks over the holiday period so haven't made any progress for over a month. Feeling motivated again to get the thing on the road for late spring so will be pushing it over the next couple of months. The new radiator was trial fitted, I've changed the position of the rad mounts to relocate them to the left somewhat. This allows an opening for the charge pipes to pass through at 90 deg to the intercooler and emerge into the space directly below the turbo. As I'm using a same-side intercooler it will give nice short pipe length.   The oil sump was installed, plus got the exhaust manifolds properly on with the new gaskets and lambda sensors.  I received a couple of newly ordered parts recently. Bought the high pressure fuel pump as the standard one won't flow enough fuel when the engine is on boost. I also got a new cat as the old one had seen better days. I had a problem getting the '6 to pass MOT emissions previously so I'm hoping the new lambda sensors and cat will help sort things in that regard. The turbo shouldn't affect things as it won't be boosting for the idle and fast idle test.   |

| |

Last Edit: Jan 15, 2019 14:12:15 GMT by Kieran

|

|

Kieran

East of England

Posts: 148

|

|

Feb 11, 2019 13:01:37 GMT

|

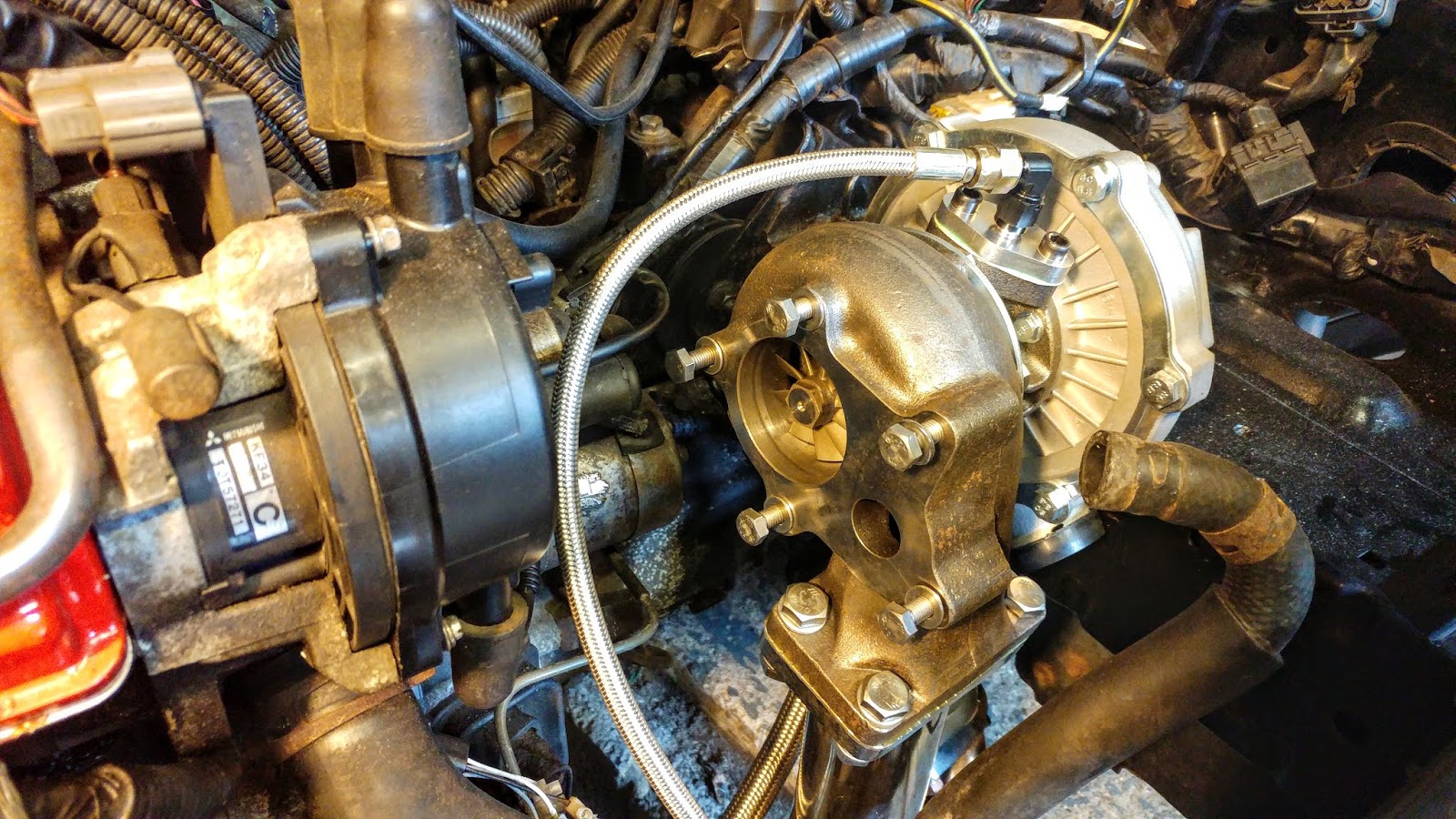

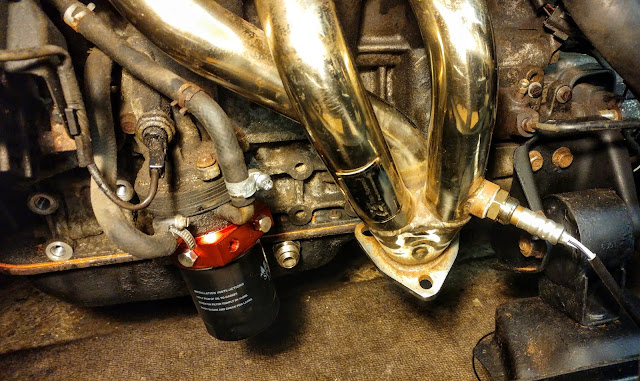

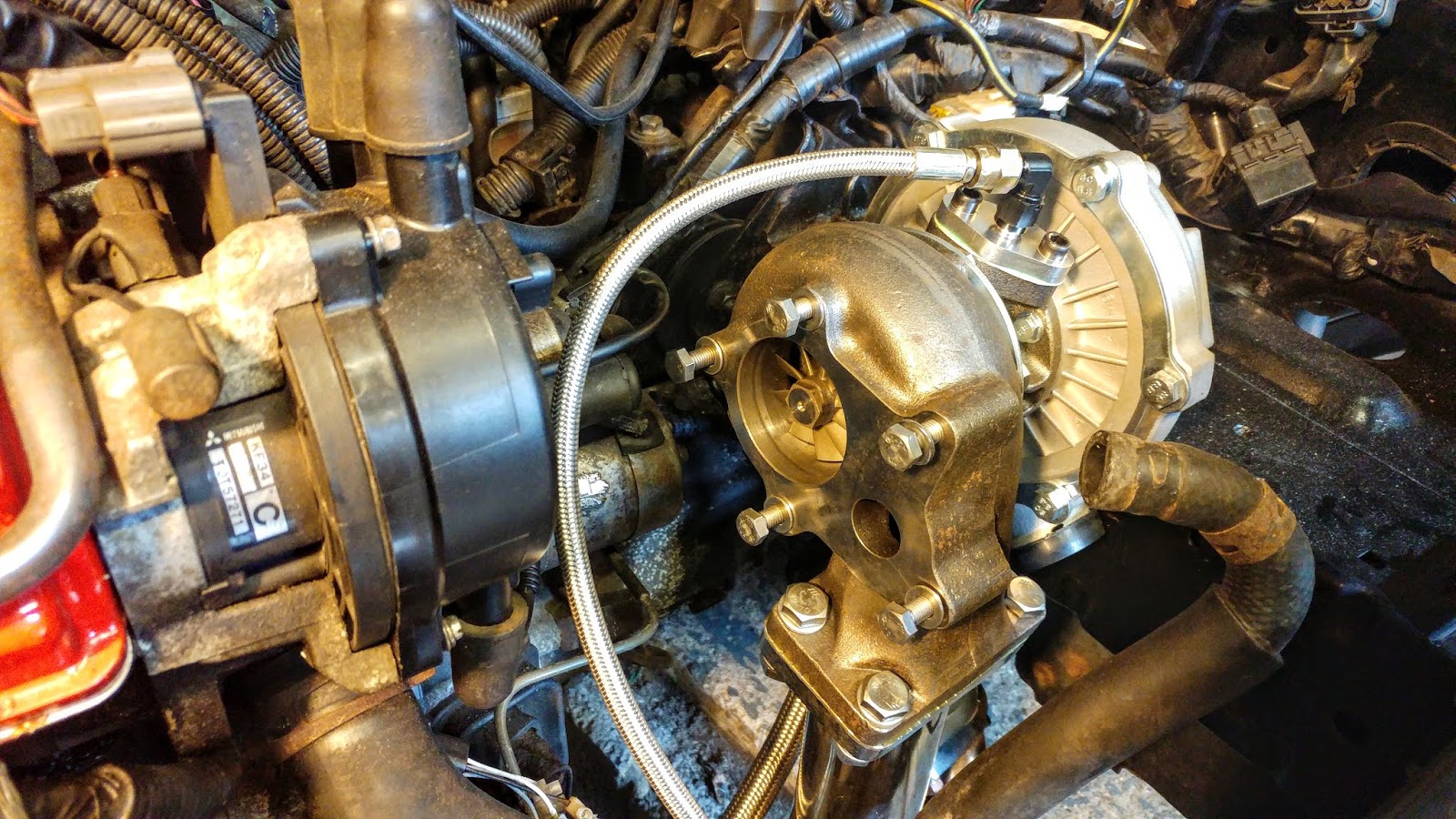

I've been nibbling away at things when time has allowed. I got the turbo and exhaust properly mounted up, I had to cut down some of the bolts I had to a suitable length for installation. Plus I fitted the oil feed and return lines.  I found that the 10AN drain line that came in the ebay kit I bought was a bit short for my setup, since the turbo is offset to the side of the engine. I was able to connect it up but I had to route it over the collector pipe to fit, which is was touching against.  Also the drain connector that fits to the bottom of the turbo touched against the wastegate housing, so I want to buy a 45deg one in place of this 60deg one I have. I will buy a longer line and route it around the front of the exhaust piping.  I received and fitted the third and final gauge I wanted, this is to monitor oil temp and sits along side the boost and AFR gauges in the 3 way panel.  |

| |

|

|

Kieran

East of England

Posts: 148

|

|

Feb 11, 2019 13:03:47 GMT

|

|

|

| |

|

|

|

|

|

Feb 12, 2019 13:45:13 GMT

|

|

This is cool, can't wait to see what it goes like!

|

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Feb 12, 2019 13:56:54 GMT

|

Very nice bit of progress there  Would it be better for the intercooler to inlet manifold pipework to go the other side of that brace bar and over the air intake side of the turbo? Looks like it may suffer a bit of heat soak to me, and the distributor is close to the turbo downpipe  |

| |

|

|

|

|

|

Feb 12, 2019 18:30:35 GMT

|

Beautiful and brave project. I think you should go full mental, BTCC style, and mount the engine low and run the driveshaft through the middle of the V...!  |

| |

|

|

|

|

|

Feb 12, 2019 19:23:09 GMT

|

|

Oh, I am a little biased on these. I had a thing for my mate's mum when I was at school, and she drove one of these...

|

| |

|

|

Kieran

East of England

Posts: 148

|

|

Feb 12, 2019 20:32:35 GMT

|

This is cool, can't wait to see what it goes like! Thanks. 👍 I'm quite impatient to see how it goes too as it's taken me longer than I hoped to get through the work. I feel like it's getting there now though, I can see the light and the end of the tunnel so to speak. I'm at that stage where I just want to get it running and on the road with a basic low-boost setup, and then I will continue to develop/improve things where necessary/desired. |

| |

|

|

Kieran

East of England

Posts: 148

|

|

Feb 12, 2019 20:45:45 GMT

|

Very nice bit of progress there  Would it be better for the intercooler to inlet manifold pipework to go the other side of that brace bar and over the air intake side of the turbo? Looks like it may suffer a bit of heat soak to me, and the distributor is close to the turbo downpipe  Thanks for the comments, yes I'd agree that it doesn't look ideal. This seemed like the best way to route the piping in terms of it being the easiest path with the least bends and shortest pipe length, but it is close to the turbo as you say. I have seen at least one other MX6 V6 turbo with the intake pipe routed in that position, but that obviously doesn't mean it is optimal. I thought that I might get a turbo blanket to help keep the temps down. The distributer is close as well yes, I don't think I can practically do much about that at the moment, but down the line I'd like to try converting to coil packs run with an aftermarket stand alone ECU so the dissy won't be required. |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Feb 12, 2019 21:08:47 GMT

|

Very nice bit of progress there  Would it be better for the intercooler to inlet manifold pipework to go the other side of that brace bar and over the air intake side of the turbo? Looks like it may suffer a bit of heat soak to me, and the distributor is close to the turbo downpipe  Thanks for the comments, yes I'd agree that it doesn't look ideal. This seemed like the best way to route the piping in terms of it being the easiest path with the least bends and shortest pipe length, but it is close to the turbo as you say. I have seen at least one other MX6 V6 turbo with the intake pipe routed in that position, but that obviously doesn't mean it is optimal. I thought that I might get a turbo blanket to help keep the temps down. The distributer is close as well yes, I don't think I can practically do much about that at the moment, but down the line I'd like to try converting to coil packs run with an aftermarket stand alone ECU so the dissy won't be required. Ah, that is fair enough then  My comments weren't meant to dishearten you, just observations. The turbo blanket should help quite nicely though, especially with some exhaust wrap on the neccessary areas  |

| |

|

|

|

|