sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Aug 29, 2019 17:06:39 GMT

|

|

And here's another video from the offroading trip

Both the 88" and Discovery have mud tyres, though not as aggressive as my Insa Turbo Special Tracks, and are both tdi's. I find it funny how both struggle through the mud hole yet my 109 powers through with no loss of momentum!

|

| |

|

|

|

|

|

|

|

Sept 2, 2019 19:15:09 GMT

|

WOW what a thread this is, retro landy build thread... I'm HOME  I'm gutted I cant access the videos to hear this beasty box burbling along, damn work internet but I will make sure I find a way to access them somehow! anyway I've got more thread to catch up on, it fantastic! |

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Sept 15, 2019 19:38:29 GMT

|

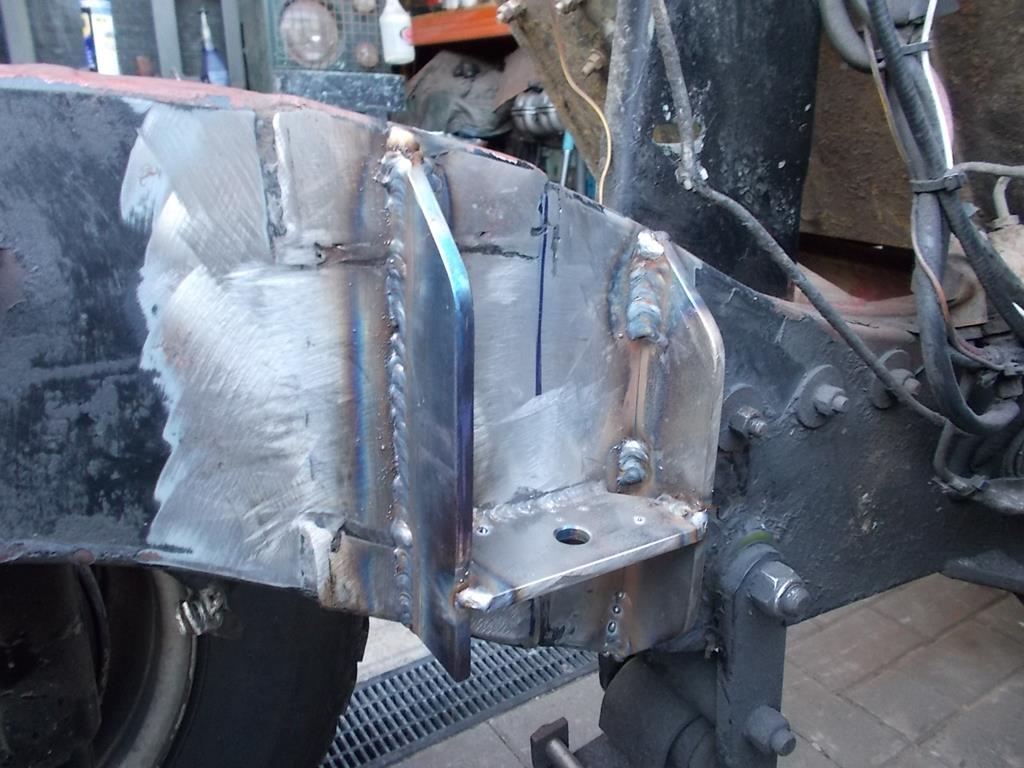

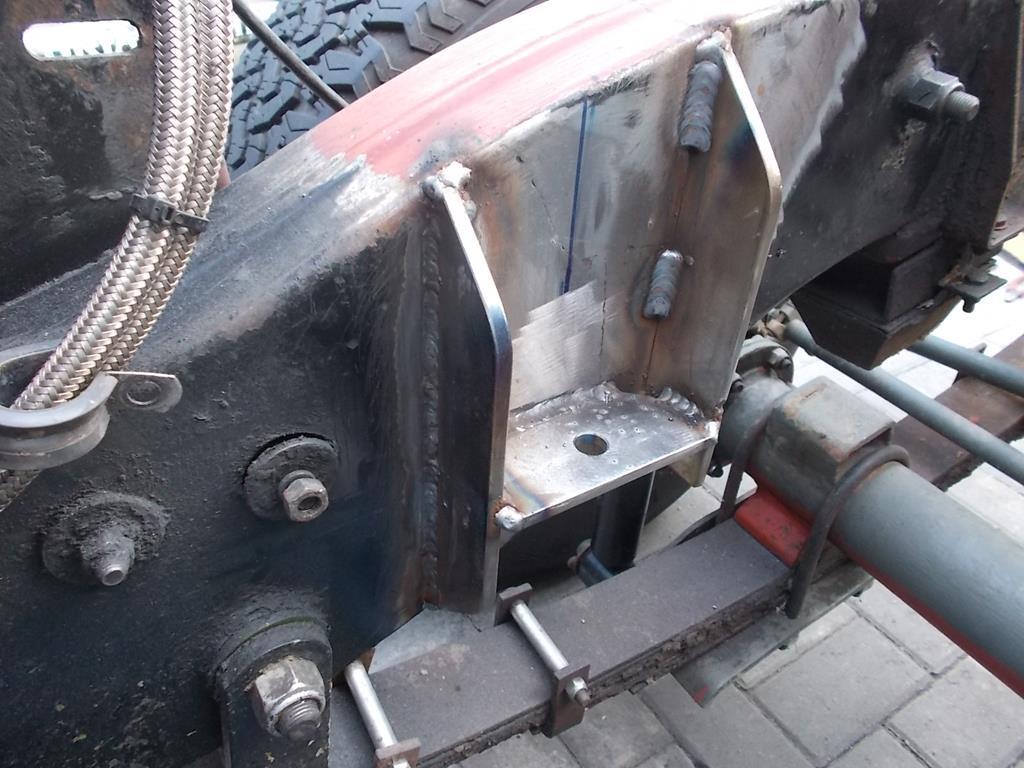

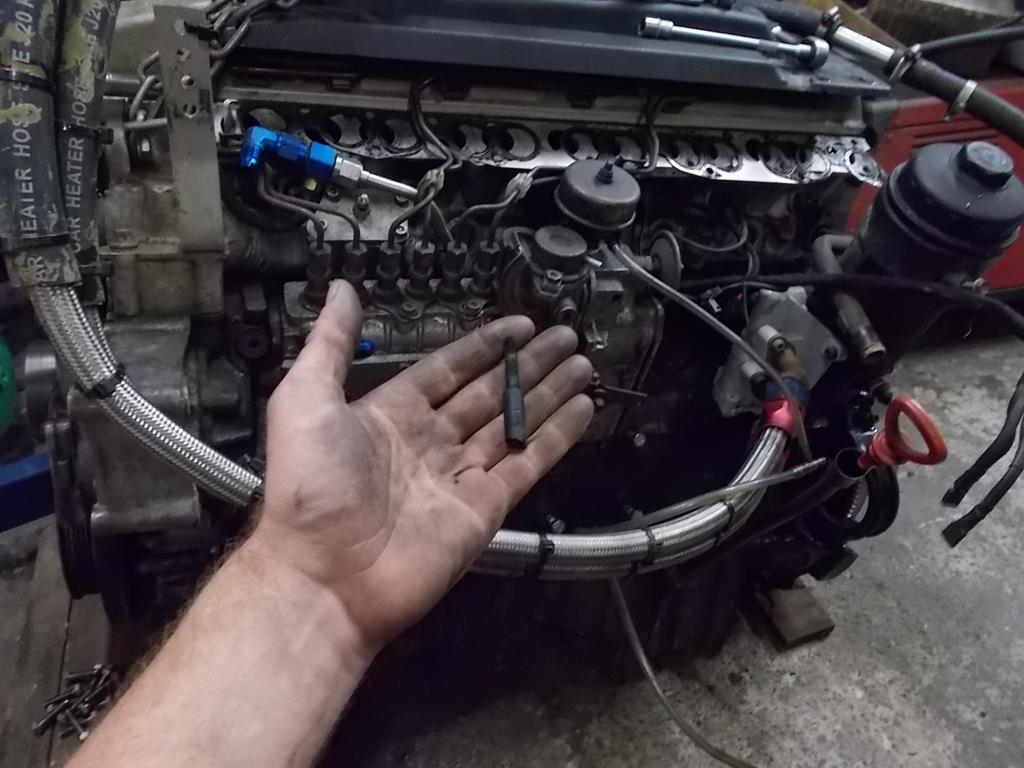

If anyone had watched any of the longer vid of me driving about the farm then they would've heard a screech when changing gear. This screech mysteriously began the day before the offroading weekend and has been steadily getting worse. Expecting the worst with a failed clutch release bearing I ordered a heavy duty one and happily it arrived with an aluminium carrier instead of the standard plastic carrier which is known to melt and fail without warning. Having finished off paving the area infront of the garage during the week I could now devote some time to pulling the engine out of the Land Rover to replace the bearing and do some other minor jobs, plan being to have it all back together by the end this weekend. I've been buying up a few things, so set them out ready to fit. A new water pump with metal impeller, a wastegate, new clutch release bearing and a Detroit Truetrac for the rear   Off with the front wings, radiator, intercooler etc for access   And out came the engine revealing the failed release bearing      Looks like the bearing had seized and was spinning on the plastic carrier. It's caused a little damage to the pressure plate fingers too. The bellhousing was cleaned up and the new release bearing greased up and fitted  Since I've done approximately 7000 miles with this setup that was thrown together from junk as a trial I thought it best to investigate further as to why the pressure plate fingers were sitting odd. Off it came and out came the friction plate which looked as good as it did when I bodged it up years back to get it to fit the Land Rover gearbox!  But look closer.....  It's cracked in a few places around the outside. I have no idea how long it'll last, maybe a few hard launches or thousands of miles? Anyway, I have a spare Sprinter single mass flywheel which I was planning on preparing to fit when I eventually get round to rebuilding my spare R380 gearbox. It only needs a spigot bush turning up in the lathe and an uprated friction plate which I'll order in the week.  So with the engine now stuck out of the Land Rover, I removed the water pump expecting the impeller to be plastic and falling apart....  And no, it's metal, and is bigger than the impeller in the new spare water pump! As there's nothing wrong with the old water pump that's going back in, and now I know it's a relatively easy job to replace should I ever need to. Then there's the wastegate, or lack of. I've seen 27psi, and usually that's about the point where the engine blows a hose off, but it doesn't feel any faster over 20psi. I've taken the old vacuum wastegate off and made a simple bracket to hold a tdi wastegate on. This should help preserve the turbo and transmission  And since the engine isn't going immediately back in, and one of the old engine mount rubbers was beginning to collapse I've chopped the brackets off the chassis and plan to fit 300tdi rubber mounts      Now I've got to order up numerous spare parts and metal so I can crack on with fixing the clutch, making the new engine mounts and shimming the locking diff. Since it's all in pieces and not going anywhere I may also make up the transfer box levers, make a new stainless hard intake pipe under the inlet manifold, plumb the raised air intake in and revisit the glowplugs.... |

| |

|

|

|

|

|

Sept 16, 2019 19:08:35 GMT

|

|

....and the winter work begins! Watching with interest as you’ve made me want one albeit OM605 flavour...I don’t think this thread covered the engine transplant and gearbox mods/ install is it on another?

|

| |

Got a garage now but still no car. Plenty of ideas tho!

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Sept 16, 2019 21:16:34 GMT

|

....and the winter work begins! Watching with interest as you’ve made me want one albeit OM605 flavour...I don’t think this thread covered the engine transplant and gearbox mods/ install is it on another? Yep, the annual winterisation! Doing far more than planned, but all part of the long term plan hence having half of the parts already. I've got all the pics on my laptop of the conversion, and will eventually be doing a second custom bellhousing to suit the different length of the stubby R380 input shaft. That job has been pushed down the list since the LT77 is coping admirably, and with a sprung friction plate on order to replace the welded dual mass and solid friction plate combo should last a fair bit longer without any attention. All the pics were on my other Land Rover thread, but it could be worth my effort now I know what does work to put something together here? |

| |

|

|

|

|

|

Sept 17, 2019 13:25:22 GMT

|

|

All the pics were on my other Land Rover thread, but it could be worth my effort now I know what does work to put something together here?[/quote]

Yes please!

|

| |

Got a garage now but still no car. Plenty of ideas tho!

|

|

scimjim

Club Retro Rides Member

Posts: 1,503

Club RR Member Number: 8

|

|

Sept 17, 2019 14:27:58 GMT

|

|

WHS ^^^ 😀😀

|

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Sept 23, 2019 21:42:56 GMT

|

|

|

| |

Last Edit: Sept 23, 2019 21:43:45 GMT by sowen

|

|

loudsam

Part of things

Posts: 50

Club RR Member Number: 138

|

|

Sept 24, 2019 10:08:30 GMT

|

|

Nice work that mate and a proper engine in a Landy 👍🏻

|

| |

|

|

|

|

|

Sept 25, 2019 20:08:22 GMT

|

cracking work  ive been eyeing up a tru-trac for mine actually, well i think i have, its the gear based auto torque biasing one? (similar to quaife, torsen etc) for me its the only one that comes in 10 spline rover flavour. |

| |

|

|

|

|

|

|

|

|

|

cracking work  ive been eyeing up a tru-trac for mine actually, well i think i have, its the gear based auto torque biasing one? (similar to quaife, torsen etc) for me its the only one that comes in 10 spline rover flavour. Go for the 24 spline Ashcroft ATB truetrac copy. They also do 24 spilne HD half shafts for series rear axles which solve all the problems. |

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

cracking work  ive been eyeing up a tru-trac for mine actually, well i think i have, its the gear based auto torque biasing one? (similar to quaife, torsen etc) for me its the only one that comes in 10 spline rover flavour. Yes this is the geared one. Some good and bad reviews on Youtube, though some of the better vids show the wheel spinning then 'locking' which is what I want. I've noticed there isn't much offered for 10 spline diffs anymore. Not suprised as the shafts are tiny and everything post 300tdi as far as I know is 24 spline? cracking work  ive been eyeing up a tru-trac for mine actually, well i think i have, its the gear based auto torque biasing one? (similar to quaife, torsen etc) for me its the only one that comes in 10 spline rover flavour. Go for the 24 spline Ashcroft ATB truetrac copy. They also do 24 spilne HD half shafts for series rear axles which solve all the problems. No good when 10 spline is the only option available like on a front axle, unless loads of money is spent on custom shafts etc. It is good however that Ashcroft are selling uprated 24 spline Rover type shafts for the series models, though even with series Landy's climbing in value, too many owners are penny pinching and will happily snap shaft after shaft rather than invest in something that won't break! |

| |

|

|

|

|

|

|

|

cracking work  ive been eyeing up a tru-trac for mine actually, well i think i have, its the gear based auto torque biasing one? (similar to quaife, torsen etc) for me its the only one that comes in 10 spline rover flavour. Yes this is the geared one. Some good and bad reviews on Youtube, though some of the better vids show the wheel spinning then 'locking' which is what I want. I've noticed there isn't much offered for 10 spline diffs anymore. Not suprised as the shafts are tiny and everything post 300tdi as far as I know is 24 spline? Go for the 24 spline Ashcroft ATB truetrac copy. They also do 24 spilne HD half shafts for series rear axles which solve all the problems. No good when 10 spline is the only option available like on a front axle, unless loads of money is spent on custom shafts etc. It is good however that Ashcroft are selling uprated 24 spline Rover type shafts for the series models, though even with series Landy's climbing in value, too many owners are penny pinching and will happily snap shaft after shaft rather than invest in something that won't break! you know what, i must have looked at that page 10-15 times and not even considered the 24 - 24 shafts were an upgrade for rover axles. i'd assumed they were HD salisbury versions (not that i'm saying they need HD'ing, in most cases they are the HD !) being post 1980 i already have 24 spline outer ends (so would not need the conversion parts) plus the cost saving between detroit and ashcroft would pay for HD shafts. |

| |

Last Edit: Oct 4, 2019 9:22:29 GMT by darrenh

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

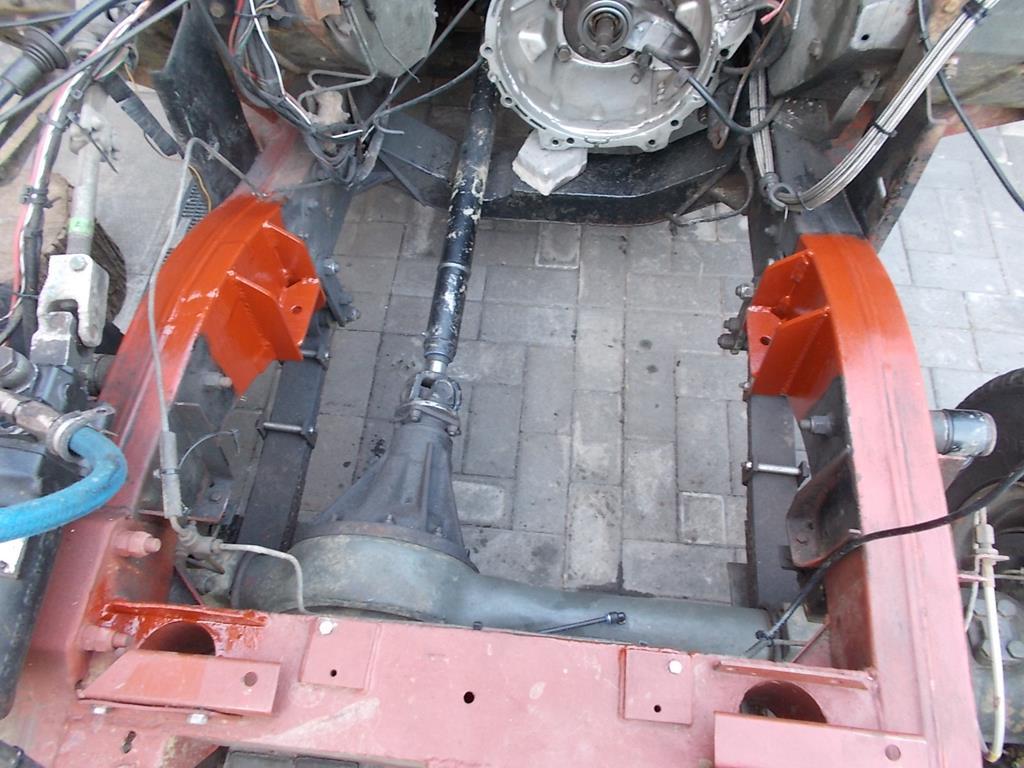

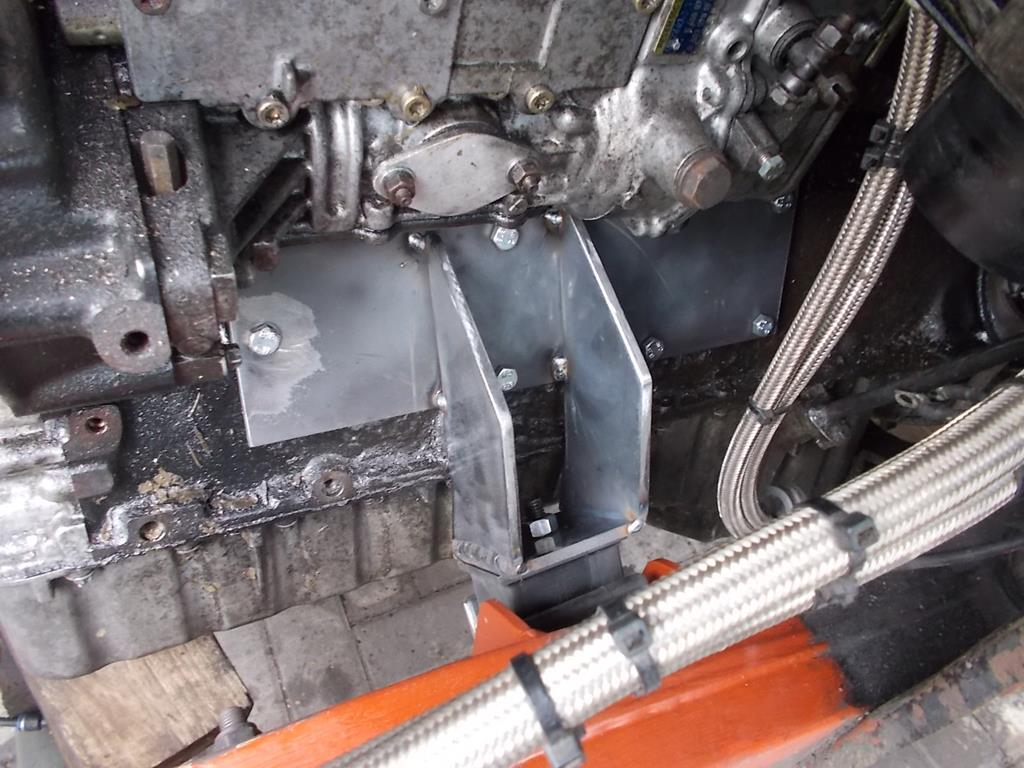

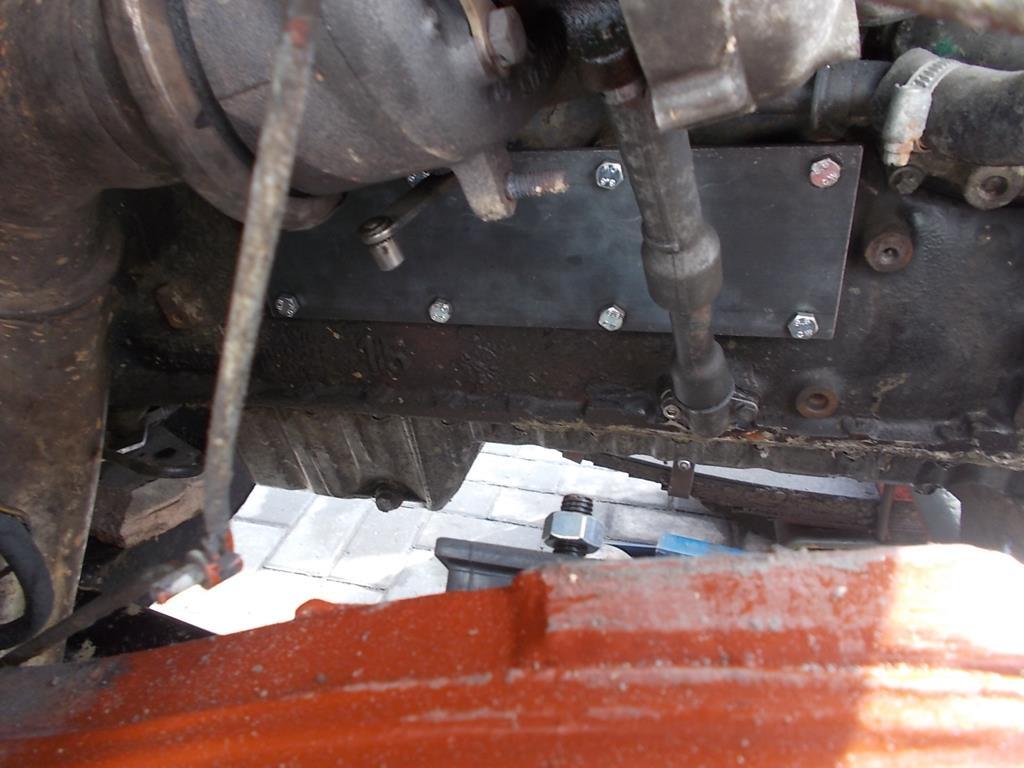

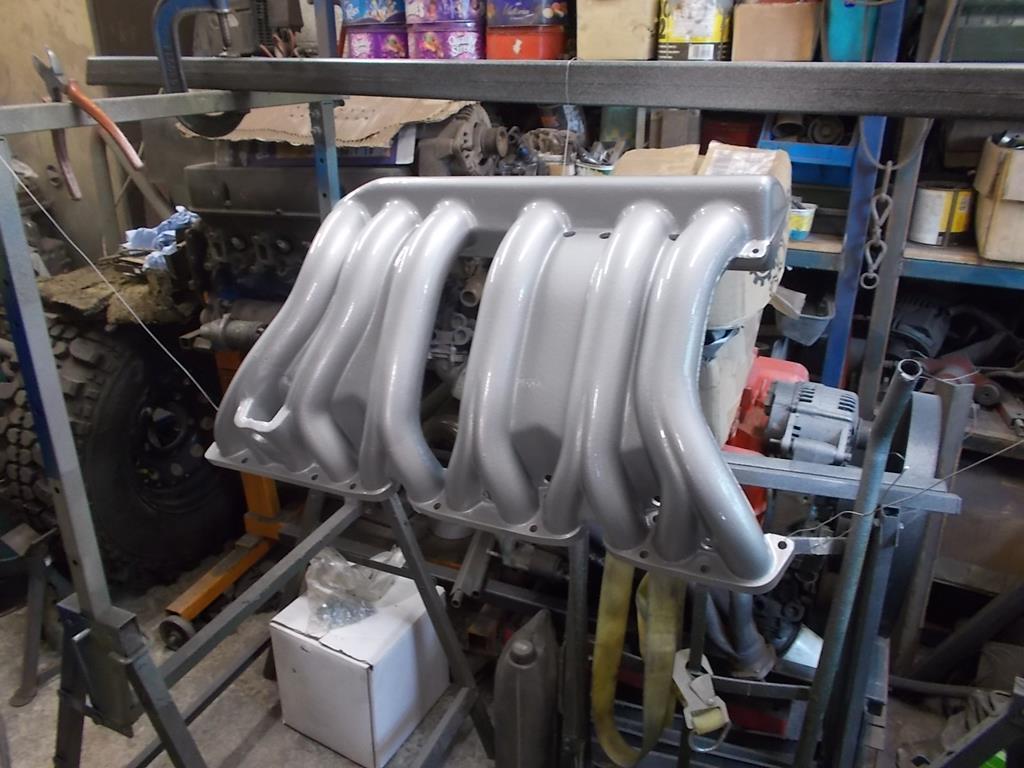

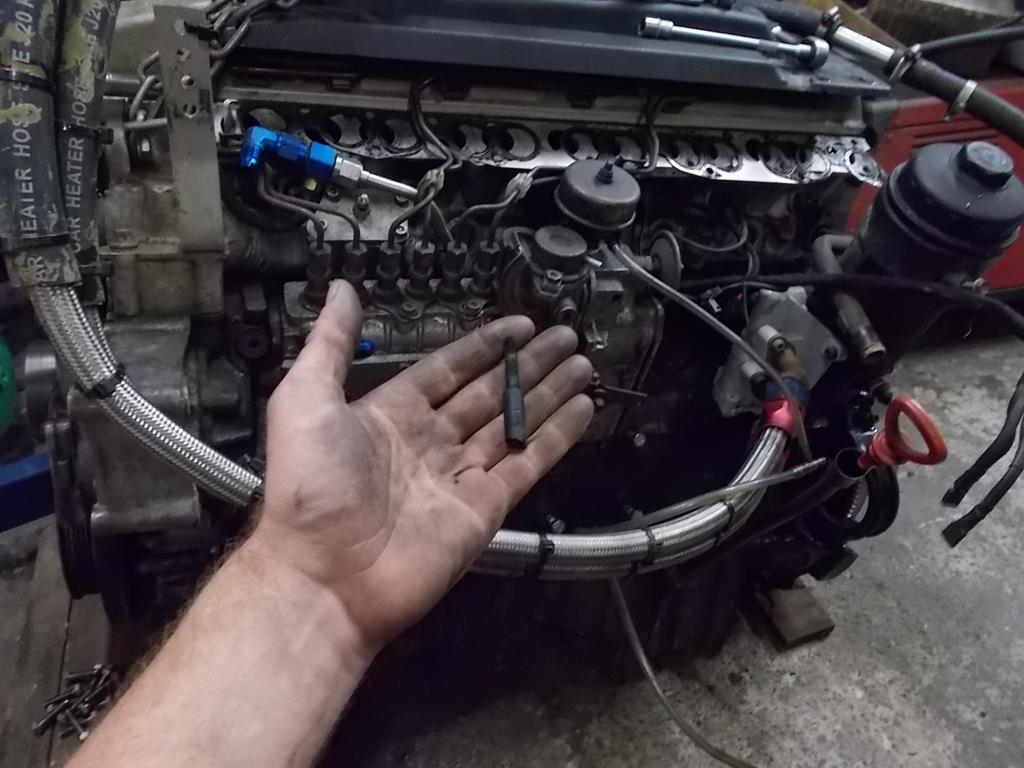

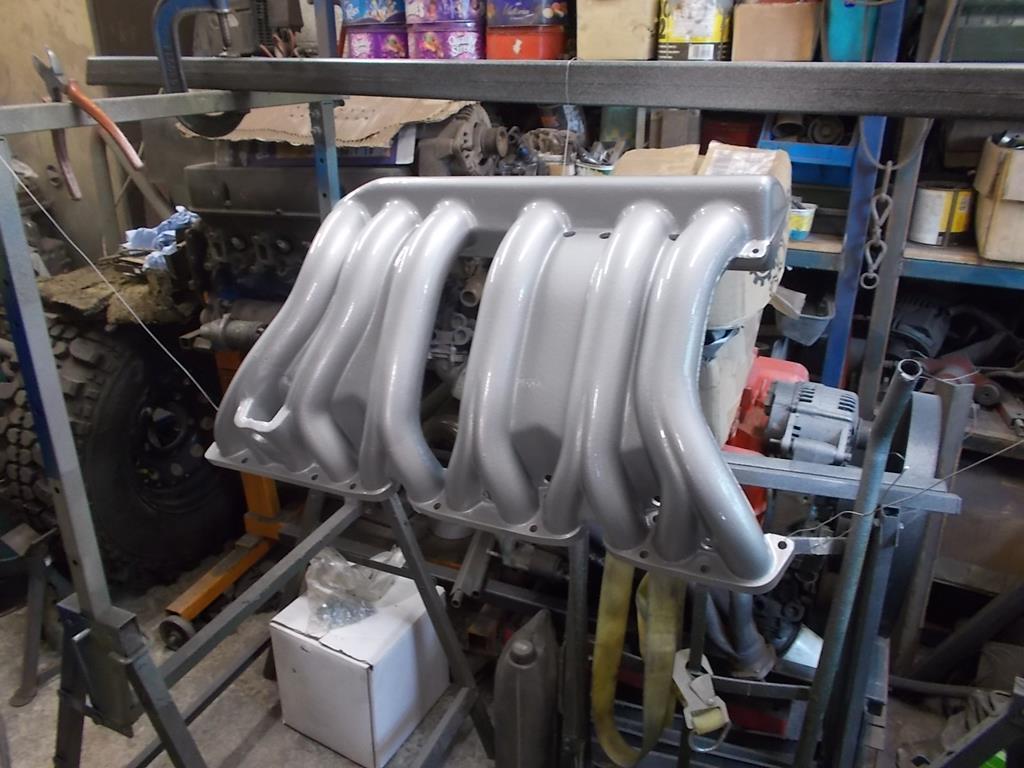

Engine mounts painted black and ready to be fitted   With the engine sat back in the garage waiting I've taken the inlet manifold and oil filter housing off, run them through the blast cabinet at work and put a few coats of epoxy primer on them   With the previous saga of the broken glowplug being aborted and a plug screwed in over the top, I had access to remove the plug and have a second attempt at removing the remains. I had noticed a 'ticking' sound had appeared on the engine at idle on the drive down to RRG and was hoping it was the glowplug unseizing itself in the head and leaking. Luckily I was right and it literally hooked out with no effort!  Next job waiting for the clutch was to make a new spigot bush to go in the flywheel. I bought a bar of phosphor bronze and set to work in the lathe....  Pressed the bush into the flywheel then bolted it on    Had a go at another broken glowplug, this time leaving it to soak in Plusgas with the diy extractor left loaded up. I'm impressed, after one night it had softened the carbon buildup enough that it pulled out with little effort!  Parcel arrived with the new 600lb/ft rated 9.5" clutch   Clutch, inlet manifold and oil filter housing all bolted back on the engine ready to lift it back into the 109   Engine bolted back in on the new mounts   And then it was the Newbury 4x4 jumble last weekend. I really wanted the 109 ready for that as it's a good tat hauler, with capacity for considerably more unnecessary junk than my Freelander, but it wasn't to be. But on a positive, the junk I did bring back fitted in the Freelander fine, and some key bits were acquired for the 109, the rest for my 88"  Best buy (for the 109) was a front bias Detroit Truetrac, brand new! The ARB RD56 air locker next to it is for the front of my 88, unless I end up finding another bargain locker then there is the option of going that route on the 109 too?  Both Detroit Truetracs sat beside eachother. Anyone wonder why Rover differentials are considered weak in comparison to Salisbury's? The size says it all!   There is one small issue with the front Truetrac I've bought, and it's 24 spline. There was a 10 spline Truetrac at Newbury, but I'd already blown my budget and 10 spline shafts are weak. Whilst going round the jumble I've formulated a plan, and that is to lash up a jig to take standard Rover axle front shafts and cut the 10 spline inner ends off and weld 24 spline ends on. There's enough material on a series front inner shaft to weld the thicker 24 spline ends on and be able to weld a sleeve over the top and still remove the bearing retaining collars. I've got a few sets of spare front shafts and a few old 24 spline shafts that won't fit a series axle lying about too. The weak link will still be the u/j in the swivel housing, but they aren't that bad to replace, and if I keep enough tools and a spare set of shafts for offroading to strip and replace then the money saving for now is well worth it compared to the cost of custom shafts to fit CV joints etc with what I've already spent. And finally I've replaced the multiple silicone hoses beneath the inlet manifold with a single hard intake pipe made from stainless elbows. No risk of blowing hoses off underneath where they can't be reached to be put back on easily!   |

| |

Last Edit: Oct 13, 2019 9:36:02 GMT by sowen

|

|

|

|

|

Oct 16, 2019 13:48:53 GMT

|

fantastic engine work to be fair the rover-type detroit diff makes it an unfair comparison, even that has much more girth (stronger) than a stock rover diff  |

| |

Last Edit: Oct 16, 2019 13:52:09 GMT by darrenh

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Oct 16, 2019 17:56:39 GMT

|

fantastic engine work to be fair the rover-type detroit diff makes it an unfair comparison, even that has much more girth (stronger) than a stock rover diff  The standard Salisbury centre has more mass than the Rover Detroit! After weighing up the options and upgrades for the Rover axle on my 88", I've since swapped in a Salisbury to that too. That's now waiting on my finances to recover a bit after this recent spending splurge to buy a matching ARB air locker to that'll be running lockers front and rear, like the 109 will be running Truetracs front and rear. I should update my other Landy's build thread sometime. A lot has happened to it the last year, and there's more major upgrade work coming as the annual pre-winter maintenance on the commuter fleet is almost complete.... |

| |

|

|

|

|

|

|

|

|

I enjoy this thread and admire both the competence and confidence you demonstrate.

Question about that intake manifold: when viewed from underneath, it appears to have two intake runners for each cylinder. Is that right? Thanks, John

|

| |

|

|

|

|

|

Oct 17, 2019 12:14:14 GMT

|

I enjoy this thread and admire both the competence and confidence you demonstrate. Question about that intake manifold: when viewed from underneath, it appears to have two intake runners for each cylinder. Is that right? Thanks, John thats a good spot ! the cylinder heads seems to have 1 inlet port per valve |

| |

|

|

|

|

|

Oct 17, 2019 16:41:23 GMT

|

|

both OM605 and OM606 have port per valve and dedicated runners

|

| |

|

|

|

|

|

Oct 18, 2019 13:29:17 GMT

|

Damn that's cool  I was thinking about potentially using an OM605 with a Landy LT77/R380 in a future project (Baja MGB), but was wondering about towing with a clutch that can take the torque. Nice to see a high-rated single-plate clutch. Have you towed with yours before? Haven't gone back far enough through the thread yet! |

| |

|

|

|

|

I'm gutted I cant access the videos to hear this beasty box burbling along, damn work internet but I will make sure I find a way to access them somehow! anyway I've got more thread to catch up on, it fantastic!

I'm gutted I cant access the videos to hear this beasty box burbling along, damn work internet but I will make sure I find a way to access them somehow! anyway I've got more thread to catch up on, it fantastic!