Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Sept 4, 2009 17:10:02 GMT

|

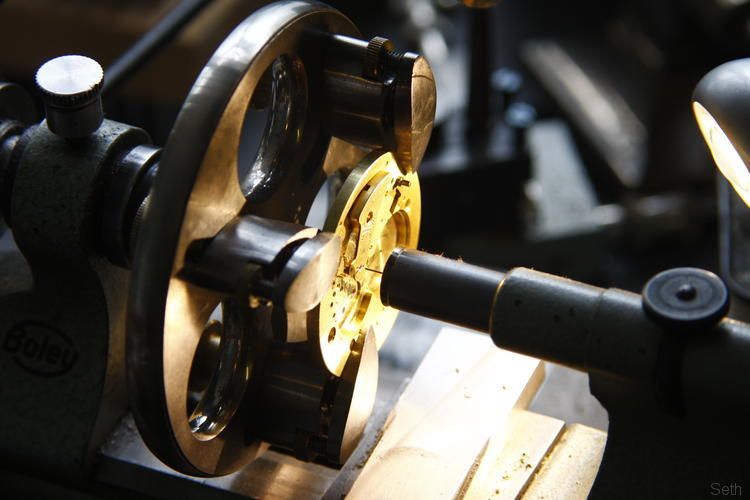

Had a fun little work project today I thought I'd share. The customer wanted a new bow (the ring the chain fits to) put on this watch - you can see where it has worn over the years and become much thinner at the top.  The bow is kinda sprung into the stem of the case, located by the two lugs machined into it.  I'd not made a bow before but I took this on as I knew I had previously acquired the right tool, this funky little jem.  Around the flower shaped piece are several cutters that leave different sized lugs. Unscrewing the larger brass thumbwheel allows the flower to rotate and it is indexed to the right place using the pin (attached to the chain) that goes in from behind. The outer edge of each cutter has teeth that mesh with the larger gear and so turning the black knobed handle spins the cutter. I formed the ring out of some wire I bought yesterday using shaped pliers and here it is fitted to the device. The sprung plunger locates it on the cutter and applies some cutting force too.  Ta Da! Didn't take much effort or time to make.  Cleaned the new bow up, removing any scratches from the forming operation, gave it a polish and fitted it back on the watch.  Hope it lasts for at least the 120 years the old on did  |

| |

Last Edit: Sept 12, 2011 20:51:09 GMT by Seth

Follow your dreams or you might as well be a vegetable. |

|

|

|

|

|

|

Sept 4, 2009 17:22:17 GMT

|

|

onehundredandtwentyyears!

|

| |

|

|

MrSpeedy

East Midlands

www.vintagediesels.co.uk

Posts: 4,791

|

|

Sept 4, 2009 17:53:24 GMT

|

|

That's a lovely little gadgey you got there.

Isn't life easier when you've got the right kit for the job

|

| |

|

|

rysz

Club Retro Rides Member

Posts: 2,558

|

|

Sept 4, 2009 18:22:43 GMT

|

|

Fantastic tool and some quality work their Seth!

I love small specific tools like this, made for purpose and work beautifully! Is this an old tool or are things like this still manufactured?

Rysz.

|

| |

|

|

93fxdl

Posted a lot

Enter your message here...

Enter your message here...

Posts: 2,019

|

|

Sept 4, 2009 22:03:34 GMT

|

|

that gadget is truely georgeous but i am predjudiced as i have a friend who is a watchmaker in somerset and some of the clocks he has had in have been amazing feats of engineering and i am a toolaholic and love beatifull craftsmanship

ttfn glenn

|

| |

|

|

|

|

|

Sept 5, 2009 19:11:12 GMT

|

|

Nice.

|

| |

|

|

|

|

|

Sept 5, 2009 19:32:14 GMT

|

|

top work mate, and what a fantastic little tool!

|

| |

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Sept 5, 2009 20:54:44 GMT

|

onehundredandtwentyyears! That's only a young'un! Most of my work is waaaay older  Rysz, I reckon the tool probably dates from the middle of the last century. Plastic/bakelite knob on the handle so its unlikely to be much older then '30's. I doubt there's anyone making this kinda thing anymore as demand would be minuscule. 93fxdl/Glenn, does your friend do watch restoration? Not many of us out there...  |

| |

Follow your dreams or you might as well be a vegetable. |

|

TS

Part of things

Posts: 558

|

|

Sept 5, 2009 22:47:50 GMT

|

|

That looks a bit like the spoke threader tool we have in the workshop. But much smaller and with multiple cutters.

Cool piece of kit.

|

| |

|

|

93fxdl

Posted a lot

Enter your message here...

Enter your message here...

Posts: 2,019

|

|

Sept 5, 2009 23:05:07 GMT

|

|

quite possible he does watches as well as clocks but don't really know as most of our encounters were at various hostelries and topics of conversation didnt usually include work, the state we were usually in the conversation didnt really include anything that made any sense

ttfn glenn

|

| |

|

|

|

|

|

|

|

Sept 7, 2009 17:18:54 GMT

|

Very cool bit of kit; I love stuff like that. At first I thought it was a miniature set of rollers with to roll the ring shape  |

| |

|

|

skinnylew

Club Retro Rides Member

Posts: 5,710

Club RR Member Number: 11

Member is Online

|

Assorted diddy engineering.skinnylew

@skinnylew

Club Retro Rides Member 11

|

Sept 11, 2009 22:54:26 GMT

|

|

wow what a piece of kit!!! They don't make em like they used to lol

|

| |

|

|

mason

Part of things

Posts: 601

|

|

Sept 11, 2009 23:05:34 GMT

|

|

that is a thing of beauty,even in its day cant have been too common. Nice to see it being used ;D

|

| |

|

|

|

|

|

Sept 11, 2009 23:52:12 GMT

|

|

...You know, I think we need some better, high quality pics of that little gem!

|

| |

1972 RA21 Celica - Stalled

1980 Nishiki International - Commuting

"The 2cv's looks at least have certain quirky charm - sort of like an old VW bug with tuberculosis."

|

|

purplevanman

Posted a lot

Way too orangey for crows

Way too orangey for crows

Posts: 3,830

|

|

Sept 13, 2009 21:36:39 GMT

|

Very cool bit of kit; I love stuff like that. At first I thought it was a miniature set of rollers with to roll the ring shape  that was my thought too  |

| |

Welder, fabricator, general resto work

|

|

tigran

Club Retro Rides Member

In rust we trust. Amen.

Posts: 6,444

Club RR Member Number: 142

|

Assorted diddy engineering.tigran

@tigran

Club Retro Rides Member 142

|

Sept 21, 2009 3:13:19 GMT

|

|

I love watching anything to do with watchmaking/repairs. The intricacy of the mechanisms, the specific nature of the tools - it absolutely fascinates me. I used to stand for ages watching the watch repair guy at the jewelers I worked at do his thang, t'is incredible.

|

| |

1964 Rover P5 i6

1987 BMW 525e - The Rusty Streak

1992 Micra K10

2001 BMW E46 316i

2002 BMW E46 330Ci

2013 BMW F31 320d

2018 BMW G31 530d

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Jun 23, 2011 21:49:33 GMT

|

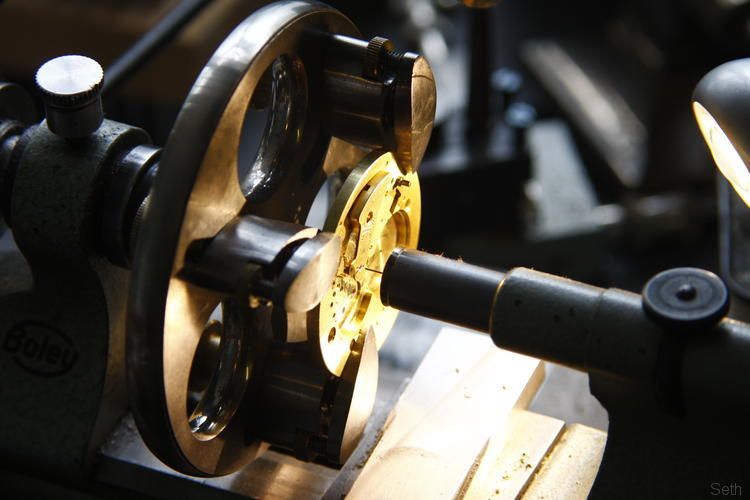

Thought I'd dig this old thread up as I've photographed another job over the last couple of days. (Better photos too as these are taken with an old Vivitar 70mm Macro lens from my AE-1 fitted to the 40d with an FD-EF converter.) I'll try and explain as best I can. While cleaning the movement of this watch I noticed that the lower balance jewel was a bit suspect. ("Jewels" in watches are for the most part used as bearings) When I got it back together it wouldn't run because the balance wheel (the bit that oscillates to and fro to regulate the timekeeping) was catching on something. Quickly became obvious it was sitting at an angle. Not only had the wrong type of jewel been used for the bottom pivot to rotate in but it had been put in the wrong place so that the balance staff (the balance wheels "axle") was no longer upright. After dismantling it all again, here's the suspect jewel, in the centre of the photo. For scale, the distance between those to pins sticking up is about 1mm. The jewel hole was about .3mm too far to one side.  I pushed out the old jewel and turned a bit of brass to suit the hole, left a bit long and them hammered/riveted into the plate to give me a blank work surface.  So how do I know where to locate the new hole? I mounted the watch plate in what is called a Mandrel Plate on the lathe, which is basically a sort of face plate which can hold a watch plate off centre but perfectly flat. I fitted the "balance cock" which contains the balance's top jewel.  With this in place I could move the plate until its jewel hole was perfectly centered. The pin (the blank end of a 0.5mm drill bit) was used as a reference to get initially close.  With the plate clamped tight and the balance cock removed I could now drill a pilot hole (0.9mm) for the new jewel. I also put a chamfer on it as the jewel is much thinner than the plate and clearance would be needed on this side.  Next this tool came into play. Its a press specifically for jewelling and comes with various sized reamers, pushers and supports called stakes. It has an adjustable depth stop so that you can precisely control how deep the jewel is pressed in.  First task is to use on of the reamers to open the pilot hole out to the right size to accept the jewel.  A jewel of the correct size was found, that fitted the pivot on the balance just right, and I used a "pump pusher" to fit it. These have a small spring loaded point in the centre to locate in the jewel hole to make sure it is pressed in evenly by the main bit of the pusher.  Pushed in to depth.  And the result. (The circular recess is to suit a second flat jewel and its housing that acts as a thrust bearing)  On the other side I found I needed to open the chamfer out some more for clearance.  So that the balance would clear without the parts at its lower end hitting the plate.  Re-cleaned the various parts that had got mucky and put it all together again. Now the balance is perfectly upright with sufficient clearance around all the other parts. Success!  |

| |

Follow your dreams or you might as well be a vegetable. |

|

|

|

|

Jun 23, 2011 22:02:35 GMT

|

|

Wow. This post really makes one appreciate the skill and prescision in the craft of watchmaking and repairing. Seriously impressive stuff.

Oh, yes, "Right Tool". *waves*

|

| |

|

|

|

|

|

|

|

|

As before Seth, Nicola and I applaude you.

Her next response was.... " I wonder if he could sort out William" Now William is a grandfather clock she got for her 21st birthday, and it would be the last thing she ever ditched should she have to.

I told her you prefer to work on older stuff, and a bit smaller.

However, here is a request..... Why don't you give us more of your work in this thread?

I suspect a lot of guys on here will enjoy it.

|

| |

|

|

|

|

|

|

|

|

Grizz,

If you send me over some pictures I will pass them onto my dad along with your number. He is a retired engineer but his main interest is Antiquarian Horologicy (sp) with speciality being french movements.

He doesn't do it professionally but he does it for beer money and enjoys every second of it. my folks house is filled with seismographs, barometers and clocks with at least 2 clocks in each room. Sleeping there is a bit of a challenge for me as I am used to the countryside with no clocks

|

| |

Last Edit: Jun 24, 2011 8:03:07 GMT by kwikkwak

|

|

|

|

Ax GTi Turbo

Ax GTi Turbo