Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Mar 28, 2024 23:22:47 GMT

|

I’ve been pretty quiet on the car front partly because work has taken over to some extent. Something I was rather privileged to get involved with at the tail end of last year was the restoration of the Silver Swan automaton at the Bowes Museum in Barnard Castle. This is a full size model, the body, feathers and neck all silver, that ‘swims’ on a pool of water represented by rotating glass rods, waves its head/neck all around, bends down and appears to grab a fish out of the water in front of it and swallow it. Music plays while it does this and the performance lasts about 35-40 seconds. It was made in around 1770 for entrepreneur James Cox and first displayed in 1773 at his museum in London. It was likely largely designed and partly made by a chap called Joseph Merlin who is a really fascinating character himself and who was Cox’s chief mechanician during the swans conception. It is totally unique and one of the best surviving automatons of the 18th century.  In 1867 it was on display with a dealer at the International Paris Exhibition where it was seen by art collectors John and Josephine Bowes. They subsequently bought it and it was later to become a star exhibit of the museum they built in Barnard Castle (opened after they had both died). Its still there. It probably didn’t work properly or at all for much of the time but then had restoration carried out in the 1960s. For a time after this it was coin operated and so probably got ‘played’ a huge number of times. It’s been apart, cleaned and conserved in recent years but was not really in reliable running order any more and was really in need of some repair and re-restoration, some of which was likely to some of the 1960s work. The person that came to the rescue was my freind Keith who runs the Cumbria Clock Company. They’re best known for carrying out the recent restoration of The Great Clock of Westminster. ie Big Ben. As well as three young members of the Cumbria team, a number of students from a couple of horological courses were brought in as interns to help – an amazing opportunity.  While CCC do deal with various size clocks, parts of the swan needed the help of someone more used to smaller things (and precious metal) and that’s where I came in. I'd also been able to take a look at it during a study week a couple of years ago so was vaguely familiar with it. And so I got to do some proper road trip miles in the Hillman....  My main job was basically to sort the head out, so one week in October I was up in The North helping take apart the Swan. The film on this BBC link which was shot one day that week shows better what it actually looks like. BBC Tees Bowes Silver SwanAnd while there I decapitated it so as to bring the head down to my workshop.  to be continued.... |

| |

Follow your dreams or you might as well be a vegetable. |

|

|

|

jpsmit

Posted a lot

Posts: 1,274

|

|

|

|

|

Puts kettle on. Waiting and very excited!

|

| |

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

|

|

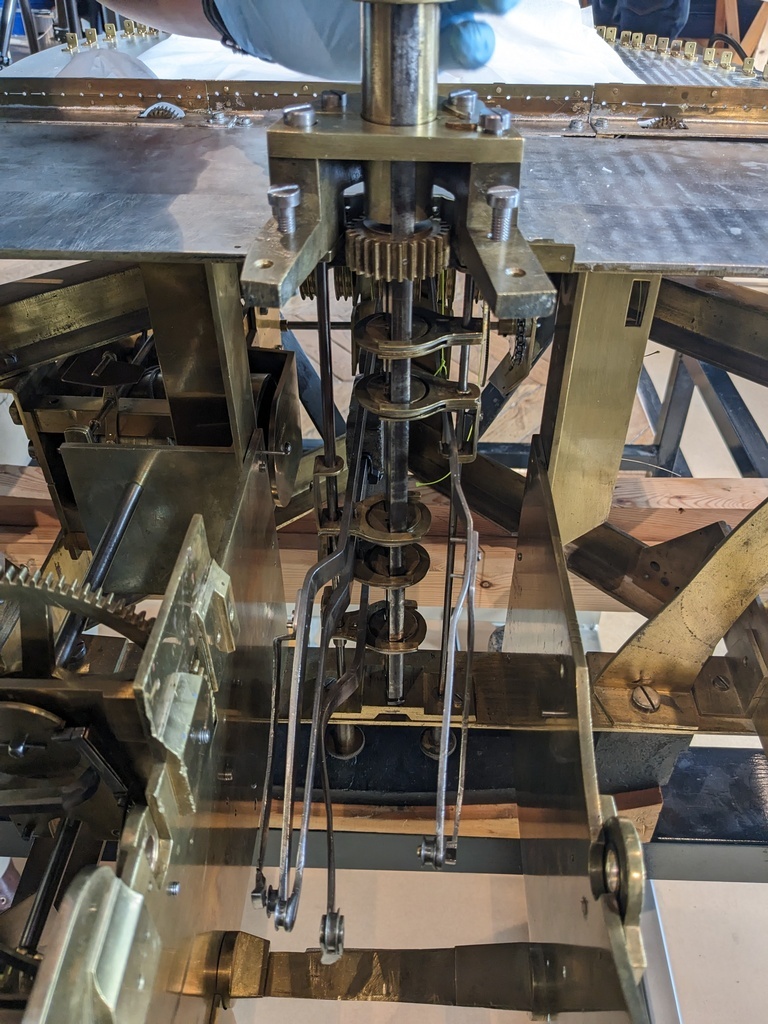

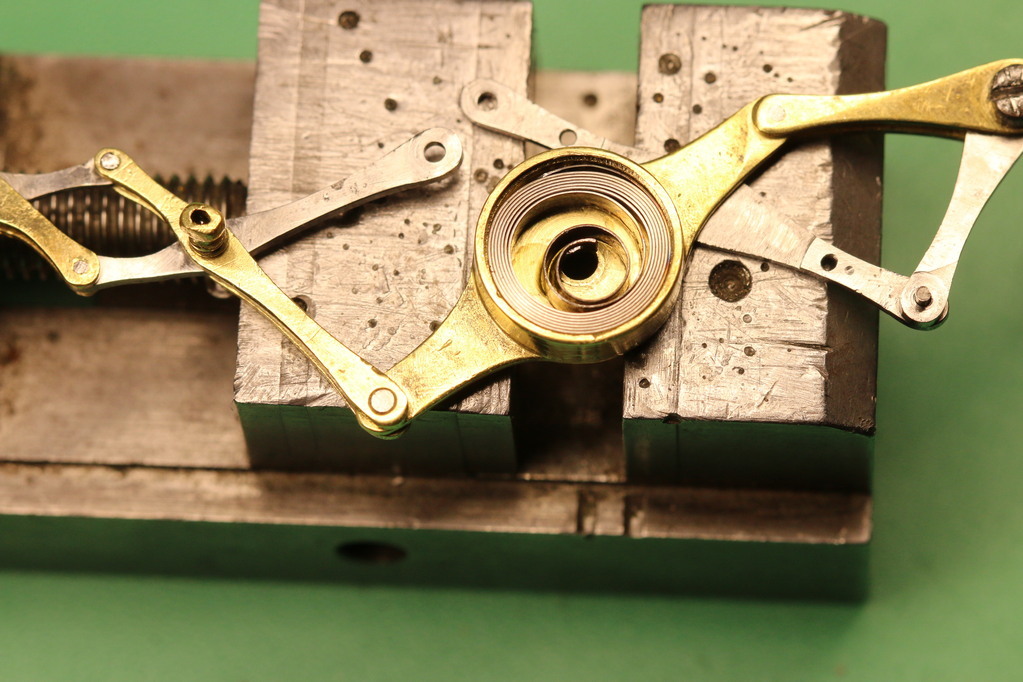

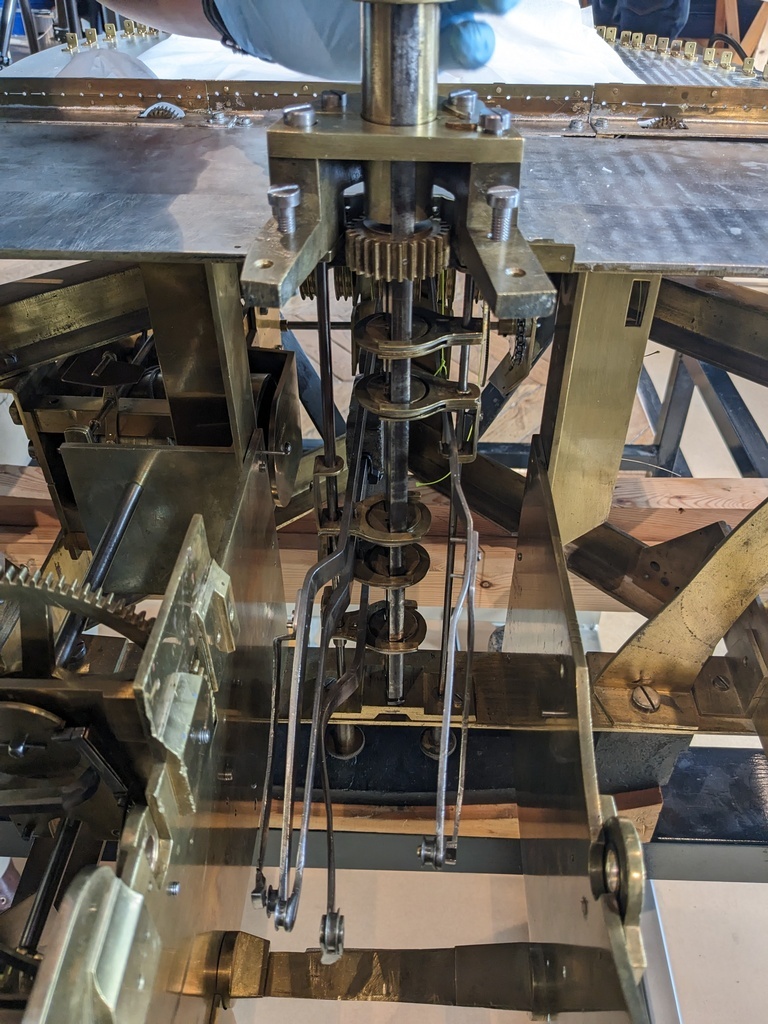

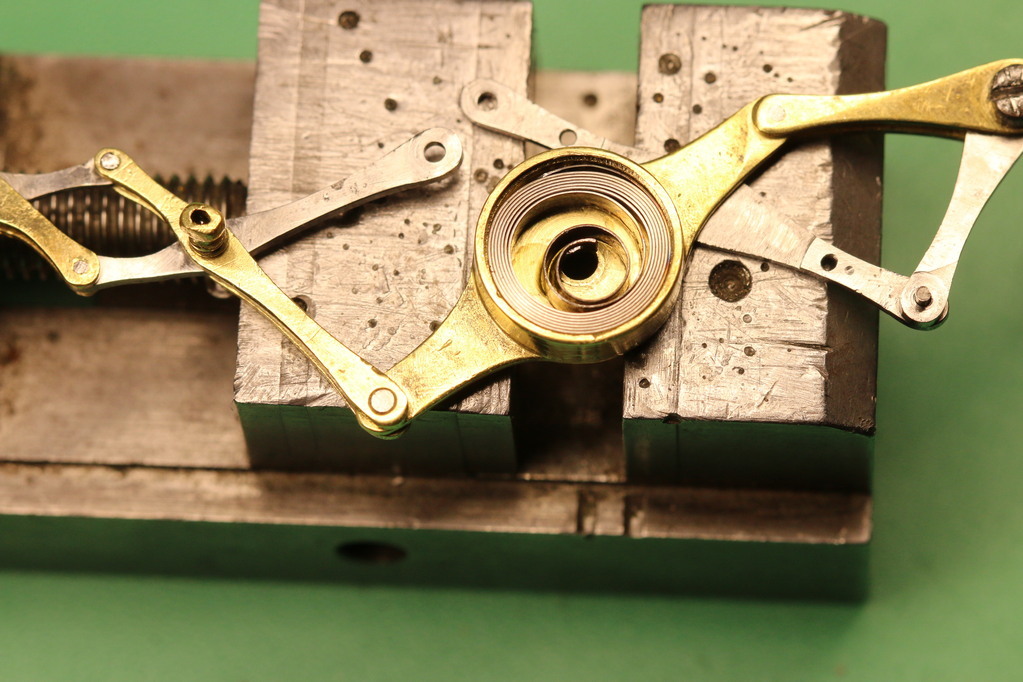

Before going in to what I did here's an overview of how it works. This is a view looking down on the main mechanism with the silver body (and all the glass rods) removed. Around the outside of the cam drum in the middle is a groove.  Within this runs a follower pin attached to that cross piece of the quadrant arm in the middle of the photo. The quadrant is pivoted at the right end and at the left, meshes with a pinion which is attached to the base of the neck. So, this provides the rotation left/right of the neck. The drum also has cams on both sides. The neck and head are operated using five chains that are pulled down by levers that follow these cams. Here’s a view looking towards the neck with the quadrant and cam drum removed and you can see the levers and the brass sliding pieces and discs they move. To each of those is attached the end piece of a long chain.  Two chains pull the neck at different points to get it to rise and lower realistically, a third pulls at the top back of the head so as to give a nodding motion and the other two smaller chains pass into the head itself. One of those pulls the lower part of the beak/jaw closed and the other pulls the fish into the mouth. (Spoiler alert – the fish doesn’t get plucked out of the water but is always in the mouth..)  Anyway, this is what landed on my bench.  ..... |

| |

Follow your dreams or you might as well be a vegetable. |

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Mar 29, 2024 13:09:35 GMT

|

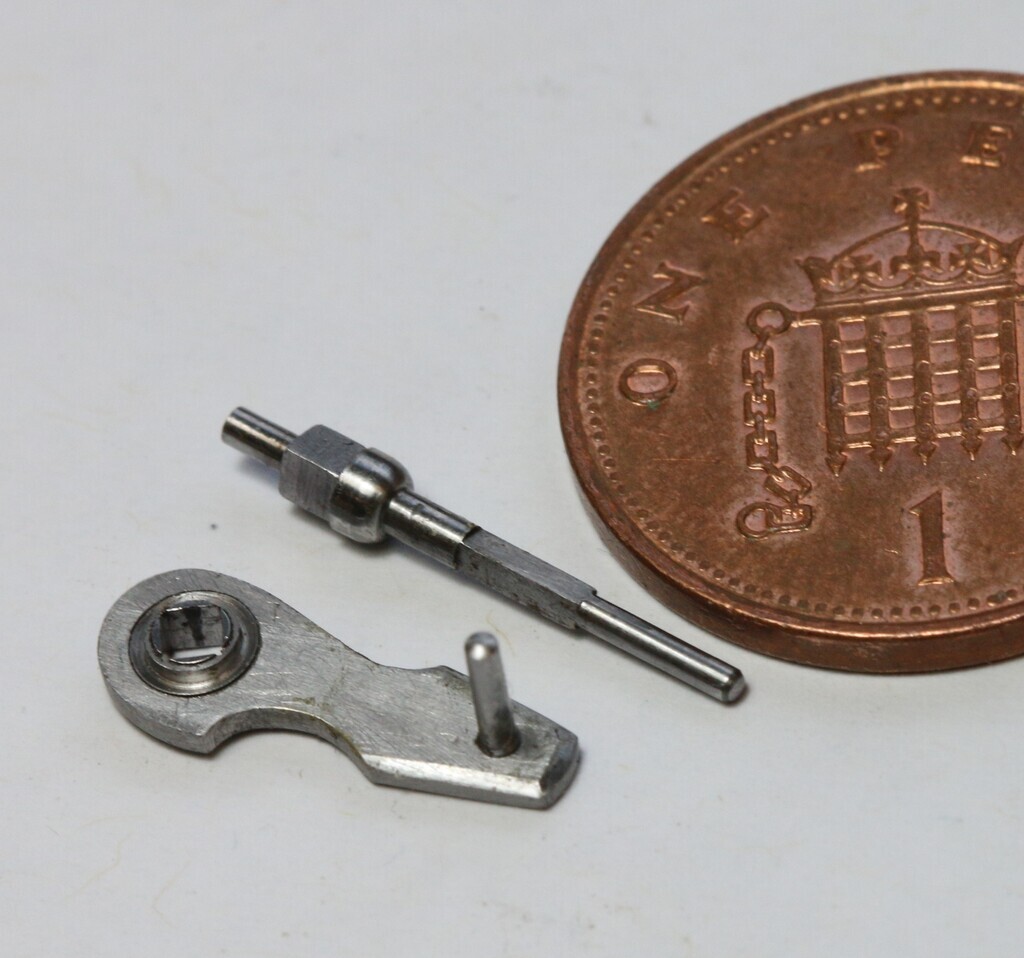

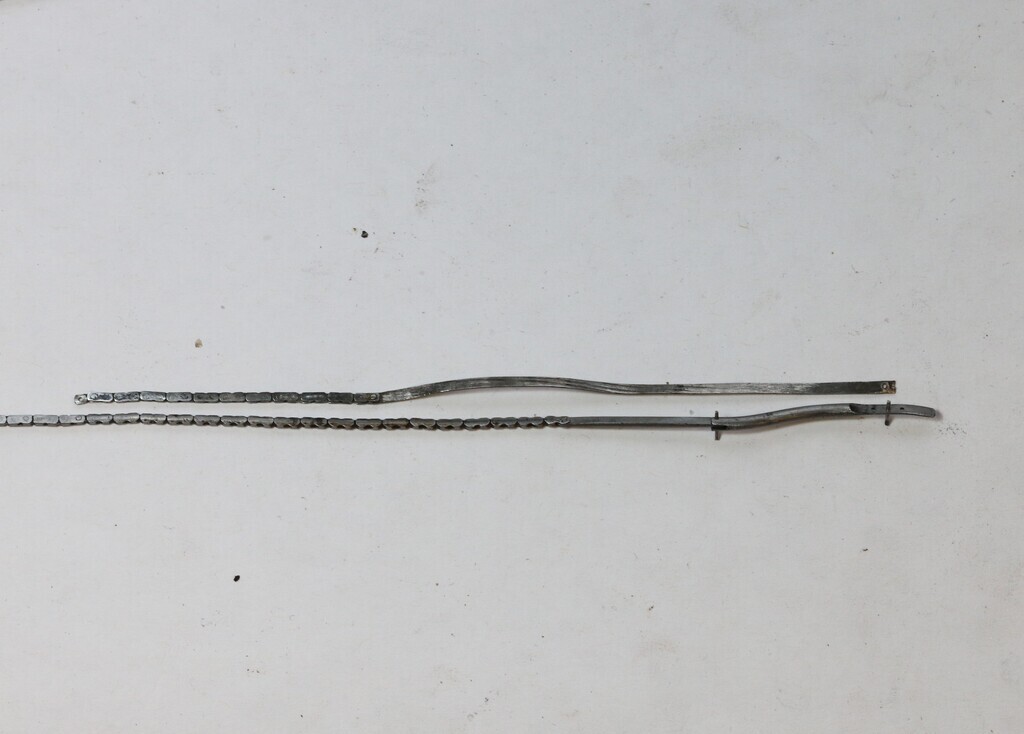

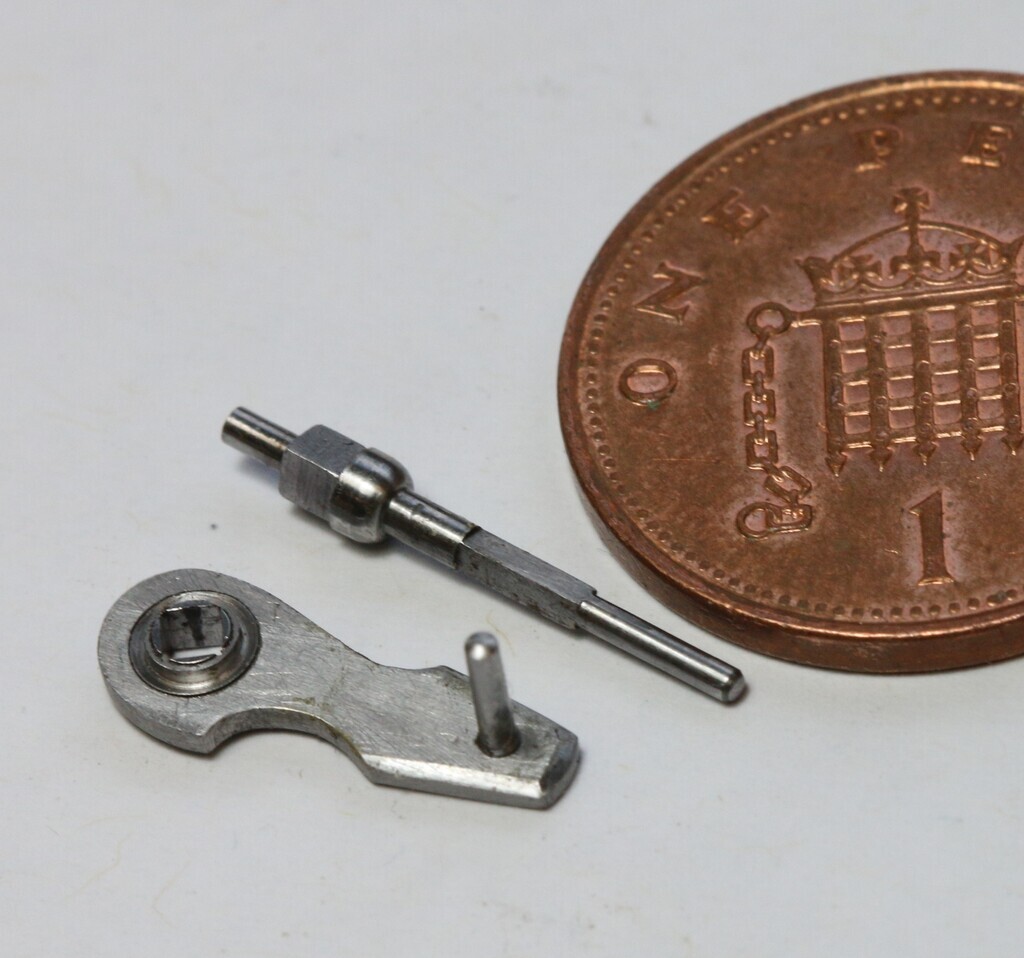

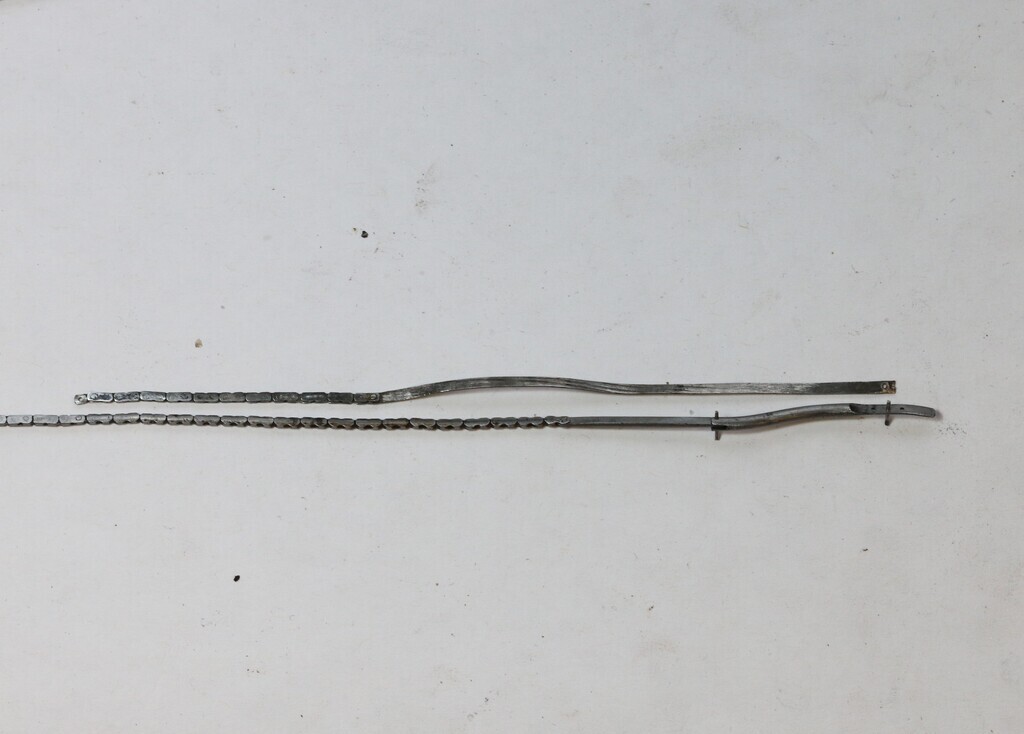

Oh, working away from my own 'shop meant trying to figure out what I'd need and while the CC guys took the bigger stuff to the museum I still had to put a kit together. So here is that little box alongside all the parts I brought south, the head, the fish and the two chains that operate the head.  I won’t go into full details of it all but there were several different elements that needed sorting. The fish is mounted on a spring loaded scissor action slide piece and there was a horrible modern extension spring helping it move. I managed to restore the original spring function which uses a watch mainspring as the source of power and so do away with the modern one.  The biggest problem was that the rotating arbor the fish is attached to was broken and so the fish would sometimes fall out. Not ideal. Certainly the part where it is fixed to the fish was not the original and I suspect some of these bits could have been 19th century repairs. I made a new arbor to fit the original slide and to also be more secure where the fish is held in place.  Here's a'scale' photo. This is actually pretty chunky stuff for me!  The jaw chain had a bad old repair - someone had used a piece of watch mainspring to extended it from an old break. So itneeded a new section adding. I made a couple of long articulated links where it runs through the head and rubs against the brass plate, so it is smoother and not going to wear out.  The lever itself had caused the mounting part on the silver jaw itself to break away so there was loads of lost motion there. An old repair used a steel BA screw through the silver but this kept working loose anyway. I made a screw in silver which, once it was in place and things had been tested, I filed the head mostly off and then tig welded the remainder to the original silver. An invisible and more secure repair.    I realised there were empty screw and steady pin holes in the side of the head near the jaw lever. And there was a notch doing nothing on the top of the jaw lever. As I said, the chain pulls the jaw closed but for many years/decades there’s been nothing to open it but gravity. As a result when the head is pointing down, as it does at various stages in the routine, the jaw just hung there and only starts moving as the head lifts to a more horizontal position. You can see this in the old videos of it running on YouTube. I realised there should be a spring there that actually opens the jaw. So I made one to fit those original holes and notch. You can see it here curling around and also the way the end of the chain links attach to the lever.  The whole process was photographed and recorded for future reference as to what had been done and the broken parts kept to go into the museum storage along with other related swan parts. They could even be refitted if someone in the future decided they wanted to make the swan not work again. This photo shows the fish on its arbor in the sprung forward position. As it is drawn back by the slide, the vertical pin on the end of the lever on its arbor runs in a slot which is shaped so as to turn the fish 90 degrees as it enters the mouth.  .... |

| |

Follow your dreams or you might as well be a vegetable. |

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Mar 29, 2024 14:44:47 GMT

|

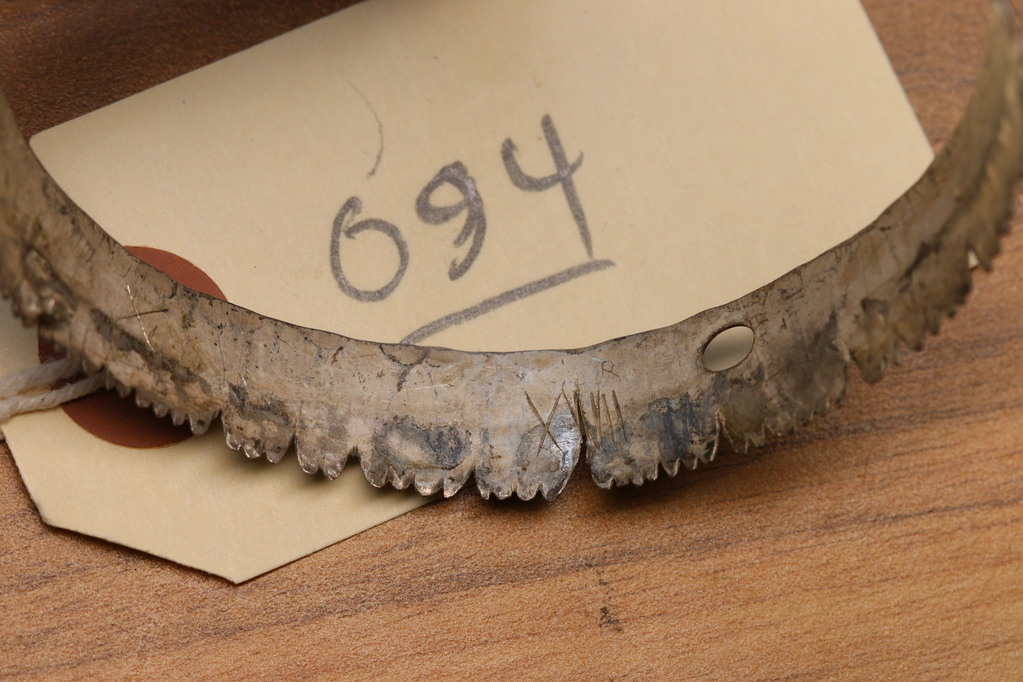

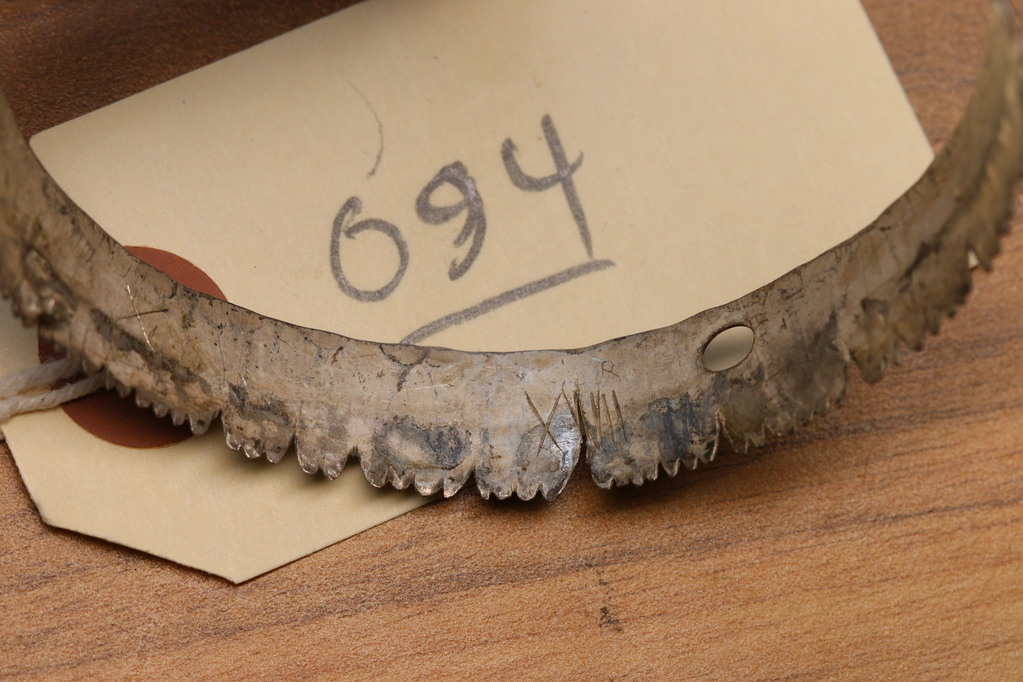

With that stuff done, in November I took the head up to the Cumbria workshops where the rest of the swan mechanism was to re-attach it to the neck and do some initial testing.   While there I did the second main thing I ‘d been employed for, repairing a number of the silver neck rings. There’s 124 of them, all individually sized, tapered and engraved with feather patterns. 250 years had taken its toll and many were cracked, some worse than others with a couple in a really bad shape. Silver soldering them would have been an option (and a couple have been repaired that way in the past) but doing that would have annealed the whole thing and in the manner of conserving something in its existing state as much as possible, I had taken my little Tig with so as to weld them. Silver is a bit tricky to weld as its quite reflective and I was advised by a laser welding chap that that process wasn’t easy. But Tig was feasible and meant that heating was just very localised. After they were all cleaned, the worst rings were identified and so I spent a while welding them up from the inside so as to give them back some structural integrity without it being visible. Here's a before and after. It had split where old numbering marks had been deeply scratched in but the shape with the feathered edge and engraving on teh outside is really condusive to this sort of crack appearing. 250 years of fatigue!   It wasn’t until a return trip to the museum in December that I really got to see if my work was going to be successful, as the mechanism was then largely back together so as to perform to an invited audience just before Christmas. There were a few long days in the run up to that, with tweaks and things as you’d probably expect a complicated, unique 18th Century machine to need having been completely apart….  We didn't quite have it all finished but it was alright on the night, performed well and made all the local news etc. Its a really finely balanced mechanism so that as you add weight to the neck by it can get really upset which means we ended up running it that evening with about 2/3rds of the silver on the neck. Since then the CCC guys have been busy, getting all that sorted and dealing with running in issues. After a period of being run in the museum without them, the glass rods finally went back on a few weeks ago and it is back to its full daily performance for visitors. And its being said that it is moving more smoothly than it has in living memory and the jaw is snapping away and the fish popping out the mouth and wiggling around better than ever. The swan is a really big deal up in Barnard Castle, the museum itself a pretty impressive thing to find in a small Northern town. (there’s a great episode of Mark Steel’s In Town on Radio 4 from there recorded in around 2018/9 I think) Many of the locals remember it from childhood. But is also a really important object on the global scale and so to have been one of the lucky ones to try and get into the head of the original designers and makers from over 250 years ago has been a really incredible experience. |

| |

Follow your dreams or you might as well be a vegetable. |

|

jpsmit

Posted a lot

Posts: 1,274

|

|

Mar 29, 2024 17:34:46 GMT

|

|

Amazing- thanks for sharing

|

| |

|

|

|

|

|

|

|

|

Stunning work and a stunning object.

Thanks for sharing.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

Frankenhealey

Club Retro Rides Member

And I looked, and behold, a pale horse! And its rider's name was Death

Posts: 3,888

Club RR Member Number: 15

|

Assorted diddy engineering.Frankenhealey

@frankenhealey

Club Retro Rides Member 15

|

Mar 30, 2024 21:31:52 GMT

|

|

Welcome back with a tour de force of Diddy Engineering.

|

| |

Tales of the Volcano Lair hereFrankenBug - Vulcan Power hereThe Frankenhealey here |

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Mar 31, 2024 19:05:17 GMT

|

|

Thanks chaps.

Repairing it is one thing, but can you imagine the twisted genius you'd have to have had to have designed it in the first place?!

|

| |

Follow your dreams or you might as well be a vegetable. |

|

|

|

|

|

|

|

Thanks so much for this update on your work - Well Done! It is amazing the engineering that went into this sort of device.

|

| |

|

|

|

|

bstardchild

Club Retro Rides Member

Posts: 14,976

Club RR Member Number: 71

|

Assorted diddy engineering.bstardchild

@bstardchild

Club Retro Rides Member 71

|

|

|

Thanks chaps. Repairing it is one thing, but can you imagine the twisted genius you'd have to have had to have designed it in the first place?! Exactly my thoughts - damn fine work Seth |

| |

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

May 26, 2024 20:45:49 GMT

|

New video of the Swan hit YouTube a couple of weeks ago including a bit of me rambling on about it. Bowes Museum Swan |

| |

Last Edit: May 26, 2024 20:47:13 GMT by Seth

Follow your dreams or you might as well be a vegetable. |

|

|

|

|

May 28, 2024 18:33:46 GMT

|

|

Nice video Seth! lovely to see it moving so smoothly.

|

| |

|

|