Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Oct 31, 2023 19:56:37 GMT

|

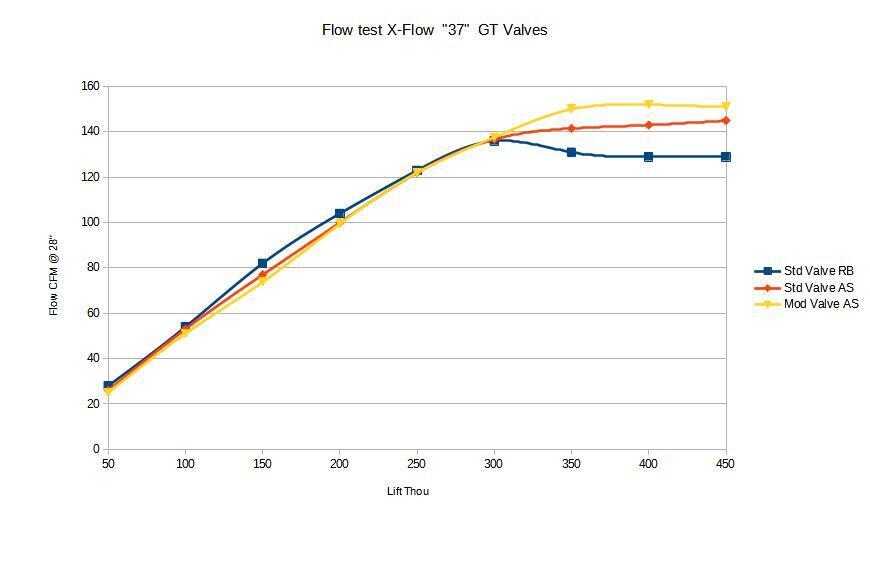

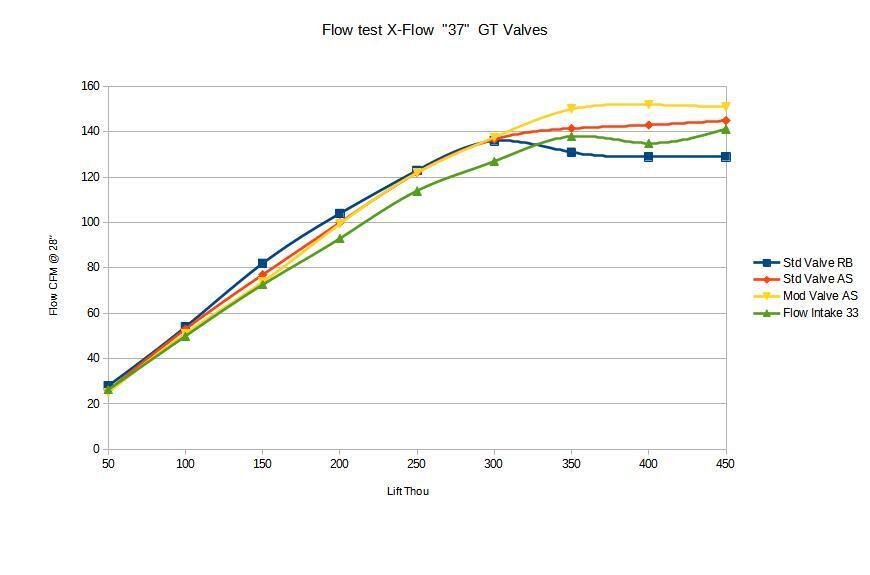

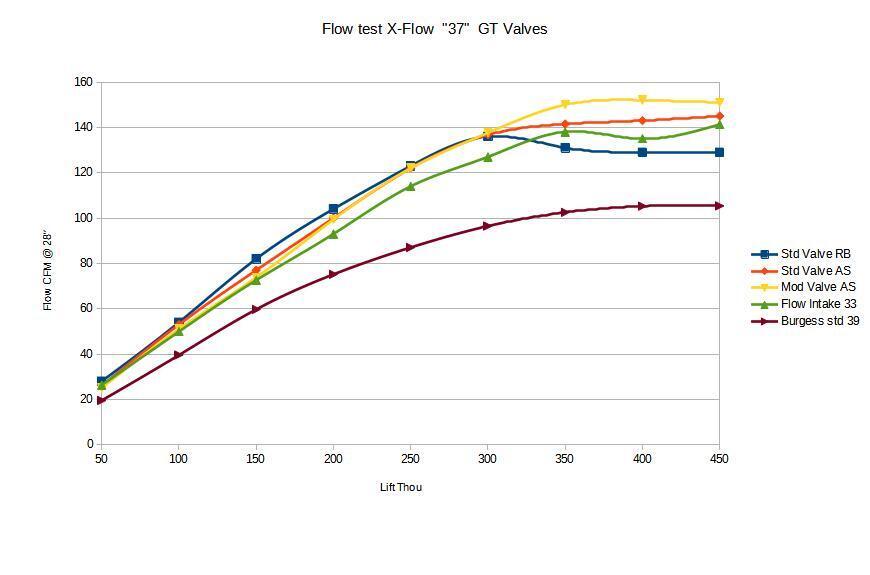

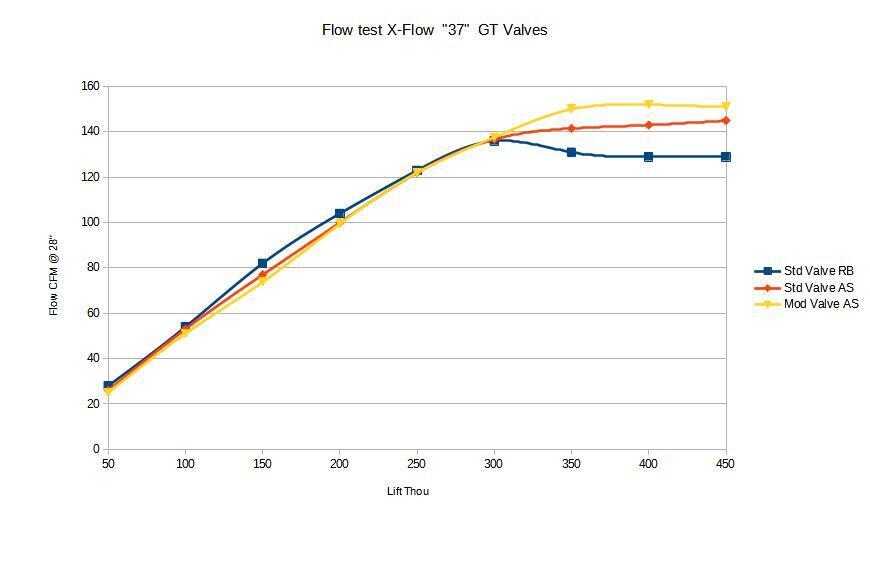

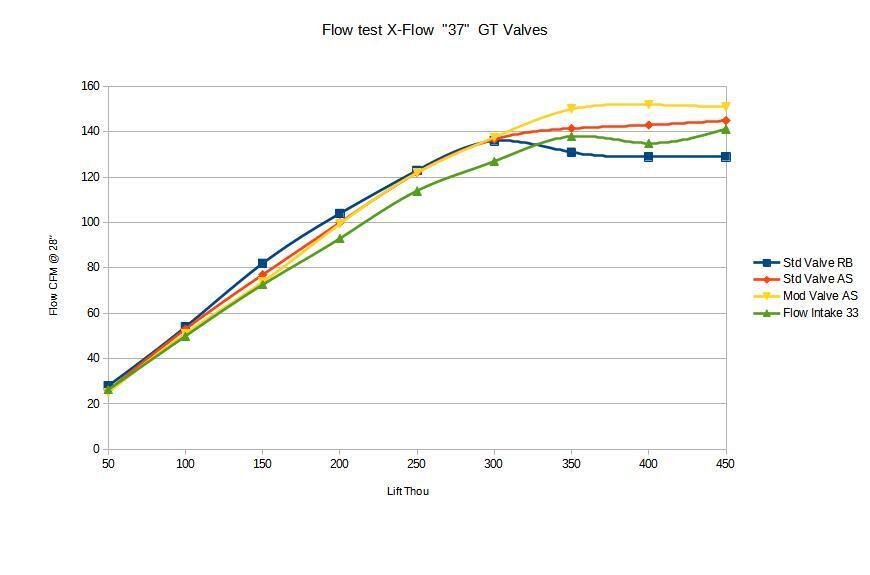

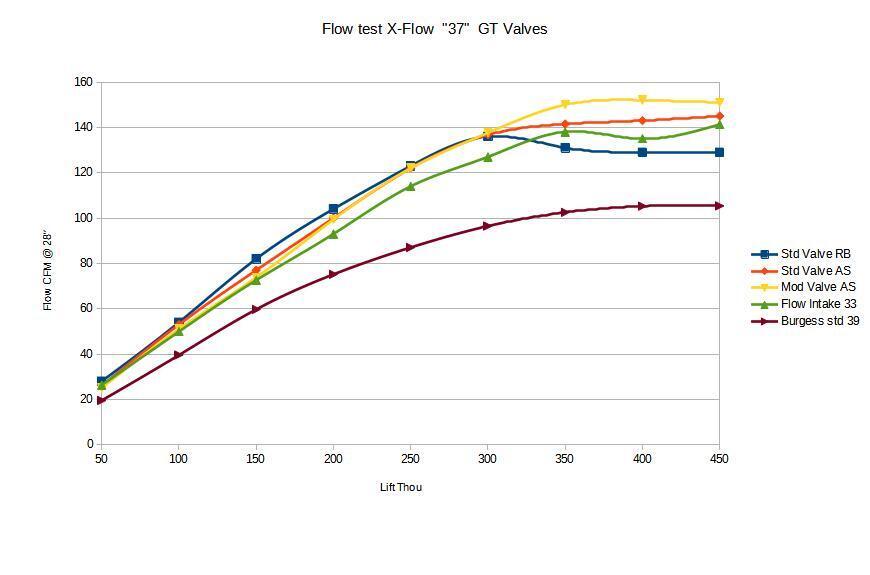

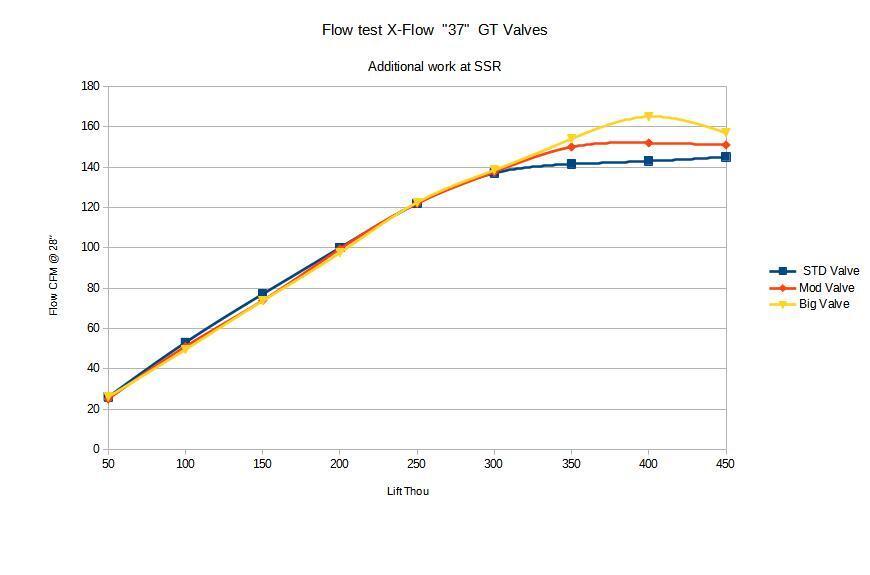

Nice work! What makes you think you've found the restriction? Was it that the standard valve had levelled off and the modified valve kept going past it? Flow is not dropping off any longer - plus I can also hear it on the bench that flow is not separating This is the final combined graph  The flow with the stock valve is the Blue and the Orange - Orange being after dropping the port floor and increasing the radius at the SSR and yellow with a penny on a stick style valve. What can be seen is the slight loss of low lift flow - but the average flow is still much higher Ave 101.78 104.91 106.87 respectively The flow curve also needs to be read with the cam curve in regards to the time the valve is going to spend at any one lift period and when you look at these you will see that 250-400-250 will be a longer period than from 0-250-0. The overall area under the graph is important but those top end numbers are where the power is. Whilst looking for the restriction I have oversized the port for the valve - As I will probably buy new valves with a better shape, going up a size is no more expensive so I can look to recover the low lift flow whilst hopefully gaining a little more at the top end as well. Its a risk when developing a head that was already perfectly adequate for the application. Thank fully the 234 can still has enough lift to adequately support a slightly larger valve. its a 39.5 valve and I have a 30.5mm port - 77% It would probably have been better to leave the port at say 29mm a 73% for a bit more port velocity - Time will tell. ETA And with the Big valve chambered race head added  Average flow 99.68CFM |

| |

Last Edit: Oct 31, 2023 20:00:30 GMT by Darkspeed

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Oct 31, 2023 22:08:17 GMT

|

I managed to find in my Speedpro book - modify and power tune cylinder heads by Peter Burgess - a curve for the X-Flow with a 39.5 valve - My head was not fitted with the 39.5 it had the standard 38.1 valve and with it pulled 102BHP on the dyno. I think these numbers could be a little low so I would push that curve up 5 CFM against my curves - It would however still be higher flow than the stock 38mm valve. So the curve as it is may be a reasoned representation of a stock 38mm valve flow  |

| |

|

|

|

|

|

Oct 31, 2023 23:37:42 GMT

|

|

Interesting stuff. Especially aiming for 73-77% port diameter vs valve. The rules of thumb I've seen have suggested 75-85% (with some even saying 85-92%!). Though I think a fair bit comes from big American V8s where you can rely on big displacement to make a lairy engine streetable.

If 77% is a decent figure then that bodes well for my Rover 2600 engine which is spot on that to begin with.

Also, I think Peter Burgess publishes his figures at 25" of water. Or something like that perhaps, could be wrong.

The general consensus is that his figures are reliable when compared to each other, but that his flowbench reads high compared to others* so it's odd to see his being the lower figures.

*This was all but explicitly stated in a thread he was participating in, where his numbers were called out for being very optimistic and he came back saying that he calibrates his bench for repeatability and doesn't care about comparisons to other machines or operators. I think it was over on the Speed Talk forum, but I can't remember the name of the thread.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

Burgess does use 25" - those numbers are corrected to 28" to be as graph scale. I suspect that what he has in the book for a STD (39.5) is in fact for the 38mm valve.

It is all about comparison flow - and in that regard he's right, what another bench says is irrelevant in that respect. Gains are all that is being looked for. Unless you are selling a head on a specific flow rate or going into battle with another tuner stating mine is bigger than yours.

The port/valve ratios - It will be simple enough to line the port with some plastic tube and blend with plasticine to reduce the diameter and see what the overall result is. Or I could roll a sheet of plasticine to line the port to see just how much difference it makes.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

However,

Don't take heed of anything I write or post on this subject ( or other subjects for that matter) - I'm just an amateur with access to a rather large amount of wind.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

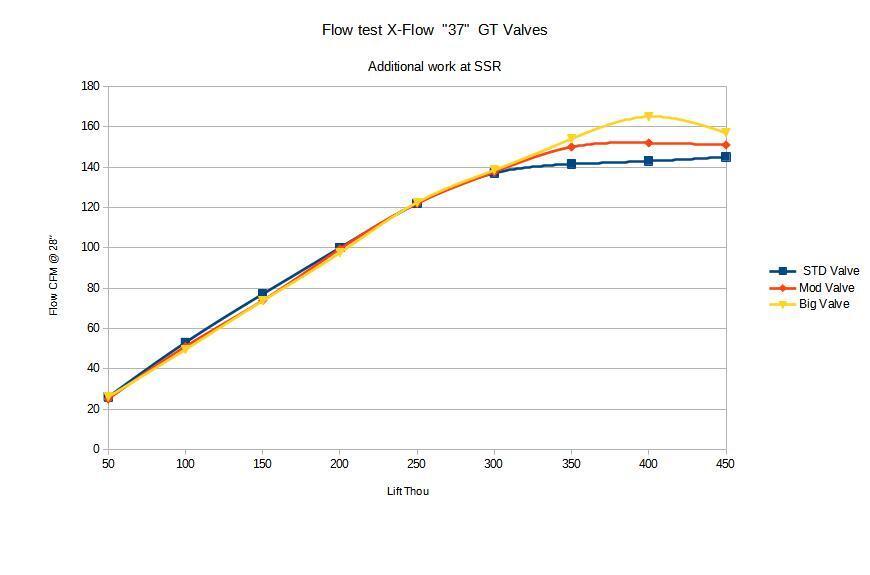

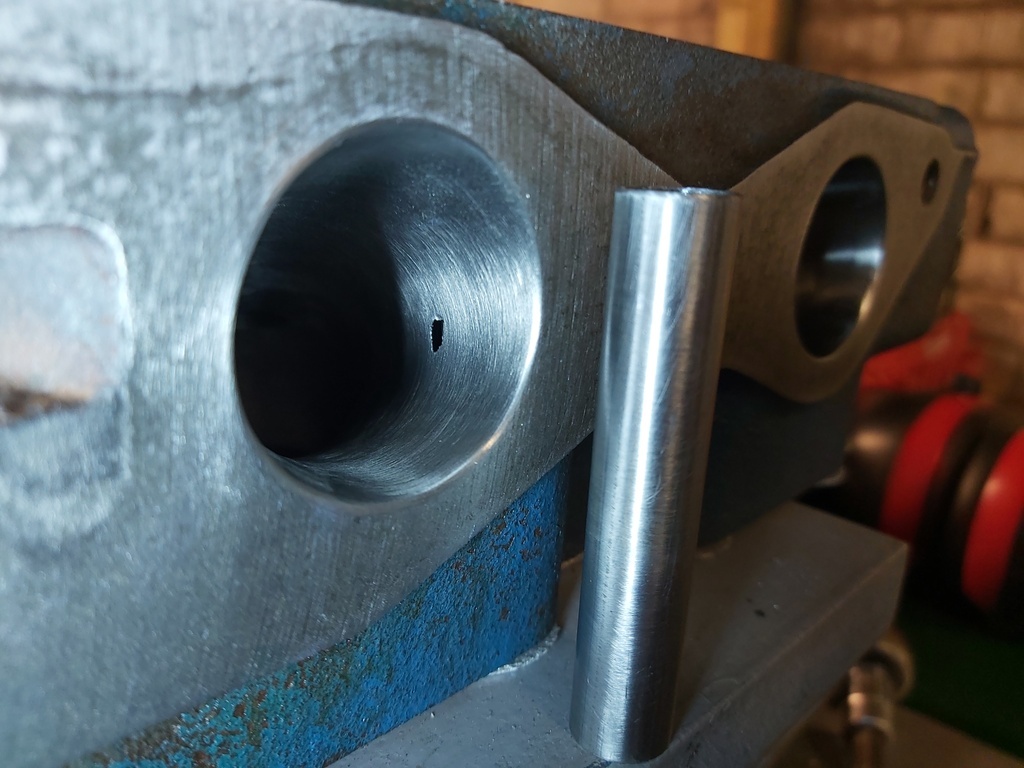

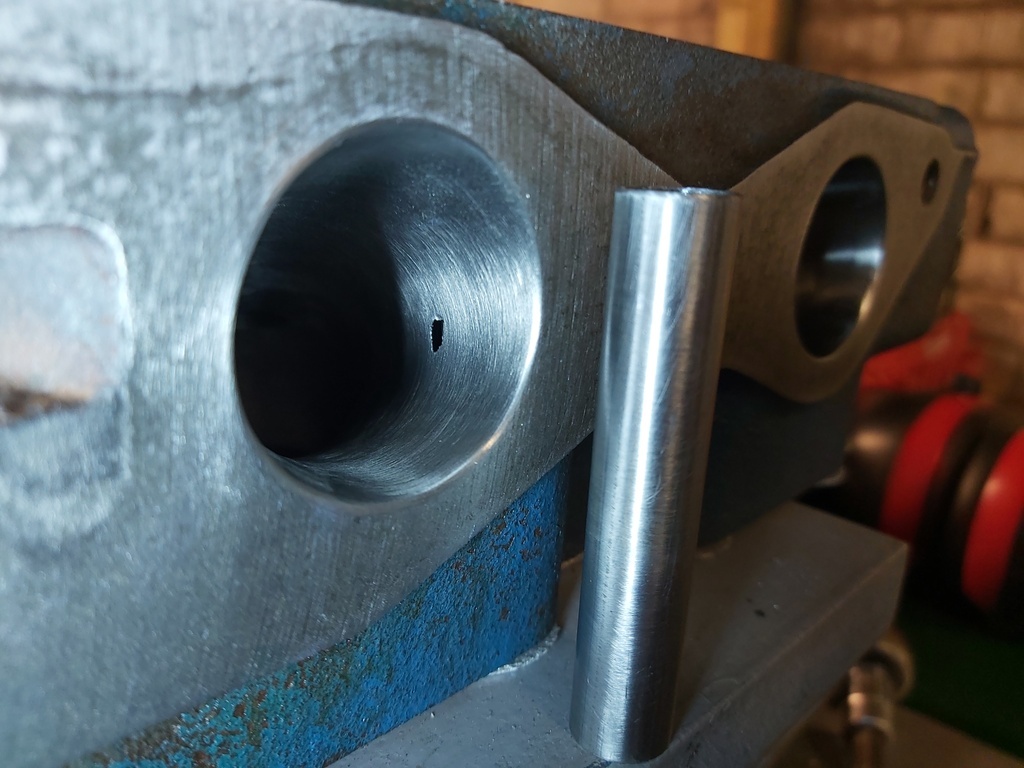

I decided to ignore the budget. Exhausts are the same at 34mm but the inlets are bigger at 40.6mm      On the bench we have picked up quite a lot at the top end.  All the ports have now been worked up to the same as the development port. There is a bit more work to do though.  Yep we found some air but not the sort that provides more power... The tube alongside is for sleeving the pushrod tube that has been broken into. That's a bit of 1/2" 1.5 wall tube that I have drilled out to 7/16 same as the push rod tube dia. The PR tube will be drilled and reamed to 1/2" and the sleeve glued in. Waiting on a 1/2" reamer. That's it for the head development its already gone far further than planned. |

| |

|

|