Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

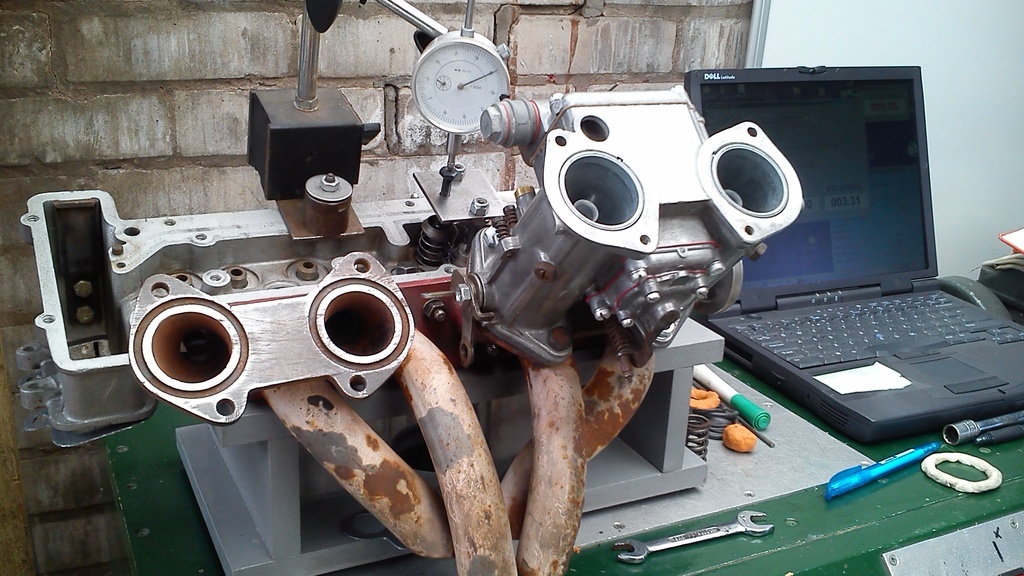

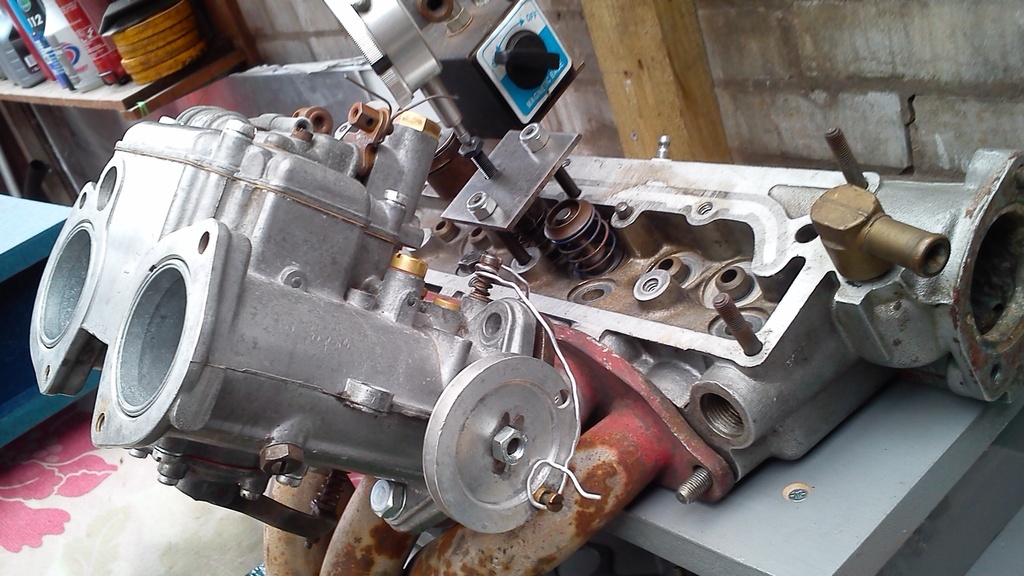

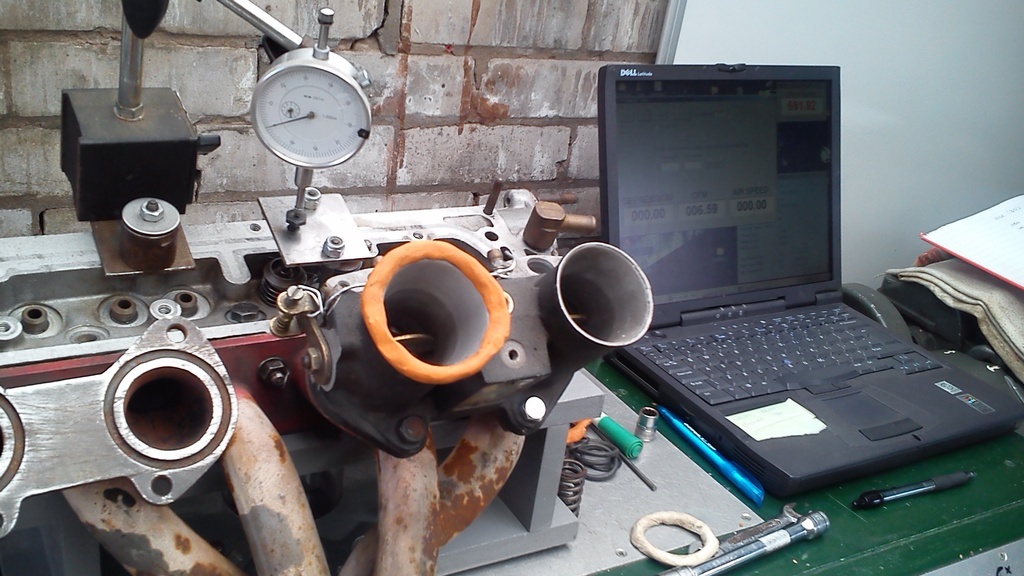

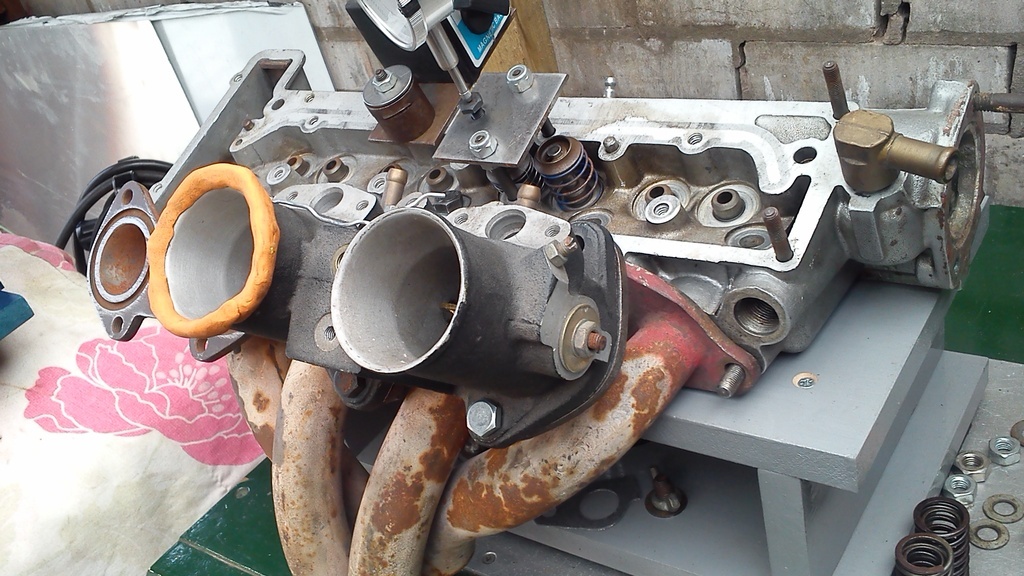

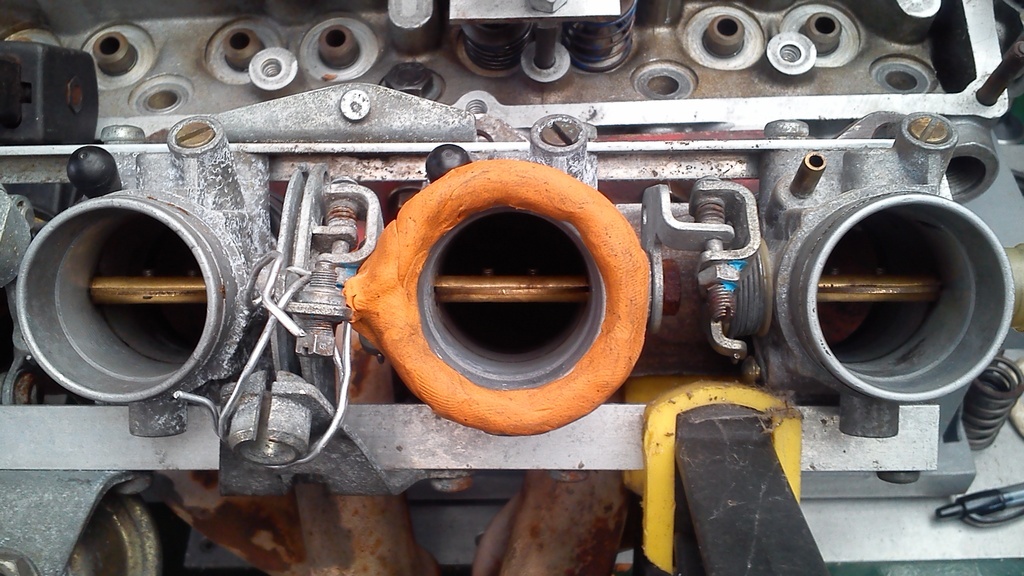

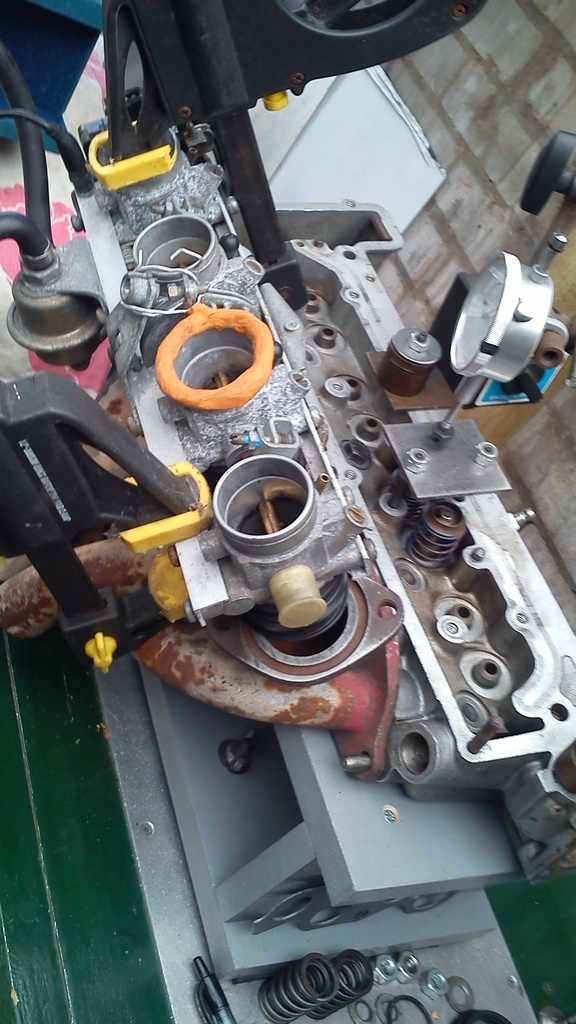

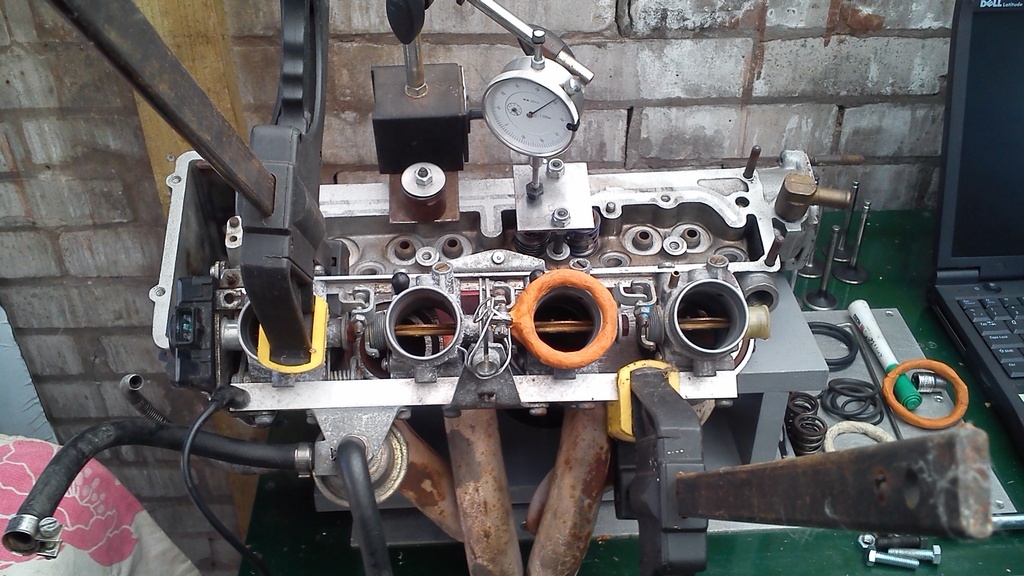

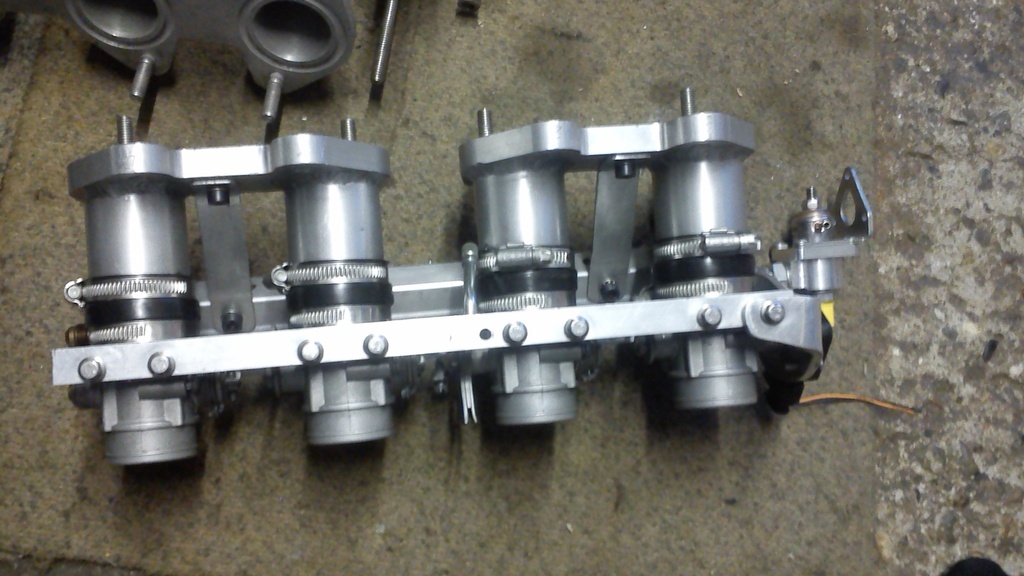

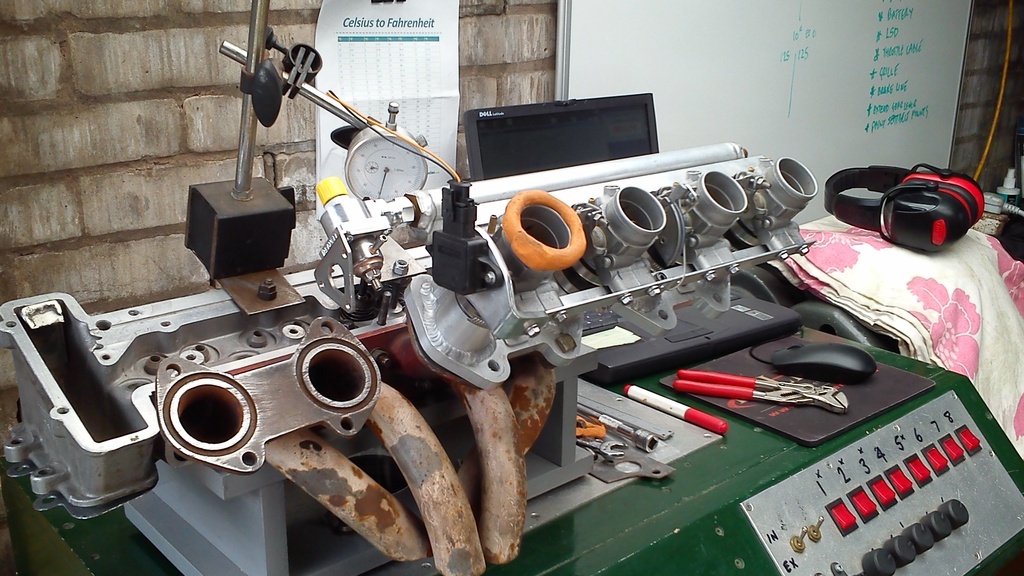

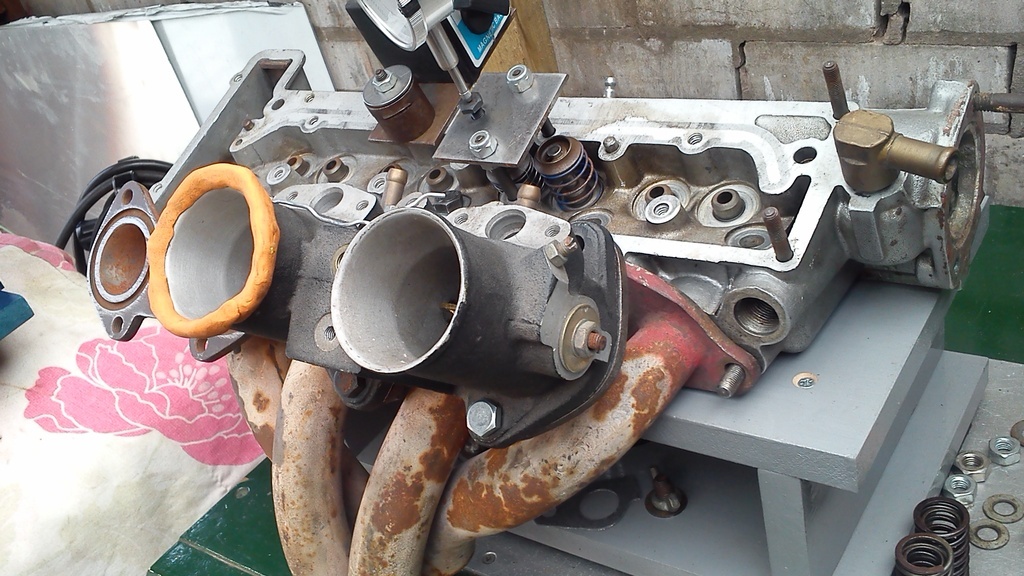

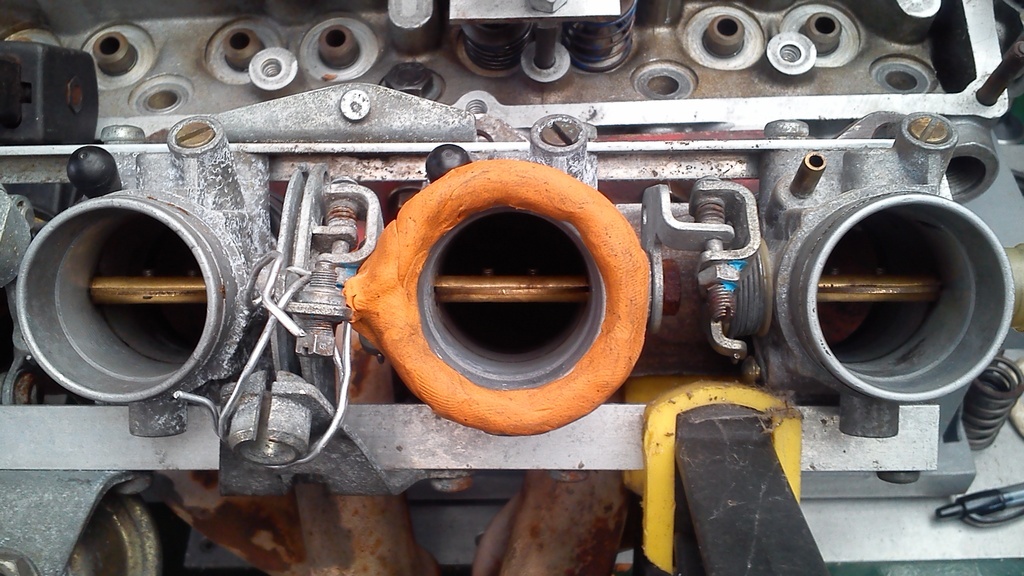

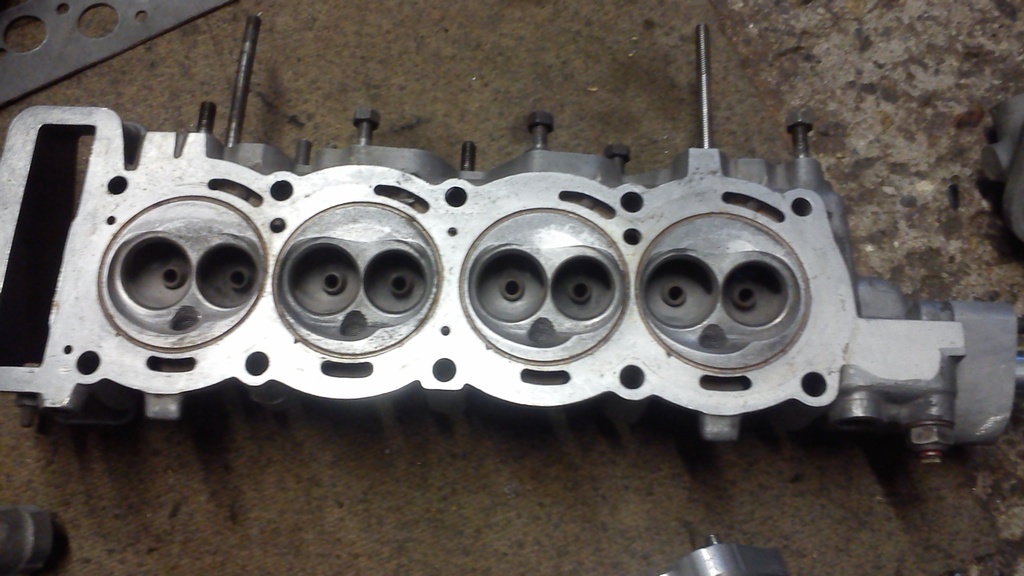

Few more tests just using the big valve full race head ACC212 Tests carried out at 28" with the twin DCOE/DHLA manifold The match to the head is pretty good but could be made better as there is that difference between the two. Manifold could do with being opened up a little more for a perfect match.  First tested with a DHLA 40 with 30mm choke - No Radius entry   050 - 23CFM 100 - 44CFM 150 - 64CFM 200 - 80CFM 250 - 87CFM 300 - 95CFM 350 - 100CFM 400 - 102CFM 450 - 104CFM Next few tests I only ran at the top end lift to see where they went. Radius entry 400 - 103 450 - 105 So not really much to write home about with the radius as we have found before with a 40 and 30mm choke Then tested with 32mm choke and a radius 360 - 101 400 - 105 450 - 107 40mm Weber ITB + Rad   360 - 107 400 - 109 450 - 112 And Finally I held a BMW ITB to the manifold + Rad - Not an ideal test due to the mismatch of the ITB outlet to the 40 DCOE/DHLA manifold - Flow should be gained with a better manifold. 360 - 101 400 - 104 450 - 107 The expectation we had that the BMW ITBs would be as good as DCOE 40's (32) is still holding true.    |

| |

Last Edit: Jul 2, 2022 18:09:56 GMT by Darkspeed

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

Tested the other two heads today First head is a 180 Sport which has had some work done to the ports and the chamber. Standard valve sizes - 1.28 / 1.06  050 - 23CFM 100 - 42CFM 150 - 59CFM 200 - 75CFM 250 - 87CFM 300 - 96CFM 350 - 103CFM 400 - 107CFM Second head is also a 180 Sport which has had some nice work done to the ports but the chamber left standard. Large valves fitted - 1.3125 / 1.125  050 - 24CFM 100 - 41CFM 150 - 56CFM 200 - 72CFM 250 - 83CFM 300 - 92CFM 350 - 103CFM 400 - 104CFM 450 - 108CFM 108 Standard valve with modified chamber  108 Big valve standard chamber.  The two tests highlight the issue with thinking that big valves must always be better. As can be seen in the results the big valve, even though the port work was only second to the ACC full race head, had poorer flow after .050" all the way to max lift. I have seen similar with the 1.4 big valve heads - These need careful modification of the chamber to get the full benefit from them. Typically better flow/power can be had with the 72-72.5 bore engines by using the 1.32 size valves. I will work on getting all the results on a graph to make visual comparison easier |

| |

Last Edit: Jul 4, 2022 20:01:04 GMT by Darkspeed

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

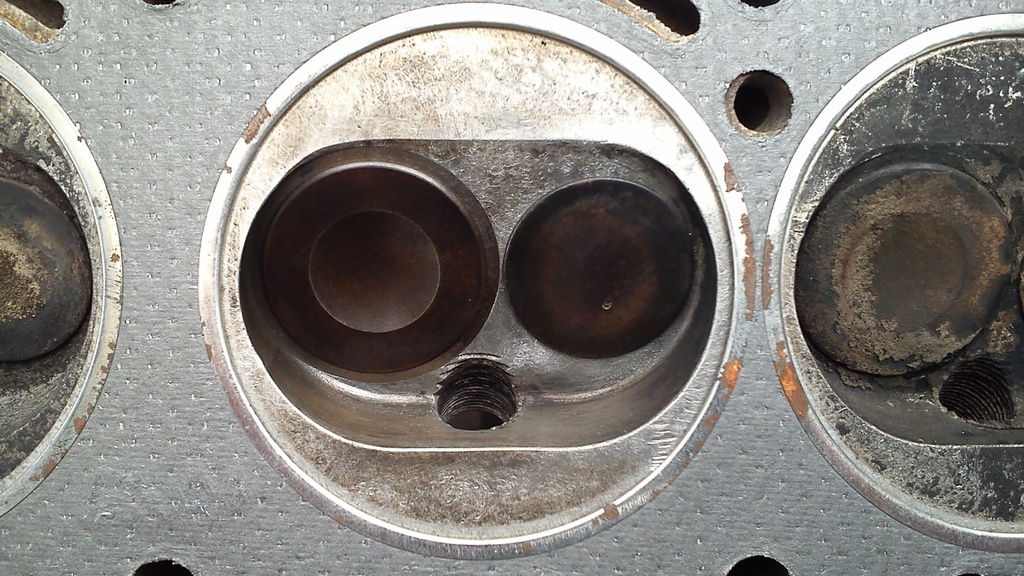

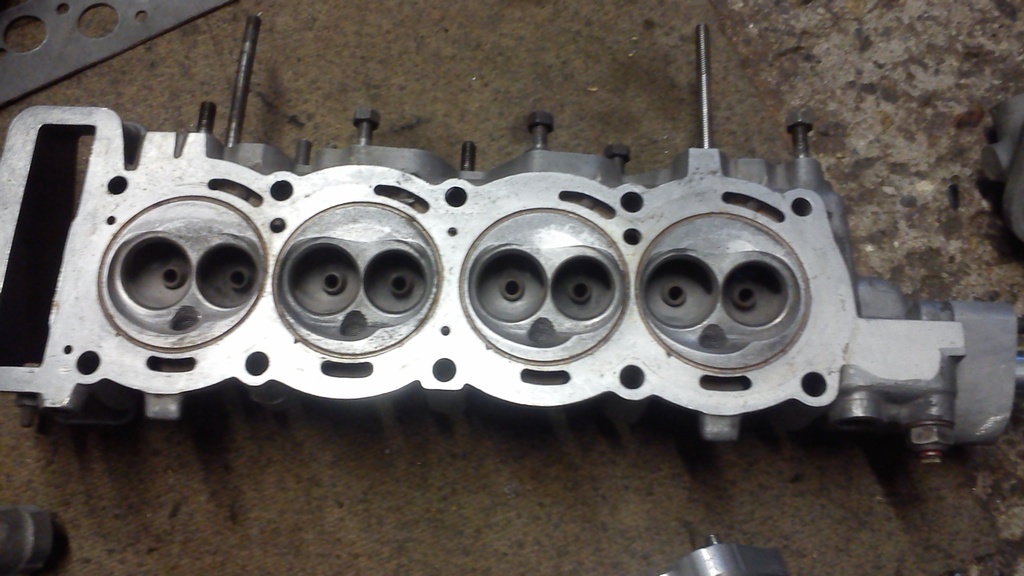

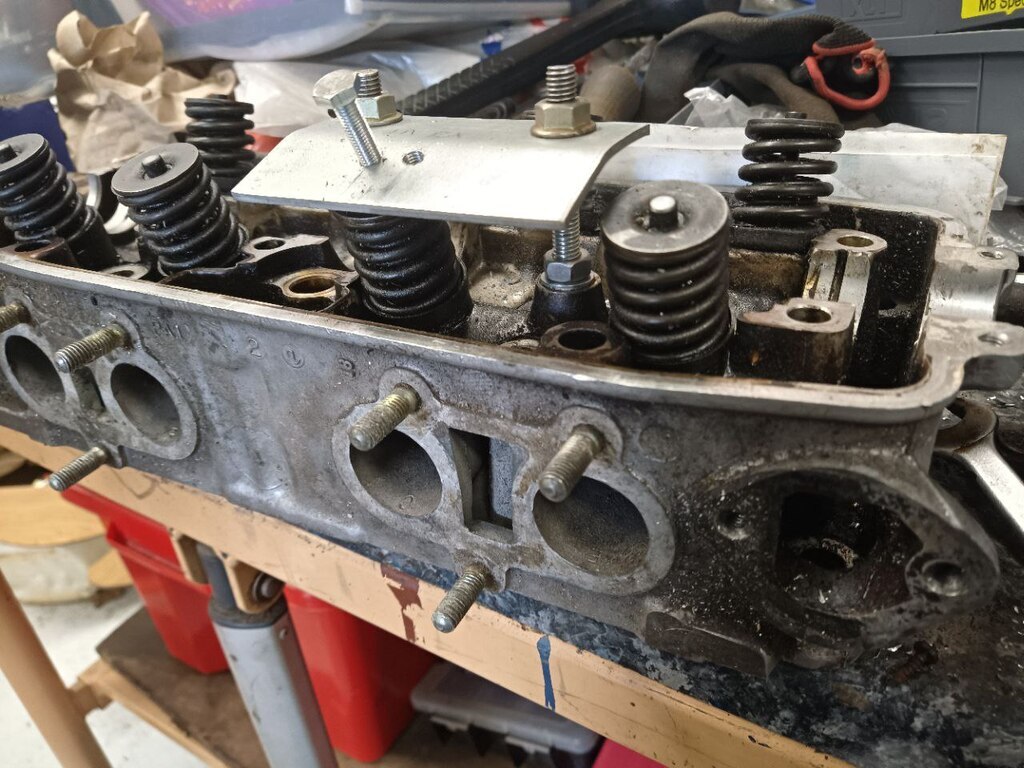

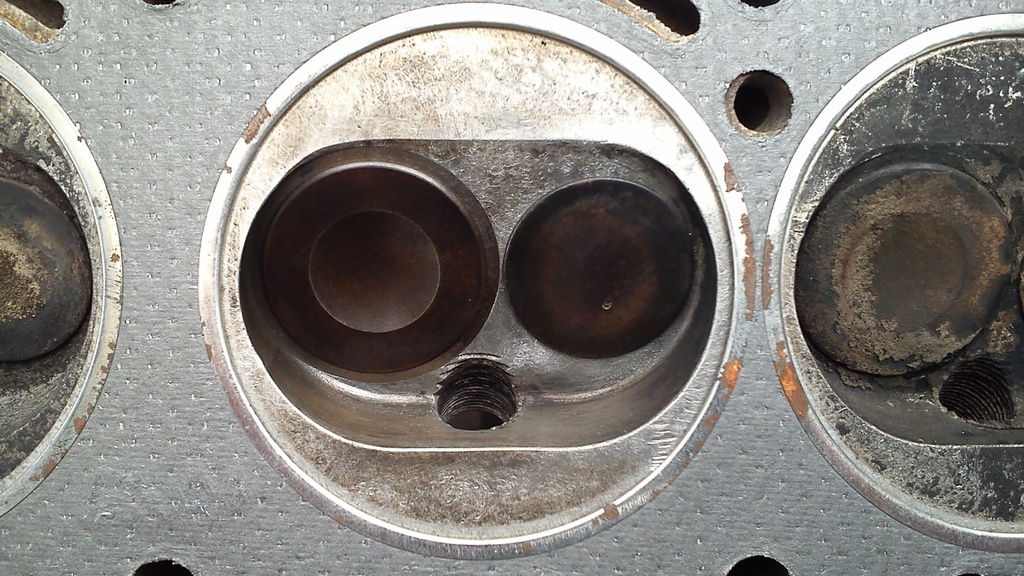

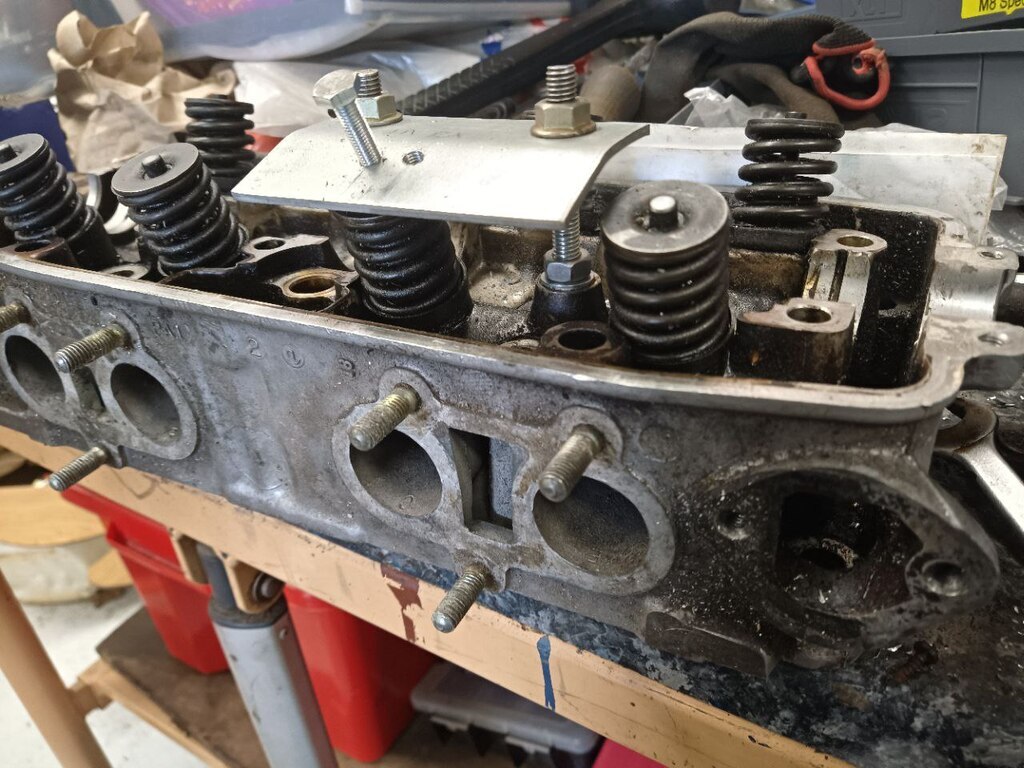

As can be seen in the heads we are using on our engines the chamber modifications for big valve engines should be extensive.  |

| |

|

|

|

|

|

|

|

|

Some years ago I did a Triumph Spitfire and a 2.5 head, Thomas came to see what I was doing as I went along explaining some of my theories, as taught to me by Lez Rider (old time guro who did the heads on the Jags that won at Le Man's on the 50s). Thomas was very appreciative of my work and theories. He took them away didn't pay for one of them saying it was to be flow tested, never saw them again, BUT a couple of months later posted nothing but criticism of my work, inspite of appreciation before, and he still owes money. I am not the only one he did the Dirty on, I have a few more tales but not enough time or space.

|

| |

|

|

|

|

|

|

|

|

I wouldn't feel too bad about the criticism, nobody escaped that.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

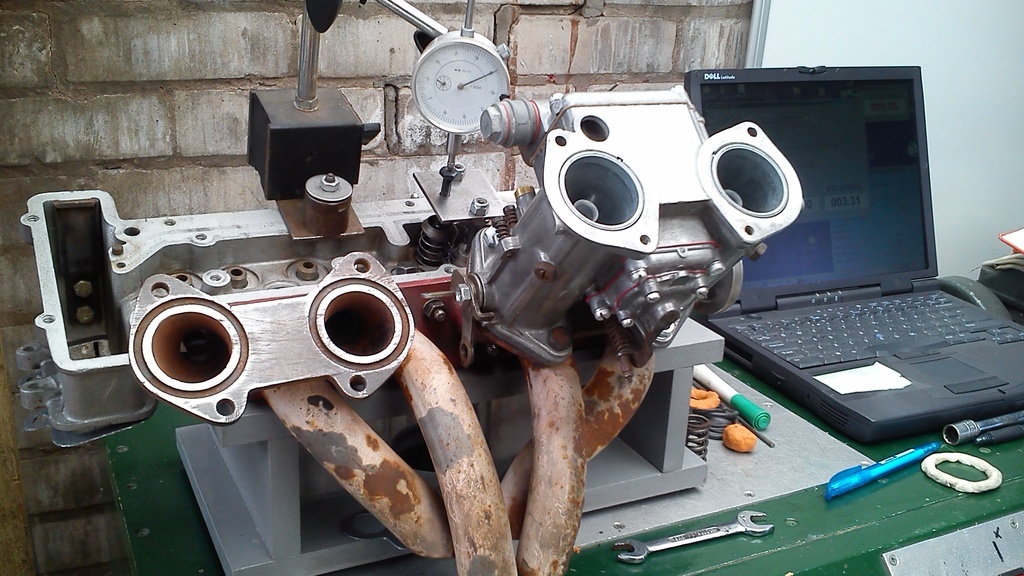

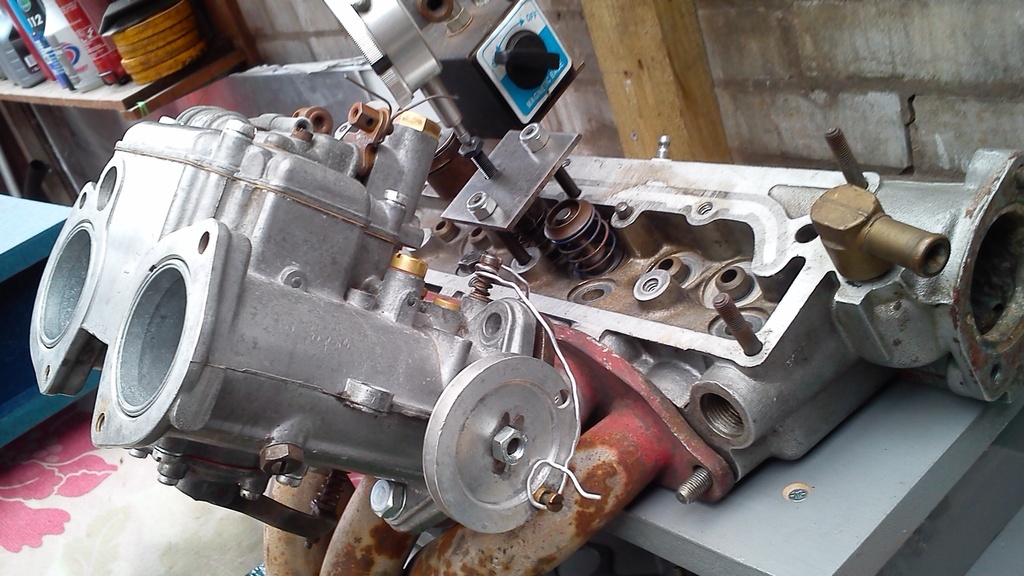

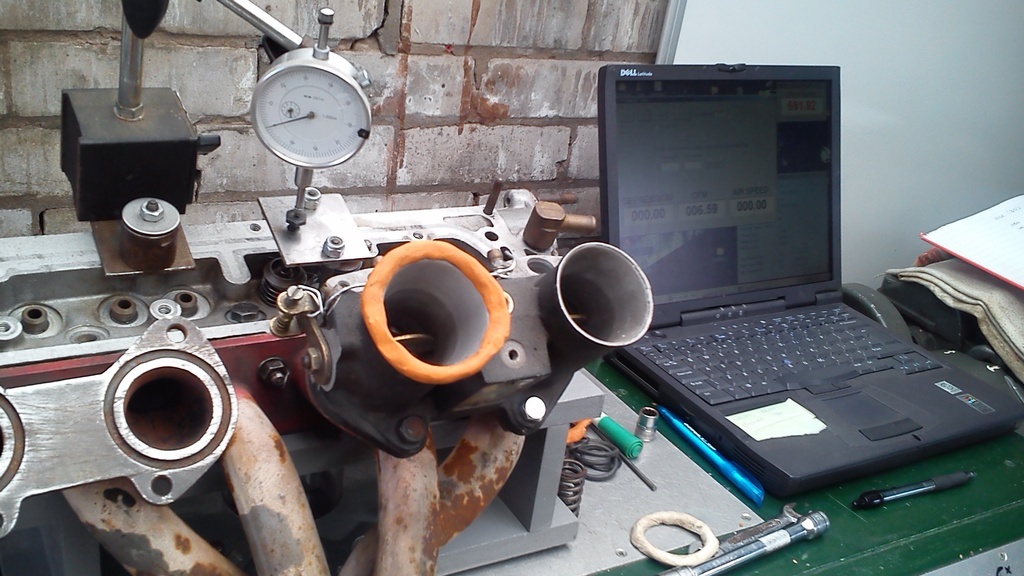

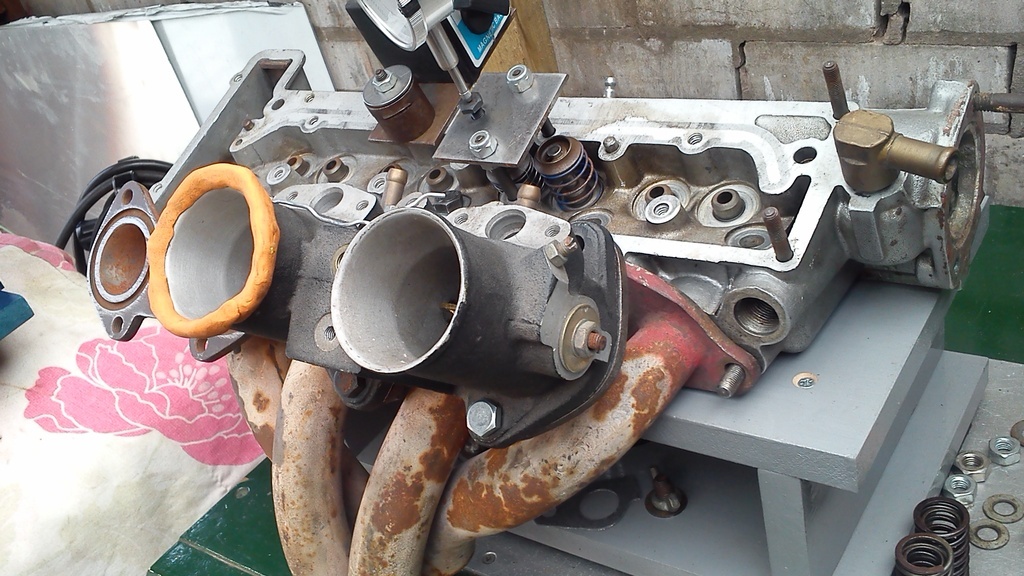

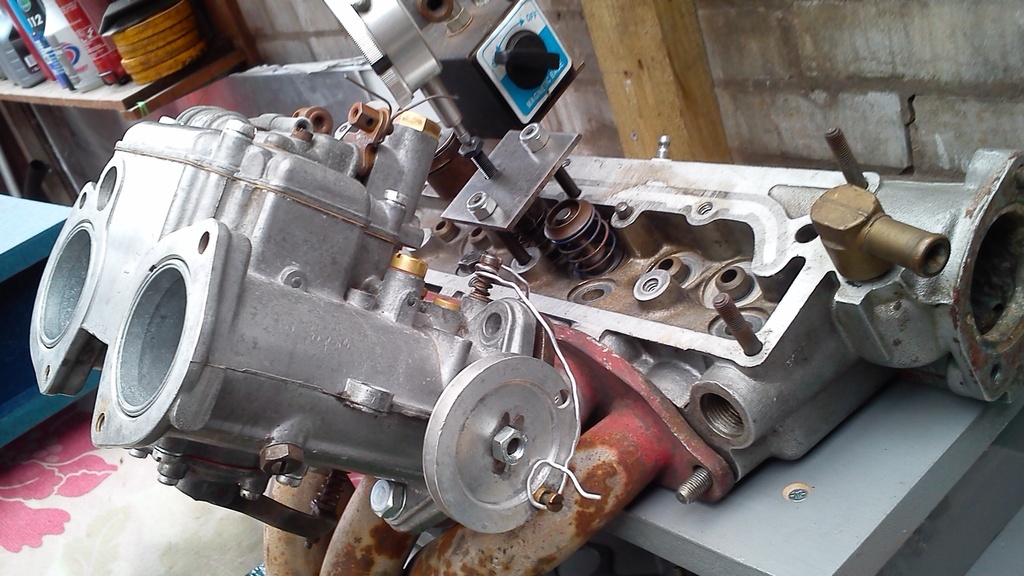

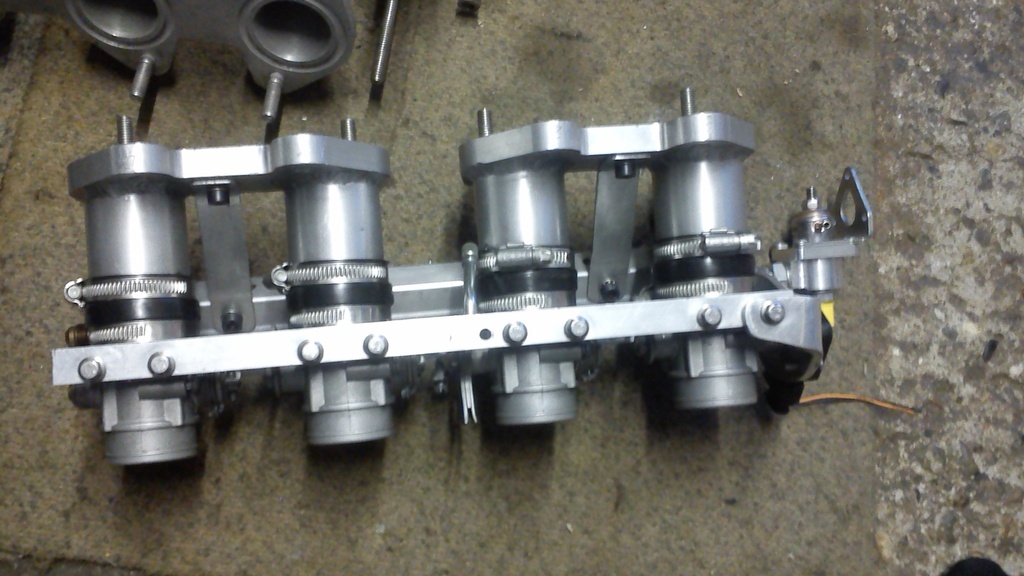

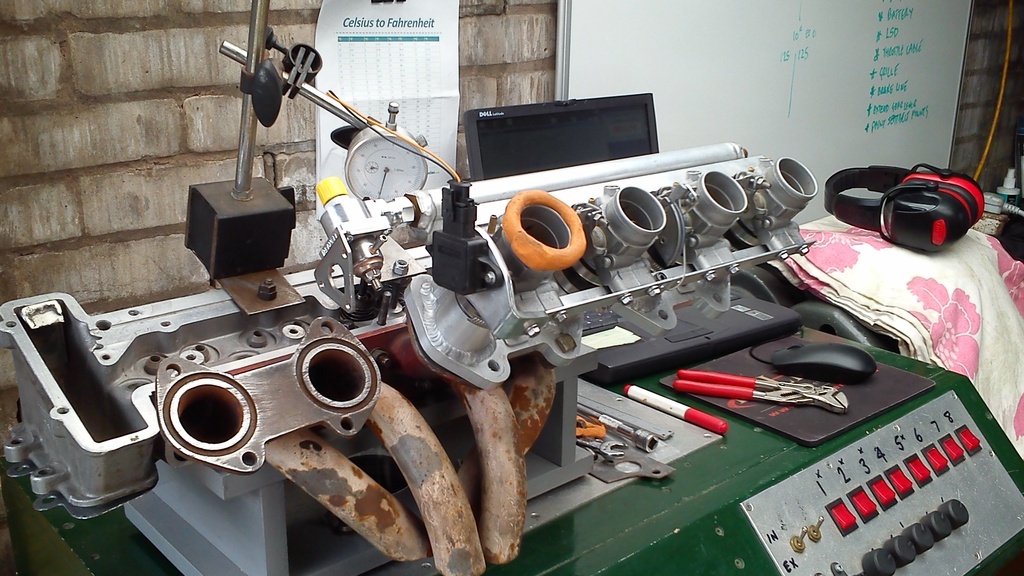

Some more test victims Full Race Carter that's going on the 1200.  My interpretation is F-R = Full Race 138/121 = Valve sizes 1.38 and 1.21 STD-C = STD Compression 10.5:1? - we will discover that when we do the volume checks.  A couple of rare V.W. Derrington twin DCOE/DHLA manifolds   And the BMW K1000 converted ITB's   There will be a short rest in Imp testing after these as I set it up for the Honda. However one of the prior test heads will return after some modifications. |

| |

Last Edit: Jul 7, 2022 21:38:40 GMT by Darkspeed

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

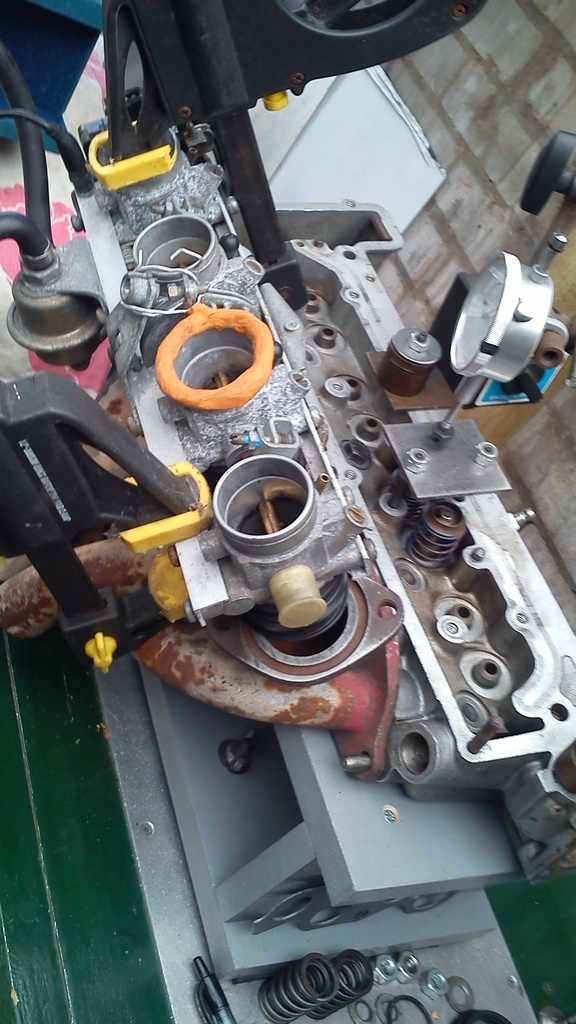

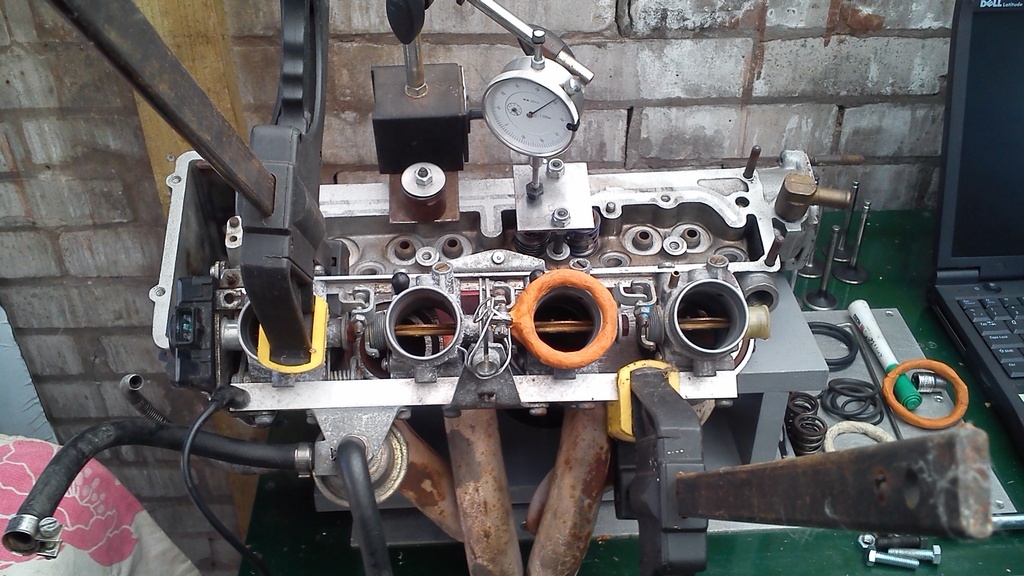

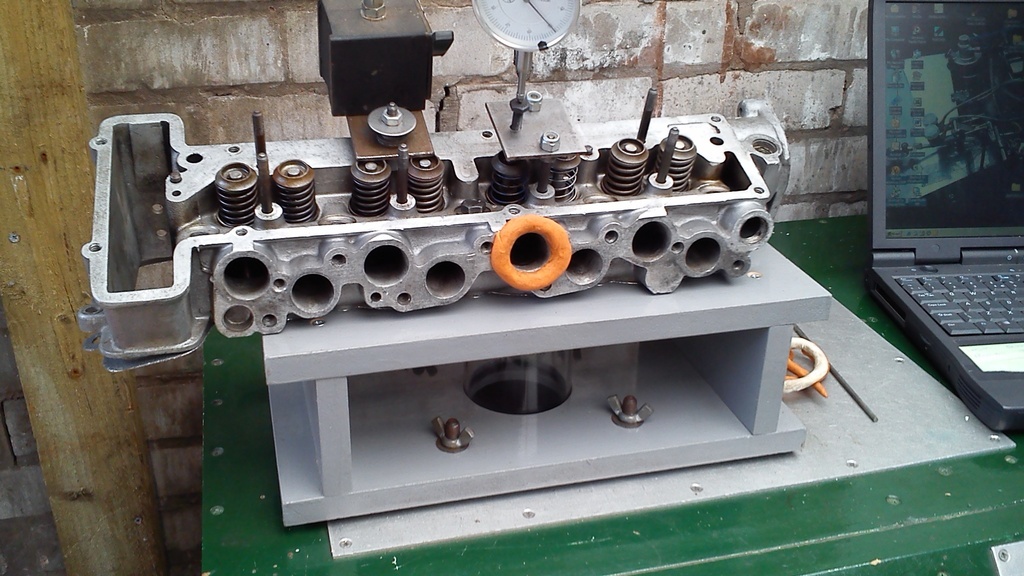

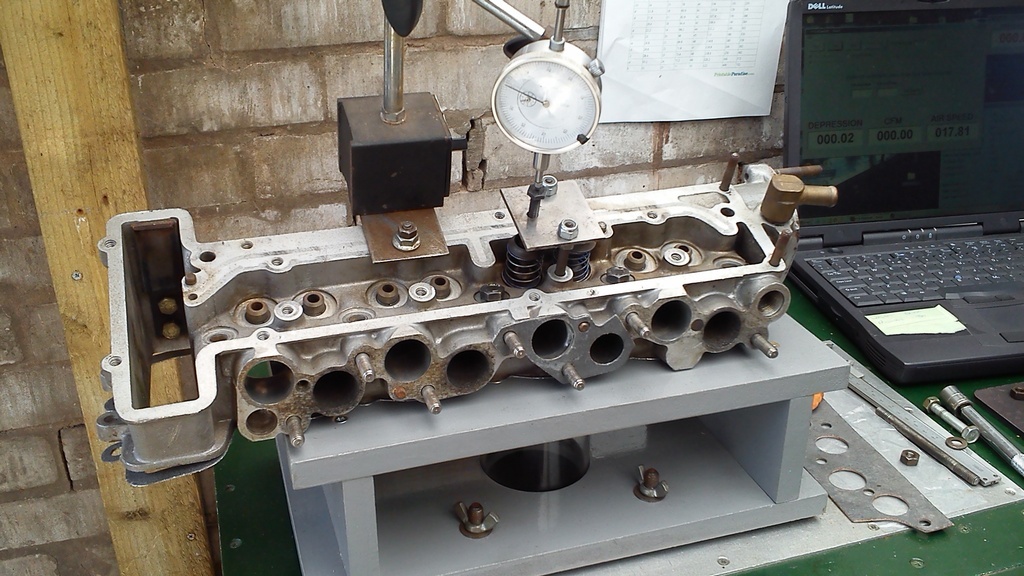

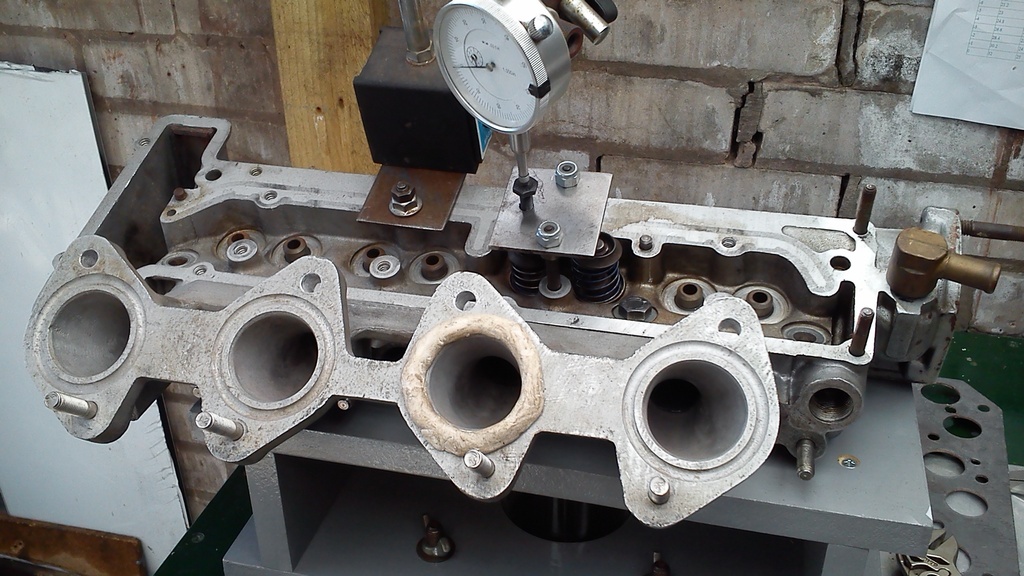

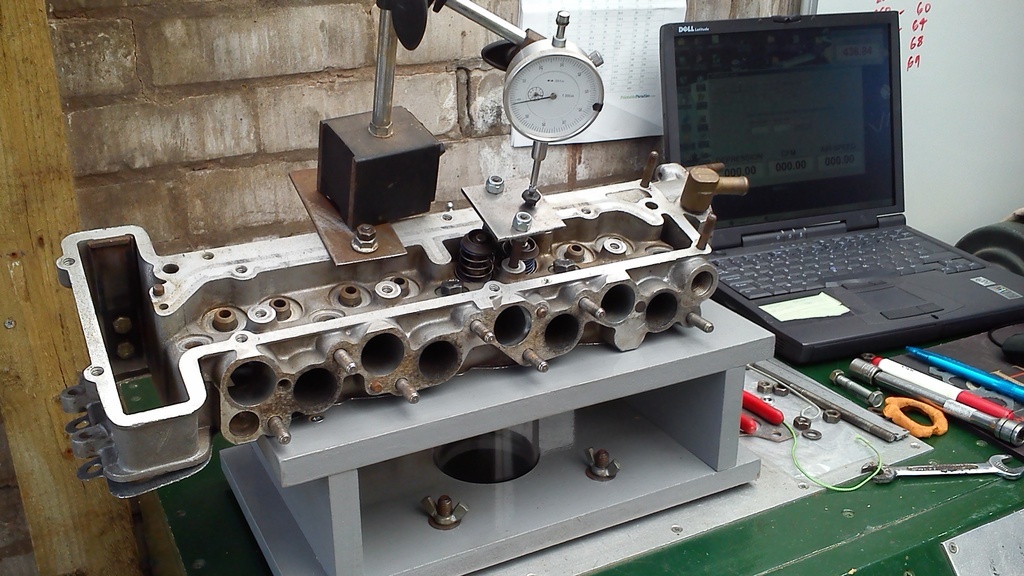

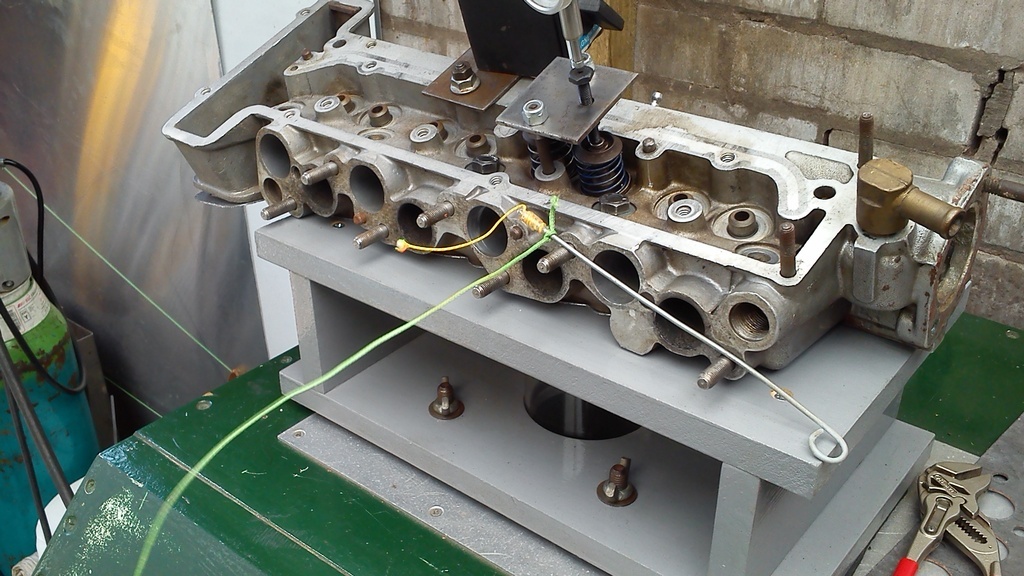

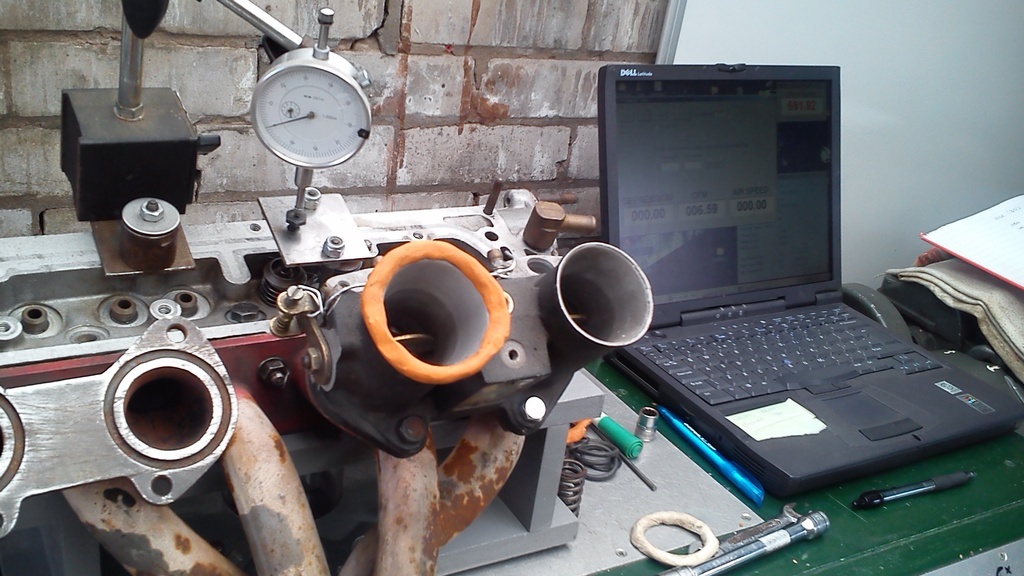

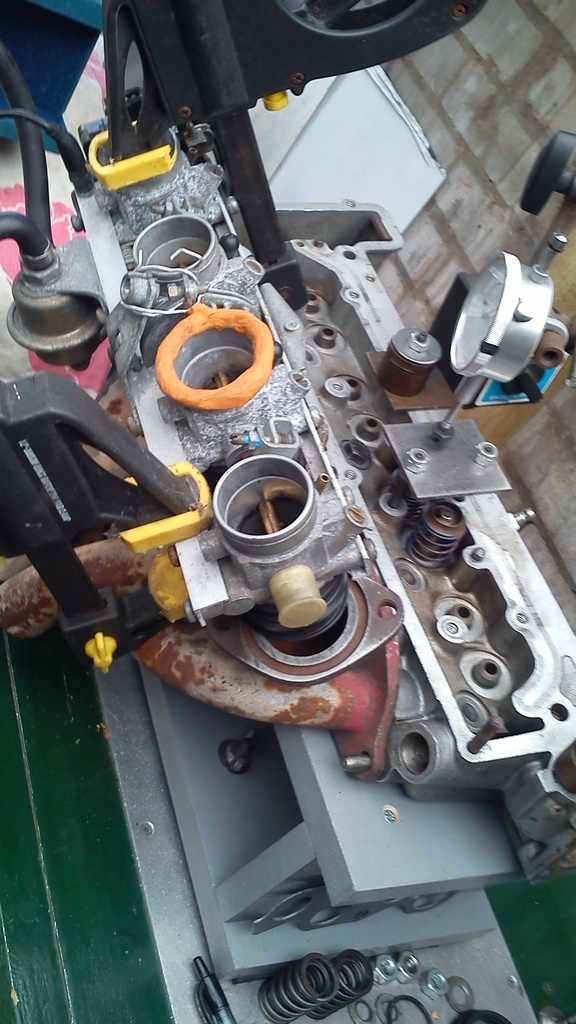

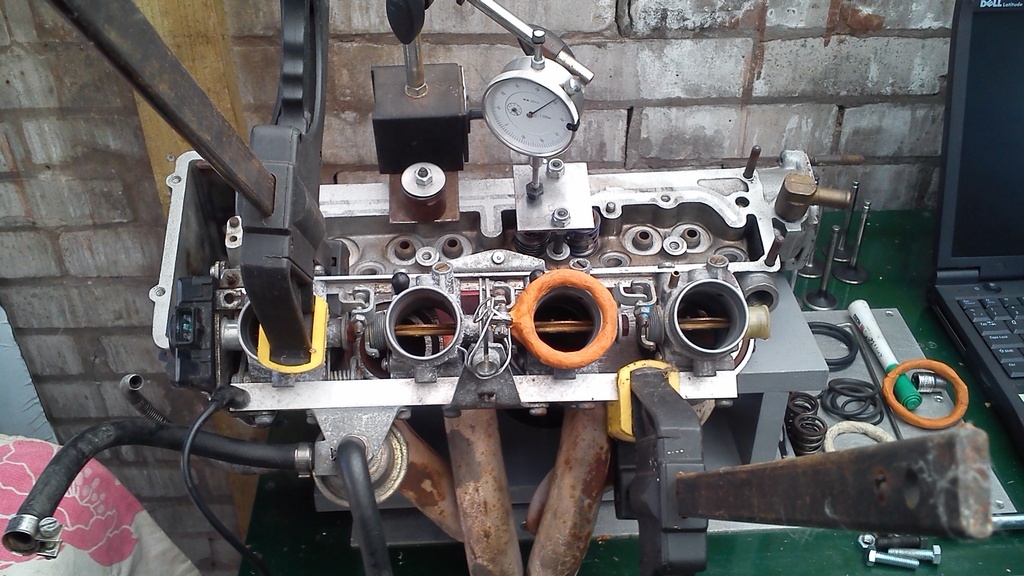

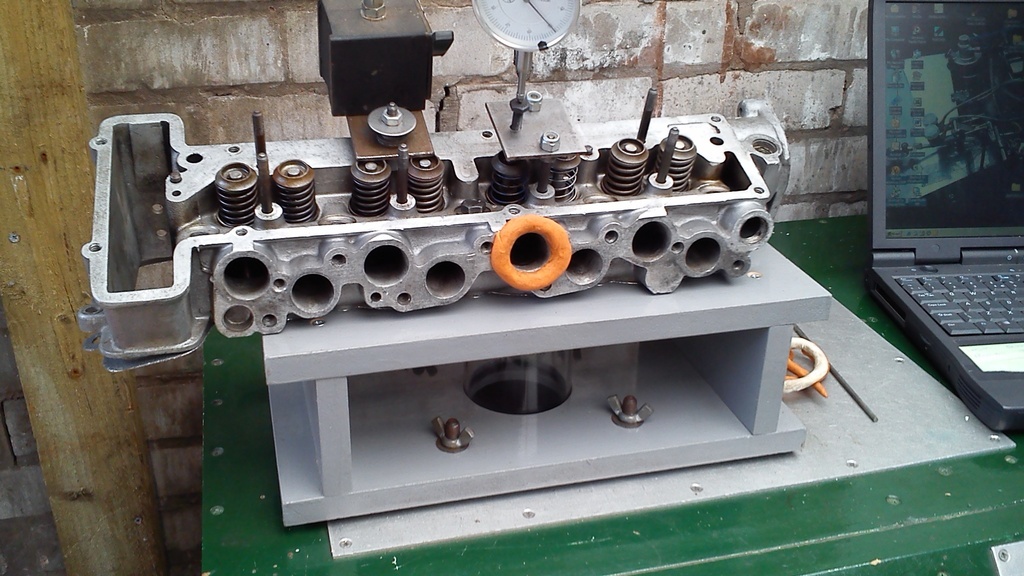

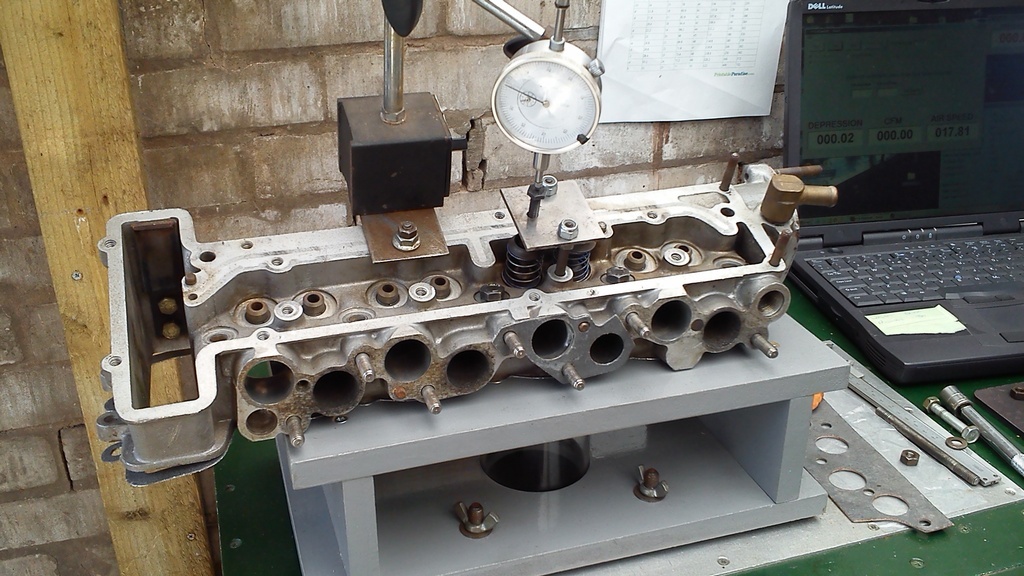

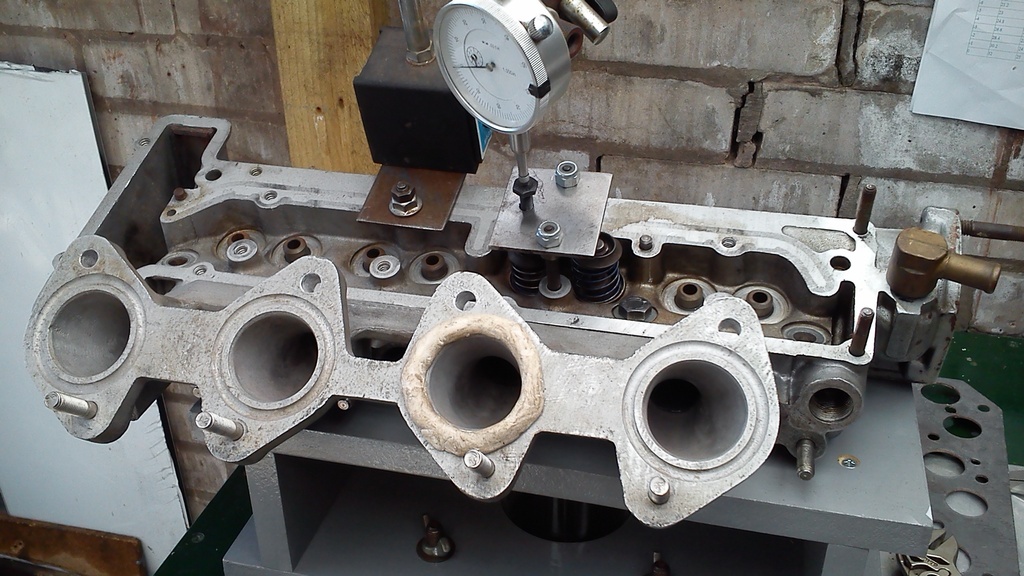

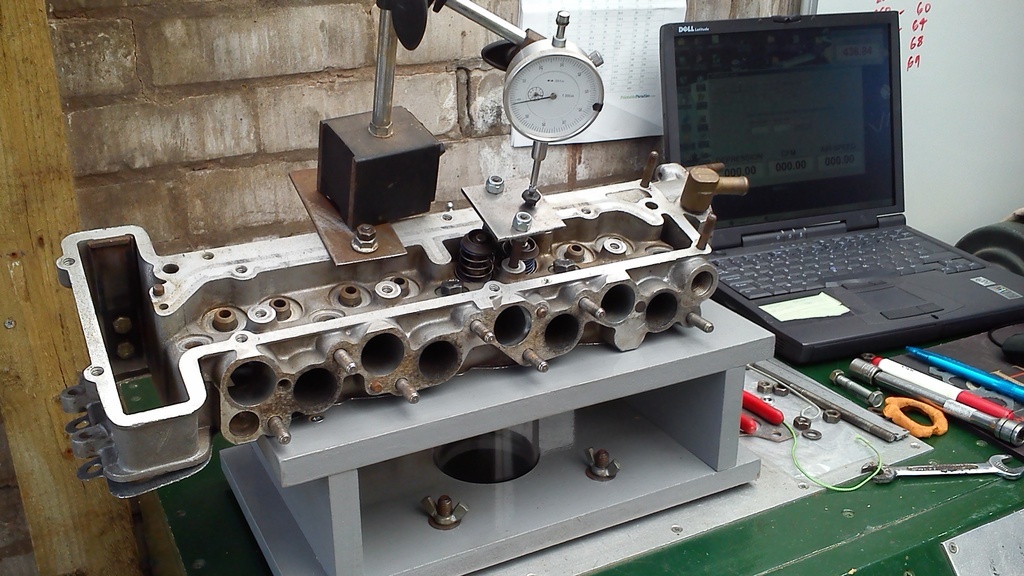

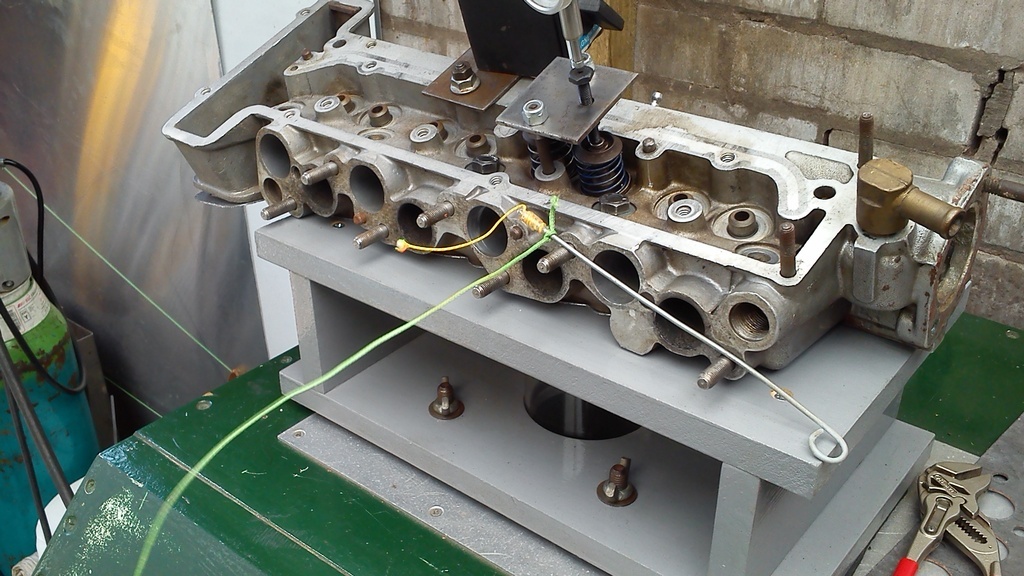

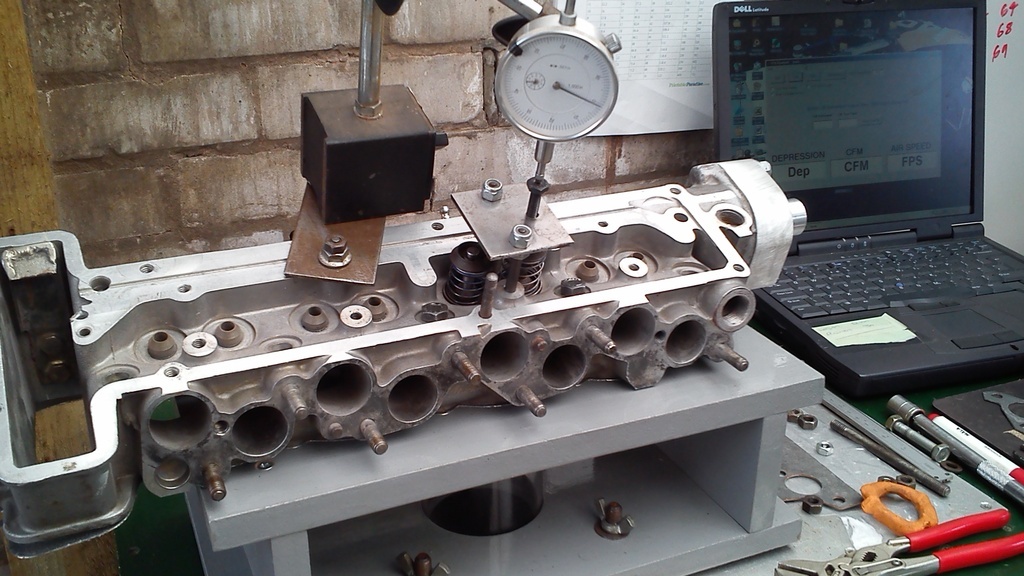

In a few weeks time, I'm planning to visit darkspeed and his flow bench to assess the acclaims breathing, to achieve this a bracket is required to act on the valve   The head will get a clean-up next, but that will be over on my acclaim thread. |

| |

|

|

|

|

|

|

|

|

I'm not sure if this has been mentioned before, but when testing inlet systems, the flow is in the correct direction but is the flow reversed for exhausts?

Also how important is exhaust improvement, given that there is a greater pressure differential due to the cylinder pressure and piston movement?

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 10, 2022 12:37:00 GMT

|

I'm not sure if this has been mentioned before, but when testing inlet systems, the flow is in the correct direction but is the flow reversed for exhausts? Also how important is exhaust improvement, given that there is a greater pressure differential due to the cylinder pressure and piston movement? Covered previously with the main comment from me being that to get the most from the air figures getting into the engine everything else must also be fully optimised. Many benches only test in one direction of flow - The bench I use flows in both directions - there is a reversal duct in the main motor chamber and an air flow direction changeover switch to the digital manometer sensors - For perfect results with the exhaust you have to get into the bench and flip the measuring orifice as these are knife edge calibrated plates that are only calibrated for one direction of flow - The other consideration is that you need to compensate for the air temp due to the heat generated by the motors. However, there are few similarities between the condition on a bench when testing exhaust flow and those in the engine. The engine will pump those gasses out. The article referenced in a previous post about a Chesman Imp head development explains the importance of the exhaust valve/port flow and it also gives a hint as to why in the later Imp head developments they actually reduced the intake valve size so that they could get a bigger exhaust valve in. There is a passage in the Vizard cylinderhead book about the Lotus twin cam - You could spend an age carefully gas flowing the intake and get a 5% increase in power - or you could just change the silencer for the same power increase - This due to the intake port efficiency being high as std. and the exhaust system efficiency being low as std in that particular end to end system. |

| |

Last Edit: Jul 10, 2022 12:39:15 GMT by Darkspeed

|

|

|

|

|

Jul 10, 2022 16:31:51 GMT

|

|

Thanks Darkspeed.

I did notice that the cylinder head around the exhaust valve still has a small "lip" and I wondered why that is not chamfered more to the edge of the cylinder wall to guide the flow rather than give squish?

|

| |

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

If referring to the Carter head that's a swirl ramp - But there are other considerations with that head. As it is being filled by 1150cc of cylinder Carter had more aluminium in the chamber to "work with". There is a limited amount of material you can remove from the head - note the proximity of the valve seat insert to the squish pad opposite the plug - you cannot skim the head endlessly for compression - The smaller intake valve allows a bit more to be taken off the surface - with the 1.4 valve you would be into the seat insert which is not good. When working with small capacities it is easy to go shaping a chamber and end up with a too low a compression.

As shown in the testing above, to get the most from a big valve you need to unshroud the valve - bigger the valve the more material needs to be removed - The incline of the valves limits what you can skim off the deck. No point doing all that great work to get the perfect chamber and get left with 8.5:1 compression - that's not likely to work with a race cam looking for a 12:1 minimum static. Wills rings provide a better gas seal and are also thin so improve compression, these help as not only do we have material removed in the head for these big valves, we also have large cut outs in the top of the piston to compensate for.

Consider how you would get the compression back when its a 998 for a 1000cc class limit! - It's all deciding where you want to compromise.

Where Imp heads are concerned - A big valve head can result in very little or less gain in flow than a stock head unless dozens of hours have been spent with port and chamber optimisation.

|

| |

|

|

|

|

|

|

|

|

Thanks again Darkspeed...as you say - "its all deciding where you want to compromise". It is good that you are able to back up those decisions with some real world facts based on measurements! It is very much appreciated that you are sharing them with us.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 12, 2022 17:06:01 GMT

|

One to test peeps knowledge What's this off?  |

| |

|

|

|

|

|

Jul 14, 2022 21:12:33 GMT

|

|

Not an "A" series, Alfa or Rover V8! Possibly pushrod Ford?

|

| |

Last Edit: Jul 14, 2022 21:13:37 GMT by flyingphil

|

|

|

|

|

Jul 14, 2022 22:00:10 GMT

|

My guess was logicaluk's Honda engine, but it's definitely not that! |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 14, 2022 22:48:40 GMT

|

Not an "A" series, Alfa or Rover V8! Possibly pushrod Ford? Possibly on the nose there - Yep its a Ford Crossflow |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 16, 2022 12:33:07 GMT

|

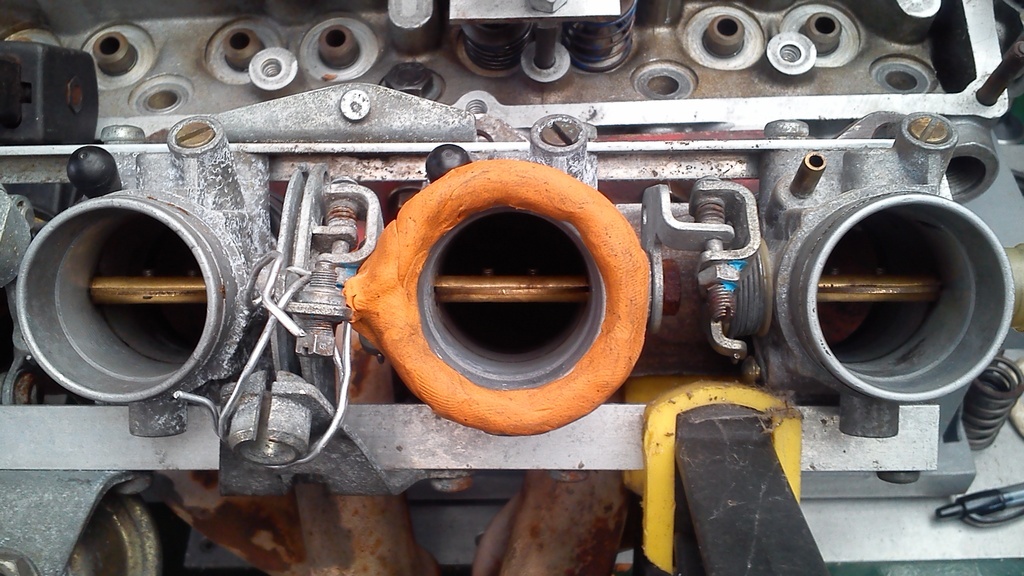

Back doing tests on the accumulated IMP stuff Dropped the Carter 1150 head - 1.38 inlet - There was going to be a testing carried out on the exhaust flow on this head - but I was given the wrong size exhaust valve 1.125 instead of 1.2.  So flow on this head - 16" corrected to 28" 050 - 24 100 - 45 150 - 66 200 - 83 250 - 96 300 - 106 350 - 110 400 - 111 450 - 113 Then carried out a test with the Combined manifold and the BMW ITB - This test highlighted an issue with the BMW manifold that had been built up on the Derrington. The DCOE flange spacing is slightly different between the two manifolds.  050 - 23 100 - 45 150 - 64 200 - 80 250 - 91 300 - 99 350 - 101 400 - 102 450 - 103 I need to make a couple of comments on this test - The inlet valve had not been fully finished for shape - The valve is an REC 1.5 reduced to 138 and a simple 45 put on the end - it had not been shaped or profiled at all and this cam makes a difference at low lift flows between .050 and .100 lifts I think there will be a couple of CFM to find with the seat shape. It may also make a difference at higher lifts as well but that depends on the influence of any chamber shrouding. Also worth noting that there was an amount of mismatch between the head and the manifold that would impact the higher flow numbers. There will be a couple of additional CFM to be had there. The conversations that I have had with the whys and wherefores of the different valve configurations appear to be confirmed on the bench if we compare the Full race big inlet valve Chesman to the 1150 Carter - The inlet flows are not significantly different. But the allowance for the fitment of the big 1.2 exhaust is. Now as I am sitting here typing this I have just realised that a standard Imp Intake valve is 1.2 and I probably have some of them so I could clean one up and give it some shape and run a flow comparison on the bench between the exhaust flow rates of these two heads. During testing today I did do a flow reversal on the intake valve on the Carter the air flow and velocity out of that port is quite something. I then dropped the Chesman head on the bench and ran the numbers on the Derrington manifolds - Test first with to confirm figure same as previously measured  Then the manifolds  The figures were identical for both Slightly ported and stock Rad 200 - 82 250 - 93 300 - 102 350 - 107 400 - 110 The flow reduction measured is mainly down to the mismatch of the manifold and the port. Some simple port matching would get the figures up to the same or perhaps better than the head and radius alone. Any Imp fanatic who is in the market for one of Derringtons featured in the tests - drop me a PM. |

| |

Last Edit: Jul 16, 2022 12:44:08 GMT by Darkspeed

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 16, 2022 13:14:10 GMT

|

Exhaust flow test on the Chesman  050 - 16CFM 100 - 30CFM 150 - 44CFM 200 - 53CFM 250 - 60CFM 300 - 64CFM 350 - 68CFM 400 - 69CFM   So just need to dig out a 1.2 and flow the Carter big exhaust valve for comparison |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 16, 2022 18:27:40 GMT

|

Shocking picture of the 1.2 inlet from a stock 533 Imp head - Given a quick clean up for test duties  Ready for the bench  On the bench  And a short clip of during test Again test at 16 and numbers corrected to 28" 050 - 17CFM 100 - 31CFM 150 - 45CFM 200 - 55CFM 250 - 62CFM 300 - 66CFM 350 - 71CFM 400 - 74CFM As this head is developed for a 410 lift Cam 450 - 76CFM These figures are not calibrated flows as the plate is upside down in the bench but these are just for the back to back on the Chesman full race with the 1.125 and Carter 1.2 Edit. I did a a calibration plate test on the reverse flow and it shows that the reading are 20% low due to the measuring plate not being in the correct orientation. I used a 100CFM plate and a 200 CFM plate and they both read 20% low. That should give actual readings for the figures above of - 050 - 20CFM 100 - 37CFM 150 - 54CFM 200 - 66CFM 250 - 74CFM 300 - 79CFM 350 - 85CFM 400 - 88CFM And for the Carter that gives exhaust flow figures at .350" lift of Intake - 111CFM, Exhaust - 85CFM - Exhaust flow figure being 77% of the Intake flow figure. Roughly. |

| |

Last Edit: Jul 19, 2022 7:44:18 GMT by Darkspeed

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

The Flowbench thread.Darkspeed

@darkspeed

Club Retro Rides Member 39

|

Jul 23, 2022 21:26:02 GMT

|

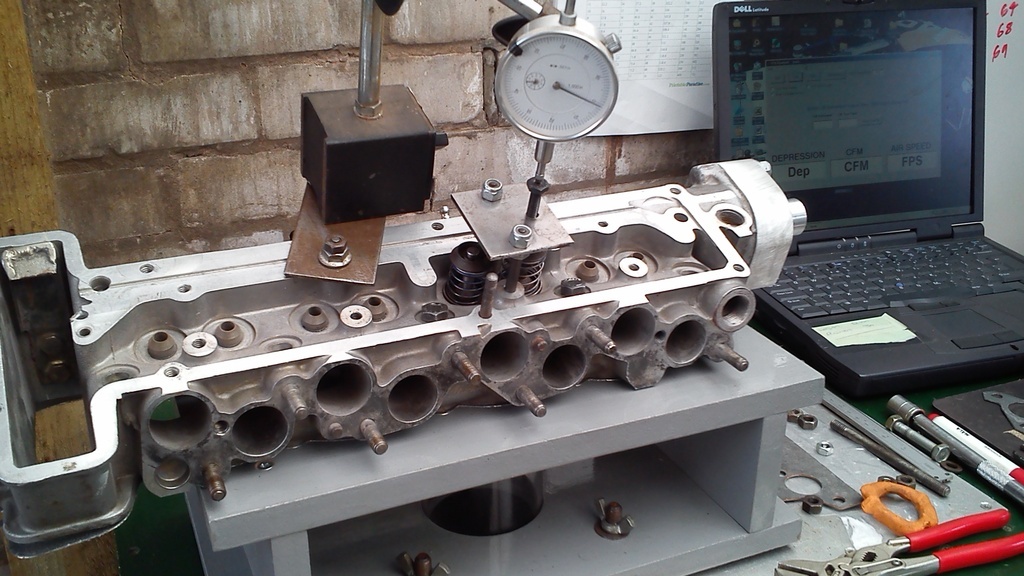

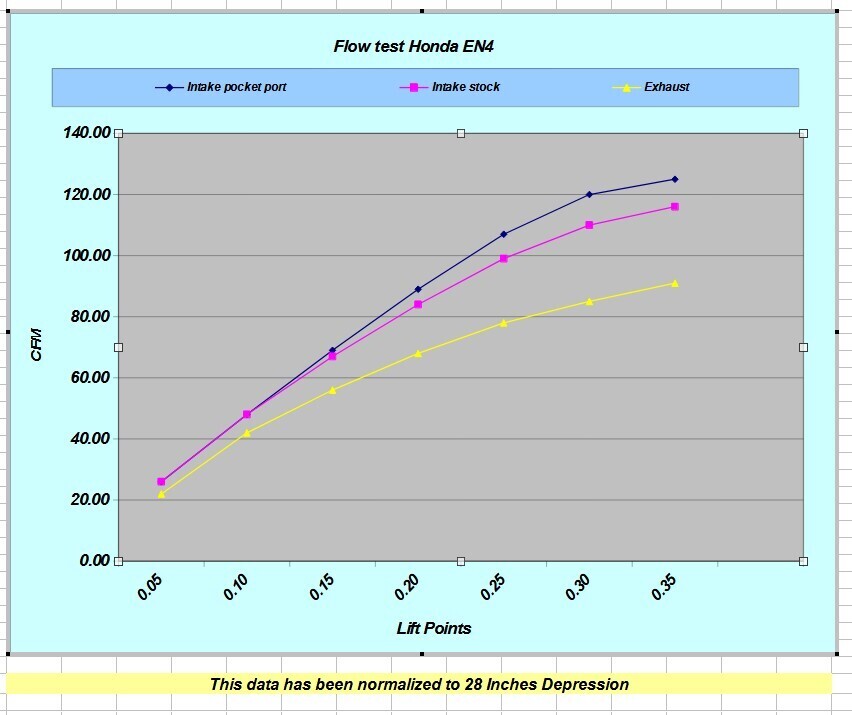

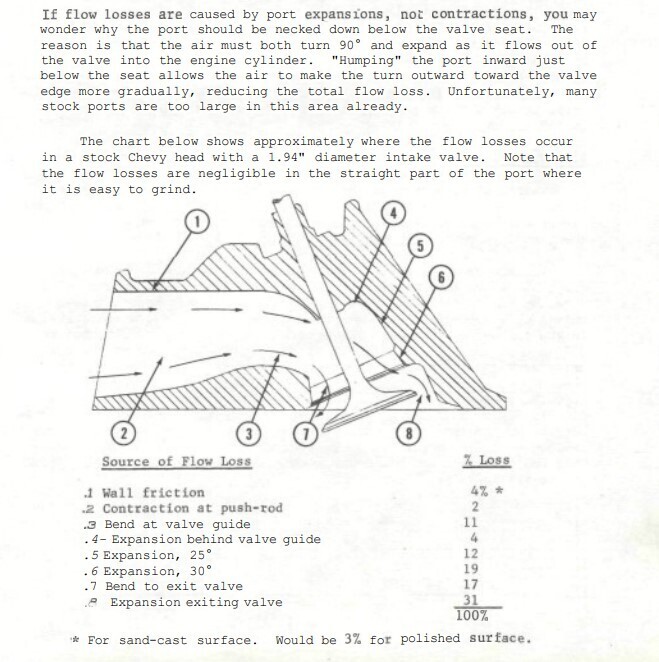

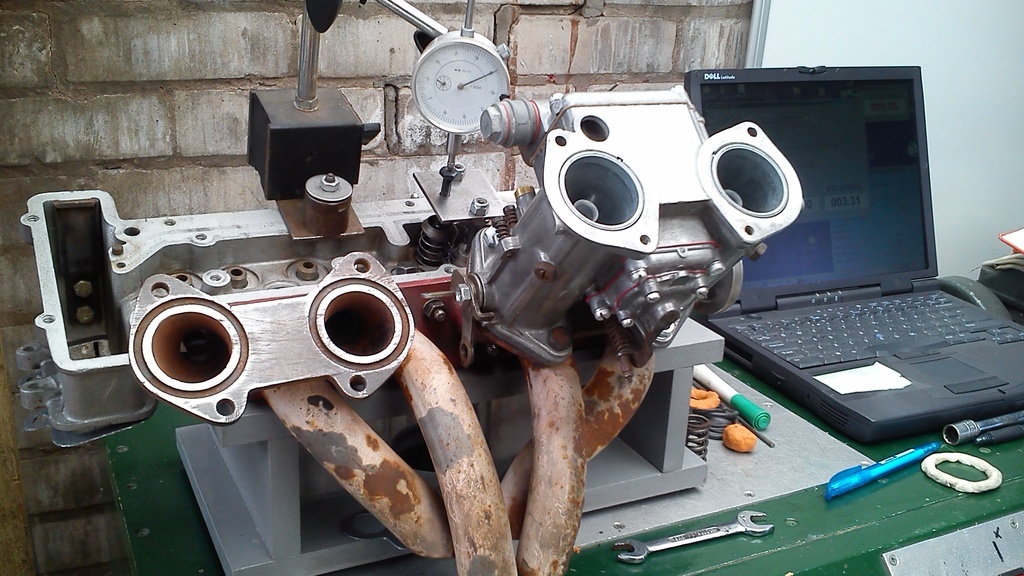

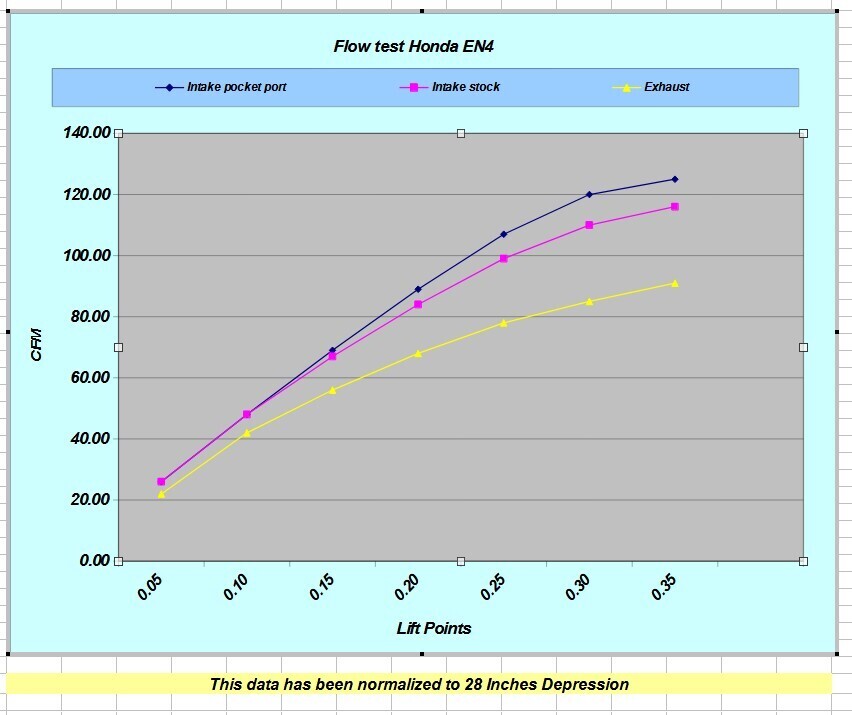

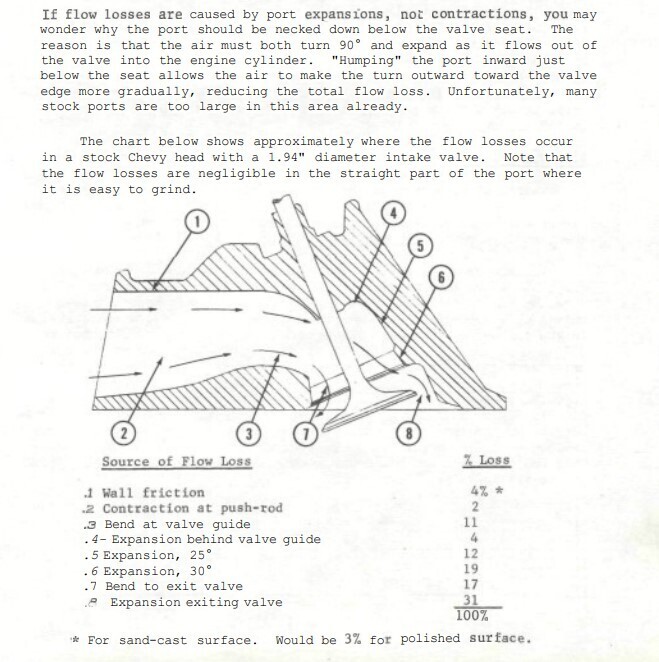

Mr logicaluk popped over today - Lovely to see you mate - to spend the day messing about with the flowbench. I will let you post up the pictures of all this Honda/Triumph Acclaim gubbins hanging off the bench. A more indepth write up will follow once I have spent some time fully going through the data, but the graph below represents the basic head testing and a tiny bit of porting I did to show where small amounts of work can make a fairly significant change. The flows on the intakes are with a clay radius on the entry with flow taken at 28" Modifications to the intake amounted to no more than taking the valve seat out from 30mm to 31.4mm and gentle blend to the SSR  This diagram shows where best to spend the time in the first instances - I focused on 3,6,7 - Nothing done in the chamber as shrouding was not excessive and the chamber was not our focus.  It would be nice to have a scrap head to play with for a bit of development as the head does flow pretty well and the figures given by the bench for such simple mods show that there may well be more to be easily extracted. |

| |

Last Edit: Jul 23, 2022 21:28:22 GMT by Darkspeed

|

|

|

|