820

South East

Posts: 793

|

|

Sept 4, 2018 13:30:38 GMT

|

|

Great looking and spec car. Well done getting through the MOT and all the other jobs to this point.

Chin up with the little issues, there will always be something with so many one off modifications.

Looking forward to more on the road updates.

|

| |

|

|

|

|

|

|

|

Sept 10, 2018 19:15:27 GMT

|

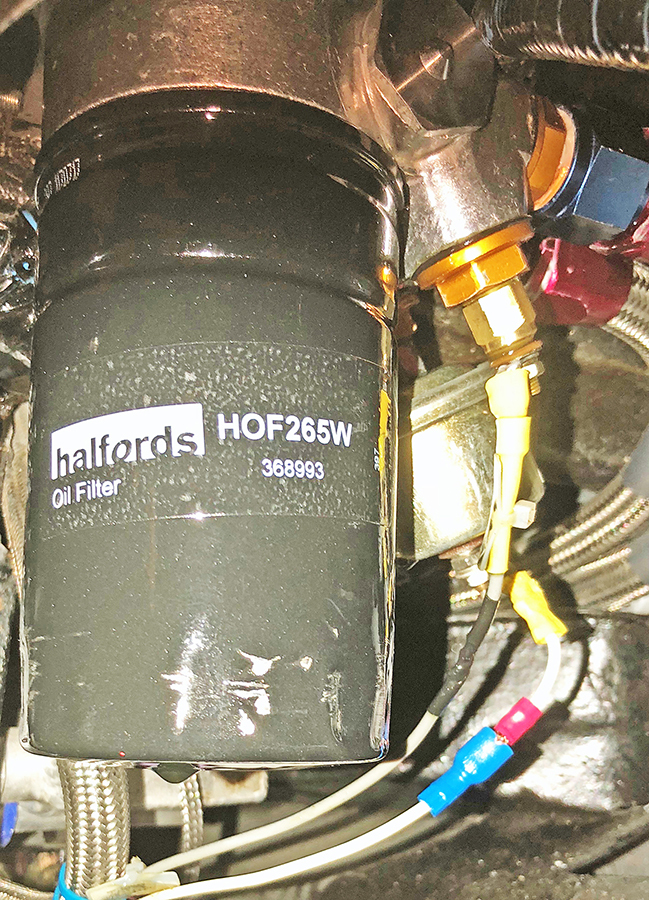

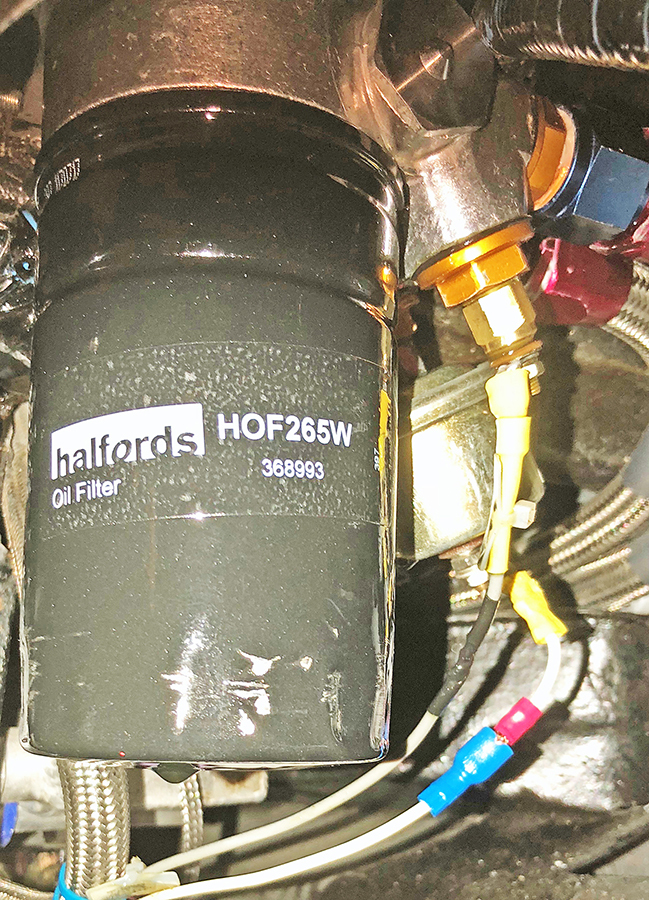

Ok guys, I've dropped the sump guard and checked the headers against the frame rails all looks fine knocking still there! Noticed a small amount of oil dripping from the oil filter took it of to check the seal.   And there's the reason. The filter is grounding out on the mounting thread/nut before it has a proper seal! So I've now fitted a filter with a concave face, trouble is its half the size. I'm having real problems finding a filter incorporating a Bypass valve setting - of 14 PSI with an Anti-drain back valve Looks like I'll have to change the existing layout for the Mocal system so I can fit a genuine Rover filter. |

| |

Bib

|

|

|

|

|

Sept 10, 2018 19:32:06 GMT

|

|

I believe Blackpopracing is onto something with the juddering when he mentioned it being fuel related.

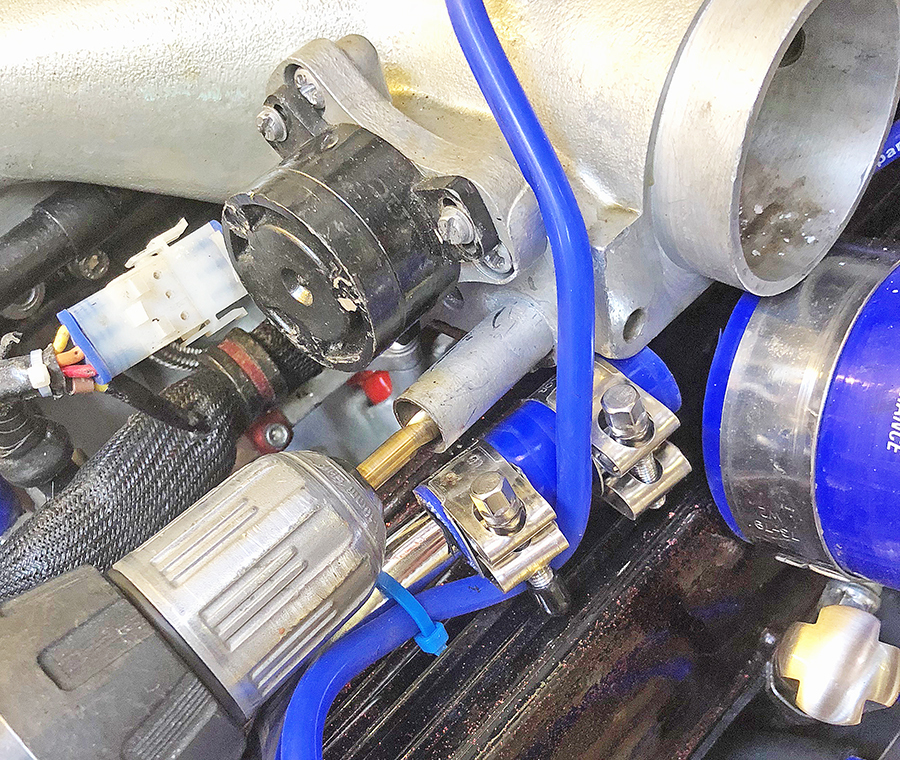

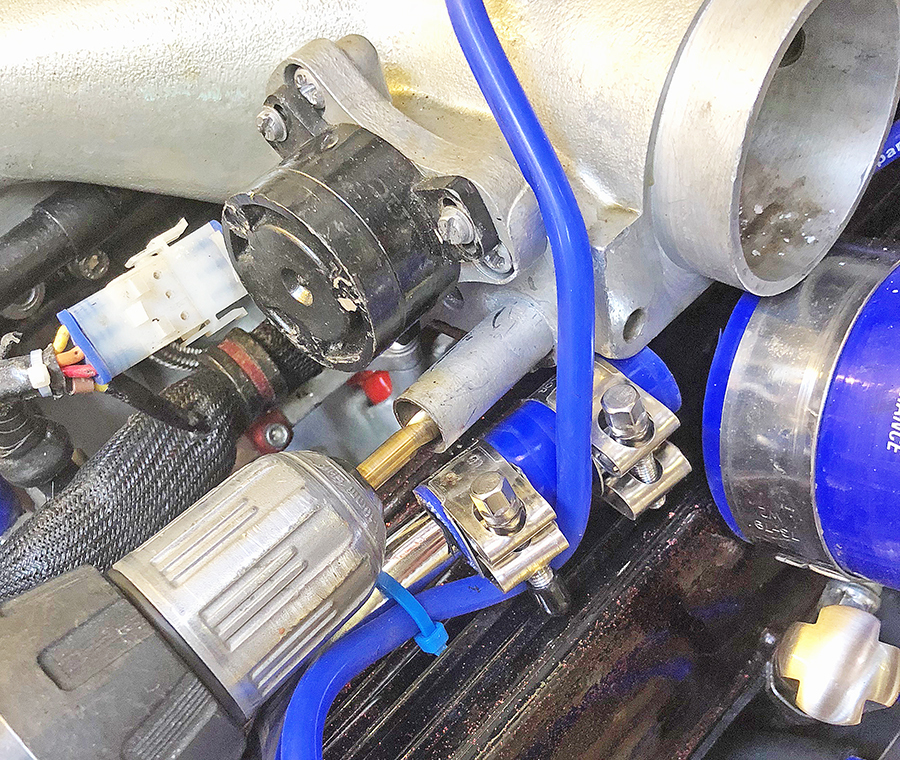

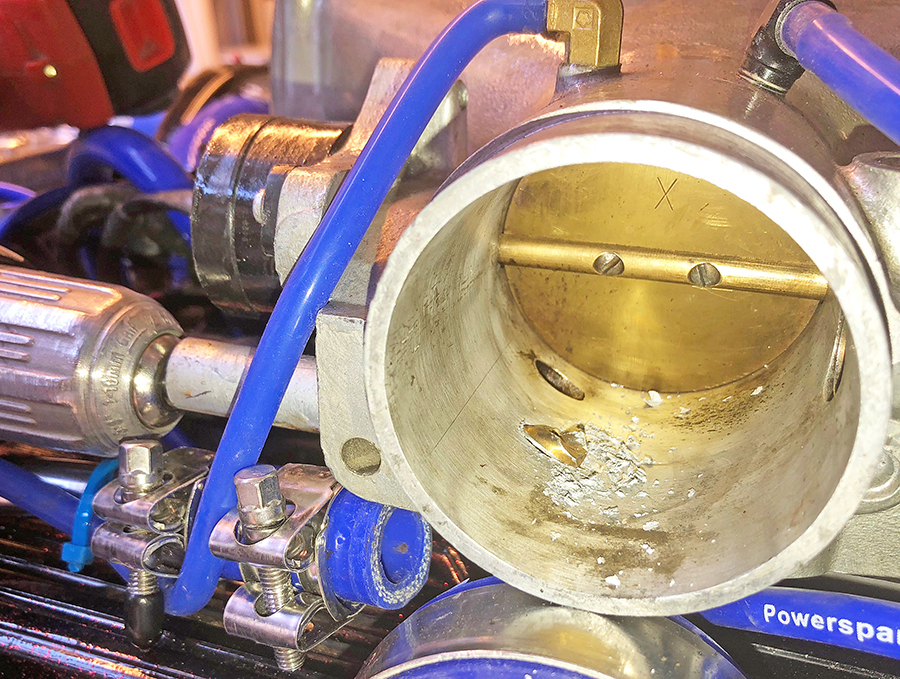

I was also told to check out the overrun valve at the rear of the plenum chamber so while I was isolating this thought I'd spray some Easy Start around the various hoses and found two major air leaks one being the centre plenum securing bolt and worse the inlet butterfly spindle.

|

| |

Bib

|

|

|

|

|

Sept 10, 2018 19:53:54 GMT

|

Anybody know how easy it is to replace the Bush on the Throttle Spindle?  |

| |

Bib

|

|

|

|

|

Sept 11, 2018 21:54:49 GMT

|

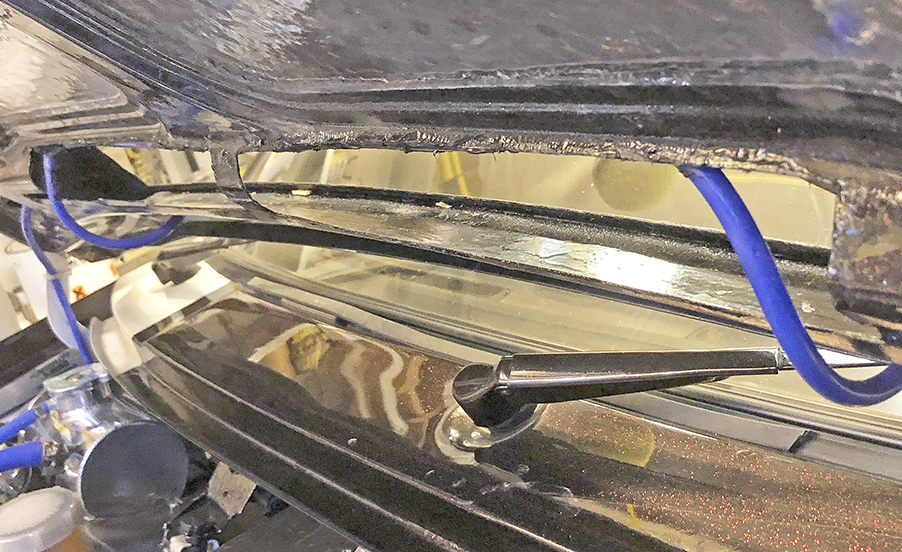

A very good friend of mine has made a sheet to protect the acrylic at the rear of the car so from this -  To this.  |

| |

Bib

|

|

|

|

|

Sept 17, 2018 18:54:18 GMT

|

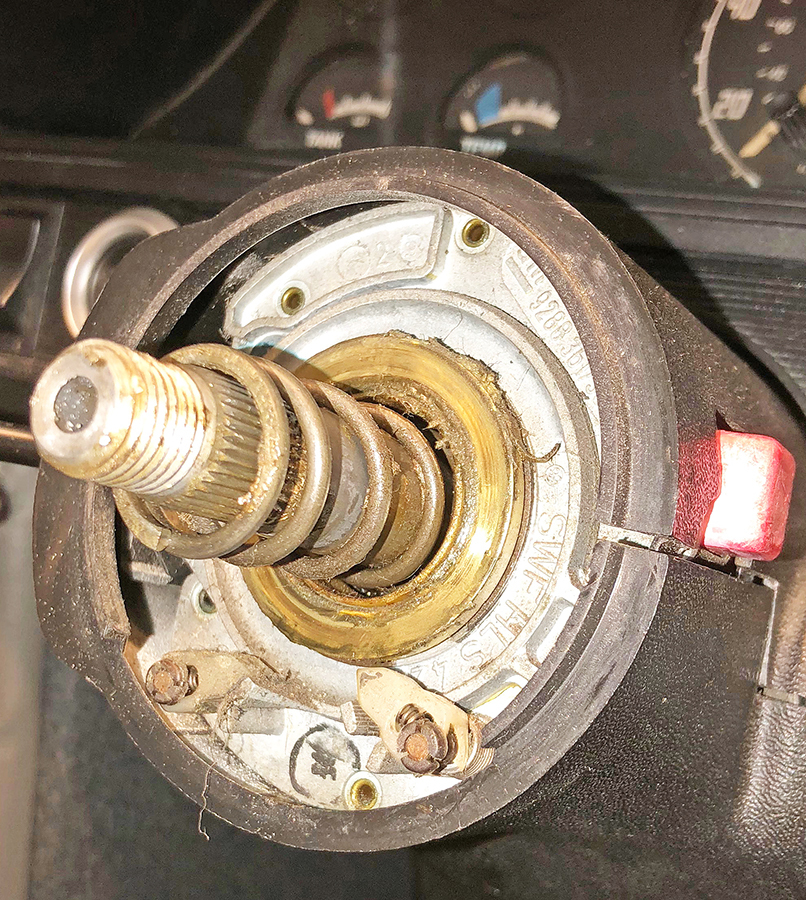

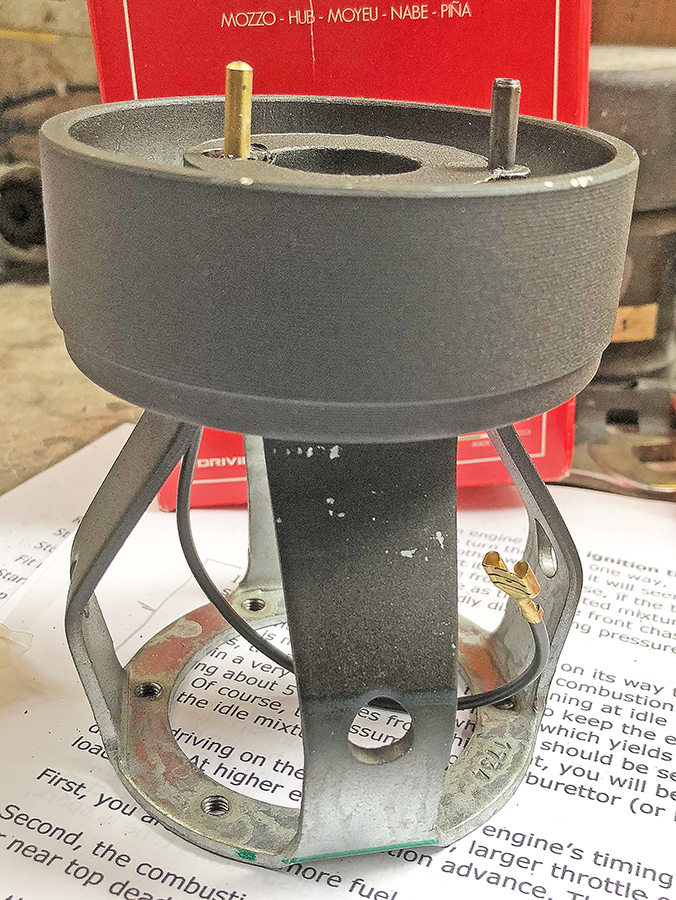

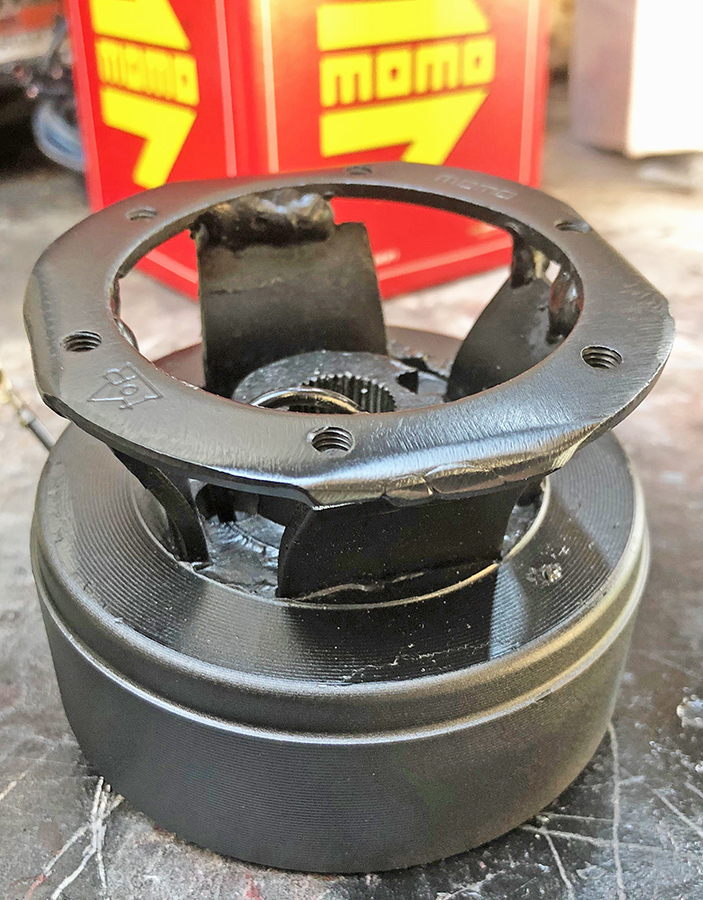

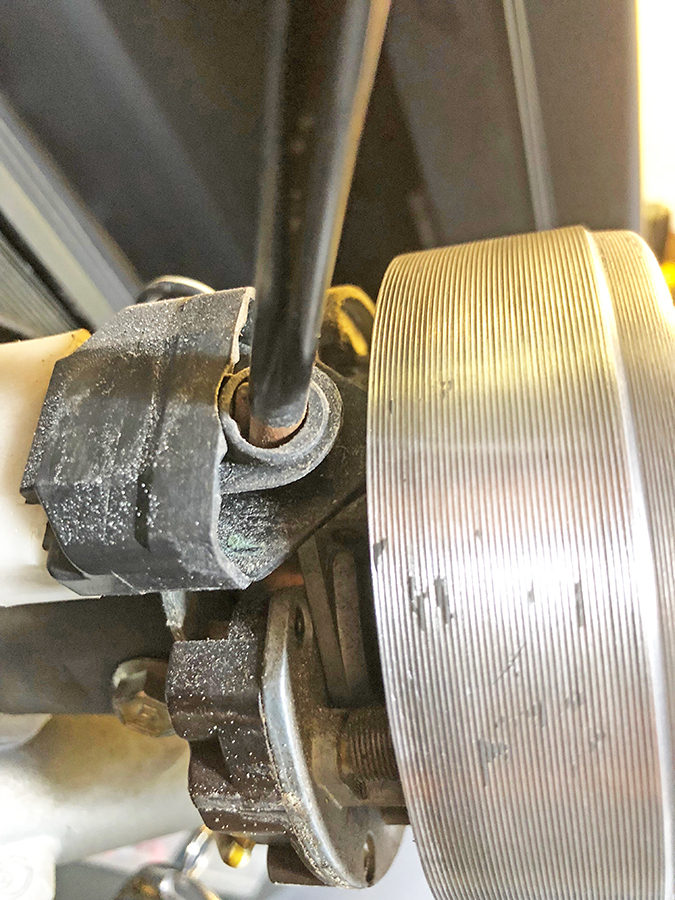

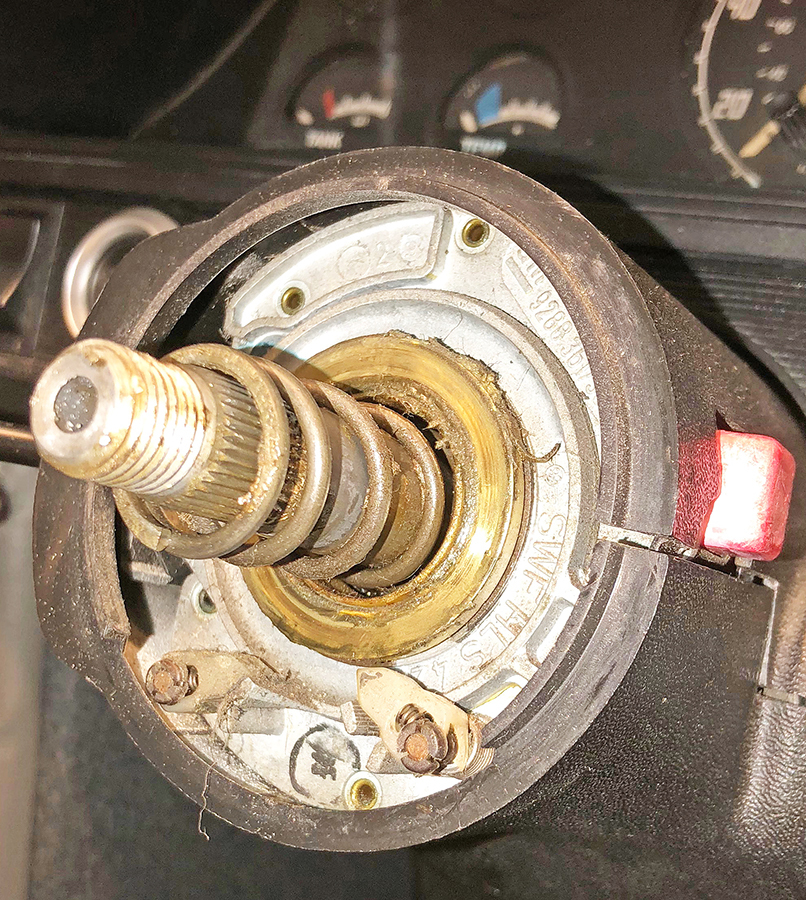

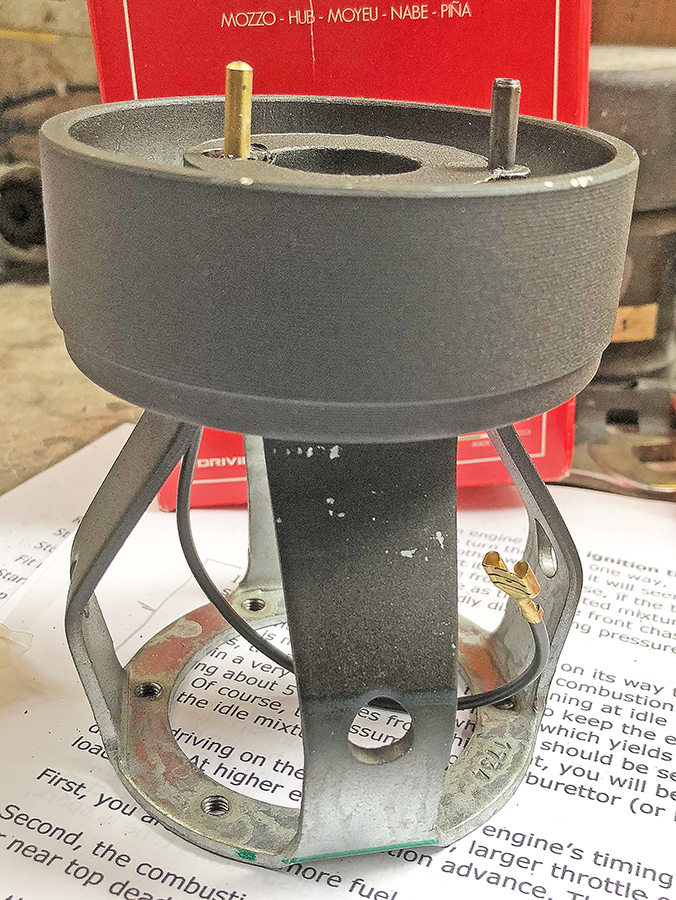

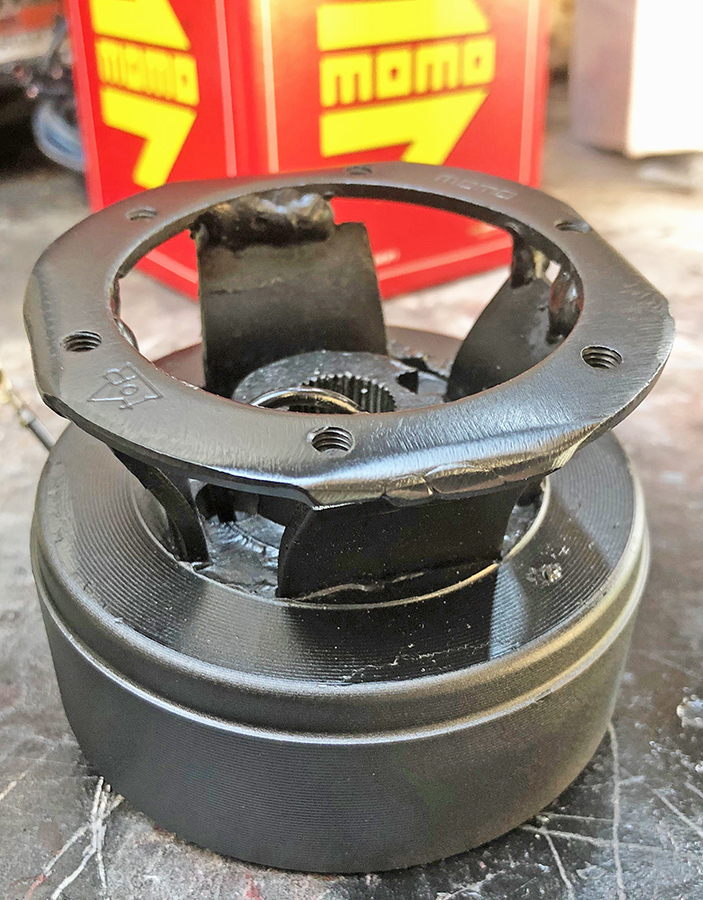

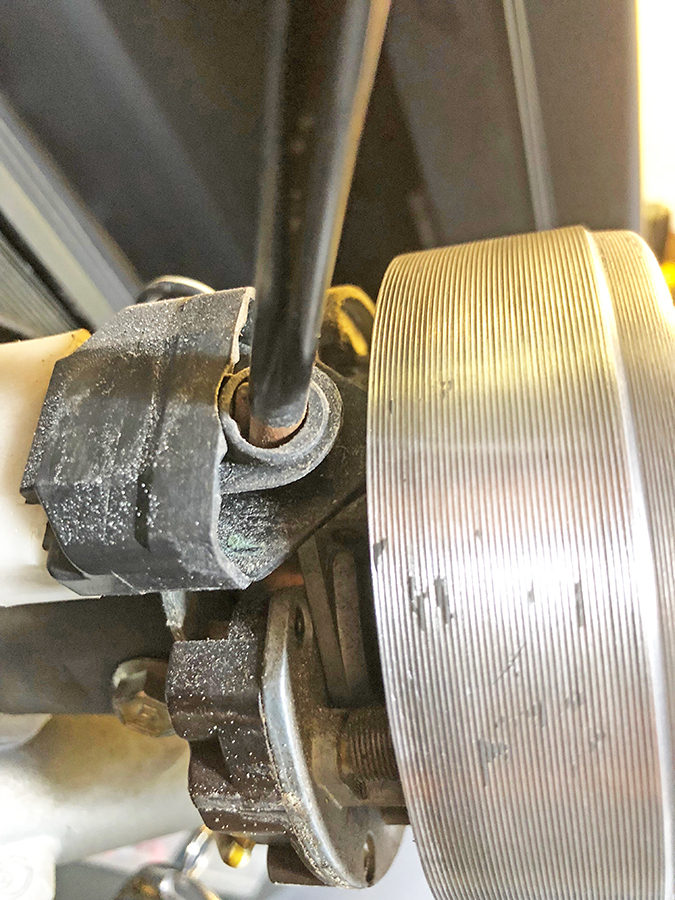

Good news, I've found the reason for the knocking! It was the nut securing the positive wire from the alternator onto the starter motor, it wasn't tight enough. Such a relief it wasn't more serious. Rebuilt the throttle spindle with the new seals all back on and running so much better just need to set the idle as its running far to fast at 1500 rpm! I've also treated the car to a new steering wheel. The old one was getting pretty rough.  Decided on a removable steering wheel, picked up a Momo steering boss which was supposed to fit the opel manta, guess what? it doesn't!  This is the rear of the old steering wheel. And below is the new boss. The little lug was fouling the indicator switches.   I had to grind out this to fit.  With this now fitting and the removable steering boss all bolted up the wheel was way to far forward!  The only way I could see in reducing the length was to cut the Momo boss down so from this,  To this. I do lose the collapsing feature but the steering column is collapsible anyway.   Then the outer ring was fouling the indicator stalk so I eventually ended taking 1/4" inch of the length.   And finally it all back together, its a marked improvement I can now see all of the dashboard and with the final position of the steering wheel being 35mm closer to the driver, that I can live with.    |

| |

Bib

|

|

|

|

|

Sept 23, 2018 16:52:49 GMT

|

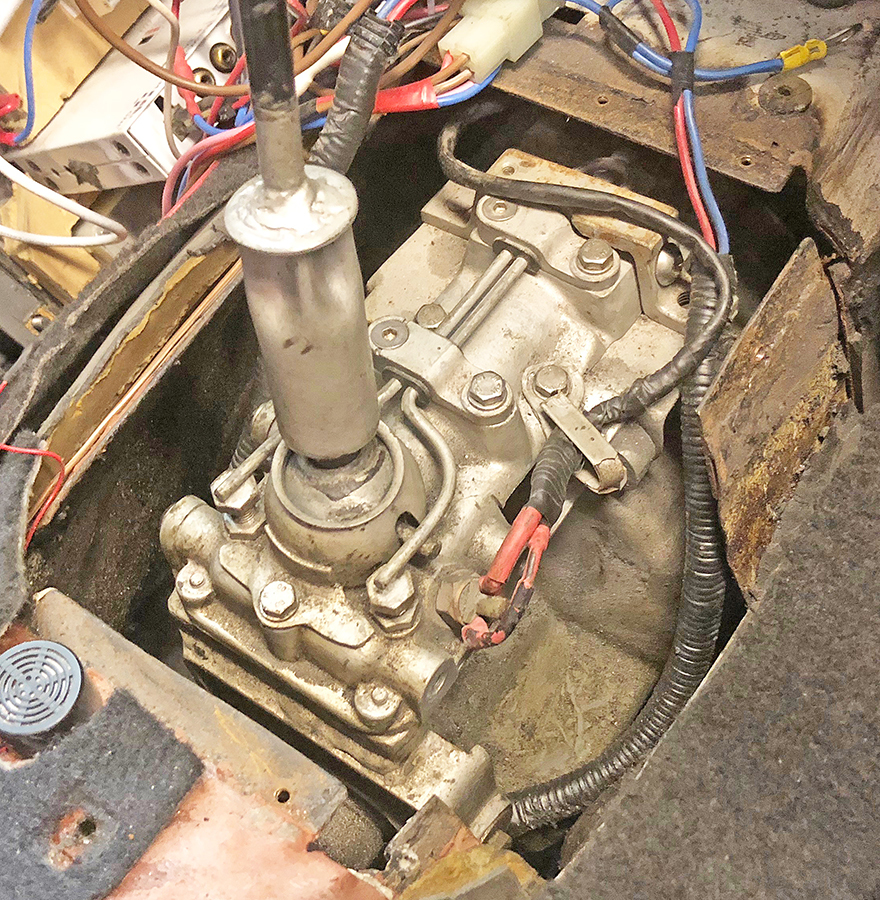

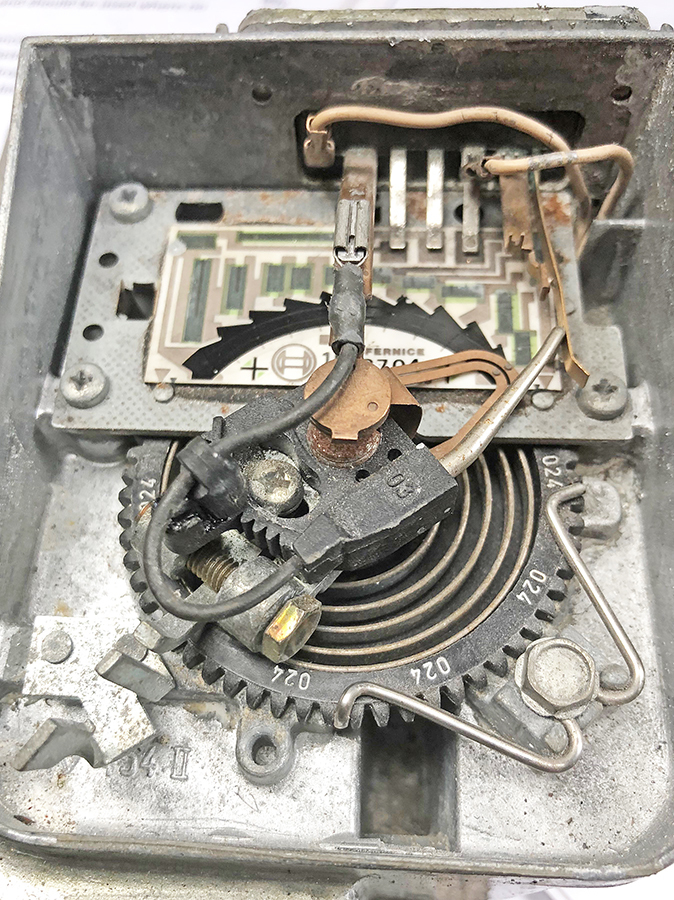

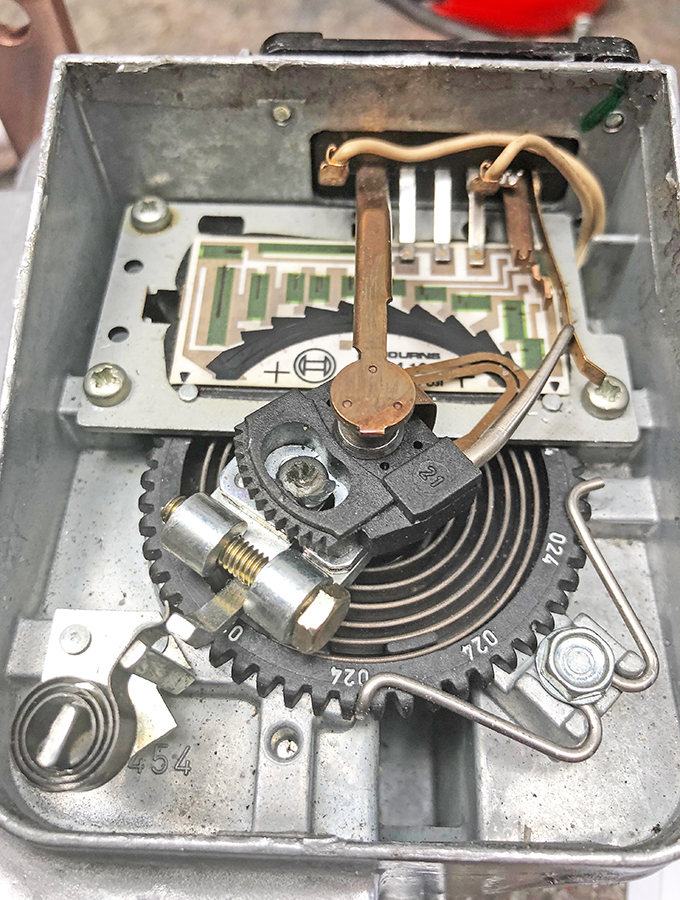

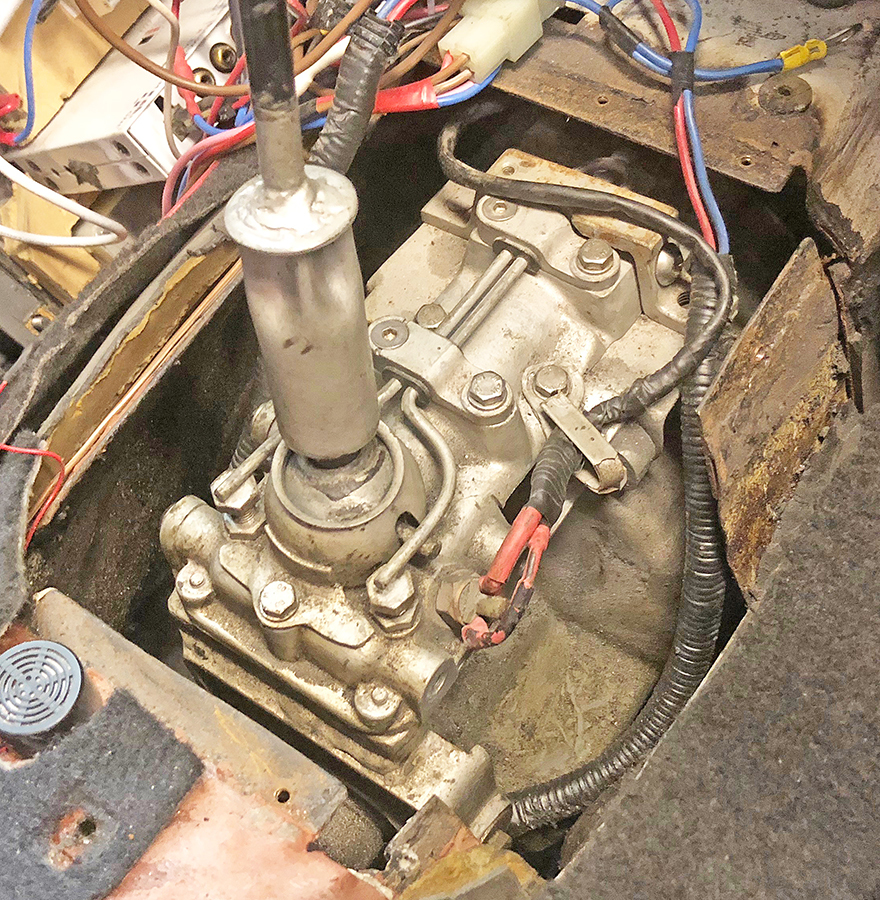

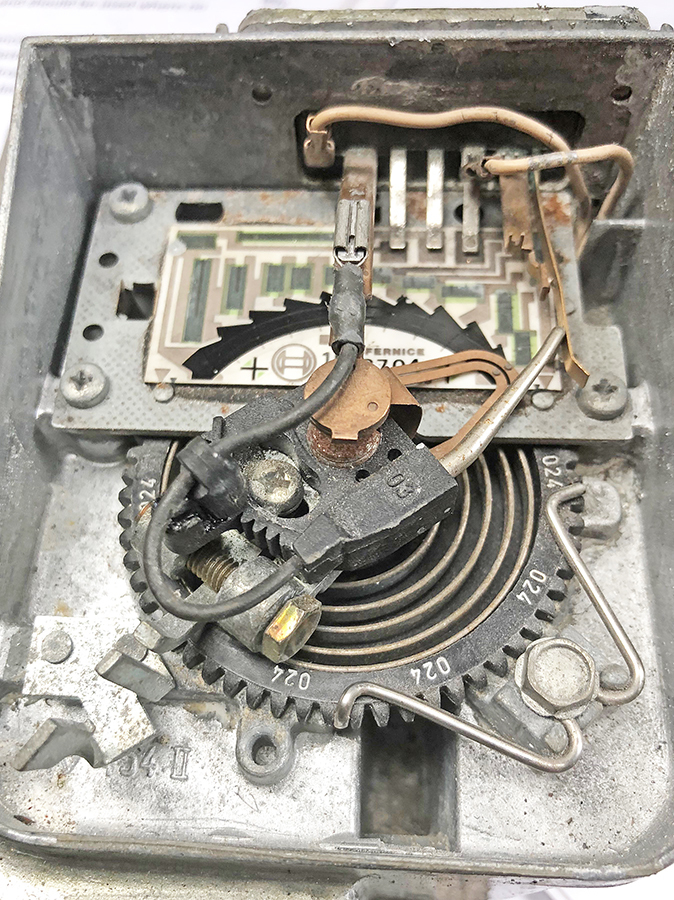

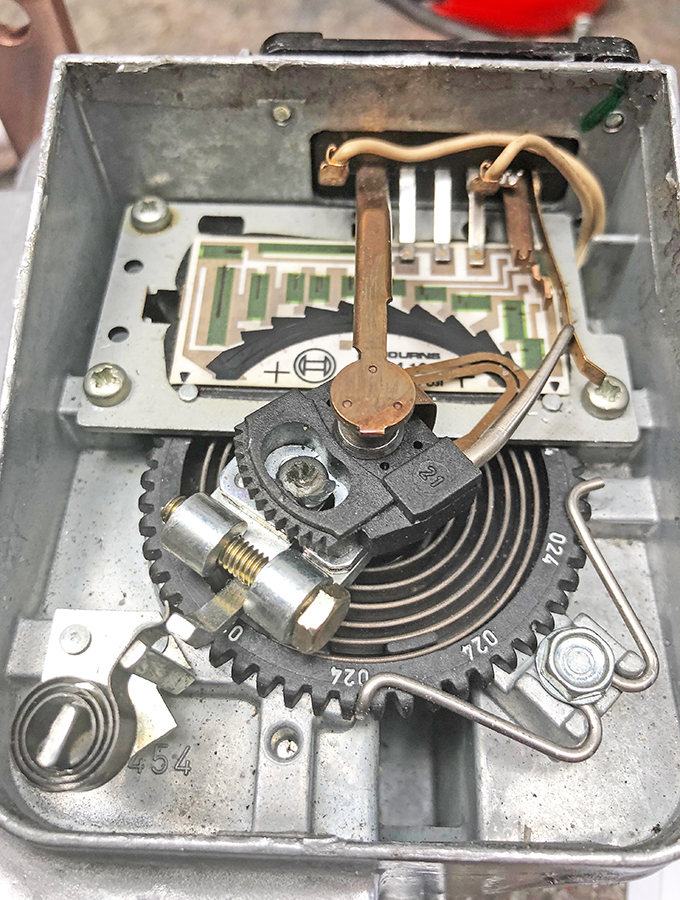

Another problem has risen now! The gear lever has got really difficult to select the right gear whilst driving, had a look underneath the car and saw the problem, the nylon/plastic bush that holds the doughnut thingamajig (not sure whats it called) in which the gear lever sits was missing.  Had to take out all the centre dash to get to the top of the gearbox.  Thankfully I had a spare one kicking about so now that's all done and working better although I'm still struggling getting from 3rd into 2nd gear! Now we come to the fast idling. My current Air Flow Meter which I got second hand did not have a lid to it so I was never sure if it had been tampered with. I've managed to get another unit and on inspection there are differences, firstly the butterfly is much harder to to open compared to mu old unit also there was a spring missing. (Bottom left).   This has definitely made a difference in driving the car. |

| |

Bib

|

|

|

|

|

Sept 26, 2018 18:30:43 GMT

|

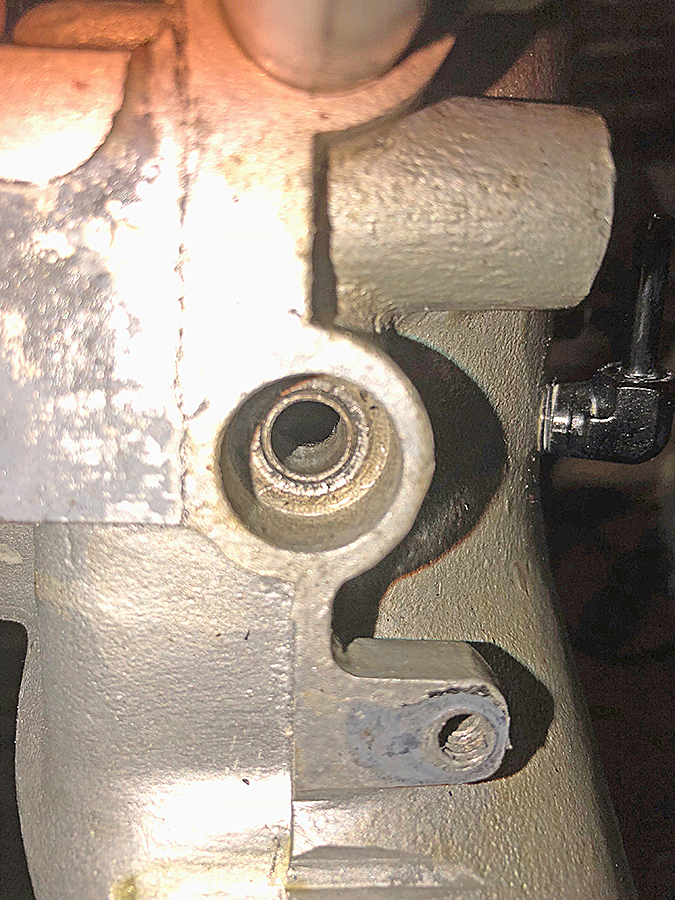

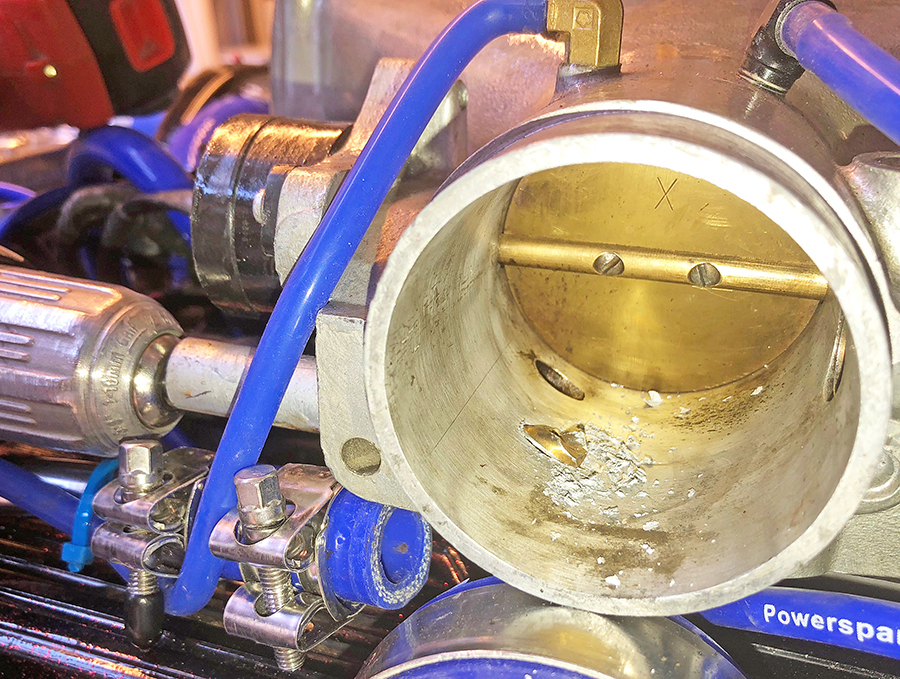

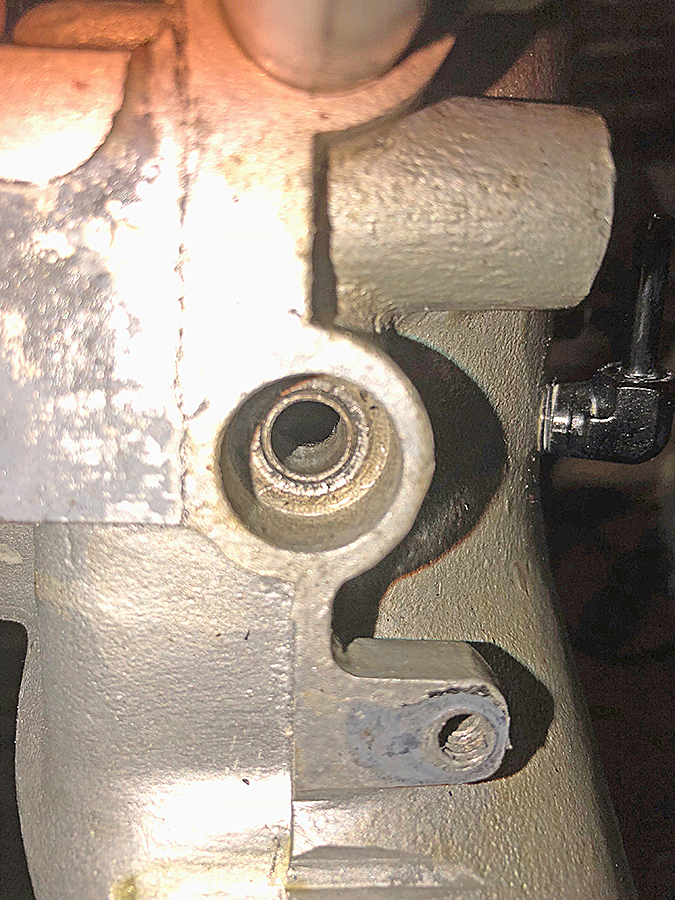

This is never ending! I've noticed whips of smoke coming out of the air inlet for the crankcase ventilation system.  Air should be sucked down through the little air filter, through the engine and back to the other rocker cover up through the flame trap and eventually into the air inlet just ahead of the throttle butterfly. Dismantled the flame trap, all clear, eventually found the blockage on the inlet of the plenum. after trying to clean it out with pipe cleaners and carb cleaner I went further by using a screwdriver, managed to get a photo down the tube.  It seems the manufacturer didn't drill the hole through!   Looking down the inlet you can see where they tried to line up the holes.  Well it all back together and running a lot better but still not perfect. I've covered approx 80 miles so far I say approx because I cant get the speedo to work as the inner cable is not engaging, and I believe the brake servo is faulty! |

| |

Bib

|

|

|

|

|

Sept 27, 2018 18:11:10 GMT

|

|

so i guess you lose self cancelling on the turn signals ?

|

| |

|

|

|

|

|

|

|

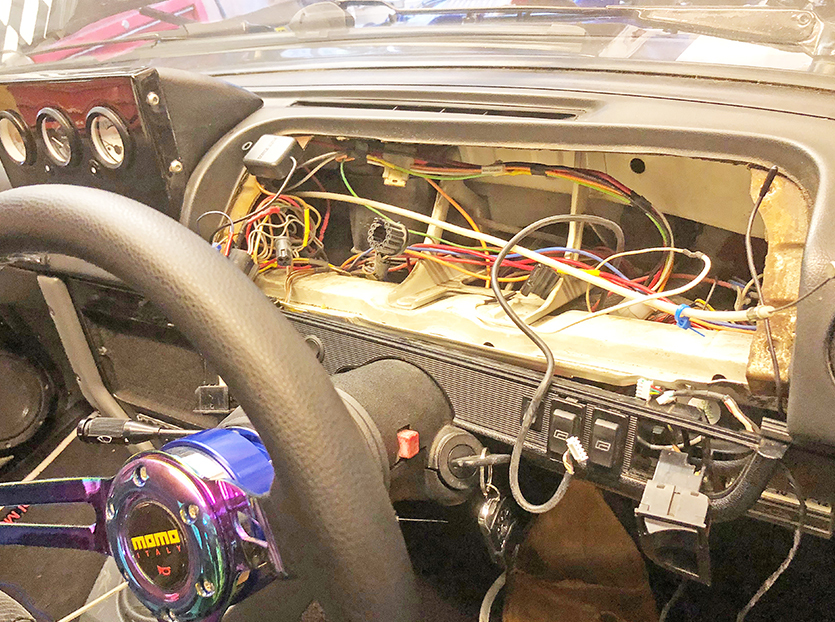

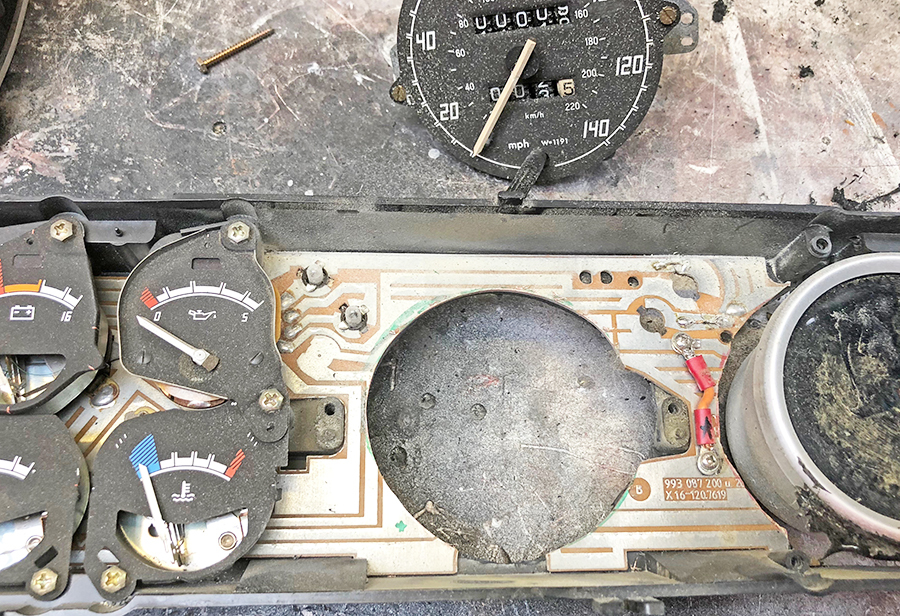

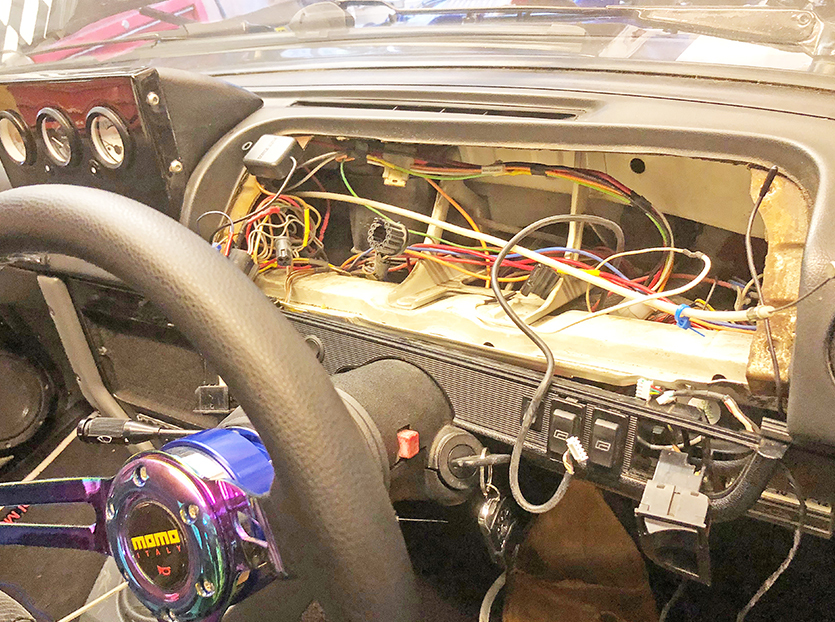

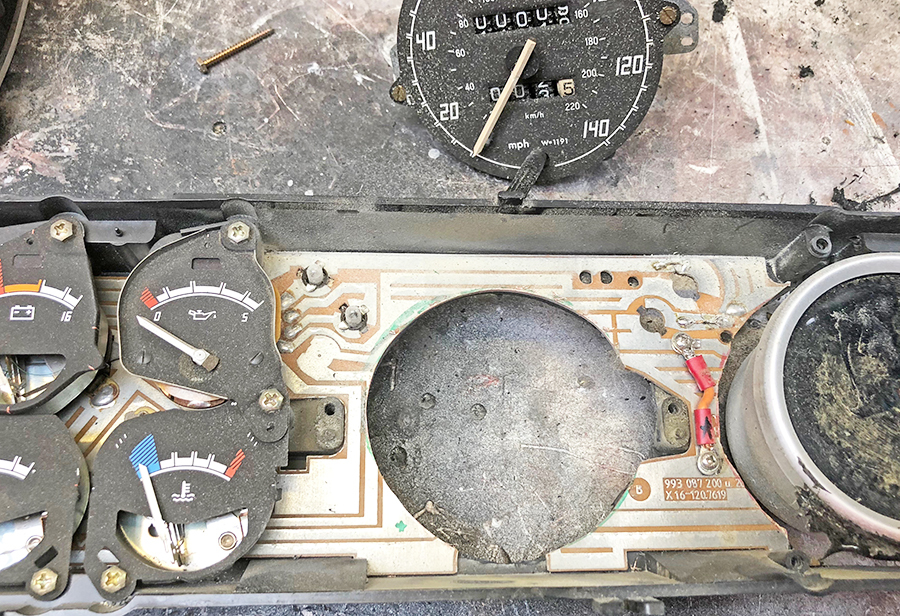

Hi Darrenh, Yes I do loose the self cancelling which is no big deal. This week the new GPS speedometer has turned up. so I've set about dismantling the dashboard yet again!  The tricky bit was cutting out the 87 mm hole to site the new dial and then linking up the printed circuit board so everything keeps working.  And here is the before and after shots. I would rather have the speedometer in blue to match the rev counter but no amount of searching could I find one unless of course I spend big bucks!   It seems to work alright it has found the satellite OK whilst locked up in the garage, just need to test drive it. |

| |

Bib

|

|

|

|

|

|

|

Oct 29, 2018 20:27:11 GMT

|

|

Well its been a couple of weeks since my last update and this is whats been happening.

Took the car out to test the speedo and it works great no problems there, thought I'd drive it through Winchester town centre it certainly raised some eyebrows! Now on the way home I hit a traffic jam, engine starts getting hot, fan kicks in which keeps the engine at a steady 90 degrees. 15 mins later still stuck in traffic then it stalls starts up fine travels 20 foot stops and it cuts out again! does this three or four times, traffic clears revs hit 1200 rpm and the engine feels like its about to stall / strangled almost like pulling out the choke whilst the engine is hot.

Changed the coil, new spark plugs, double checked the timing still the same, unplugged the ECU to check the connections all seems to be ok reconnected it started up fine problem seem to have disappeared!

Took it out for another spin well I'll be damned if I didn't hit another traffic jam, and it starts all over again managed to pull over to a lay-by pulled the ECU left it 5 mins reconnected and no change, limped home again!

Left it for an hour with the ECU out reconnect and its all hunky dory.

I've now come to the conclusion it an overheating problem - not with the engine directly but the environment its in.

The engine bay is compact with the exhaust manifolds running forward to the front of the engine then under and out with an extensive sump tray, the bonnet is limned with reflective foil, the only air flow is through the radiator around the engine and the only way out is down under the car.

As we all know heat rises and its being trapped in the engine bay the inlet manifold is so hot you cant put your hand on it which I believe is causing the fuel to evaporate.

So the only thing I can think of is to cut a vent in the bonnet and try not to damage the paint work!

|

| |

Bib

|

|

|

|

|

Oct 30, 2018 13:18:41 GMT

|

|

As a temporary fix and to see if it cures it, undo the bolts that hold the bonnet on and fit some 1" spacers between hinge & bonnet. Heat can escape through the gap and hopefully the bonnet will still open/catch as std.

If it works then you know cutting the bonnet will be worth it.

|

| |

|

|

|

|

|

Oct 30, 2018 18:28:44 GMT

|

|

Great looking car and nice build! .I did a Rover V8 conversion on an MGB and this is also a tight engine compartment for a V8. These conversions are quit common and lots of these also face overheating problems. Luckily not mine. This summer we were stuck in traffic with 35 C and no overheating or fuel evaporation although it does get hot in there. I used a new radiator and the MGB has 2 electric fans standard. I fitted a Kenlow adjustabel switch for the fans so i can adjust the "kick in"temperature fairly precise which i believe helps a lot. I did the conversion and then drove the car some times and then restored it. During the restoration i also got the exhaust manifold ceramic coated which seems to help also.

Maybe it is worth to install a Air-fuel ratio device to check if it is not too lean or get it on a roling road also to check the ignition timing Its critical but it should be possible to run it without overheating

Good luck and keep posting

Peter

|

| |

|

|

|

|

|

Oct 30, 2018 22:49:34 GMT

|

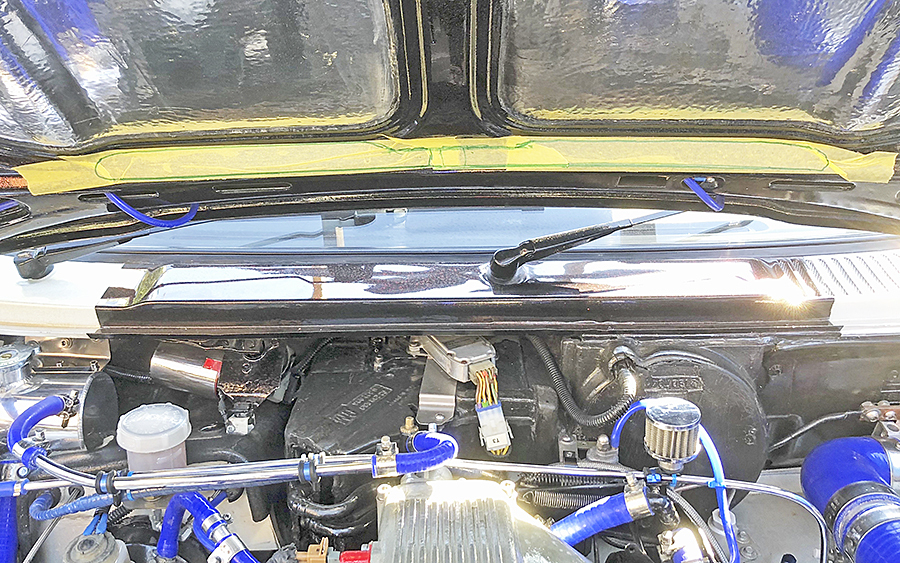

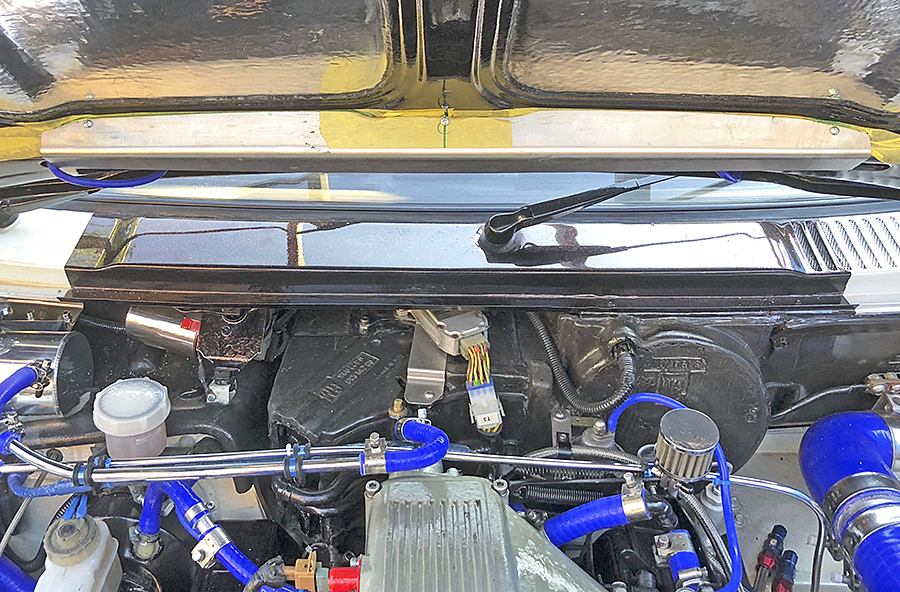

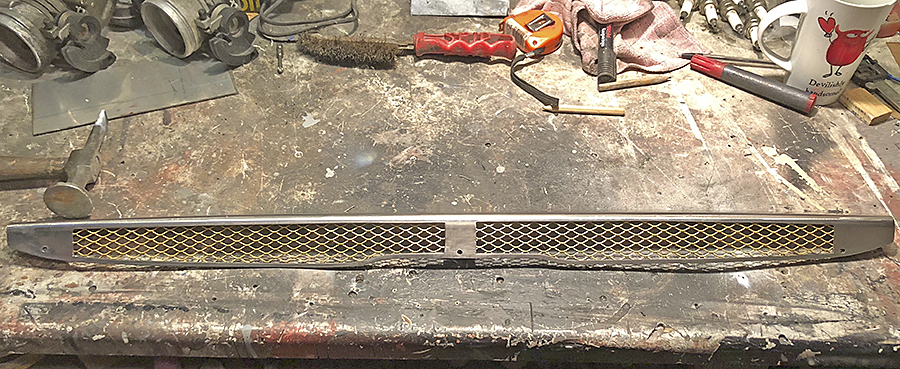

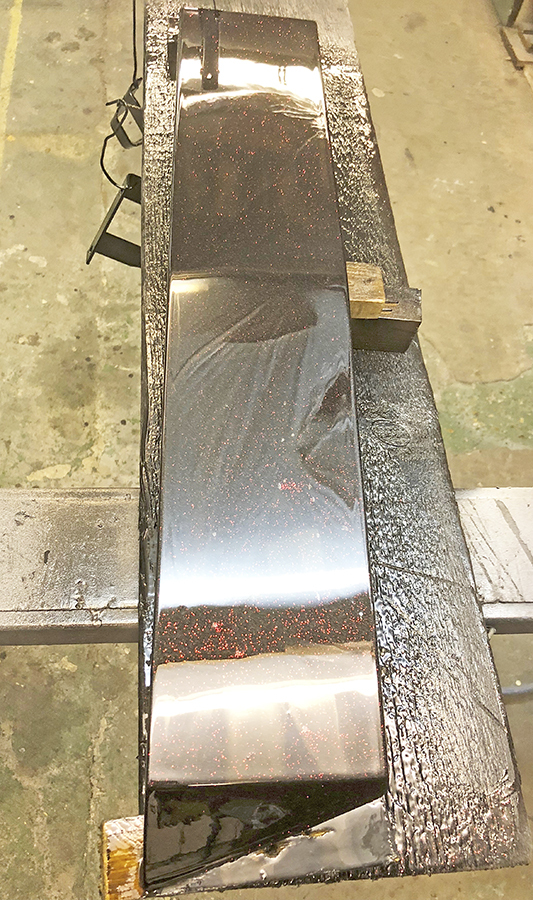

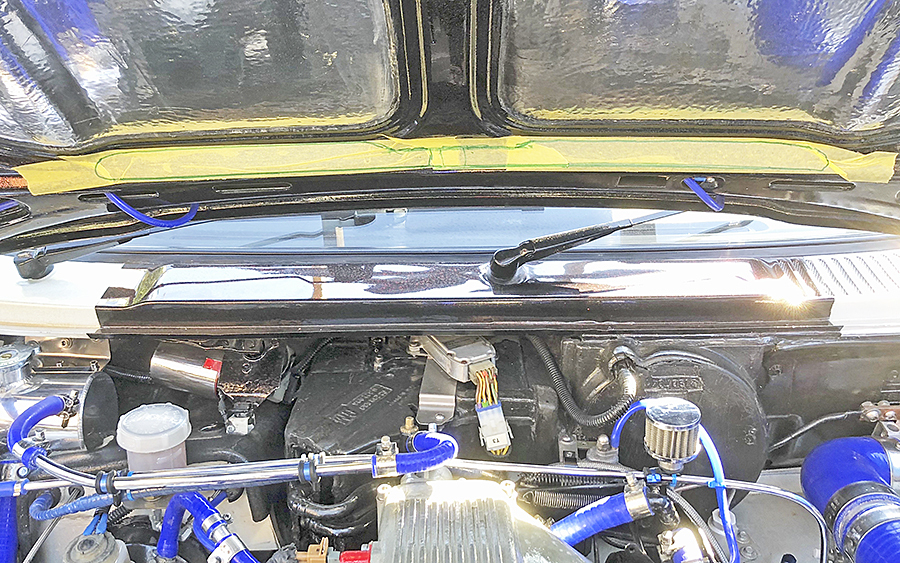

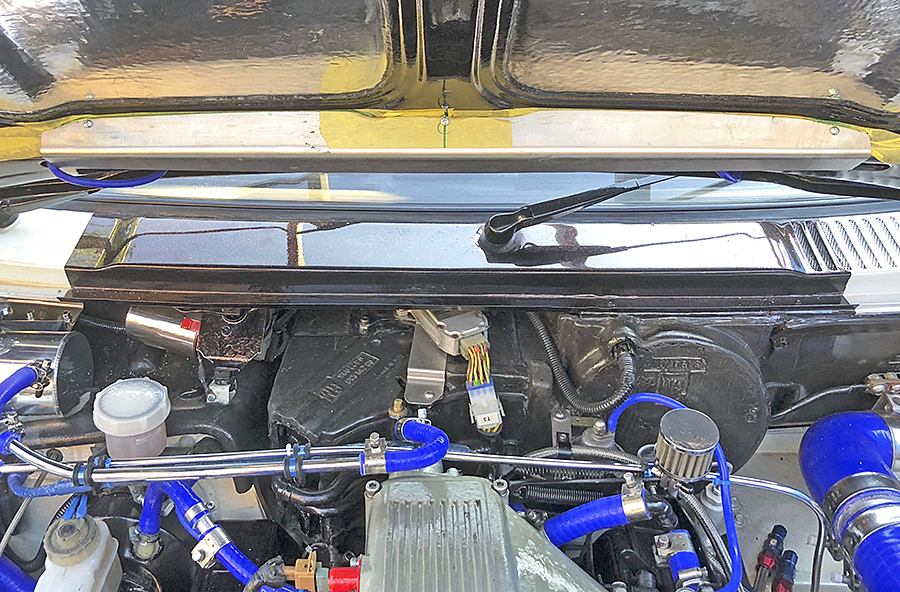

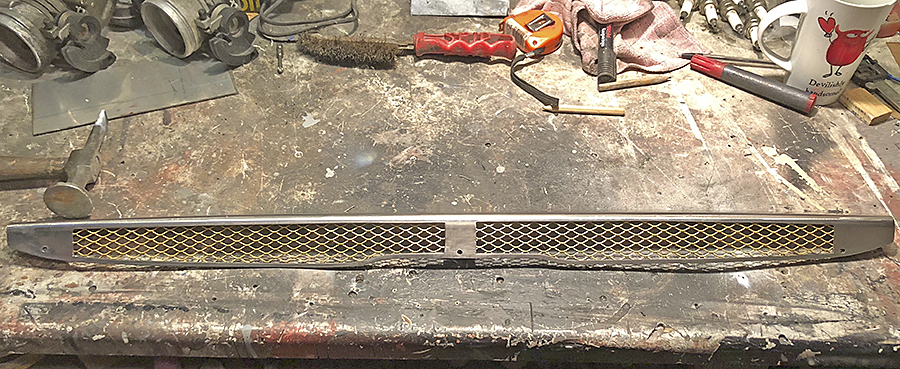

Thanks for the feedback guys, much appreciated. I did look at raising the rear of the bonnet but the bonnet pins wouldn't allow it. I would love to get the manifolds ceramic coated but funds are rather tight at the moment, but I do have further plans for the engine so will definitely consider it then. I've decided that this is the position of the outlet for the bonnet vent, looking around it's not easy trying to find something that would suit this car.  Found a piece of stainless steel at the back of the garage and this photo is prior to me bending it.  A bit of careful grinding and it sit fairly well.   The next part was to cut out the vents in the stainless.   With the vent in it temporary position i've marked out the area to cut out in green marker. This is a job for tomorrow night. Fitted a piece of mesh to the rear which tidys it up nicely.   |

| |

Bib

|

|

|

|

|

|

|

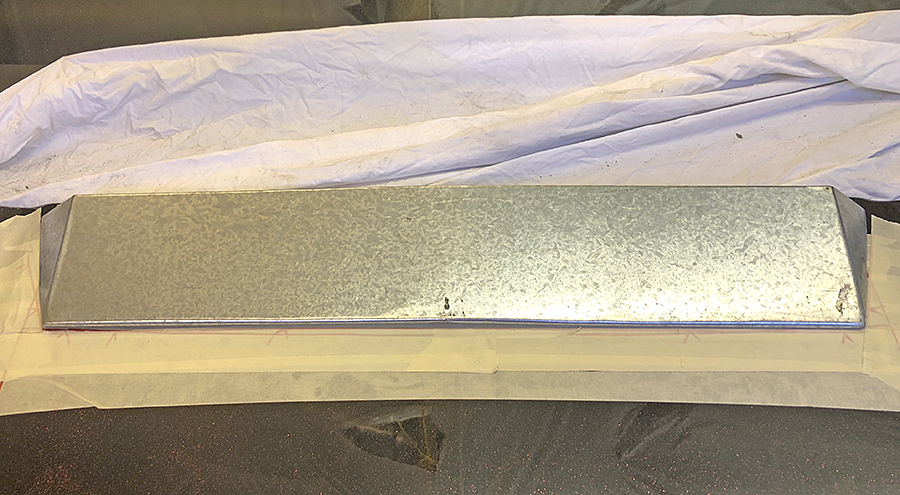

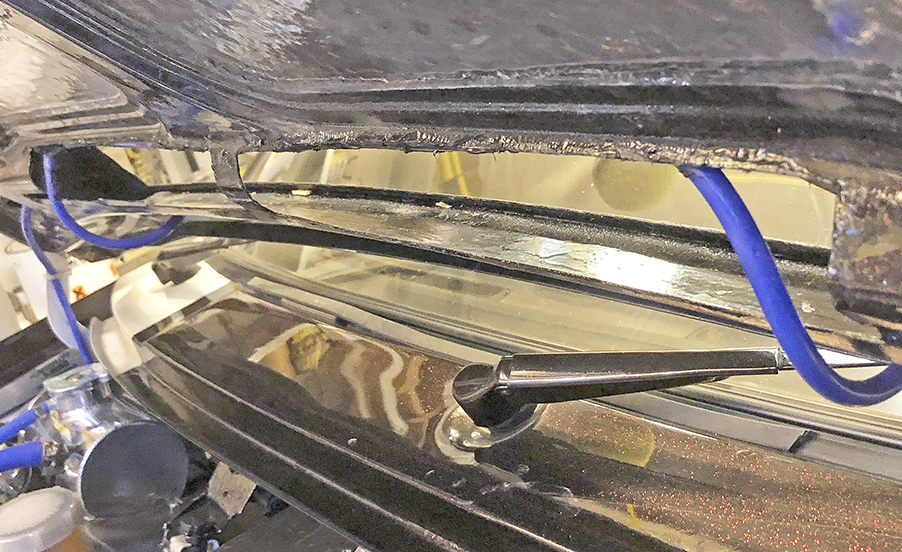

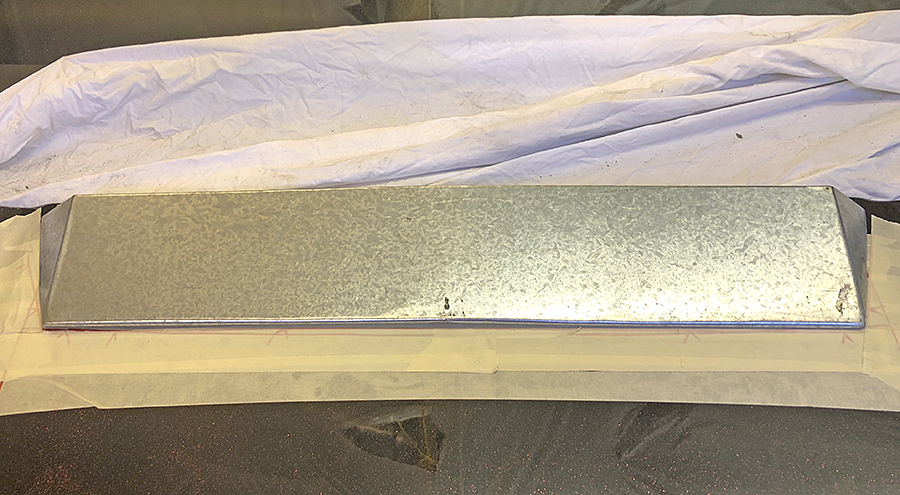

A very busy night last night, cut out the rear section first, this then allowed me to drill a small pilot hole through the rear of the bonnet to get the main section centralised.   Laid out masking tape across the face of the bonnet to mark out the final cut. Firstly got a piece of galvanised sheet steel and made up a hood as low as possible.   This view is the underside of the vent I've given myself an 30 mm lip to secur it to the bonnet.  The next part was to lay it out onto the masking tape and mark out the inside of the lip and very carefully cut it out with a 4" disc cutter and a dremel.  Thankfully there was very little damaged of chipped paint, with this done I repositioned the vent and secured it with mini G clamps and drilled 3mm holes through from the rear with the aim of using self tapping screws. Painted all the edges and hole to minimised any chance of water getting in.  Back on the bench to give it a skim of filler, that'll be a job for friday!  |

| |

Bib

|

|

|

|

|

|

|

|

|

|

Just love the work you are doing...very nice fab work there.

keeping a car running is one thing...keeping it running in style like this is yet another!

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

|

Yes that’s very neat. Must have been a relief to get it done without damaging the paint!

|

| |

|

|

|

|

|

Nov 12, 2018 18:01:12 GMT

|

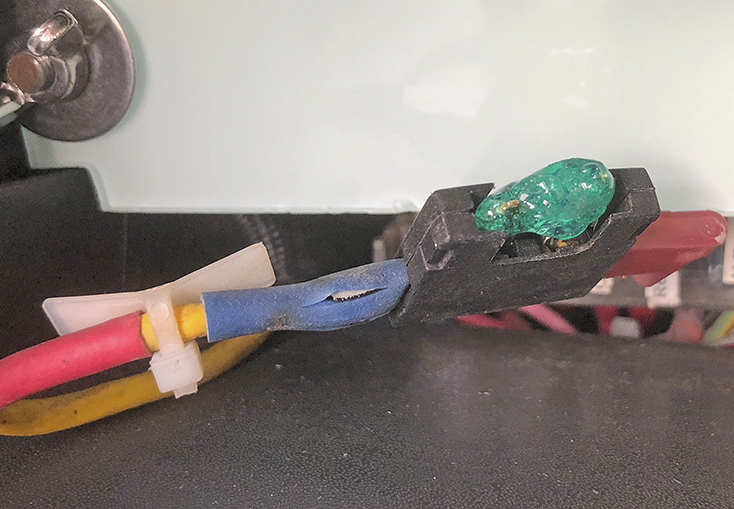

Took the car out friday night in torrential rain definitely not the best time to test drive the recent mods it seems to have cured part of the problem, it runs ok but still it cuts out on idle now and then! Anyway arrived at my destination only to find the electric radiator fan came on even though the engine wasn't over heating so I had to pull the fuse this didn't look good!   I presume there is a short somewhere which only appears when its raining and to top it all when I flash the headlights the dam interior lights flash too! I must have moved something when the dash was out. |

| |

Bib

|

|

|

|

|

Nov 26, 2018 19:57:14 GMT

|

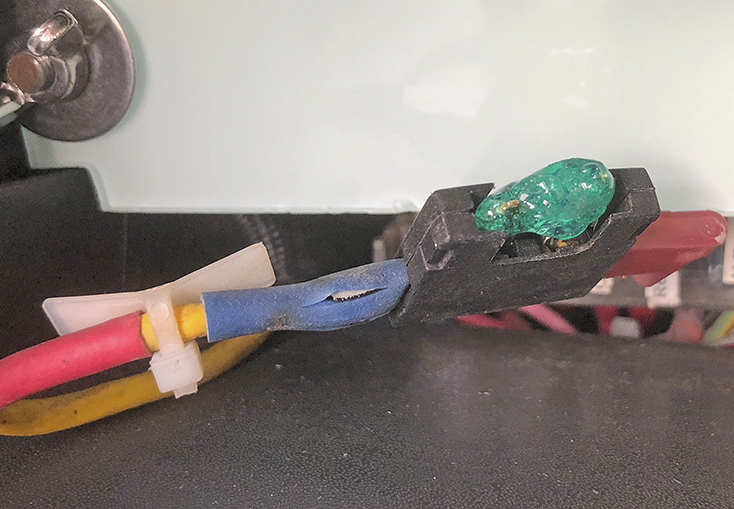

Well it's been a hectic couple of weeks since my last post, I've sorted out the electric fan another faulty solenoid that's the second time. Decided to rewire the loom and change the fuse holder to a 30amp glass holder, seem ok now. In regards to the bonnet vent its all very well removing the hot air, but I decided to add additional cold cross flow air by utilising one of the bonnet scoops.  The marked out area is the amount of metal to the underside of the bonnet that I could remove safely.  Using stainless steel I made up a small unit to accumulate the air.  And once screwed into position the air will be directed over the inlet manifold.  |

| |

Bib

|

|

|

|