|

|

|

Apr 16, 2020 18:58:35 GMT

|

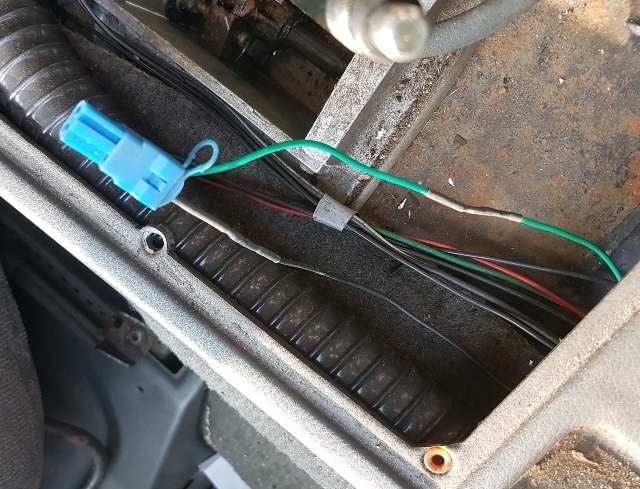

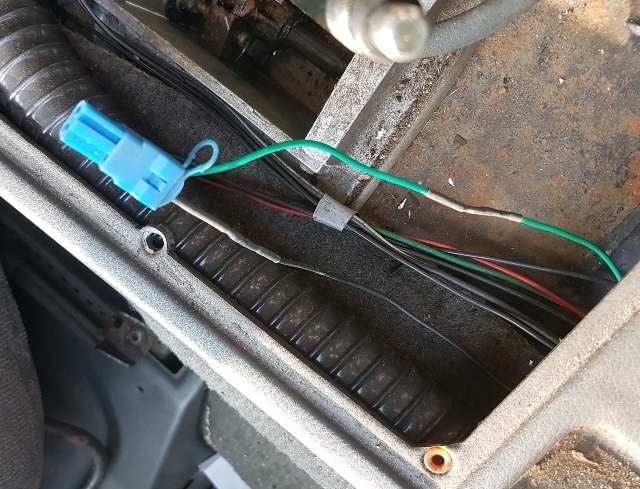

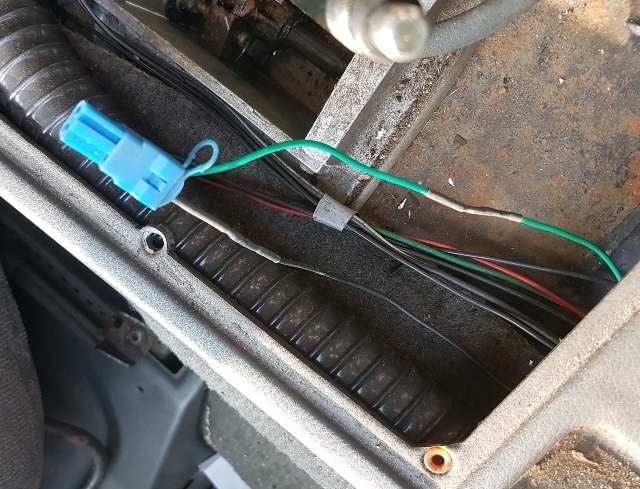

Found some time to look at the range rover today, firstly cut out this .  Then re-connected the original wiring.  Problem now was the PRNDL lights were on all the time. Dug out the wiring diagram and found it is supposed to share the ignition feed with the cigarette lighters, further digging revealed these had been re-wired to be permantly on rather than ignition fed. Its been done at the back of the fuse box and uses a mixture of the blue crimps and scotchlocks not pretty but it seems robust and is in a dry area. Given none of it is critical, it is a pig to get to and it is still fused I plan to leave it as it is at the moment, so I just tidied up the routing, tied it to the original loom and re-connected the original feed too the PRNDL. Also took a look at the TPS wiring, this is the original connector.  Un sealed, no support for the wiring heavily corroded and not easy to get the pins out, after breaking a pin trying to get it out I decided to replace it with a modern connector, a bit fiddly and the wiring on the engine loom is getting brittle but I managed ok.  Need to fit the mating half to the sensor tommorow and it can be fitted. |

| |

Last Edit: Apr 16, 2020 19:01:04 GMT by kevins

|

|

|

|

|

|

|

Apr 18, 2020 17:44:01 GMT

|

So with the wiring done i added some rubber backed felt and put the console back together  Also fitted the connector to the tps an re-fitted it.  Threres still a few things to tidy up inside, chief among them seat backs where the cloth has come unstuck and is baggy, Took the drivers one off easy enough just 5 screws.    There is a new much bigger issue though, there seems to be a fault with the transmission, from cold it won't change out of 1st gear for the first half a mile or so once it does its perfect. Apparantly this is the plunger in the governor sticking which is likely to be due to debris finding its way into there. It can be changed with the trans in the car but the transfer box has to come off first. I was pretty cut up about it yesterday but am coming to terms with it now, it won't take too long to get appart now all the issues with exhsust etc have been sorted out. In the meantime I have adjusted the kickdown which was right at the bottom of the pedal, this could help, and plan to use it a bit in the vein hope it might clear it's self. In other things today I sotrted out the steering on the KA, it's never felt right to me and the wheel was not straight ahead, we had had a local tyre place check i but it came back the same, so today i got the string out. Two 8ft planks with 4mm holes drilled an identical distance appart, each stood on axle stands at each end of the car.  String between them set equidistant (side to side on each axle)from the centre of the wheel then just measure from the string to the rim, with the steering wheel straight ahead (I had checked it is in the centre of the rack travel) the right hand was 10mm toe out, the left 8mm toe in, so overall 2mm toe out, it's supposed to be 1.4mm to toe in. Clearly they had only adjusted one side, one adjuster was free the other virtualy seized, with some penetrating oil and lots of phaffing around measuring and re-measuring I managed to set it up correctly. Took it for a drive and is vastly improved much more stable and less torque steer. Finally had a go a pushing the ding out ofvthe wing, unfortunatelly it is very closely double skinned in the area, managed to push most of it out but its far from perfect, might have to fill and paint it eventually, at least it's a tiny panel, one pro aerosol will do it easily.  |

| |

Last Edit: Apr 18, 2020 17:51:06 GMT by kevins

|

|

|

|

|

Apr 19, 2020 20:31:12 GMT

|

Done a few miles in the range rover, no improvement in the trans though, consistently it sticks in 1st gear for about 1/2 mile, thats 3000rpm at 30mph so not undriveable but clearly not right either, a phone call coming up to ashcroft tomorrow. In the meantime I had a look at one of the seat backs. Pulled out the staples and seperated the cloth, whag has happened is the same as the headlinings the foam layer between the bloth and backing has disentigrated.  So I cleaned it all off with a stiff brush and coated the cloth and original backing which was still firmly attached with trim adhesive. Carefully pressed it back together.  Threaded some shock cord through the top of the pocket.  Wre attached the pocket, drilled a couple of holes and pulled the shock cord tight.  Then back on the car.  |

| |

Last Edit: Apr 19, 2020 20:36:30 GMT by kevins

|

|

|

|

|

Apr 20, 2020 20:11:39 GMT

|

|

Had a chat with Ashcroft, they confirmed that it is almost certainly the governor sticking which is an achilees heel for these transmissions, probably some sort of contamination. They offered to fix it at Luton but with the current restrictions I agreed to fit the parts myself and they would supply them FOC.

Probably be a couple of weeks as I have other things to do which fit in easier with grabbing a few minutes here and there while working from home and it can still be driven in the meantime.

|

| |

Last Edit: Apr 20, 2020 20:12:57 GMT by kevins

|

|

|

|

|

Apr 22, 2020 19:44:48 GMT

|

On the Range Rover other seat back is done, also fixed the fuse box cover which was broken, still got a speaker grille to re-fit and some fixings to add to stop the carpets moving around, today it was only 100yds before it started changing gear ok but it had sat idling for a few minutes first. Also dug this out.   The minor currently has a fiberglass bootlid which doesen't fit very well and is cracking already. Its pretty rusty but so are all the secondhand ones and a new one is almost £500. Its the seams around the edges which have gone mostly accross the top and bottom, repair sections for the bottom are affordable but the top will have to be done from scratch, replacing the lip 6 inches at a time I will probably completely unstitch the inner and skin to make sure all the rust is sorted one thing I have at the moment is time. Andrew wants to fit a boot rack anyway so strength is more important than a perfect finish. Also what do you do nowadays when you want a bespoke cup holder and usb power supply. Apparently you print it,  Andrew having had his A levels cancelled now has time on his hands and despite having no idea when he can take his driving test is getting into the minor I also plan to get him to print some of the plastic parts broken / missing on the TR. |

| |

Last Edit: Apr 22, 2020 20:02:42 GMT by kevins

|

|

|

|

|

Apr 23, 2020 17:33:59 GMT

|

So here is his cup holder fitted, apparantly this is the prototype, the final one will be made from a more robust material.  We also fitted a centre brake light, fro ebay we bought a led strip meant for mopeds, it can do indicators and sidelights but we are only using the brake function, a couple of bits of bent alloy which slide under the screen rubber and we had this.  From the outside.  |

| |

|

|

|

|

|

Apr 24, 2020 18:10:10 GMT

|

Only a few odd jobs today, sucked some trans oil out if the range rover to replace with the addative, oil I took out was crystal clear pink, took it for a 30 me drive (wife too work then delivering shopping), shift points do seem to have changed slightly, we'll see if it helps the cold issue tomorrow. Also tidied up the front mats, they are suposed to stay in place with velcro but it's hopeless and they creep forward and bunch up, so I have added a turnbuckle fixing.  Do need to take passenger side up again though as there is fair bit of surface rust on the floor. Also polished the mazda up, up close it has quite a few blemishes but looks OK from a couple of feet away.   |

| |

Last Edit: Apr 24, 2020 18:15:02 GMT by kevins

|

|

|

|

|

|

|

|

been using the range rover quite a bit, the not changing up from 1st is down to a couple of hundred yards from home now so I plan to keep using it for a while longer, it has developed a couple of other minor issues though, it's leaking from the transfer box sump bolts, I was a bit sceptical whether it would leak, the procedure in the manual which uses these for the lifting fixture and says put them back in with fresh sealer (to a hole which is bound to still have oily residues), still its an easy one to do on the car, just 8 bolts to drop the sump off. Today the speedo has stopped working, I suspect the cable ahs snapped at the gearbox end, it didn't look brilliant when I took it out, a bit fiddly but not too major a job, in the meantime google works fine.

On the minor I have tidied up one bit I really rushed originally, the right hand gutter looked like the north sea, so half an hour spent gently straightening it out then a light going over with some flexi filler and brushing on a primer / topcoat seems to have it looking much better.

The main thing I have been doing is the car port roof, it is a wooden frame covered with poly tunnel plastic, but over the years the plastic has got damaged (loads of ivy growing over it) and it leaks in several places, I have been given a load of polycarbonate so I have been replacing the roof with this, but also have found quite a few rotten areas, so working through all the old timber I can find around the place It has been cut out an replaced, plus the drianage improved.

|

| |

|

|

|

|

|

|

|

Been getting some house jobs done the last few days, firstly tidying up the outbuildings, a bit of rot in one of the window frames cut out and replaced, then painted it all.  Also rummaged around the back of the garage and found enough guttering to fit to it, something I should have done years ago. I'm finding this lockdown is a boon for all the old junk I've hoarded over the last few decades, I also re-roofed half (only had enough polycarbonate for half) the car port, again finding rot to cut out in several places. Including the bottom couple of inches of the main beam.  On the cars the range rover transmission seems to be working fine at the moment, hopefully whatever was jamming the governor has cleared, the speedo seems to be the cable, its not turning at the head, just waiting for a new one now. Today we used it properly, a friend had an ash tree which had come down in their paddock blocking a ditch, we trimmed all the top growth off then dragged it out, the Range Rover did it at idle in low ratio.  We then cut half of it up to take home,  Steering was a bit light but it did it with no struggle. Hope to get a bit more time on the others this week, Some painting on the TR, the RR speedo and exhaust leaks and possibly the splits in the seat on the mx5. Basically all things I can do in my lunch hour. |

| |

Last Edit: May 9, 2020 20:41:29 GMT by kevins

|

|

|

|

|

May 17, 2020 21:41:36 GMT

|

For the last week or so only small jobs on the cars, on the range rover the transmission seems to be shifting fine now so that's ond job off the list, on saturdat we went back to plank up the trunks of the tree, Andrew splashed out a whole £70 on a factory re-furb 50cc Titan chain saw (chinese made) as his 30cc stihl isn't really powerfull enough, it did a stirling job and after a couple of hour we had the back of the Range Rover full of planks.  While he was doing this I took some time to touch in all the stone chips and paint damage on the Range Rover with a small brush, when it's had a few days to harden I will polish the most obvious ones back but even now it looks much better. I also crawled underneath to take a look, the transfer box leak seems to have almost dried up (just damp now no drips), and the exhaust seems to be leaking at the extra joint I had to add in to make it fit, some paste should do it, the joint to the muffler was also loose so I tightened that up. Hopefully this week I will seal the exhaust and fit the speedo cable. On the Minor I started welding a new top edge on the 'new' bootlid, used a series of strips about 6 inches long to maintain the shape and double curvature.  Plan is to start on the bottom next, making my own repair sections for the skin as I go then split the inner and to allow me to treat any rust in between and repair the inner. |

| |

Last Edit: May 17, 2020 21:44:56 GMT by kevins

|

|

|

|

|

May 19, 2020 21:30:43 GMT

|

Decided to push on with the TR today, a couple of weeks ago I sanded back the crazed paint on the drivers wing, next up is sorting the fiberglass spoiler which got damaged when it got caught on the ramp, initially I was going to do it on the car and ground the cracked area back to give me this.  In the end though I got carried away and pulled the bumper and spoiler off.  Fortunatelly only a small area of rust where the wing joins the front panel.  Easy enough to fix, and I can now work on the spoiler outside in the sun. |

| |

Last Edit: May 20, 2020 6:09:54 GMT by kevins

|

|

|

|

|

May 20, 2020 20:10:17 GMT

|

Spent luñchtime doing a few dirty jobs. Firstly ground back the welds on the minor bootlid.  Still a few bits which I missed but generally came out well, onto the bottom now. Also cleaned up the surface rust on tbe range rover footwell.  No serious rust so I cleaned it up with a knoted wire wheel and treated with converter, once dry it got a coat of epoxy primer, also found out where the water was getting in, there was a twinkle of light to the front wheel through one of the welds, obviously I missed it with sealer 4 years ago, so that was re-sealed as well. That though caused the grinder to pack up, I guess these brushes will be the problem.  Found a pair of old washing machine ones as on the right in the photo below, after some filing I ended up with one that fitted on the left.  With those fitted I finished off cleaning up the cracks in the spoiler with it off I could also clean the back, hopefully I can start the repairs tomorrow. Final thing was to cut the rusty bit out of the TR, I'll butt weld a new piece in when I get the chance.   |

| |

Last Edit: May 20, 2020 20:12:33 GMT by kevins

|

|

|

|

|

|

|

|

You do keep busy! It must have felt good when that auto transmission fixed itself.

Best, John

|

| |

|

|

|

|

|

|

|

|

I certainly did, I wasn't looking forward to taking it all apart at all, it seems the additive that Ashcroft gave me did the trick, having driven it more I've also realised the lock up never really worked on the original transmission either, bit of a double edged sword though because its not as smooth a drive with the torque converter locked as it was with it slipping, might improve the fuel consumption though (it was doing around 14mpg), at least fuel's cheap at the moment.

I can't recommend Ashcroft enough after this as it often been said its what a company does when something goes wrong which separates the good from the bad and they have been brilliant.

|

| |

|

|

|

|

|

May 21, 2020 11:54:18 GMT

|

|

Agreed re shops who do well by us. I have a 911SC and have done almost everything myself, but didn't want to tackle the transaxle1st/2nd shifting issue. The P.O. had a shop in there before but they hadn't resolved the problem (ca. 50% of the time, not going into second, either on up- or downshift). We have a well-known p-car shop in the area, all sorts of amazing cars in there for restoration and regular service and repair. I asked if I could just bring them the 915 transaxle; sure they said. We agreed up front that they'd just fix what was wrong, and they found the 1-2 synchronizers and dog gears to be somehow incorrect and replaced them, totally reasonable amount of money.

After I put the unit back in and test drove the car, it was worse. I almost soiled my shorts, and imagined an ugly situation ahead of me, with conflict, unpleasantness etc. But I called and they said "bring it over"; their mechanic drove it, agreed it was awful. I was asking shop owner when I could bring the transaxle back in (taking it back out myself ... engine out job but not too bad on a 911 (or Beetle!). He thought for a moment and said, "Bring us the car, we'll handle the whole thing. If it needs any parts you didn't pay for the first time, you'll pay for those. OK?"

Yes, OK! It turned out the $200 1-2 shifter sleeve was bad. They'd thought it looked fine (it does, and still lives on my desk at home). It was just a great experience.

I was a dealership service manager for fifteen years and remember sometimes taking guff from senior management when I did the right thing for customers in similar situations. To receive the same treatment I'd given others was a rather lovely thing!

Best, John

|

| |

|

|

|

|

|

May 21, 2020 20:36:50 GMT

|

Today I finished a few odss and ends off on the range rover, waxed the floor I had painted yeterday,  In this weather the wax hardened in about 10 minutes! Then I got sidetracked on the passenger door, the fit is terrible.  It's never going to be brilliant as the front and back doors are different shapes. These with the panels all painted off the shell were renound for appauling panel fit, the average door gap is around 10mm. After a bit of fiddling around and elongating the striker pin hole slightly I got it to this. Far from perfect but about as good as it's going to get without major reworking and all the doors growing by 2 or 3mm in length.  After that I replaced this.  Its called a multi function unit in the cluster, one thing it does is voltage stabalisation and my fuel and temp gauges fluctuate by an 1/8 of travel randomly, its only held in by a couple of screws and seems to have fixed it, also threaded the new speeďo cable through the dash and connected it, just the crawling around underneath bit left to do. |

| |

Last Edit: May 21, 2020 20:46:23 GMT by kevins

|

|

|

|

|

May 23, 2020 20:10:13 GMT

|

Fixed the range rover speedo cable, wasn't too difficult, and managed to use the old one to pull the new one over the gearbox. It had broken about 8 inches from the gearbox where there was a clip.  Then I took a look at the wheelarch on the TR, what looked like a small hole in the inner arch soon became much larger.  Outer arch is perfect though even got primer on the inside, cut the whole lit out and cleaned up the edge.  Leaving this pile.  After this I cut some card templates out ready to transfer to metal. |

| |

Last Edit: May 23, 2020 22:12:38 GMT by kevins

|

|

|

|

|

May 25, 2020 20:50:43 GMT

|

On saturday I lost the keys for the range rover, I have spare set but no tab for the immoboliser, so I pulled the lower dash and bridged out the circuits it was cut into. Come sunday I found the keys in the garden (must have dropped out of my pocket when I took my boots off) so I had to put the car back together. One thing led to another and I ended up re-doing large parts of the immoboliser and LPG system to get tidier routings and rid of coiled bunches of excess wire. That done I also noticed the oil pressure light wasn't working, turns out the terminal had dropped off the switch, so a new one is on it's way. On the TR I made the first section of the inner arch.  Not the pretiest but it fits realy well so I decided not to risk distorting it trying to get a better finish, hopefully get a chance to weld it in in the next couple of days. Unfortunately the a angle grinder failed in a spectacular way with sparks pouring out of it, one segment of the commutator is loose so that's in the bin and a cheapie from argos bought for the moment, not sure what is a good make nowadays, so many of the old favourites seem to have gone downhill. |

| |

Last Edit: May 25, 2020 20:55:18 GMT by kevins

|

|

|

|

|

May 27, 2020 20:39:22 GMT

|

Broke down in the minor today fortunatell was able to coast into a layby, at about 60mph it missed a couple of times then cut out. I called the AA but they were going to be 3 hours, so my wife walked the mile or 2 home, and bought back the MX5, after some testing it was either the coil or ignition amplifier (late metro distributor). The amplifier is the same as the rover V8 so I went home pulled it the coil and king lead off the TR. Turned out it was the coil. This is where I get a bit confused, The metro is supposed to use a 1 ohm coil which is what failed, the TR on the other hand has had a lucas gold 3 ohm coil fitted for 10 years and 40,000 miles with no problems at all. So at the moment I have fitted a bosch equivalent to the 3 ohm gold coil and it seems to run fine, I assume a higher resistance will put less load on the amplifier so if it runs OK it shouldn't do any damage, anyone have any insights? On the TR I spent the evening welding up the wheelarch.  Bit of a pig to weld mostly upside down with all the underseal and wax on the back of the arch melting and running down plus continuously putting fires out, but ended up with a strong if not pretty weld. Also butt welded a piece in to replace the rusted seam between the wing and valance as I could clean the back up.  |

| |

|

|

|

|

|

May 29, 2020 12:13:13 GMT

|

Thought I would post mortem the coil.  The fault was pretty easy to find.  I'm pretty surd it is a fatigue fsilure due to high frequency vibration, obviously it can't stand being strapped to the top of the alternator, as a precaution I'll fit the new on on the inner wing. |

| |

|

|