|

|

|

Mar 24, 2020 20:21:05 GMT

|

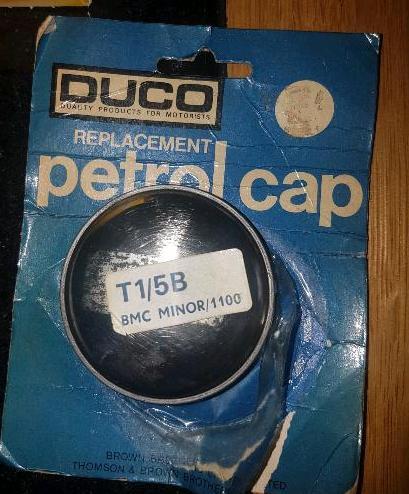

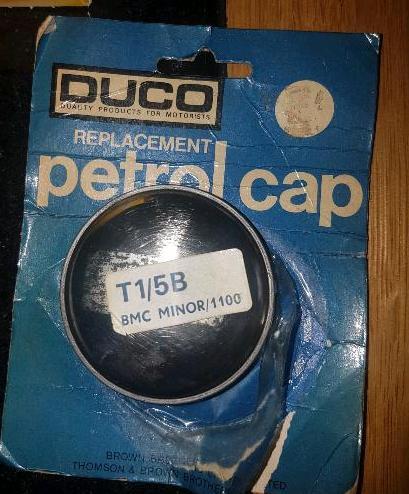

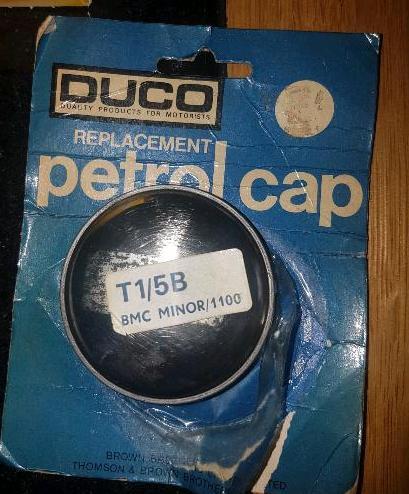

Finished the input gear on the transfer box, also toom a look at the hi-low which always seemed very stiff when in the car, but the box seems free moving as does the linkage only thing I can think is it is to do with adjustment so I will have a play when its back together. Also unfid the centre shaft and knocked it 115mm back to change the o ring which was as hard as plastic, I'm suprised it only weeped, unfortunately the o ring I bought was the wrong size so I'm waiting for the right one, it's got a collapsable spacer between the bearings so I marked the nut to do up to the same position, never had a problem doing this on Ford english diffs. Finaly fitted a new old stock fuel cap on the minor It had a locking one on an adaptor which leaked like sieve and had no provision I can work out to seal the adaptor to the neck.   |

| |

|

|

|

|

|

|

|

Mar 24, 2020 20:43:59 GMT

|

|

Think they made hi lo lever short to stop people changing at speed. They are stiff and need a deliberate shove/prod to change. Best when just rolling in neutral. On the hi/lo select neutral then the change to hi or lo.

|

| |

Last Edit: Mar 24, 2020 20:44:41 GMT by vincento

|

|

|

|

|

Mar 24, 2020 21:29:43 GMT

|

|

It was definitely better when moving as you say but it also got lot better when warm, perhaps the viscosity of the oil is a factor as well (none in it at the moment) and what came out looked a bit thick I wonder if it had 90 rather than 80 in it.

|

| |

|

|

|

|

|

Mar 25, 2020 20:17:57 GMT

|

Not much progress on the RR as I really need at least a couple of hours to get stuck into fitting the gearbox, I did measure the torque converter to block face dimension which is 50.3 mm (ashcroft instructions say it should be 51mm so that looks fine and is obviously engaged in the pump properly, measured the block to flex plate which was 48.5 so the gap is fine at around 2.2mm and the crank shim doesen't need changing. Just need to knock up a bracket to hold the torque converter in place during assembly and it can go in, hopefully on Saturday. I did find half an hour to look at why the TR gearshift felt odd and the spring load between 1st and reverse had become weak. As I thought the spring had come off the peg on the lever (to right of not very good picture).  The reason for this is the cup retaining the pivot had broken.  Some 2mm steel a bit if metalwork and a spot oc welding got me this.  Fitted it all back together with some grease and all is fine. In other news the 6 month extension to MOT's means it will never need another one as it is 40 on the 1st August, this means I can now pull all the LPG gear off it as it was always a struggle to pass emissions on petrol, 10% weight reduction and significant restriction on the intake removed should liven things up! |

| |

Last Edit: Dec 20, 2020 22:43:52 GMT by kevins

|

|

|

|

|

Mar 26, 2020 16:05:26 GMT

|

Back on the range rover, one of the things you have to be carefull of is that thr torque converter doesen't move forwsrd and drop out of engagement with the pump, ashcroft supply it with this  Problem is you obviously can't fit it like this so I knocked up this up out of scrap  It fits through the inspection hole in the bottom and can stay in place until the trans is bolted up to the engine.  Also started on tidying the atic of the loft, first thing though was to fix the lights which my son had disconnected to power the lights in his workshop. Now I can clearly see the full horror of the mess it is up there. |

| |

Last Edit: Mar 26, 2020 16:08:28 GMT by kevins

|

|

|

|

|

Mar 28, 2020 19:41:28 GMT

|

Took my wife to work in the TR7 (asda so now apparantly a key worker,a lot of risk for minimim wage!), got home and noticed dripping under the front, opened the bonnet and coolant all over the place, water pump has gone, the sd1 pumps are £120 but range rover ones £40, might try taking it off and pressing it appart to see if it looks like I could transplant the bearing and seal from the range rover one. Anyway I left that , its not like I need it in the next few weeks and started on the range rover. First I made a plywood frame to support the trans on the jack.  It worked but not entirely sucsessfull, I made the front to rest on the sump flange missing that the sump flange is not horizontal, a small block of wood sorted it easily enough. With that it went in easily. Torque converter to flex plate gap was spot on at around 2mm.  Bolted the torque converter up which is a right phaf, then fitted the cover and dipstick tube. Next up was the cooler, flushed the cooler and pipes out with brake cleaner using my home made method for getting oil etc out of 5 litre containers, its a steel plate with rubber bonded to the bottom and 2 holes, one for a pipe which goes into the bottom of the container and other a tyre valve, strap the whole lot to the container with a bungee strap, add pressure to the valve and oil comes out the tube.  I ran cleaner through in both directions until it ran clear the ran some atf through it which came out crystal clear. Worth doing this is the colour of the cleaner afterwards.  Connected cooler, the cables up and fitted the hi lo lever, to get me to this.  Can't do much else until the O ring turns up for the transfer box but I am getting carried away cleaning / painting parts.   |

| |

Last Edit: Mar 28, 2020 20:02:01 GMT by kevins

|

|

|

|

|

Mar 30, 2020 17:39:01 GMT

|

Back to work (at home) today so not much time but managed to make a replacement for the gearbox heatsheild which fell apart.  The original was made from a fiberglass like material, ( glass fibre and a phonelic resin I believe), I made the replacement out of alloy covered in stick on heatsheilding material.  It goes in the car like this with the exhaust underneath.  |

| |

|

|

|

|

|

Mar 31, 2020 14:35:32 GMT

|

The O rings finaly turned up today, we seemed to get a weeks post in one go.  I've found a compamy called simply bearings on ebay seem pretty reliable. So I took 10 minutes at lunchtime to fit it. Greased it and pushed it over the shaft.  Fitted the lock plate and nut, tighted it back up to the same marks and job done, its now ready to go in.  |

| |

|

|

|

|

|

|

|

|

Been a bit quiet, for the last few days we have been coughing, feeling very tired, sore chests, sore eyes etc, no temperature but it looks like the corona virus, 8 people at the supermarket my wife works at went off on the same day!

Fortunately we are in pretty good health not too old (53) and seem to be getting away with fairly light symptoms.

As I am feeling better but not wanting to overdo it fitting large lumps of Range Rover today I carried on doing all the odd jobs I have been meaning to do for ages, wired up thermostatically controlled under plant heaters for the greenhouse, then sealed the rear screen on the minor(never did it when I fitted the screen 2 years ago) filthy job but done now.

Also looked at the other job I have been meaning to do for ages which is fit some sort of high level stop lamp to it, we bought one to go inside the screen but it is a bit of a lump and could cause injury to rear seat passengers in an accident. So I have bought a LED strip meant for motorcycles, which also does the indicators, idea is to see if I can fit it accross the bottom of the glass, it was only £4 so not the end of the world if it doesn't work.

|

| |

|

|

|

|

|

|

|

|

wish you a good recovery. Supermarkets were and maybe are not a good place to be. My daughter has a weekend job in a Lidl supermarket. I went there to see how they followed the rules and was not impressed so asked my daughter to stop working there for a while as my wife belongs to a high risk group

|

| |

|

|

|

|

|

|

|

|

They try to introduce some measures but there is really very little they can do and virtually no protection for the staff, a lot of the customers take no notice and if anything it makes it worse as they are arguing and moaning at the staff about the measures, they have even stopped bringing things like loo rolls out while the store is open because the staff get mobbed, 2 metres doesn't seem to apply if the are bog rolls to be grabbed!

You've made the right decision, I wouldn't go anywhere near one if someone vulnerable was in the house.

|

| |

|

|

|

|

|

|

|

|

Bit of a disaster today, started well, did several odd jobs outside in the sun then thought I would spend the afternoon fitting the transfer box to the range rover, got it all on the transmission jack, it slotted in easily with about a 1/4 of an inch gap to the trans, I assumed this was the dowels, fitted the bolts ran them all down and it still wasn't moving, thought something is wrong here undid the bolts and it wouldn't come off again, the trans out put shaft seemed to be stuck in the input gear.

Then it got worse, put some tyre levers between the 2 to try to separate them and then crack, I have broken a lug for one of the transfer box to gearbox bolts off the transmission, now the language was really turning blue.

Took the rear cover off the transfer box and undid the centre bolt so the shaft came off the transmission then it all came out easily, once appart a fairly light tap was all it took to get the shaft out of the input gear, the problem then became apparent, when I bought the transmission I also bought a new long spline input gear but the transmission hadn't been built with the long spline shaft to match, my fault I suppose I should have specifically requested this.

So what have we got, the cracked lug is pretty flimsy one which sticks out at the bottom on a couple of webs so I can't believe it was doing much in the first place, plan is to make a steel bridge to link it to the surrounding case and fit it with csk bolts.

Hopefully putting an end load on the output shaft hasn't done any damage, it all turns smoothly and park works fine but the only way to be sure is going to be to put it all together and check it works OK. I've ordered the correct shaft now lets see when that turns up!

|

| |

|

|

|

|

|

|

|

|

Bit of a pig that. Hopefully alls well when it’s put back together. Fingers crossed.

|

| |

|

|

|

|

|

|

|

|

Decided to do something different on the range rover today as I can't go any further on the gearbox until parts arrive. For ages the rear dampers have been weeping and some time ago I bought a pair of Britpart ones, cheap and they should last a couple of years, ultimately I realy want to pull both axles off ,clean them all up and fit new bushes etc. Went easily enough, took the chassis brackets off so I could clean and treat the chassis behind (only surface rust).

Didnt finish though because the hot water packed up, the pump had packed up I had a spare but the flange spacing was wider so in the end I had to move loads of plumbing around to get it in 4 hours later and it is working, just waiting for it to warm up enough to have a shower.

|

| |

Last Edit: Dec 20, 2020 22:46:45 GMT by kevins

|

|

|

|

|

|

|

New shaft arrived today.  Fitted it and the transfer box went on ok, connected all the linkages up but came up against a problem, one pair of plastic bushes were missing from the hi-low linkage, I stole the centre pair from the diff lock to finish that the machined up a brass bush using fro a piece of brass tube a drill to bore it and file with it in the pillar drill for the outside, result came out surprisingly well.  After that fitted the rear mounts and called it a day, brake, propshafts, exhaust, kickdown cable and fluids to go.  Also got the remaining damper ready to fit, had to take both top brackets off to drill out the split pins but its only 3 bolts which someone had previously greased.  |

| |

Last Edit: Apr 8, 2020 7:20:25 GMT by kevins

|

|

|

|

|

Apr 10, 2020 19:02:10 GMT

|

|

A few hours on the range rover today, handbrake, propshafts and speedo cable fitted, just the fluids, kickdown cable exhaust and x member to go, though the x member won't be fitted until I've driven it as with it out I have a fighting chance of getting at the various linkages and cables with it out.

Big issue will be the exhaust in just about every way possible the y pipe doesent fit, front pipes too far appart, pipes wrong diameter, outlet at wrong angle and it hits the transfer box. Can't do much else except make it fit though.

|

| |

|

|

|

|

|

Apr 12, 2020 19:05:18 GMT

|

Rather apt given the day but today the range rover rose from the dead. Spent yesterday tidying up all the junk which had accumulated on / around it over the last 3 months. Today I fitted the second damper, painted the chassis with waxoyl filled the transfer box with oil and then started on the exhaust, I found an old TR7 downpipe which was the perfect diameter to slide over the pipes on the y pipe, fitted the muffler, cut the lateral part of the y pipe and chopped the lh side down until it fitted with a sleve onto the downpipe, then chopped a pit out of the width and re joined it with another sleeve, the rh side fitted OK as the downpipe had been shortened anyway this is the finished job.  Fitted the kickdown cable then found another problem, the cable has a ferulle crimped on it and you are supposed to adjust it until the ferrule had around 1mm gap to the abutment, the ferrule on the new cable supplued with the transmission is loose though!. For now I have set it to the same dimension as the old one from the end of the cable, I'll give Ashcroft a ring in the week to see what they recommend. Filled it with £70 of syntheyic ATF connected the maf and battery back up and started it up, cycled it through the gears topped it up and went for a short drive, all seems fine, no clonk engaging gears and otherwise it drives as well ss it ever did. So just a couple of things to finish off, firstly make some sort of gaiter for the high low lever, the old rubber one was in shreads, the exhaust seems to have a small leak somewhere, I had ran out of paste so may need to take it appart / re-seal it, and give it a wash, it looks like it has been in a barn for years not a garage for 3 months! |

| |

|

|

|

|

|

Apr 13, 2020 19:19:54 GMT

|

Did another errand in the range rover today.  All seemed fine until it started juddering on acceleration solution proved simple though it was running out of LPG, a quick switch to petrol and all was fine. Need to sort out a tps though it does stumble if you slam the accelerator down, fortunately in clearing out the garage I found a sierra pinto efi one which is the same resistance range and similar size, just need to make a shaft as it a female and the original a male shaft. Also found what I think is a Fiesta gearstick gaiter which might just do for the hi-low lever, all this hoarding is coming in usefull at last Cheap chinese radio in the ka packed up but it was only £15 and it has lasted 3 years as Lucy is using in every day I swapped the one out of the TR into it. As the range rover is off the ramp I put the TR on, crank is not leaking oil now but it looks like the oil pressure switch is leaking as well (its also stopped working), hopefully I can find one of those somewhere tomorrow. Finally I was requested by she who must be obeyed to find a way of making alchohol for hand sanitizer, some years ago our local market had someone selling a load of science equipment including glass distilling tubes for £1, I couldn't resist a bargin so bought one, today it finaly came in useful. Add a kettle, temperature measurement, garden hose and bottle of cheap Vodka and off we go.  |

| |

Last Edit: Apr 13, 2020 20:39:07 GMT by kevins

|

|

|

|

|

Apr 14, 2020 18:05:24 GMT

|

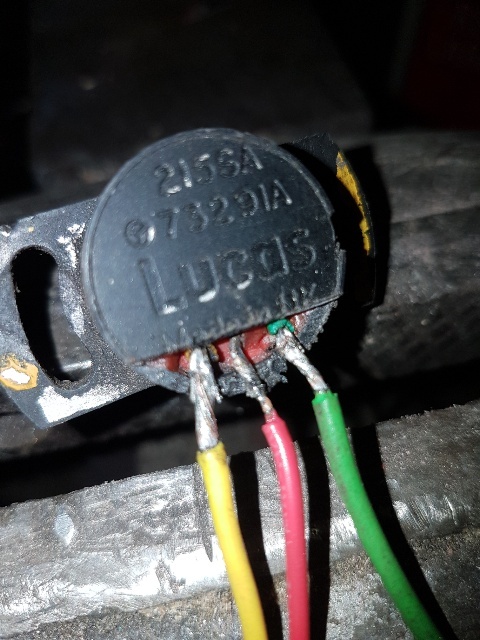

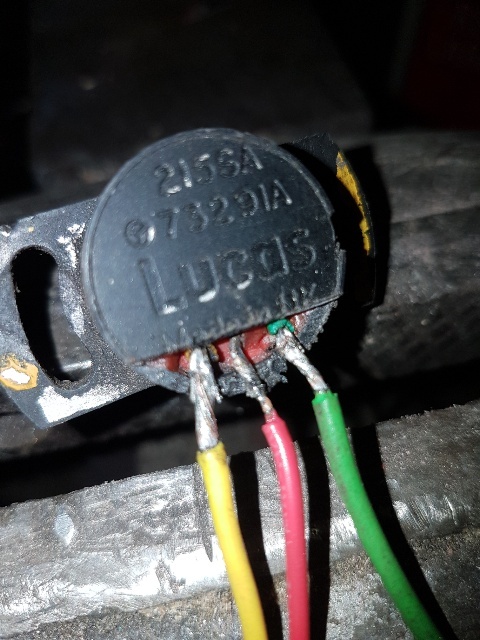

Took the range rover for a longer drive, appart from the exhaust leak which seems to be getting quieter it all seems fine, gave it a good wash as well.  Might tidy up a few of the paint chips tomorrow, this is the gaiter I found which I might try to make fit under the high low lever.  Then turned my attention to the TPS for which all 3 wires had broken off, I had planned to try making a Ford one fit but thought I would see if I could do something with the original one first. Cut the top off and barrred the wires.  They were oxidised but with some flux I managed to tin them.  Soldered some wires to them.  Sleeved with shrink  Then re-potted the whole area with araldite.  I've left the plug off the other end in white vinegar and tomorrow I will try to get the pins out so I can replace the wires completely, they are pretty brittle, I think ultimately I might have to think about replacing most of the injection harness as it's all going the same way. Also looked at the oil leak on the TR.  This what leaked overnight. It seems to be coming from the oil pressure switch behind the brown wire.  Searching through my store I found 2 switches, the right one is the old one the middle one seems to fit, will need a jumper for the different conector though but it fitted fine.  Also washed the street ka, Came well as always.  This is pretty annoying though.  Someone must have given it a fair wallop with a door, paints not broken though so a chance to remove the liner and practice paintless dent removal. |

| |

Last Edit: Apr 14, 2020 18:07:05 GMT by kevins

|

|

|

|

|

Apr 15, 2020 21:09:36 GMT

|

Started trying to sort out the centre console on the Range Rover, its all cheap nasty materials most of which are in somevway cracked but once assembled it just about hangs together. Pulled it all out to reveal what was underneath.  The gaiter was in shreads  Ended up making a new gaiter out of an inner tube, by using the outer part I had a shape which allowed for movement.  The wiring is also a mess there is a melted bulb holder which I think was supposed to be for the ash tray for some reason they had also been rewired to come on with the ignition.  Also took the prndl appart, the internals were filthy, left side cleaned right as found.  Also bent up a steel plate for the cup holders  Covered with vinyl and fitted.  Hopefully I will get a chance to finish it tomorrow. |

| |

Last Edit: Apr 15, 2020 21:26:56 GMT by kevins

|

|