|

|

|

Feb 12, 2023 12:30:17 GMT

|

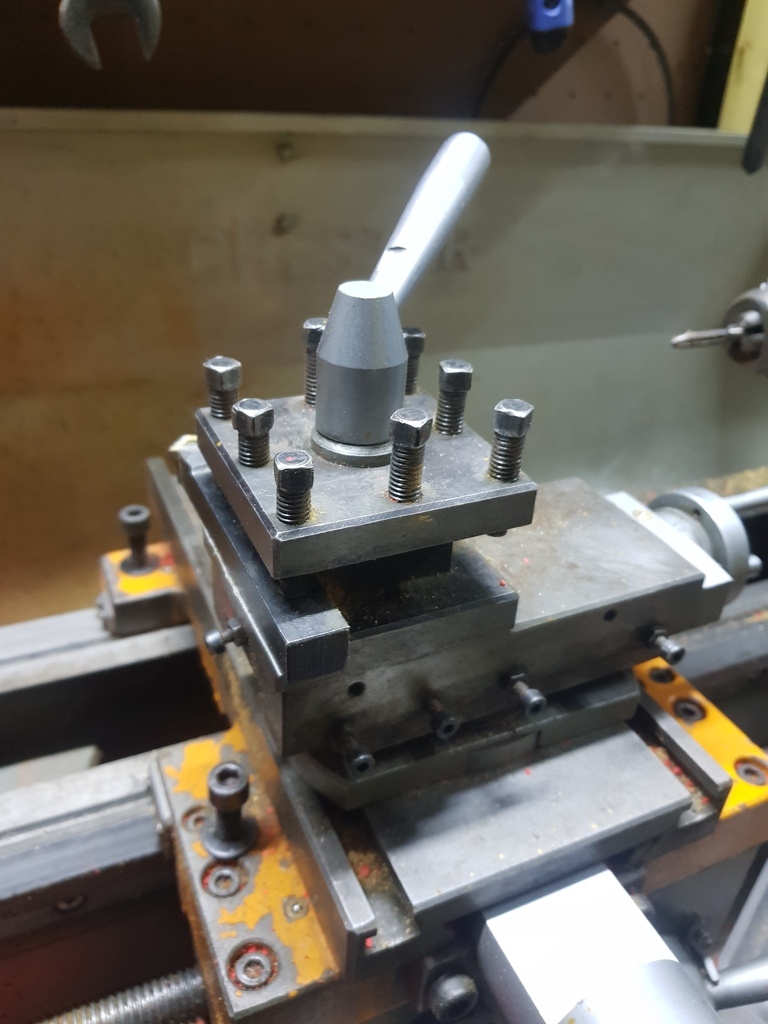

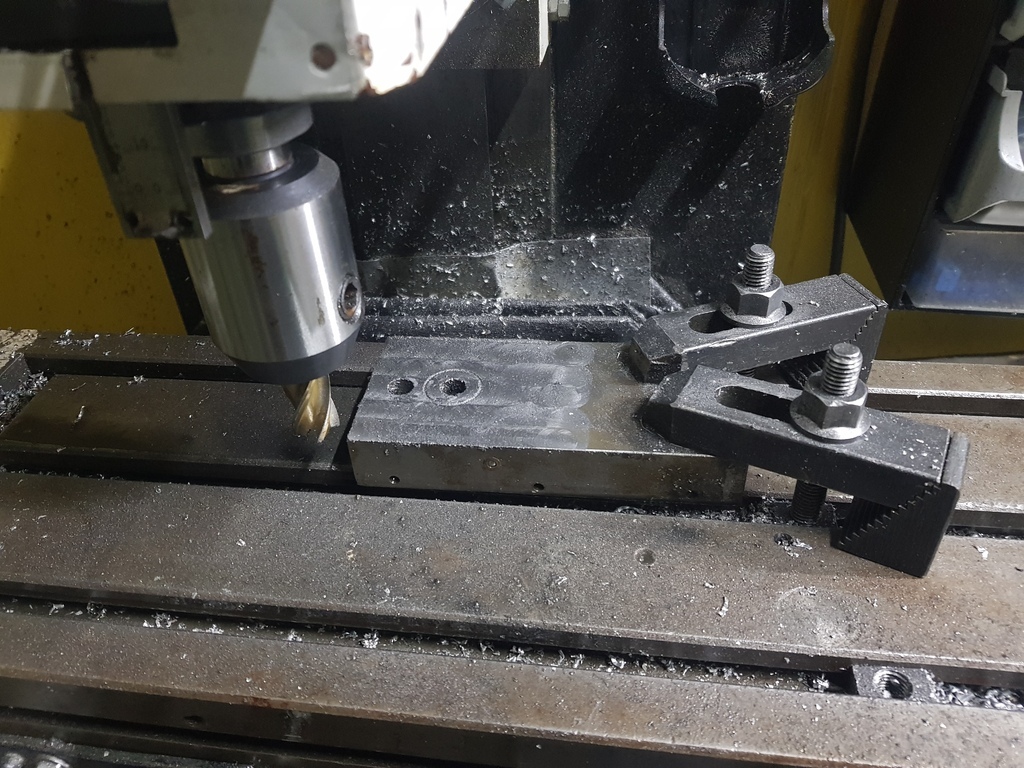

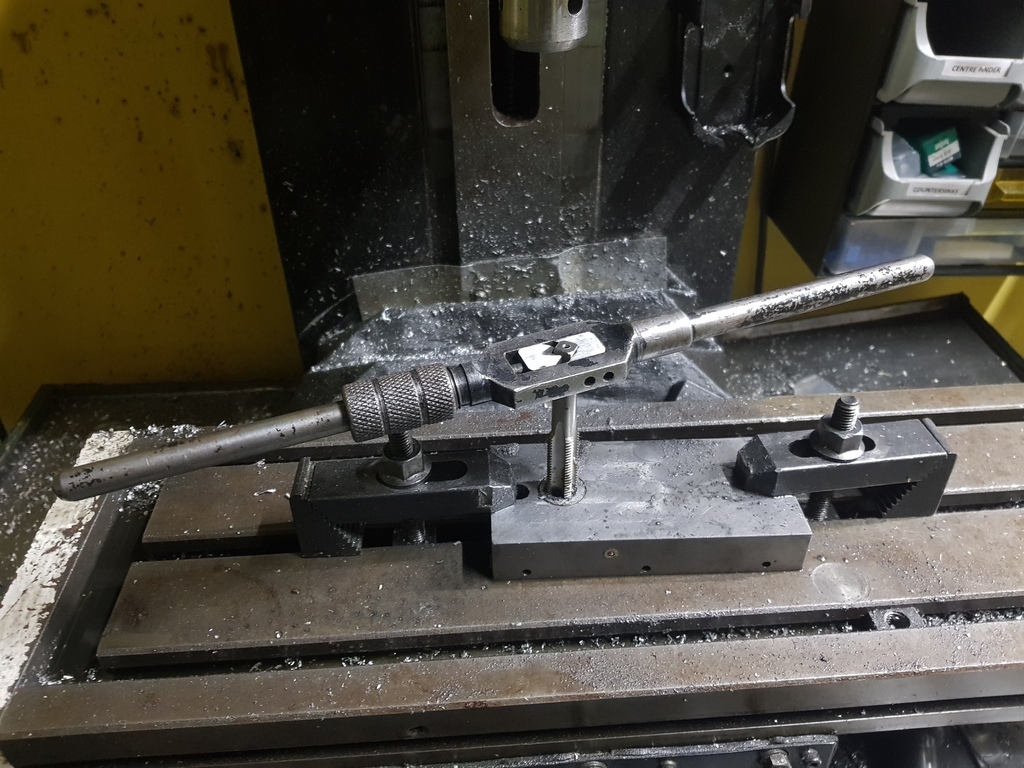

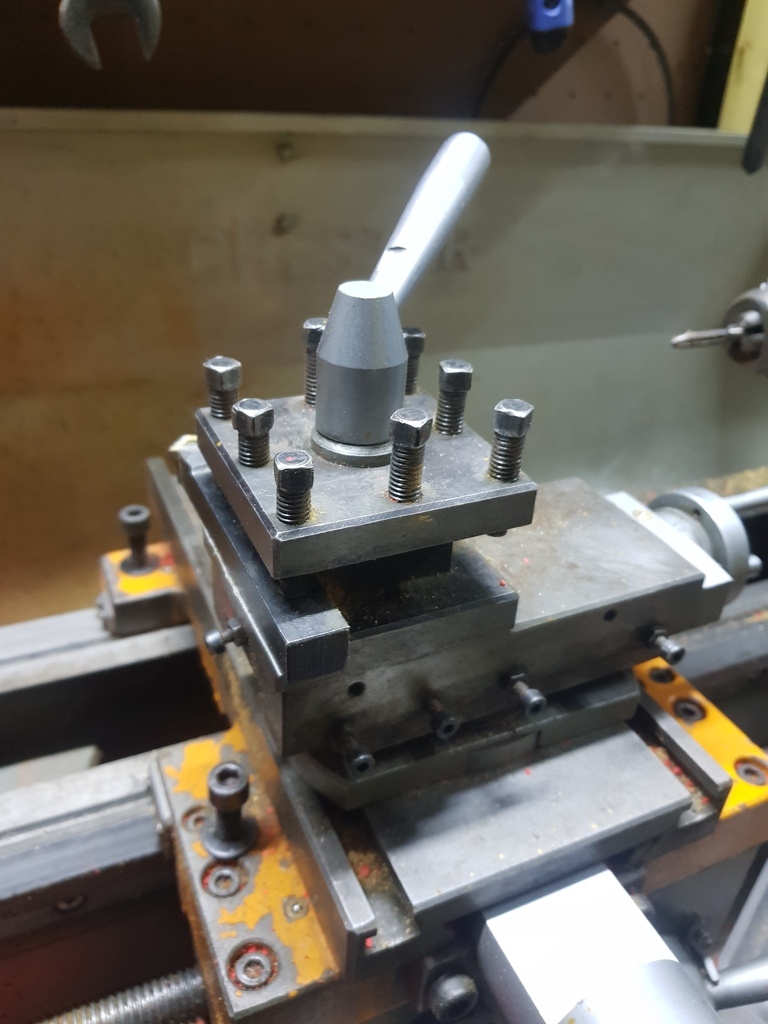

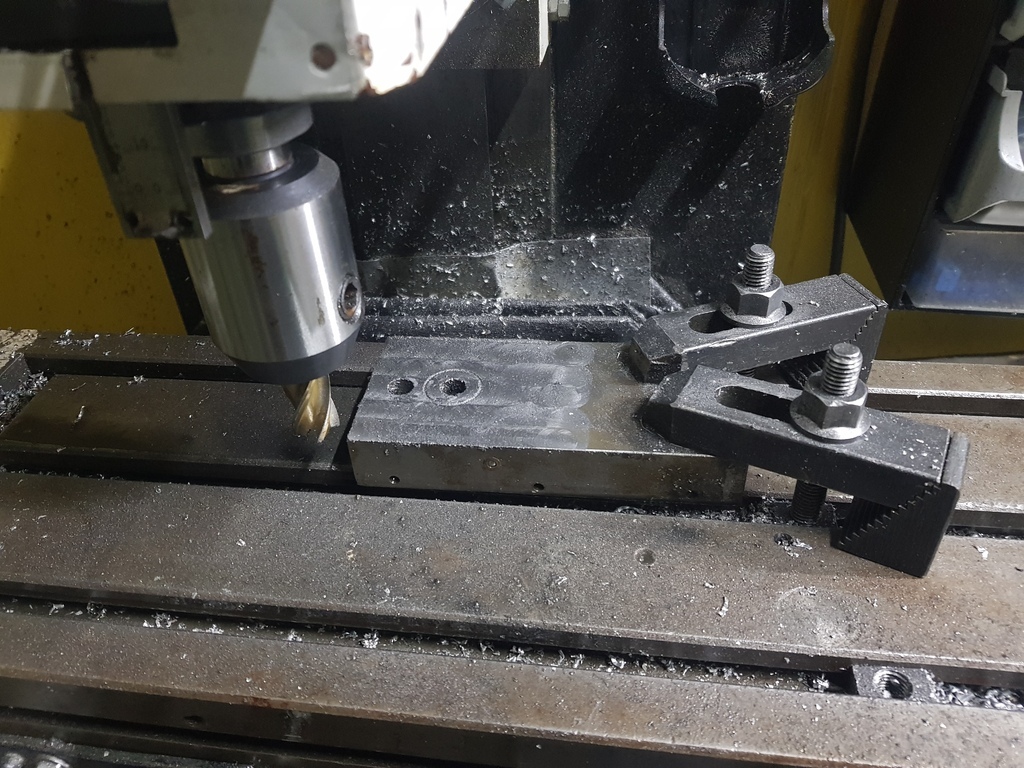

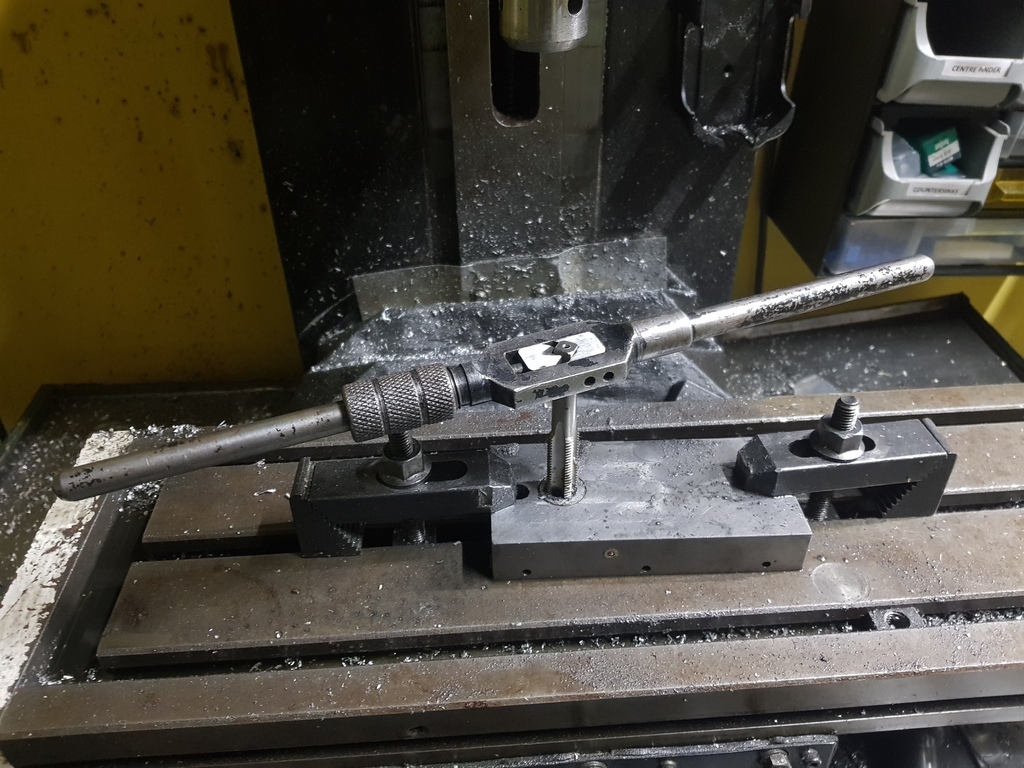

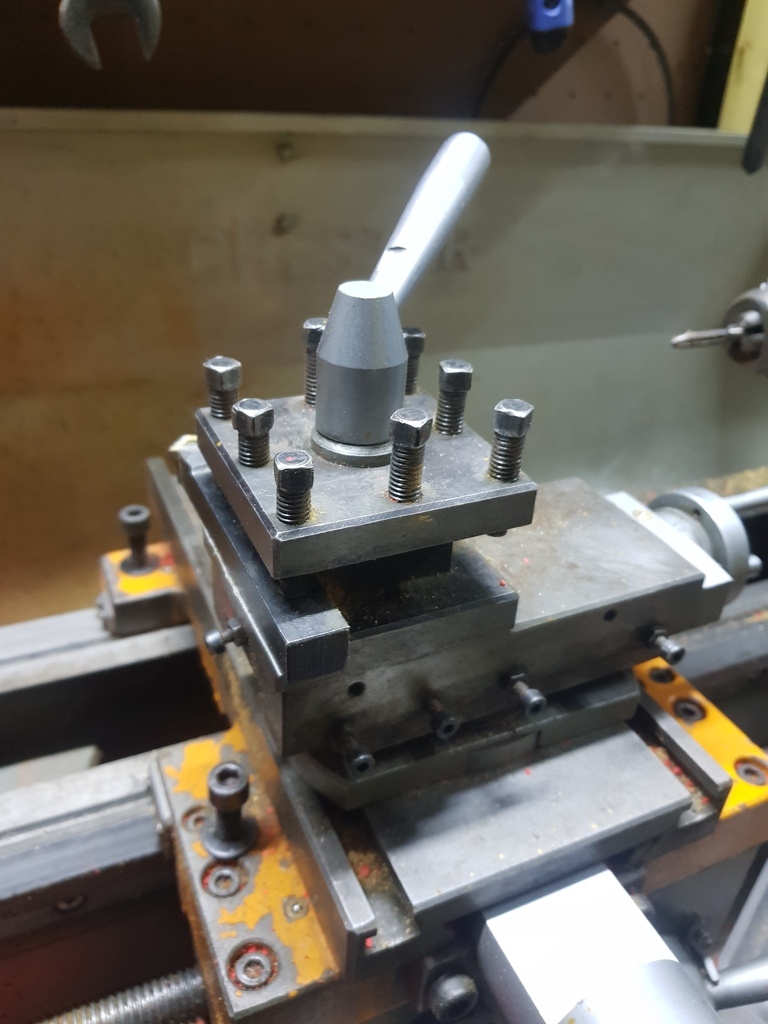

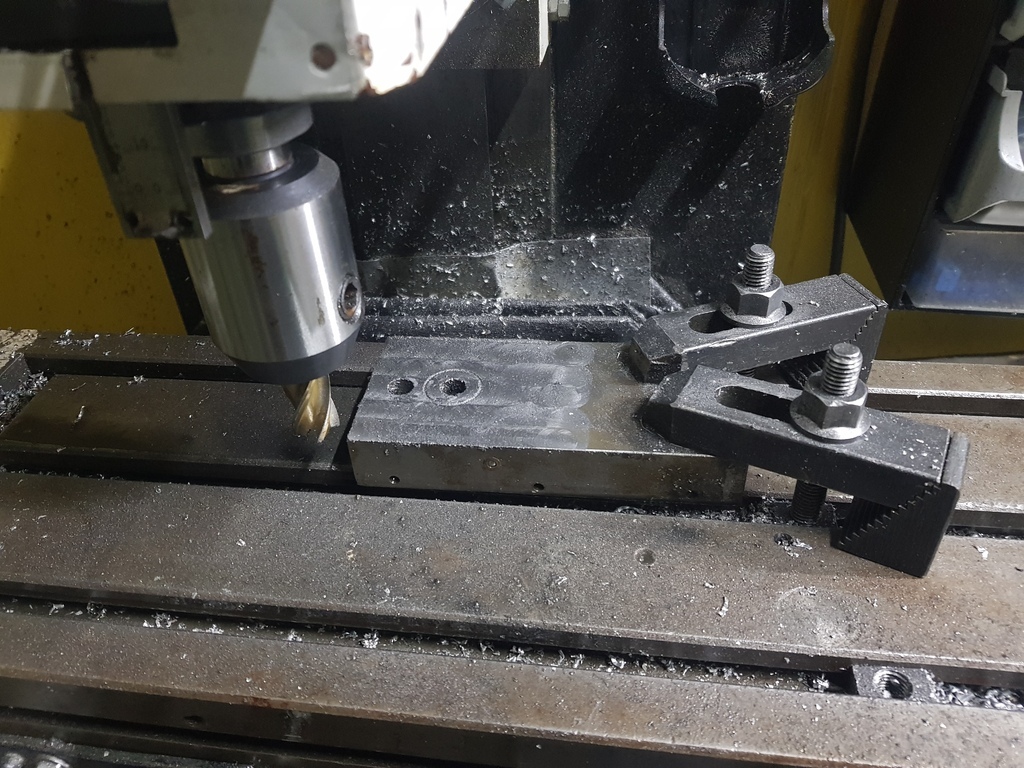

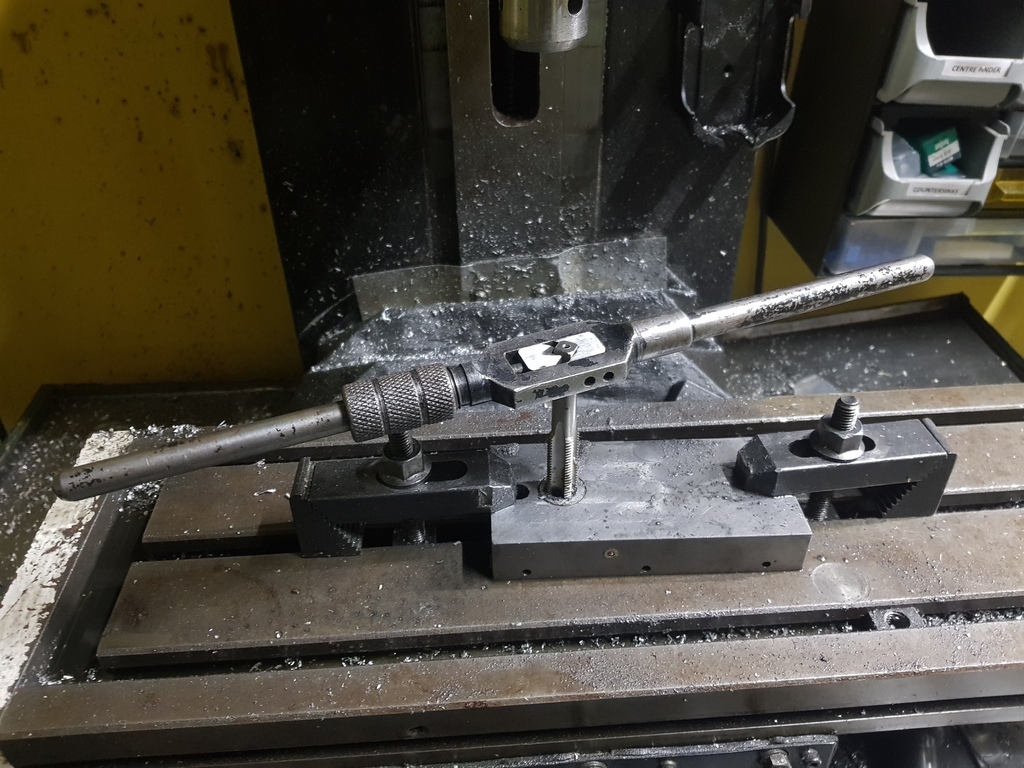

Still treading water, so decided to up upgrade the tool holder on my lathe. It was till fitted with the standard tool holder it came with 12 years ago. Perfectly functional but not conducive to multiple tool changes during a machining project as the tools have to be removed and replaced and the cutting tip height checked and adjusted with shims.  I have wanted a quick change tool holder for a few years but they are not cheap so have put it off until now. Finally bought the tool post with 3 tool holders. However, I knew that it wouldn't be a straight swap (what is?) and some machining would be required as the securing bolt was a different size. Took the top slide off the lathe and set about pushing out the existing post. However, it exploded in the press! Only then did I realise that I was pushing it the wrong way. I thought the the wide shoulder was part of the stud. Duh.  First thoughts were to install a rod in the centre and fill the crater with JB weld. Would have worked, I think, but I needed a lathe to make the centre rod :-) On talking to the company I bought the lathe from, they offered me one removed from a display model for £50. Pretty good deal at time I thought, but when it arrived I was a tad disappointed. It was filthy, missing a couple of the gib screws (can use ones from original) and the locking pin was seized (not required). Nothing serious but I called them, laid it on thick and received a £30 gift voucher which I will use to get another tool holder. Right, down to modifying the new one. Pushed the stud out the right way and cut off the shoulder. On to the mill where I cleaned up the surface and tapped a new M14 thread. Just need to install on the lathe and start playing again.         |

| |

Last Edit: Feb 12, 2023 12:42:43 GMT by nalesutol

|

|

|

|

|

|

|

Feb 12, 2023 11:52:25 GMT

|

I would have thought it unlikely to have been an image of the world, but you said it was dark and the brain tries its best to interpret what the eyes see and doesn't always get it right :-) |

| |

|

|

|

|

|

|

|

This weight reduction process is a lot easier, cheaper and way more effective than centre drilling titanium bolts! Just make sure you don't start drilling speed holes on your body😉 :-) The existing 7 holes will just have to suffice :-) |

| |

Last Edit: Feb 9, 2023 20:11:13 GMT by nalesutol

|

|

|

|

|

|

|

Good point about the driver weight! It often amused me to be told about the latest whizzo weight reduction or BHP increase by a fellow competitor, with a huge beer belly! Agreed, but I didn't want to mention that :-) Some of them are HUGE. If you listen carefully you can hear the car go oooofph as it sinks closer to the ground :-) |

| |

Last Edit: Feb 9, 2023 12:20:14 GMT by nalesutol

|

|

|

|

|

|

|

|

Continuing my anal quest for lightness, I decided to address the Elephant in the room or, rather, the one behind the steering wheel :-) Easiest way for me to further my quest.

At 6' 1" and 86.4kg, I was medically obese! This was not good as I have type 2 diabetes and high blood pressure. So, we both decided to try the intermittent fasting diet. With this you eat normally but have nothing other than water or black tea/coffee for at least 13 hours on the trot. This tricks the brain into going into starvation mode and use stored body fat as fuel. So, finish dinner by 7pm and then have nothing until breakfast at 9am, or later if possible as the longer the fast the better.

We started this on Jan 1. I am now under 83kg so in the normal range for my height. My plan is to get to 80kg but there is no rush. We are also taking more exercise in an effort to get me off the drugs.

6.4kg is just under 1% of the car's total predicted weight. This equates to an increase in the bhp/tonne from 857 to 865bhp/tonne :-)

This weight reduction process is a lot easier, cheaper and way more effective than centre drilling titanium bolts!

|

| |

|

|

|

|

|

|

|

|

Why do you want such a drastic increase in bar stiffness?

|

| |

|

|

|

|

|

|

|

Another little job. Charge the battery. After many years of inactivity everything has got rather dusty so a major clean up is in order when it returns.  |

| |

|

|

|

|

|

|

|

|

|

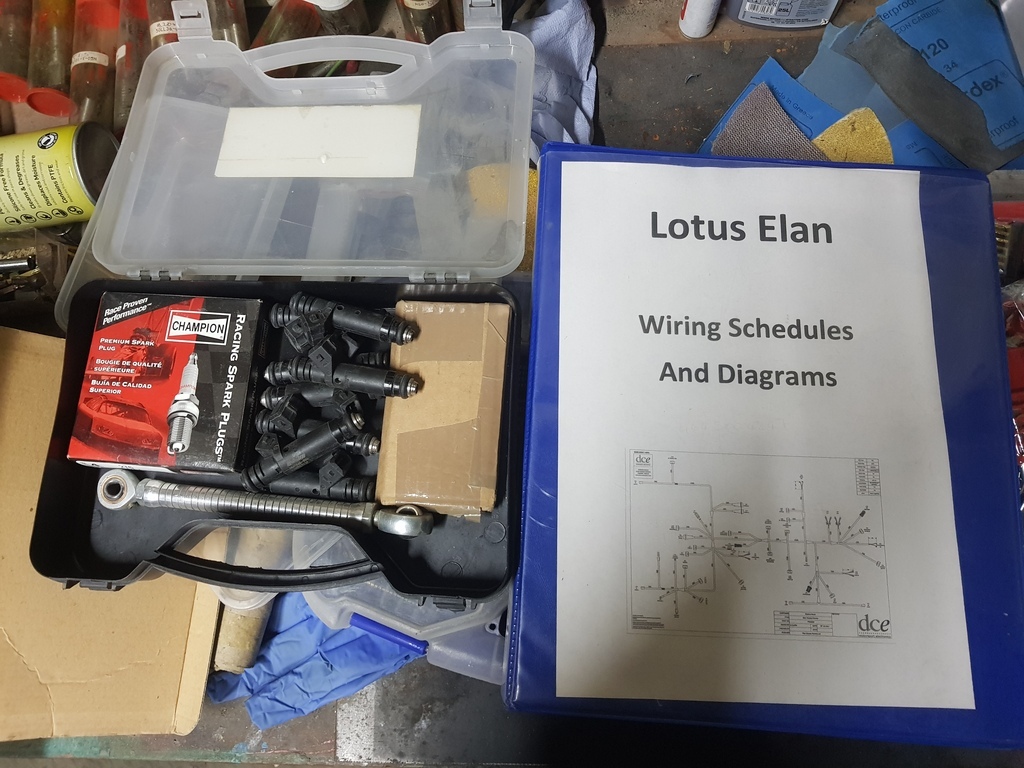

Dug out the injector test we did a while ago, they look pretty good so no messing around trying to match them up. Posted this video a few years ago so some you may not have seen it :-)  |

| |

Last Edit: Feb 8, 2023 9:56:36 GMT by nalesutol

|

|

|

|

|

|

|

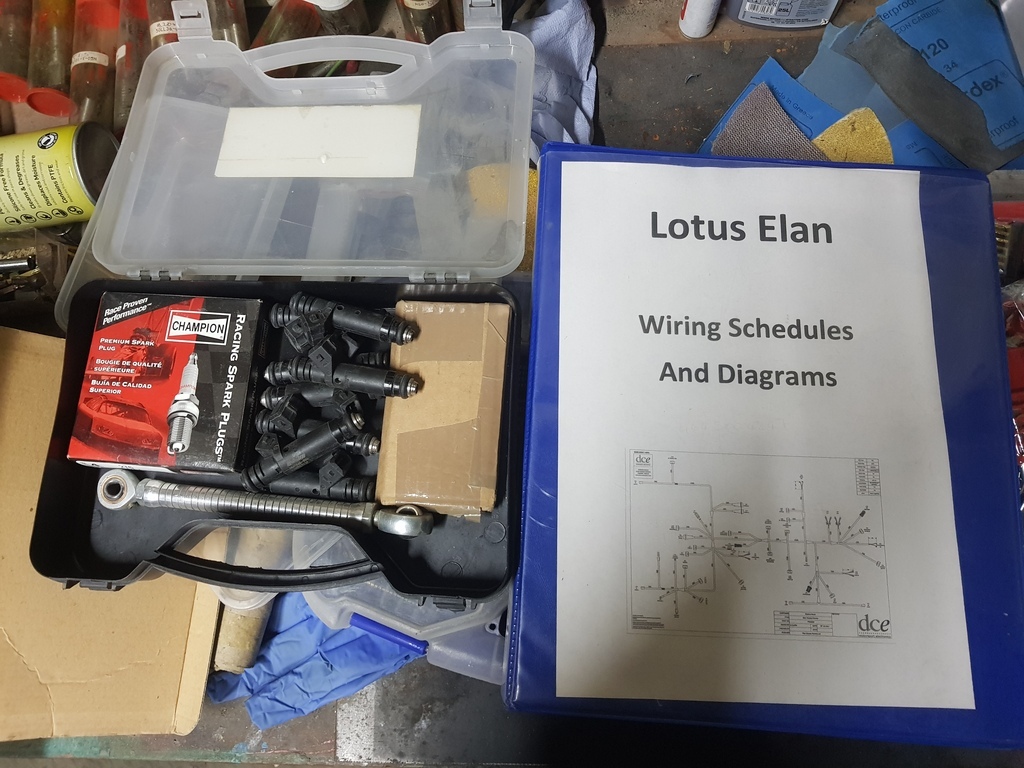

Treading water at the moment, waiting for a space at the workshop to become available. In the meantime I have updated my file containing all the electrical info they may require and I am in the process of putting together a box of bits they will require.  |

| |

|

|

|

|

|

|

|

|

2mm stainless is around £140 for 1000mm x 1000mm

3mm Aluminium is approx £90

The aluminium will be a LOT easier to work with.

|

| |

Last Edit: Feb 5, 2023 20:44:39 GMT by nalesutol

|

|

|

|

|

|

|

|

Just stumbled across this video series regarding keeping your car road legal and other driving matters. Found them very interesting, especially coming from a correct road traffic cop who happens to be a petrol head.

|

| |

|

|

|

|

|

|

|

|

I would guess that it would cost more than $15 to get yours re-engraved.

|

| |

|

|

|

|

|

|

|

|

Thanks Pete, good to be back.

|

| |

|

|

|

|

|

|

|

|

Plug leads ordered. Not cheap but going fast never was :-)

|

| |

|

|

|

|

|

|

|

Glad you're back dude! Missed updates on this thing. I've done a smidgeon of work with UHMW. Only cutting spring spacers and the like. I was surprised at how much more work it is to hacksaw/holesaw through than HDPE. It's tough stuff. It's also a thermoplastic so if it needs to fit a curved shape you can form it with a heat gun. Holds its heat for a long time so careful without heat resistant gloves of some variety (unless you're one of those people whose skin's made of asbestos). Yes, forming it isn't a problem. The choice is between Steel, Aluminium and UHMWPE. The cost difference is significant but has no bearing on choice, weight is my only concern. For the size I require, 3mm Steel will weigh 1.766kg, 6mm aluminium 1.215kg and 5mm UHMPE 0.356kg. Ooooo, difficult choice :-) |

| |

|

|

|

|

|

|

|

|

Woohoo!! We have started. Son Alex and I measured the spark plug leads in order for them to be made up. Not much but at least it is a start :-) Car should be going in within the next couple of weeks, as soon as they make some space.

|

| |

|

|

|

|

|

|

|

You could have cut some nice holes in it and cover them with rubber flaps. Vw did this on the golf mk2. As air gets pushed through the radiator when driving it will push the flaps open. When the fan kicks in while stationary it will suck the flaps closed so it needs to pull the air through the radiator. That is a very interesting idea and goes into the memory bank. |

| |

|

|

|

|

|

Jan 30, 2023 21:49:40 GMT

|

Fit lights ? If I remember you were looking to go daylight MOT ? so indicators and brake lights only? List isn't that scary if you consider all the work done so far. James Correct, indicators, and brake lights only. However, I did have all the wires and switches for a normal lighting system added to the loom and dash (hang the weight penalty :-) ) just in case. |

| |

|

|

|

|

|

Jan 30, 2023 21:38:30 GMT

|

I've ordered the -11 versions, 44thou so not much to open them up by. Just paid under £20 for 8 of them  £2.50 each? Geez, that's cheap! Mine are around that each. |

| |

|

|