|

|

|

|

|

|

Just found this, brill!!

I will be impressed if you can keep it below 800kg, as it is surprising how much all the little bits you forget about end up weighing :-) Using thin wall T45 will help. I am struggling to keep my Elan build below a basic Elan's weight (700kg). How much did the complete body end up weighing?

|

| |

|

|

|

|

|

|

|

|

|

|

Personally, I wouldn't use repaired alloys, let alone widened ones! Even more so if you will be using them as depicted in your avatar!!! Any welding will alter the structural integrity of the surrounding metal due to the heat, unless they are retreated after the work. If you need to fill the arches you could consider spacers. 25mm would not increase the the stress on the bearings by much and a lot cheaper then widening the wheels :-) Or look on ebay etc for a suitable set as these will be safer (IMO) and probably cheaper than getting your wheels widened.

|

| |

Last Edit: Mar 3, 2023 10:19:16 GMT by nalesutol

|

|

|

|

|

|

|

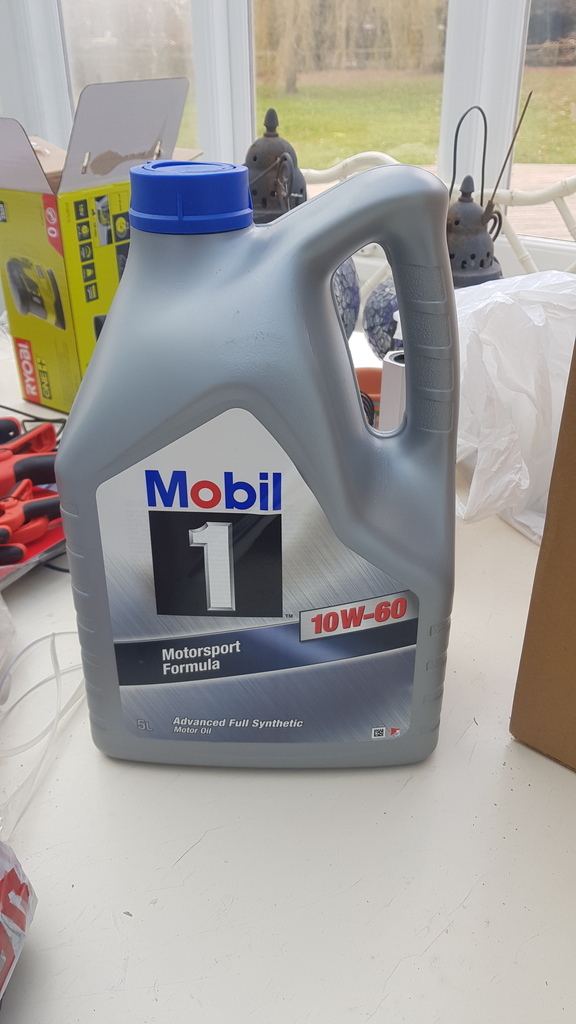

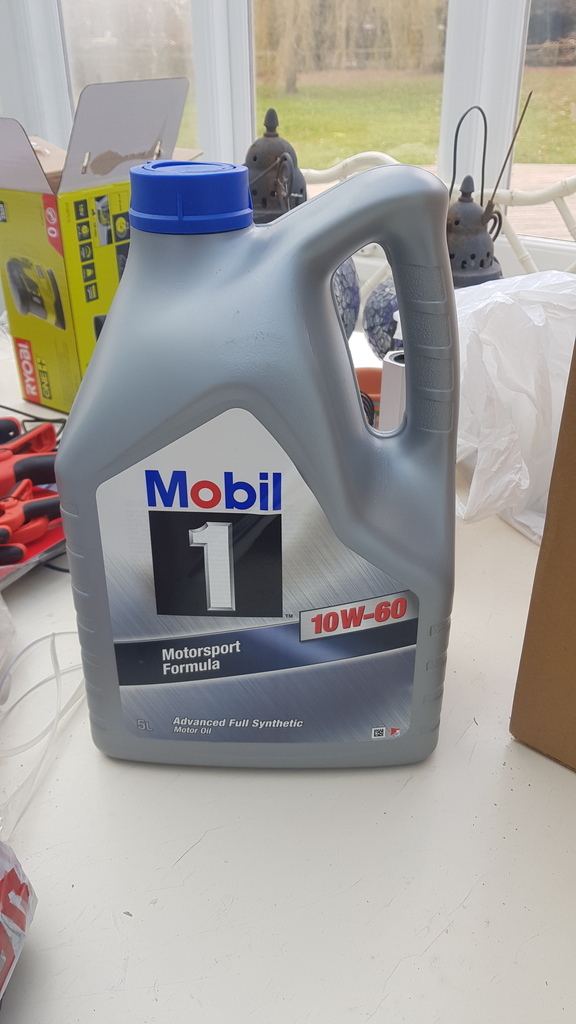

Especially for bjornagn :-) Lots of stuff arrived today. JCS high grip stainless hose clips, engine oil, brake fluid and header tank cap. The cap has a pressure release lever. I know, excess weight :-) However, it was the only one I could find that had a large enough diameter bottom seal. I will just have to get used to it. I was planning to use Mikalor clamps and to that end I bought a load some time ago. However, the JCS clamps are used at GPE where the car is going, are cheaper and less than half the weight, saving over 1.5kg! If they are used on race spec RS200s and 1980s F1 cars they will do me just fine. If they are an issue at high boosts then I still have the Mikalor.    |

| |

Last Edit: Mar 2, 2023 11:54:45 GMT by nalesutol

|

|

|

|

|

|

|

Man...feels like the old days when I could count on a post a day for this build. Might have to get back on another project of my own cause now I feel like a slacker! Or I could just build a rec room and chill. Edit: I DID buy this nifty LS L33 with not real purpose other than to say I built an LS engine. With a bit of gearing and adaptive engineering it would make one amazing margarita mixer for the wrecked room!  :-) Maybe not every day yet, but as soon as the car goes and comes back I will get on with it so there will be frequent updates. They make good coffee tables :-) |

| |

|

|

|

|

|

Feb 26, 2023 17:53:47 GMT

|

|

On a bit of a roll now 🙂 Couldn't remember how far I had got with the flappy paddle install. However, scrolling through the Lotus build files I found this and it triggered the old brain cells into action. I built the system myself as the commercial ones are silly money. On the first attempt I used an actuator that was too small (diameter) as I had failed to allow for the area lost to the shaft.

This actuator seems to work OK but the proof will be when we finally fire the beastie up. I hadn't made the steel sleeve for the securing bolt (to prevent the titanium bolt elongating the hole in the aluminium bracket) at the time, hence the movement, it wasn't due to band workmanship 🙂 I have gone down the pneumatic rather than the electric route as it gives a softer kick to the gear lever so less shock to the system.

|

| |

Last Edit: Feb 27, 2023 17:11:42 GMT by nalesutol

|

|

|

|

|

Feb 23, 2023 13:34:34 GMT

|

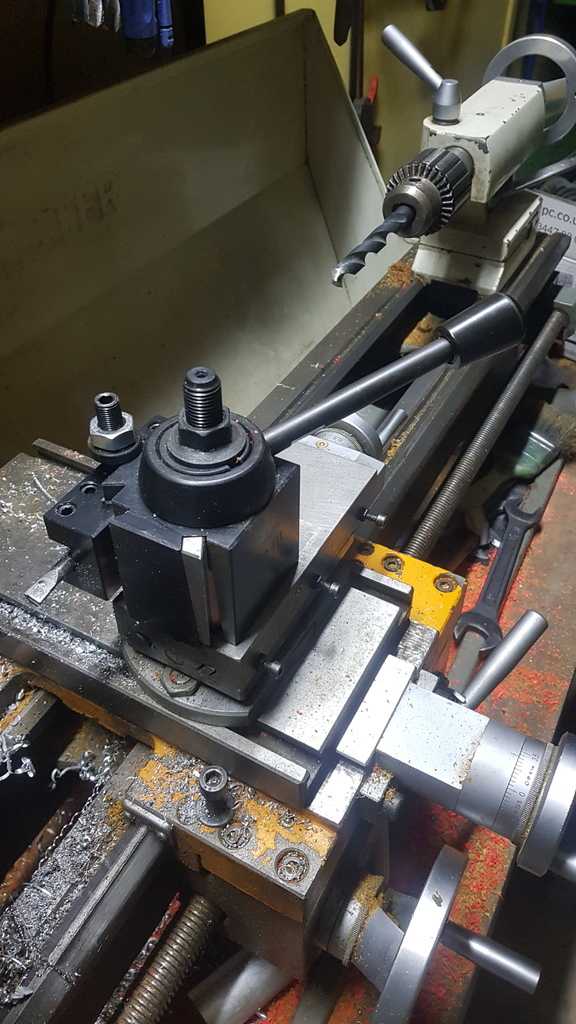

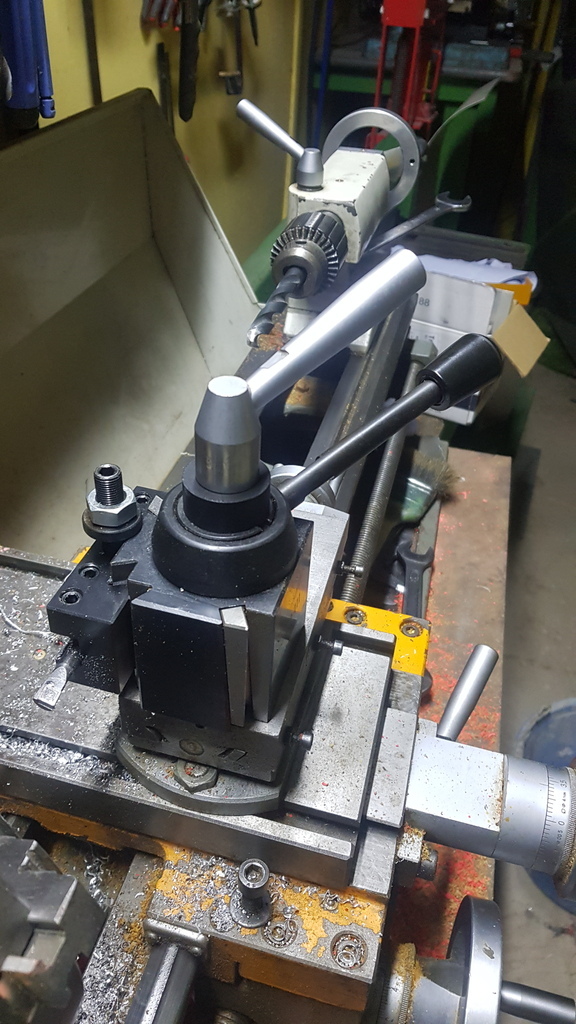

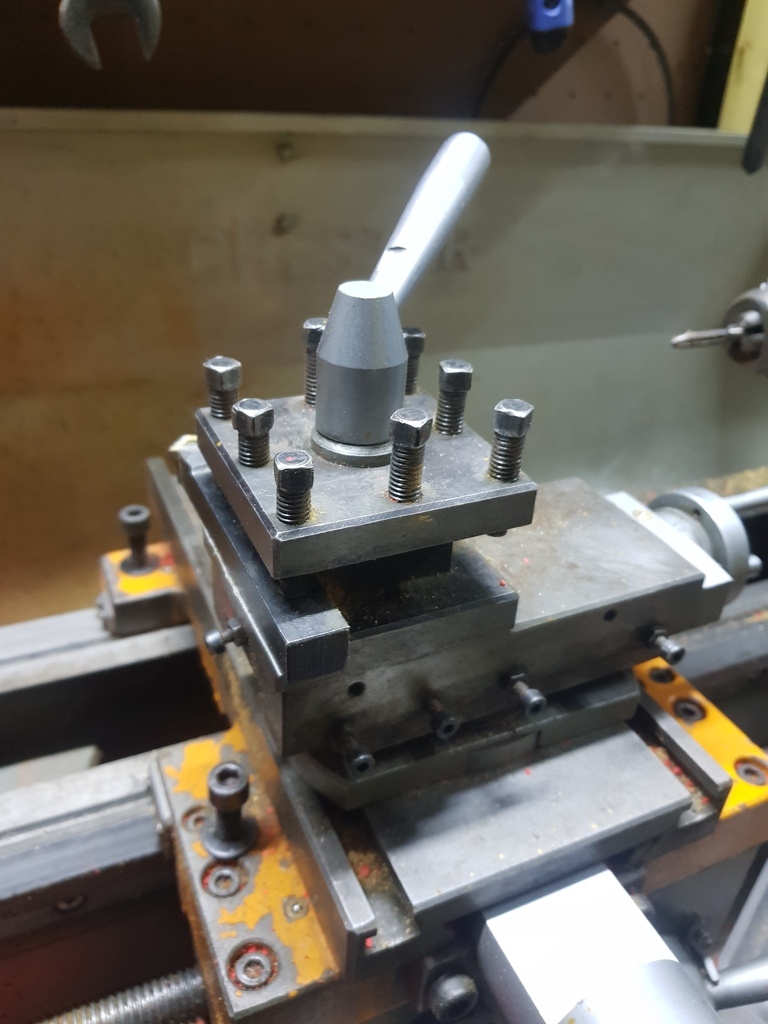

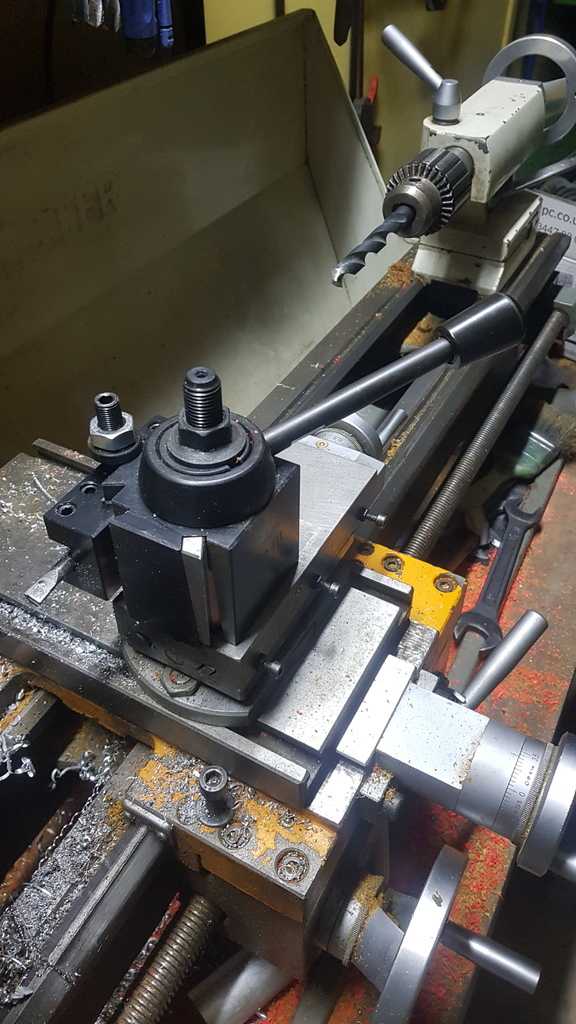

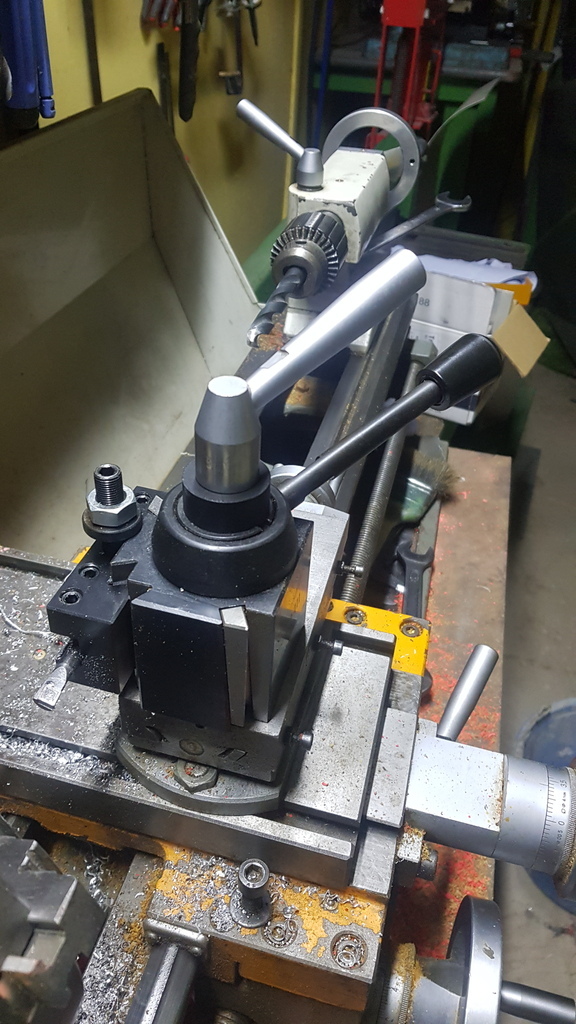

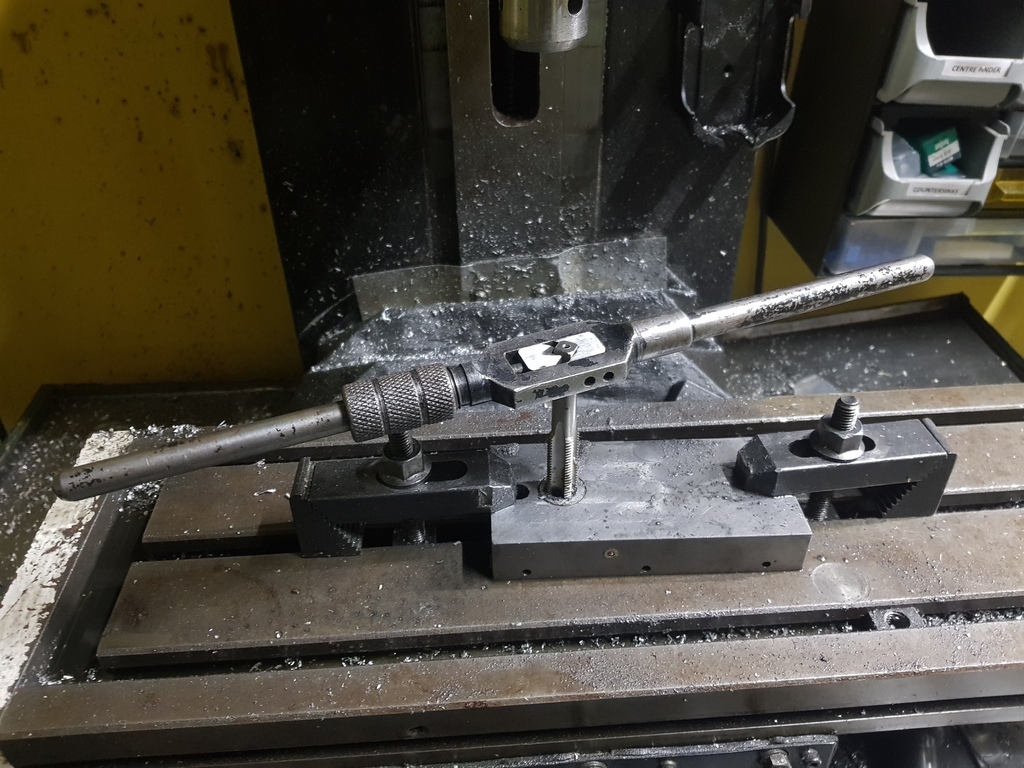

One positive from deciding to get the car electrics sorted has been that I have stopped fretting about it and can get on with other stuff without thinking that I should be working on the car :-) To that end, more mods to the lathe. The new quick change tool post is secured using a nut and spanner but the original used a handle, a much easier way. So I modified the old handle by increasing the thread to M14 and made an aluminium spacer. Much easier now. By fine tuning the thickness of the spacer I was able to keep the handle out of the way.   |

| |

Last Edit: Feb 23, 2023 13:35:02 GMT by nalesutol

|

|

|

|

|

Feb 23, 2023 10:53:41 GMT

|

|

Any other suggestions for road legal tyres?

185/60/R14 or 165/50/R15

275/35/R15

|

| |

|

|

|

|

|

Feb 22, 2023 16:32:20 GMT

|

Nice looking wheels to come! But will you shave the tyres to reduce their weight or just accept the excess weight and get more use out of them? Maybe I could get some part worn tyres :-) At £600 a piece I wouldn't be shaving them! However, I can't get the sizes I want in the Michelin TB5s so I am looking at the Nankang AR1. The price difference is staggering. £2270 for a set of the TB5s compared to £660 for the AR1s.  |

| |

Last Edit: Feb 22, 2023 16:32:50 GMT by nalesutol

|

|

|

|

|

Feb 19, 2023 20:30:33 GMT

|

|

If you look closely you can see the mess of the brackets holding the radiator in place. This is the result of fine adjustments being made to get everything to fit in the confined space. Once settled they will be made good

|

| |

|

|

|

|

|

Feb 19, 2023 20:27:42 GMT

|

I haven't bought the wheels and tyres yet, these just hold the corners up for the moment :-) Looking at 6 or 7x14s front and 11x15s rear using Michelin TB5 tyres. Wheels are Image Wheels 3 piece billet and they can remove quite a bit of surplus aluminium from these, based on car's weight and usage.   |

| |

Last Edit: Feb 19, 2023 20:43:33 GMT by nalesutol

|

|

|

|

|

Feb 19, 2023 19:31:11 GMT

|

|

|

| |

|

|

|

|

|

Feb 18, 2023 14:41:09 GMT

|

|

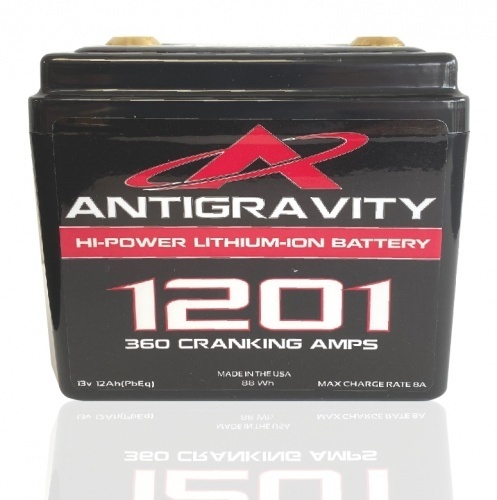

They are also MSA approved. Only official distributor outside USA.

|

| |

|

|

|

|

|

Feb 18, 2023 11:50:41 GMT

|

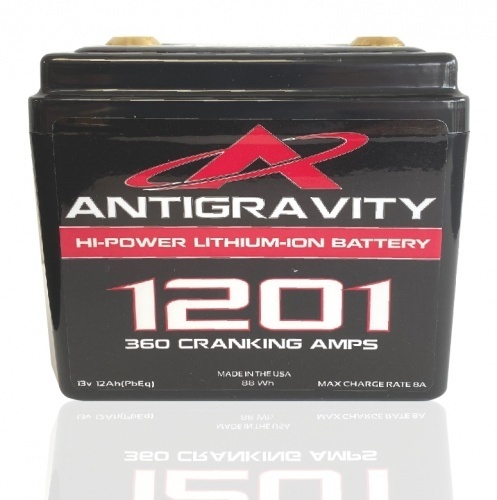

For anyone remotely interested in car batteries: Approx 7 years ago I though that I was near to starting the car up so decided to get a battery. Being, as you are all no doubt aware, somewhat anal about the car's weight, I decided to grit my teeth and go for a lithium jobbie. After a fair amount of research I settled on Antigravity Batteries as they seemed to give the best value for money and the lightest units. After a long chat with Peter we agreed that their YTX12-12 battery would best suit my needs. As they are situated in Southend-on-Sea, only 30 minutes away, I popped down to see them. Peter handed me the battery and I thought that he was playing a trick on me with an empty case! But, no, this was the actual battery! (I weighed it when I got home and it is 953gms!!!) At £200 it wasn't cheap but the weight saving over a traditional battery was amazing.  Over the years I have kept it topped up (they need very little maintenance as opposed to lead/acid ones) every 6 months or so. The topping up process it quite long winded as the charger (you need a Lithium battery charger) goes though quite a long checking and monitoring process which can take over a day. However, last week was different. Even after 3 days it never got out of the testing phase so I thought that it had died. Rang Antigravity and spoke to Peter who suggested that, after 7 years of inactivity, it could be on its way out. They do a replacement that is 110gms heavier but ridiculously small (115mm x 80mm x 108mm). So off I go to Southend.  When I got there Peter took my battery to test it. The tests he could do without hooking it up for 24 hours seemed to indicate that it was OK. He suggested that I fit it to a car to see if it works before forking out £260 for a new one. Got home and put it on the Fox and it started! So the plan now is to fit it and see if it works once the car is ready. I can't fault their service. I quite expected to walk out with a new battery as he could have quite easily convinced me that my battery was on its way out and sold me a new one. Regarding their batteries. The manufacture works on the mantra of under promise and over deliver. Although the 1201 sates 360 cranking amps Peter has tested them at over 700! Enough cranking amps for a measly 2 litre methinks :-) #NotSponsored :-) |

| |

Last Edit: Feb 18, 2023 11:56:32 GMT by nalesutol

|

|

|

|

|

Feb 17, 2023 15:16:32 GMT

|

Another little job done. As I converted the box to flappy paddles I cut the gear lever down to a stub. However, in the event of an electrical issue it would be difficult to change gear manually, so I needed to make up an emergency handle. This was a simple task of making an adapter to fit the original handle back on the the stub. One more small box ticked.   |

| |

|

|

|

|

|

Feb 16, 2023 14:34:27 GMT

|

|

That should be enough power and you can incinerate the cuttings at the same time :-)

|

| |

|

|

|

|

|

|

|

|

Have you considered droop limiters?

|

| |

|

|

|

|

|

Feb 14, 2023 21:38:27 GMT

|

|

Lawn mowers are fitted with a governor that limits the RPM to around 3600rpm. This is because these engines aren't designed or built to rev much higher, as opposed to similar sized engines in bikes.

If you do a search on YouTube for adjusting lawn mower governors to get maximum rpm you will find loads. Even if you can't find one for your exact engine they are all fairly similar as to how they work.

How do I know? I have one fitted to my gokart and have been trying to find ways to speed it up. You can remove the governor but you risk the engine exploding :-)

Sharp blades make a hell of a difference, but long, wet grass will stop most hand propelled mowers and even ride-ons can struggle.

|

| |

Last Edit: Feb 14, 2023 21:41:06 GMT by nalesutol

|

|

|

|

|

Feb 14, 2023 16:04:32 GMT

|

|

|

| |

Last Edit: Feb 14, 2023 16:05:07 GMT by nalesutol

|

|

|

|

|

Feb 13, 2023 17:52:26 GMT

|

|

|

| |

|

|

|

|

|

Feb 12, 2023 12:30:17 GMT

|

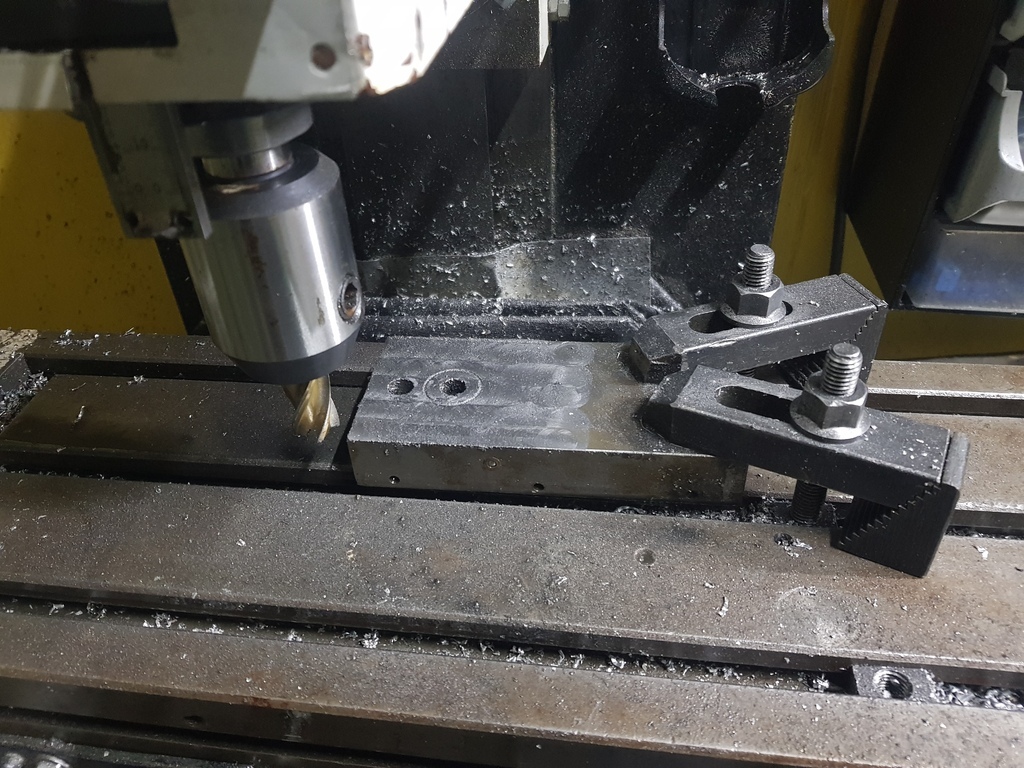

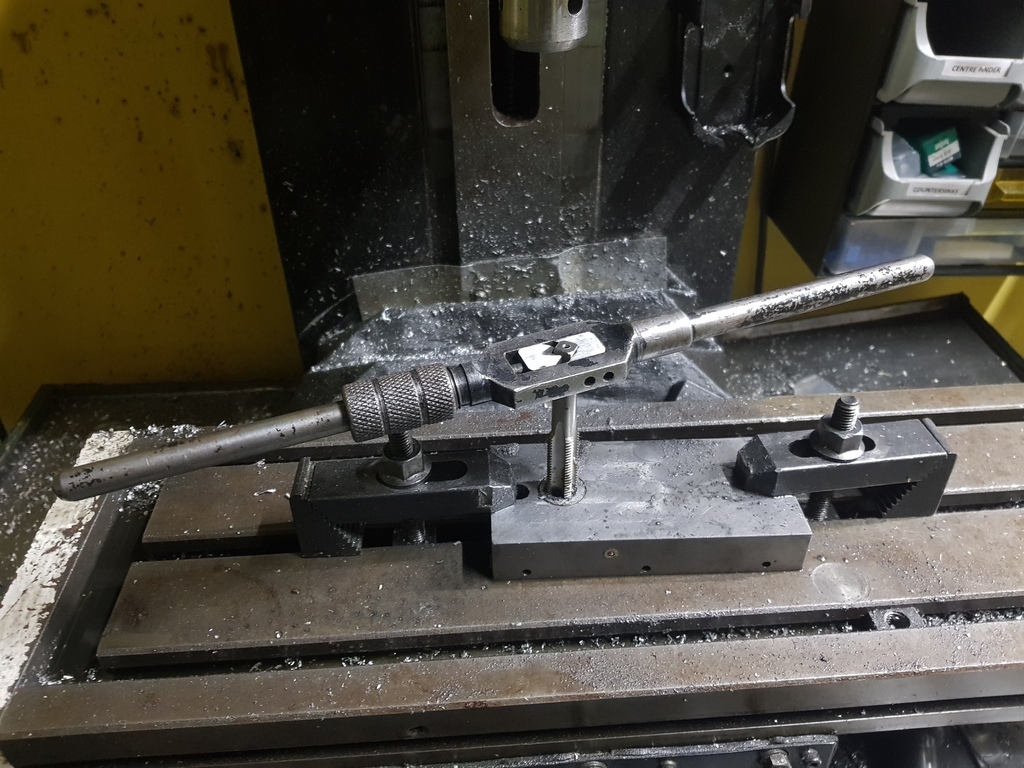

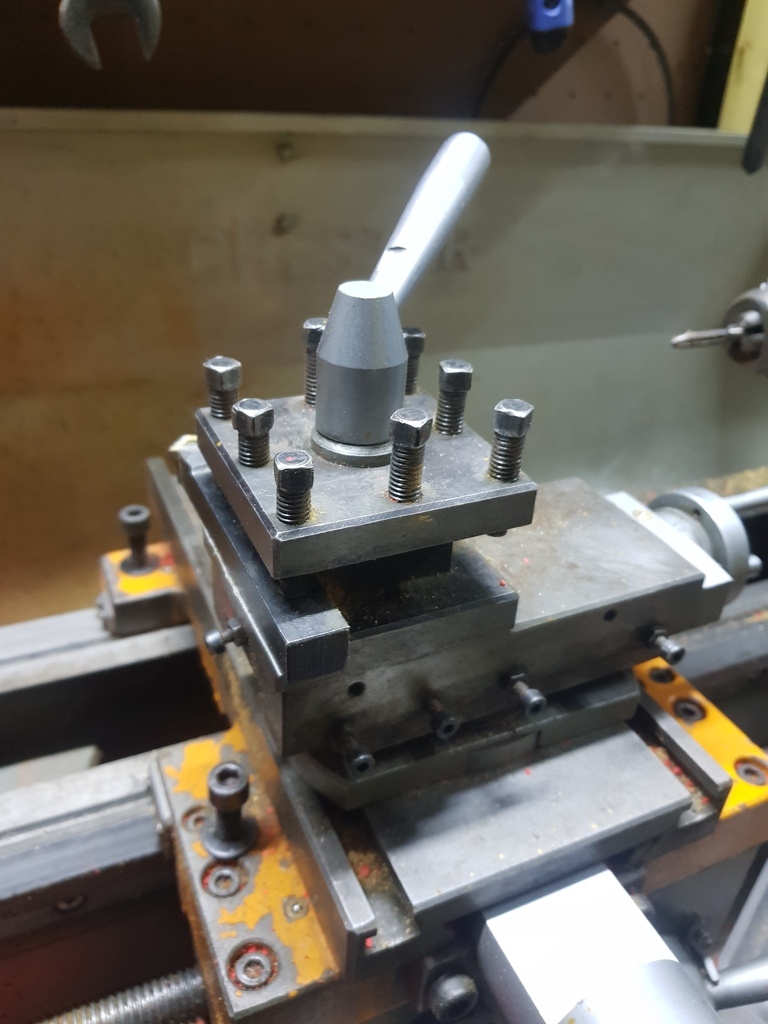

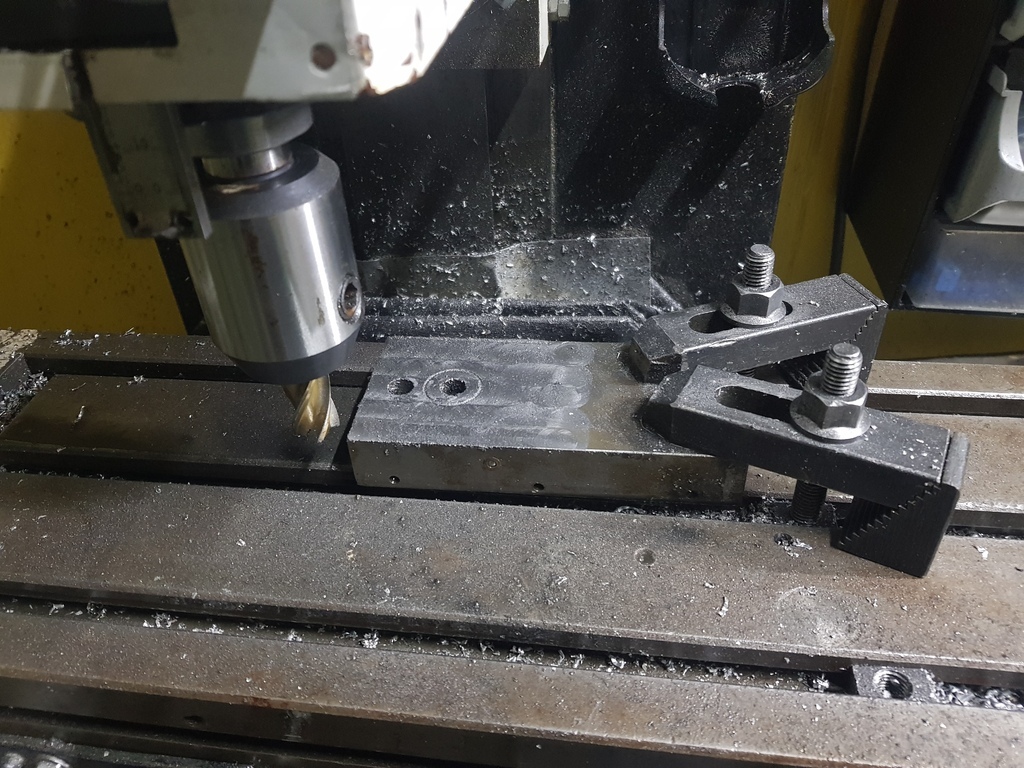

Still treading water, so decided to up upgrade the tool holder on my lathe. It was till fitted with the standard tool holder it came with 12 years ago. Perfectly functional but not conducive to multiple tool changes during a machining project as the tools have to be removed and replaced and the cutting tip height checked and adjusted with shims.  I have wanted a quick change tool holder for a few years but they are not cheap so have put it off until now. Finally bought the tool post with 3 tool holders. However, I knew that it wouldn't be a straight swap (what is?) and some machining would be required as the securing bolt was a different size. Took the top slide off the lathe and set about pushing out the existing post. However, it exploded in the press! Only then did I realise that I was pushing it the wrong way. I thought the the wide shoulder was part of the stud. Duh.  First thoughts were to install a rod in the centre and fill the crater with JB weld. Would have worked, I think, but I needed a lathe to make the centre rod :-) On talking to the company I bought the lathe from, they offered me one removed from a display model for £50. Pretty good deal at time I thought, but when it arrived I was a tad disappointed. It was filthy, missing a couple of the gib screws (can use ones from original) and the locking pin was seized (not required). Nothing serious but I called them, laid it on thick and received a £30 gift voucher which I will use to get another tool holder. Right, down to modifying the new one. Pushed the stud out the right way and cut off the shoulder. On to the mill where I cleaned up the surface and tapped a new M14 thread. Just need to install on the lathe and start playing again.         |

| |

Last Edit: Feb 12, 2023 12:42:43 GMT by nalesutol

|

|