teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 11, 2023 21:24:22 GMT

|

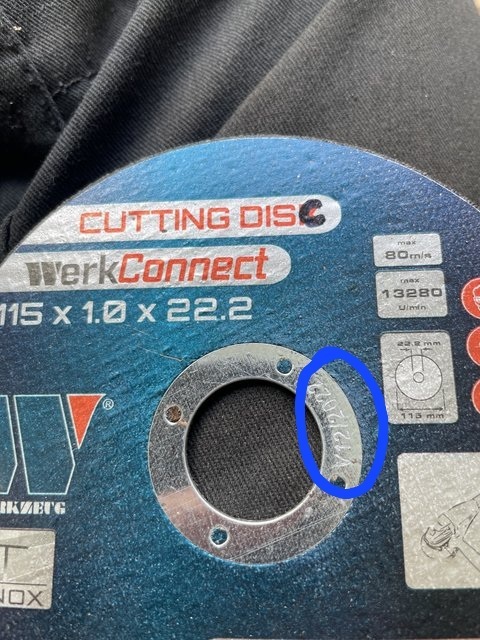

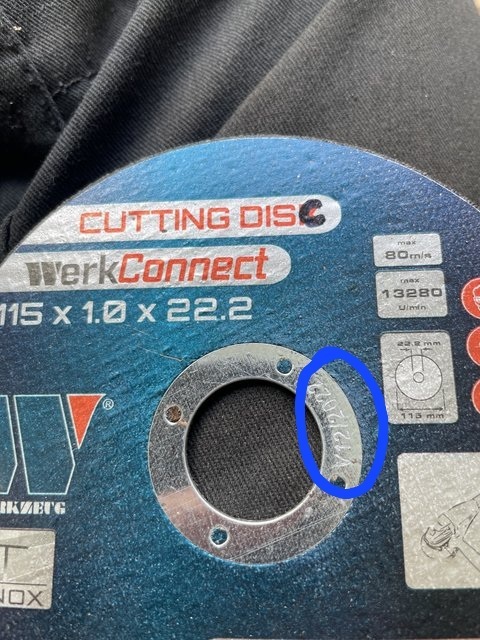

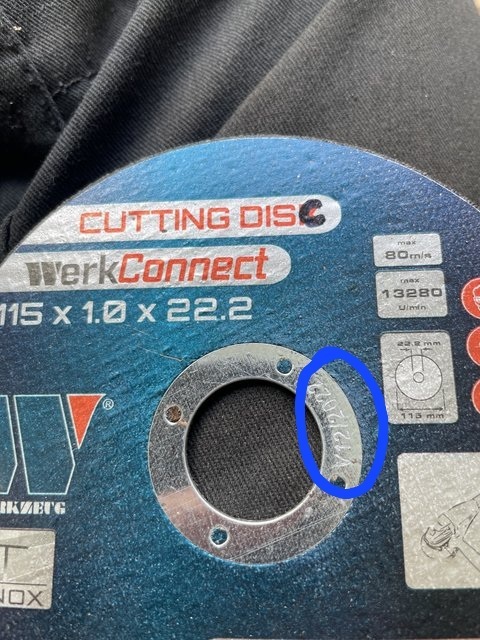

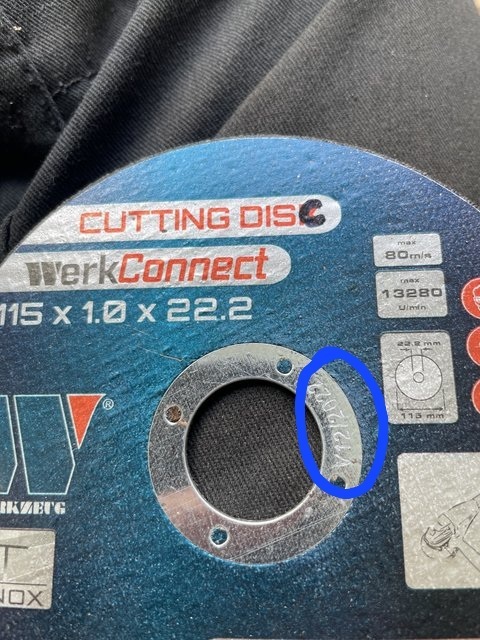

I managed to survive the rigours of Bradford today and I even made it away from the hideousness that is the M62. Buoyed with my good fortune I had another look at getting the arch repair panel in place. First I chopped off the front bit which I don't need.  Well I hope I don't need it... Next I started to bend the top edge over to match the wheel well.  This made it go a bit wrinkly because there is now too much metal there.  A quick run through the shrinker made it a bit less wrinkly.  It still wouldn't fit in though, so I sat and looked at it for a bit and contemplated. That didn't help so I got a cup of tea and contemplated it some more. I couldn't avoid it any longer, I had to get one of these out.  Once I had translated it into English...  I put it to work removing the ridiculous return lip from the inner edge.  It is a terrible design because the arch lip is folded 90* then it is folded a further 90* to create a lovely trough to fill up with mud and rot your arches away. Like this.  I will not be putting it back like that. With the bonus extra lip cut off I tried to offer it up again but it still didn't want to go in. I know I said these repair pieces were part finished panels that get you into the ballpark but that isn't quite right. They get you to the back of a massive queue for the turnstiles to get you into the ballpark which is three streets away. I'm not complaining though, it's still easier than starting with a flat sheet of metal. I couldn't avoid it any longer, I had to cut the old bit out.  I went at it very carefully because it would have ruined my equanimity if I had ended up with a cutting disc complete with a letter 'C' sticking through the outside of the rear wing. Luckily that did not happen.  Would you believe that this had looked to be in really good condition before I removed the textured undercoating from it?  The factory cavity wax hadn't made it to all areas but I suspect the rust is more due to the poor design of the double lip than the lack of wax.  Now I just need to shape the new bit to be a bit more like the old bit, minus the holes, of course.  That is the job for next time. Cheers. |

| |

|

|

|

|

braaap

Posted a lot

Posts: 2,750

|

|

|

|

Once I had translated it into English...  Rather half-heartedly, ey?   |

| |

|

|

|

|

|

|

|

|

I sometimes spell disc with a K as I can never remember which is correct. I could use the excuse that it’s because I’m Welsh and not English. However, this argument falls over on two counts due to the fact that I can’t speak Welsh, and also there is no K in the Welsh alphabet anyway.

|

| |

Last Edit: Aug 12, 2023 6:02:19 GMT by jonsey

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 12, 2023 21:17:20 GMT

|

Once I had translated it into English...  Rather half-heartedly, ey?   Well, now you mention it, I did consider doing all that but the reason I didn't was because the other bits looked to be German and I'm working on a German car. Disk, however, is most definitely American. Now, I don't have any problem at all with Americans 'talking American' because that is what they do. What does make my teeth itch is when people who are not American insist on doing it. It seems to be especially prevalent when said non Americans are talking about cars. I see things like, 'Imma tear down the motor and go ahead and change out the rod bearings'. What he means is, 'I am going to strip the engine and replace the big ends'. I'm not sure why our friends across the pond always have to ' go ahead' before they do anything or why they need to change things out , why can't they just change them?

Still, that is what they do so good luck to them, but if you are an ex-collier from Barnsley and you are talking like that you really need to get a grip on yourself.  Sorry about going off on one, I do like Americans and I can even tolerate people from Barnsley but remember the immortal words of Popeye the Sailor Man, 'I am what I am'. I sometimes spell disc with a K as I can never remember which is correct. I could use the excuse that it’s because I’m Welsh and not English. However, this argument falls over on two counts due to the fact that I can’t speak Welsh, and also there is no K in the Welsh alphabet anyway. No 'K' in Welsh, that's interesting. I wonder if there is anywhere in Wales that manufactures cutting discs?  I had a relatively leisurely morning with the Doc, we had to go into town and to the tip and what have you but we also had breakfast at Ten Acres which was nice. I had to do other things this afternoon, non of which I really wanted to do but that's life. I didn't get into the shed until about half past six and by then most of my energy had been consumed but I wanted to do something at least. This repair panel, which I have said comes as a part finished item is made from two parts and they are just tacked together, which you might be able to see here.  Now that I have to start putting more shape into it I really should complete the join, so that is what I did.  I used the TIG for this but it was really annoying because the high frequency start began to play up so I ended up having to scratch start the arc which then messes up the tungsten and can make the arc wander. I wanted to TIG weld it because it is easier to work with the part because the weld is a lot 'softer' than with the MIG. It will be ok I think because it will be hidden from sight when it is fitted.  That was all I got done because the Doc asked me if I fancied some jelly and ice cream which was too good an offer to refuse. Cheers. |

| |

Last Edit: Aug 12, 2023 21:18:27 GMT by teaboy

|

|

braaap

Posted a lot

Posts: 2,750

|

|

|

|

What went wrong in Your west-indian colonies, that Your language got vandalized that much? One might think that all those melting pot ingredients didn't have a very good opinion towards Your country?  Thanks for another lesson. I just recently learned something about commonwealthian food culture here at RR. And now some language obscurities: no K in welsh and in the more familiar (to me) english language there is even more than just the tyre / tire controversy!  |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 13, 2023 22:21:58 GMT

|

It is good to have a plan and today I knew exactly what I was going to do. The lovely Doctor is heading off 'darn sarf' to see our granddaughter for a few days and then I can get stuck into shaping up my arch repair panel. She is going in her 'dogging car' so I loaded it up with all the glabber she is taking, which is quite a lot. I've fitted the roof box because my daughter wants to borrow it and I even loaded a small chest freezer into the back. I don't know why she is taking that, maybe there are people darn sarf with small chests which are too hot but I didn't ask too many questions about it. She was going to set off after we had been for breakfast at Wolds View cafe. Because the dogging car was stuffed to the gunwales we went in her emergency backup Audi. On the way back from a lovely breakfast I went to open the window and it didn't open but there was a strange twanging noise. Marvelous, I'd better have a look at that. I took the door card off and removed the motor.  So that's the twanging noise then. I had a root through my shed and I just happened to have a spare window regulator.  Doesn't everyone have a spare Audi window regulator in their shed? Fitting it is like the Krypton Factor, I didn't enjoy it at all.  I had the window frame in and out three times before I got it sorted, what a horrible thing it was. When you pull the door card off the clips that hold it on are invariably broken in the process because they are made of the most brittle substance in the known universe. Luckily, in my other shed I had a couple of bags of spares.  It is just as well I had a few because they are that rubbish that they can break just clipping them to the card before you even attempt to fit it to the car.  So that was five hours of my life I'll never get back. After that I had absolutely no enthusiasm left for working on cars so the wheel arch panel will have to wait. I told you it was a good idea to have a plan... Cheers. |

| |

Last Edit: Aug 14, 2023 0:05:32 GMT by teaboy

|

|

braaap

Posted a lot

Posts: 2,750

|

|

|

|

|

I want such a shed, too, that contains and/or delivers needed parts, even on saturday evenings (need to mention that in germany most shops are closed on sundays).

Usually jobs end on that saturday evening.

Or questionable bodging will be involved.

|

| |

|

|

nze12

Part of things

Posts: 193

|

|

Aug 14, 2023 16:25:45 GMT

|

Minis do that too. Always reminds me of the scene from Lady and the Tramp where the 2 dogs are eating spaghetti. |

| |

1986 BMW E30 refreshed to original spec

1973 BMW E12 520 converting to Motorsport 530

1982 XJS V12 converting to 5 speed manual

Many landscaping projects overriding above!

Cogito cogito ergo cogito sum!

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 14, 2023 21:19:57 GMT

|

I've had a look at making the arch repair panel fit tonight. I offered it up into place on the car and it is nowhere near fitting. When I looked at the old piece along its edge (imagine you are laid on the floor under the wheel arch looking directly upwards) it looks like this.  You see the pronounced arc? This is the replacement.  The arc is not there. It is easier to see if I put them together.  I thought that the best way to introduce that curve would be to shrink the return flange.  The problem is, this thing is made from 1.2mm steel which is very difficult to move. It is very tough, trying to panel beat it is like using a toffee hammer on the hull of the Admiral Graf Spee. My shrinker also had very little effect. I decided to trim down the return flange so that there was less metal to move.   Even like that I couldn't shift it so I did something I really don't like to do, I cut slits in the flange.  That has got it a bit closer. Lots of hammer, slapper and even a bit more shrinker and it looks like this.  I know, it doesn't look any different. I decided to leave that part for a bit and try to bring the top edge of the panel over a bit more.  After two hours of hammering my arms and man boobs were aching enough for one night. So this is where we currently stand.  I know earlier I said that this was a part finished panel that gets you into the ballpark but now I think that assessment might have been premature. Now I'm not fully convinced that this part is made for a BMW, let alone an M3... Cheers. |

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

|

Aug 14, 2023 23:50:37 GMT

|

Potentially teaching people to suck eggs, but did you know the cutting discs have a best before date? The glue breaks down and they're more likely to shatter afterwards. Obviously we're blokes and its 'best before' not 'use by' so i wouldn't be too worried, but i learnt a lesson with a haul of discs out of grandad's shed after one let go! Threw the rest away and also stopped purchasing in bulk. Aside from that, sensible decision on the battery tray, and nice progress, even with the infuriating wheel arch repair piece |

| |

|

|

braaap

Posted a lot

Posts: 2,750

|

|

|

|

75swb, thanks a lot for that hint! Every day is a school day as You say.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,882

Club RR Member Number: 39

|

|

|

|

|

I did have concerns about that repair panel when it first showed up - Wondered if that's a bash it over the top of the rust and fill it type repair panel especially with that stitched seam. Stop now and hang it in the shed with the rest of the experiments, get some 0.7 and form it as you would have done if that poor effort never existed. If the other side needs doing, parcel tape and GRP to make a form. Sadly no longer possible on the current work side. I think as soon as I had found out it was 1.2 I would have shipped it back. Then again easy for me to say.

|

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 15, 2023 21:44:17 GMT

|

Potentially teaching people to suck eggs, but did you know the cutting discs have a best before date? No, I didn't know that. I did have concerns about that repair panel when it first showed up - Wondered if that's a bash it over the top of the rust and fill it type repair panel especially with that stitched seam. Stop now and hang it in the shed with the rest of the experiments, get some 0.7 and form it as you would have done if that poor effort never existed. If the other side needs doing, parcel tape and GRP to make a form. Sadly no longer possible on the current work side. I think as soon as I had found out it was 1.2 I would have shipped it back. Then again easy for me to say. I must admit that I'm a bit disappointed. I bought this because I thought it would make this repair quicker and easier but it looks like that won't be the case. It was not a cheap part to buy either which makes it doubly annoying. The sun has been out all day over here today so I took the opportunity to repair my flood defences. My sand bags were starting to fall apart.  I got a message from the couriers saying that my driver, Allan would be delivering my new bags whilst I was at work and there was a link to request having the parcel left in a safe place so I ticked the option for shed/outbuilding. When I got home it was on the doorstep of the coal shed. FFS Allan just open the bleedin door and put it inside you plank! Anyway, I managed to scoop up the split bags and get them into the new ones with minimal spillage.  I had no enthusiasm for that horrible wheel arch panel after wrestling with it last night, I wanted something a bit easier. A while ago I had welded up a grommet hole in the back corner of the boot and when I sanded the welds back there were a couple of pin holes left which I didn't do at the time so I attended to them tonight.  As I had carted the welder down from the shed I thought I should make it worthwhile so I did this other grommet hole in the rear edge of the boot floor.  There was also this one in the front of the 'not really a spare wheel well'.  These are quite small, probably about 20mm-ish.  Because they are only that size I stick the patch in with a bit of masking tape because it is too small to use a magnet.  The one right at the back was awkward to get at so I tacked it from above but had to weld it from underneath.  I really don't like upside down welding. It is not pleasant to do, you are usually in a very uncomfortable position and I find myself looking upwards and trying to see but I end up either looking over my specs or straight at the frame of them so I have to try to twist my neck further than it wants to go. Then there are the sparks dropping on you. I burnt my left boobie tonight... Anyway, all this discomfort enabled this hole to be filled.  That one is the 'not the spare wheel well' one and the black scorching around it is from the masking tape setting on fire when I tacked it in. These are the two at the back of the boot floor, the one on the right is the one that had the pin holes filled.  Inside view is just as thrilling.  As is the inside of the 'not the etc etc'.  That was enough for one night and I was lucky to retire with minimal injuries, just a burnt boobie and blood down my cheek from where I caught a flying wire off the wire wheely thing. Cheers. |

| |

Last Edit: Aug 15, 2023 22:01:23 GMT by teaboy

|

|

|

|

|

|

|

|

“Inside view is just as thrilling”

I quite like seeing all the “thrilling” pics. It’s all these bits that add up.

If you don’t put them in the thread will be about you taking the axle off and putting it back - for no good reason😁.

Nice work as always 👍

|

| |

Last Edit: Aug 16, 2023 7:03:37 GMT by jonsey

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 16, 2023 20:14:44 GMT

|

“Inside view is just as thrilling” I quite like seeing all the “thrilling” pics. It’s all these bits that add up. If you don’t put them in the thread will be about you taking the axle off and putting it back - for no good reason😁. Nice work as always 👍 Cheers Phil. Now when the Doc says to me, 'Who wants to look at that sh**e?' I can say my pal Mr Jones from Wales loves it.  The reason I post all the odd pictures is because that is the type of stuff I like to look at on other people's threads. That explains why I like reading about your stuff. Have you ever had one of those days where it starts off badly and goes downhill from there? It was like that for me today at work and it also made me late home so I didn't have a lot of energy left or time to do very much stuff. So it was just a simple job just to say that I had done something. A while ago I fitted new exhaust mounting studs to the bracket for the driver's side.  Tonight I did the passenger side. There are four on this side, I stuck them into the holes.  They didn't all dangle straight down so I got an old exhaust mount.  Which I cut up.  Then I could bolt that on and use it as a jig.  I could then be reasonably sure that the new exhaust mounts would fit. The ones I fitted on the other side of the car I brazed in and I would have preferred to do that here but it wasn't possible, my hoses don't reach down to the tent and it would be a logistical nightmare to move the gas cylinders closer, so I had to mig them in. From inside the boot they are right up against the side wall.  Another awkward job to get to them. I ended up getting my leg over. That isn't as exciting as it sounds, it just means I had my right knee inside the boot. I couldn't get my head inside the boot with my welding helmet on so I was half in and half out. The torch shroud also obscured my view. I decided it was best just to blob on a fair bit of weld then I could sand it back after.   They seem to be stuck in now.  I know that looks just like the earlier picture but in the earlier one the studs were just dropped through the holes, honest guv. I thought I'd taken a picture of them with the welds ground off but it looks like I didn't I stuck a bit of spooge on there and also on those ex-grommet holes from yesterday.  I didn't spooge the one in the 'not a spare wheel well' because when I was wiping it up I noticed there was a pin hole but I had already put the welder away.  I marked it up to remind me because there is a reasonable probability that I will have to get the welder out again at some point... Cheers. |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

Aug 16, 2023 23:06:59 GMT

|

I showed my wife the video that grizz posted about Fin and I collecting the Canta. Her reaction was an identical "who on earth would watch that?". She was most perturbed when I showed her how many people had watched me trundle around a yard in my lorry, and walked away shaking her head muttering something about "bunch of lunatics..." |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Aug 17, 2023 19:39:31 GMT

|

I showed my wife the video that grizz posted about Fin and I collecting the Canta. Her reaction was an identical "who on earth would watch that?". She was most perturbed when I showed her how many people had watched me trundle around a yard in my lorry, and walked away shaking her head muttering something about "bunch of lunatics..." I’m quite happy that SWMBO thinks all these posts are bonkers… it means she would never be tempted to get involved herself |

| |

Ich habe kein Geld!

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Aug 17, 2023 21:43:31 GMT

|

I showed my wife the video that grizz posted about Fin and I collecting the Canta. Her reaction was an identical "who on earth would watch that?". She was most perturbed when I showed her how many people had watched me trundle around a yard in my lorry, and walked away shaking her head muttering something about "bunch of lunatics..." Just imagine if you had driven it around the yard with your world famous tin hat on, it would have gone viral.  My man Bernard had a job just around the corner from the zinc platers on Monday so I got him to collect my stuff for me. I met up with him today to get it from him.  Yay shiny stuff! Except what is this...  Oh bum, they haven't done it all.  I got in touch with them, (I don't use the term 'reached out' because it sounds too much like 'reach around' and makes me feel queasy) and they said I should drop them in when I can. Do you remember that I had a replacement for this pipey thing that goes near the fuel filler and I was hoping it would turn out nicer than the original?  Well it turned out like this.  I'll have to play the waiting game again with that. They did do that exhaust mounty thing that I repaired.  That became the job for tonight, to fix it to the new battery box. First thing was a bit of weld through primer.  The box too, after a bit of a rub down with some scotchbrite.  Note the old battery box above it with the dimensions written on it. I set it in place to my measurements.  Then marked where it fitted.  This was so I could clean off the weld through primer because it just isn't.  The ones at the top of the picture were a bit awkward to get the torch in to but it would have been much worse if I had left it until the battery box was fitted to the car.  You can see on this picture how the vertical part of the panel obscures the four welds on the other side of the bracket.  Once it was done it got a bit of temporary spooge to stop it rusting.  Some of The bits that were zinc plated were the bolts for the trailing arm brackets, so I stuck them on to have a look at sizing up my next bit of the boxy thing.   But it was too late in the evening to get anything done on that. Maybe next time. Cheers. |

| |

Last Edit: Aug 17, 2023 21:56:43 GMT by teaboy

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

|

|

|

How frustrating.

You have to wonder how anyone could “miss” stuff like that.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

braaap

Posted a lot

Posts: 2,750

|

|

Aug 18, 2023 19:25:30 GMT

|

did you know the cutting discs have a best before date? Since I have only learned this recently, I looked at a 10+1 set (10 cutting, 1 grinding disc) I have in my garage. Expired 2019, damned. So I thought I could use a few of them on cutting down an old brake drum for some project. But damned again, I didn't even use one of them completely! But I was lucky, it did not explode.  |

| |

|

|