goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

Thanks everyone. 🙂 I did manage to get my first few spare minutes to work on the car today. If I can just keep finding half an hour here and there to keep chipping away rather than letting the project completely stall, then that will make me feel a lot better about it. I started by finishing up cleaning up the welds that I did back in December before the girls arrived. Then I welded in the spring cup and bump stop, both of which I’d prepared in the previous session. Nice quick wins.  After that I started making a panel to fill the gap in the front edge of the arch, which meant starting from scratch with card templates, then cutting out a steel patch, shaping it and drilling for plug welds, so not quite as quick progress. As you can see I didn’t get it all welded in before I ran out of time. Its a bit of a bigger patch than the other side, so needs a bit of compound curve to it, which with my basic metal working tools is generally less tidy than the more simple patches. Once it’s all in it will do the job just the same.  You can also see that I ran out of grey primer! So rather than leave it exposed I used a bit of red I had left over, which spoils the nice consistent look underneath! Still it’s only primer and will obviously be covered at some stage. I shall buy more grey before my next session! |

| |

|

|

|

|

|

|

|

Jan 12, 2022 11:04:53 GMT

|

|

Looking good, I found that was the way to make progress when the kids were younger, break it down into small tasks and grab whatever opportunity presents it's self in the domestic / work life to knock them off the list.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Jan 15, 2022 22:06:06 GMT

|

Yes that’s pretty much the plan kevins! With that in mind, I’ve managed a couple of hours over the past week, and have been chipping away on these underfloor repairs. I started by finishing off welding the patch at the front of the wheel arch from last time, which was closely followed by cutting out a pretty agricultural patch that had been previously done to the rear of the arch and making up a replacement.  This was fairly straight forward to weld in and with a fresh application of grey primer things were once again looking tidy!  The last section to deal with on the underside (for now…) is the jacking point. When the floors were replaced they were cut round the original jacking point, and as such it’s not really attached to anything strong. I removed it and the rusty remains of the old floor.  I should point out, at this stage I’m ignoring the state of the inner and outer sills, and the closing panel that joins them to the inner arch. That I will tackle at a later date, coming at it from the side rather than from below, when the car is back the right way up. Finally I made up a little repair piece to fill the gap and to give the jacking point something to mount to. The original jacking point was ok on this side so I’ve just given it a quick clean up.  And thats where I ran out of time for this week. From here it should be fairly straight forward to weld in those repairs to the jacking point and then I’ll be ready to roll the car back over so it’s right way up! After a bit of finishing work on the floors from inside the car, the next chapter of the repairs can then start, with the major work on the rear quarters & wheel arches. Thankfully for that I’ve bought panels, so I don’t have to try and create any of those complex shapes myself! |

| |

Last Edit: Jan 15, 2022 22:11:52 GMT by goldnrust

|

|

|

|

|

Jan 17, 2022 21:16:28 GMT

|

|

Congratulations to the baby girls.

Nice thread to follow just like the Daimler.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Jan 30, 2022 20:37:33 GMT

|

I had a couple of hours on the car this weekend, and made a small bit of progress, but it does feel like a mini milestone. I started by welding in the jacking point repairs that I prepared last time.  Which means that the underfloor welding is done for now! So after a bit of a pause to a tidy up, I could flip the car back the right way up.  It was really nice to see it back the right way up, reminds me I’m working on a car, not just a chunk of metal.  I probably should have spent the rest of my time inside the car tidying up various bits and bobs on the floor I couldn’t get at while the car was on its side, but I’m impatient and so wanted to start on the first of the arches…  What a lovely mess there was to greet me under the shiny paint. I got the outer arch cut off and have started drilling the spot welds for the inner arch. Sorting the arch itself shouldn’t be toooo bad, as I have the repair panels, but the structure behind the rear edge of the sill is a bit more complex. It’s not helped by the previous ‘repairs’.. I think I’ll need to put some bracing in to help keep things strong so I can cut out the back of the sill area. I’m also thinking I should put the door back on so I can make sure the door aperture doesn’t shift while I'm working on the sills. |

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

|

|

|

|

Such a shame as the paint looked great, love the colour. Congrats on finishing the floor.

I would put the door on and check the aperture, perhaps some wedges/spacers to maintain a constant gap. I can't imagine the 500's are that rigid a structure with sills removed.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

Yeah, the paint did look pretty good. It was a shame, as it was a classic ‘poor repairs with nice paint over the top’. It wasn’t even the usual over fillered job where he body lines get a bit soft! As you’ll see as this progresses though, there’s not going to be much of that paint job that’s staying, as both rear corners need substantial repairs and most of the front will be cut off and replaced. I had a decent chunk of time of the car yesterday, and made some good progress. Picking up where we left off, I’d decided I needed to get the door back on and brace up the shell… As I was refitting the door, I remembered that the drivers door had hung a bit low when I bought the car. I presumed it would be wear in the hinges or just a case of adjusting or shimming the hinges, as it is on my Daimler. But when I put it back on I found that the was no play in the hinges and very minimal adjustability. I tried shimming the lower hinge to bring up the door, but this brought the back edge of the door too far over and it rubbed the frame. After a bit of head scratching, I decided that the most likely cause was that the previous person who repaired this car didn’t bother to check the door alignment / brace the shell, and so the door frame itself had shifted when the floors or sills were done. So to try and rest this idea I applied a bit of pressure, nothing drastic, with a bottle jack and a bit of wood at various angles and places, to see if It improved the door alignment.  With the jack pushing the bottom edge of the sill out, the door came right back into alignment and latched very nicely. Nice even shut lines all the way round, or certainly nice enough for me!  So that was good news to have found the issue, and realistically it was only a very minor adjustment. I could now add some bracing to hold the car in the right position while I rebuild the rear quarter and sill to the correct shape.  Confident that the car wasn’t going to fold in half when I start chopping away the rust and previous ‘repairs’, I broke out the angle grinder and got busy.  Soon after I had a slightly daunting looking pile of rusty bits on the floor and a car with some big holes in it! But it’s always a nice feeling to know I’ve got to the bottom of the rust and can start to rebuild now. Lastly for this week I spent a few minutes offering up the new inner arch and trying to line it up so it will meet up with the outer arch repair section.  As you can see I also started on the first of many small card templates needed to fill in the areas I haven’t bought repair panels for. So a good chunk of progress there, feels like quite a step forward.  |

| |

Last Edit: Feb 5, 2022 8:55:29 GMT by goldnrust

|

|

|

|

|

|

|

|

Your doing well to get time on it, especially with twins :-) Good man!

|

| |

|

|

|

|

|

|

|

|

Nice job. One trick is to tack weld the doors to the rear quarters during repairs.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Feb 20, 2022 10:20:57 GMT

|

It’s a good tip blackpopracing.  I managed another session on the Fiat yesterday. I made good progress, but didn’t stop to document much of it and I was just pushing on making the most of the time I had. I started by filling in a couple of small patches needed to the lower edge of the rear inner arches and by Tuning the cardboard template for the outer edge of the rear seat base/inner sill into steel. Once that was done I could fit the rear inner arch. I spent some time offering up both the inner and outer arch sections, clamping both in place and making adjustments till I was happy with how things line up. Once I was happy with the alignment I marked the positions and then prepped the arch for welding by cleaning off the paint along the flanges, drilling for plug welds and then recovering it with weld through primer. Finally I could weld it in. The penultimate piece of inner structure to go back into this corner was the closing panel/middle sill. While repair panels are available, it’s a fairly simple piece, so I made my own up. This all got welded into place tying lots of the other elements of the sill together.  I said that was the penultimate price of inner structure, I have also got to add the ‘lifting support bracket’ behind that middle sill, but I might wait till after I’ve got the outer wheel arch on first. Access won’t really be any different, and this way I’ve got a bit more flex in the bottom of the inner arch to help it line up with the outer arch. Speaking of which, my last job was to offer that up again and start clamping it in place to work out where I’m going to need to trim it back to to fit it.  The pressing for the bottom edge of the door frame is nowhere near where mine is, but it lines up nicely on the inner arch, jacking point and rear seam. So I don’t know if it’s just an issue with the repair panel (the one I have for the other side of the car is the same, or if there’s some weirdness with my car. Possibly with the car being an early 8 bolt F the door frames are different? I don’t know if D sills are a slightly different profile? |

| |

|

|

|

|

dikkehemaworst

Club Retro Rides Member

Posts: 1,636

Club RR Member Number: 16

|

|

|

|

|

"The pressing for the bottom edge of the door frame is nowhere near where mine is, but it lines up nicely on the inner arch, jacking point and rear seam"

it's the old tooling they make the pressings with. They just don't care. It's a whole different discussion , but i rather pay good money for good pressings than less for curse word ones.

it's all about price these days , not quality. really bothers me.

I saved up all NOS panels over the last 25 years if i found them on the bay of e ,and i have a good selection at home now, so i can buy , build and restore my dream version ( Giannini ) or a Steyr Puch.

Just have to buy some time on ebay......

Have you already checked the A pillars were the doors hang?

Terrible rustspot and not available as a repairpannel....

epic build and slightly jealous of your build!

keep up te good work!

bookmarked.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Feb 21, 2022 10:20:16 GMT

|

Thanks dikkehemaworst  I'm aware that the replacement panels aren't meant to be great, but I was expecting the usual soft creases/body lines and poorly trimmed edges with some ripples where the metal has pulled and stretched in the press. I wasn't expecting key features to be inches out of place! I will be reusing my old door frame corner anyway, I had only cut it out for access to the middle sill, I just didn't wan to think I'd got the wrong panel! I've not delved into the front much yet at all really, but I do know I will but cutting most of it off and starting over! The hinge plate area of the A pillar looks good, but obviously I can't see what the area hidden by the wing looks like. If its hidden I can definitely make my own repair sections for it  To be honest it's been a luxury having any repair panels to work with, as most of the cars I've welded up have either had zero panel availability or they are prohibitably expensive. For example a front wing is available for my Daimler, but it's hand beaten and £500+, same went for the Lancia. £50 for a Fiat front wing... |

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Feb 28, 2022 23:18:46 GMT

|

Time for anther welding progress update. It doesn’t necessarily look much further along that last time, but it’s been a surprisingly large amount of work/time. The last piece to go on before the outer arch was to refit the door frame corner that I had removed in order to get at the middle sill strengthener. It needed several small repairs and then aligning with the door to maker sure the shut lines were ok.  Not very visually impressive, but it needed doing and it needed some care and attention. Much more impressive was finally fitting up the outer arch repair section.  It’s easy to underestimate just how much time and work there is in aligning a repair section like this, and working out how it needs tweaking to fit the car right. But it’s nice to see the hard work pay off when it’s tacked in place finally and things are lining up nicely. Obviously the next stage was to slowly but surely work my way through welding it in and cleaning the welds down.  As you can see, night was falling by the time I’d finished that task! It’s not perfect, but with a bit of hammer and dolly work, a thin skim of filler (and I mean thin, 1-2mm not the bucket load I’ve chipped off many cars) and some paint you’ll never know it’s there. I’ve just got two more repairs to make on this rear quarter, to replace the closing panel that fits underneath the car behind the wheel arch and to weld in the lifting point repair section that goes behind the back edge of the sill. So hopefully get those two done in my next session out there  |

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

|

|

|

|

That looks fabulous. Must be a real morale booster getting the visual step forward with the arches.

|

| |

|

|

|

|

|

|

|

|

Classy work as usual 🙂

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

|

Thanks guys, yes it's nice to see at least one solid corner of the car! Just 3 more to go! haha

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

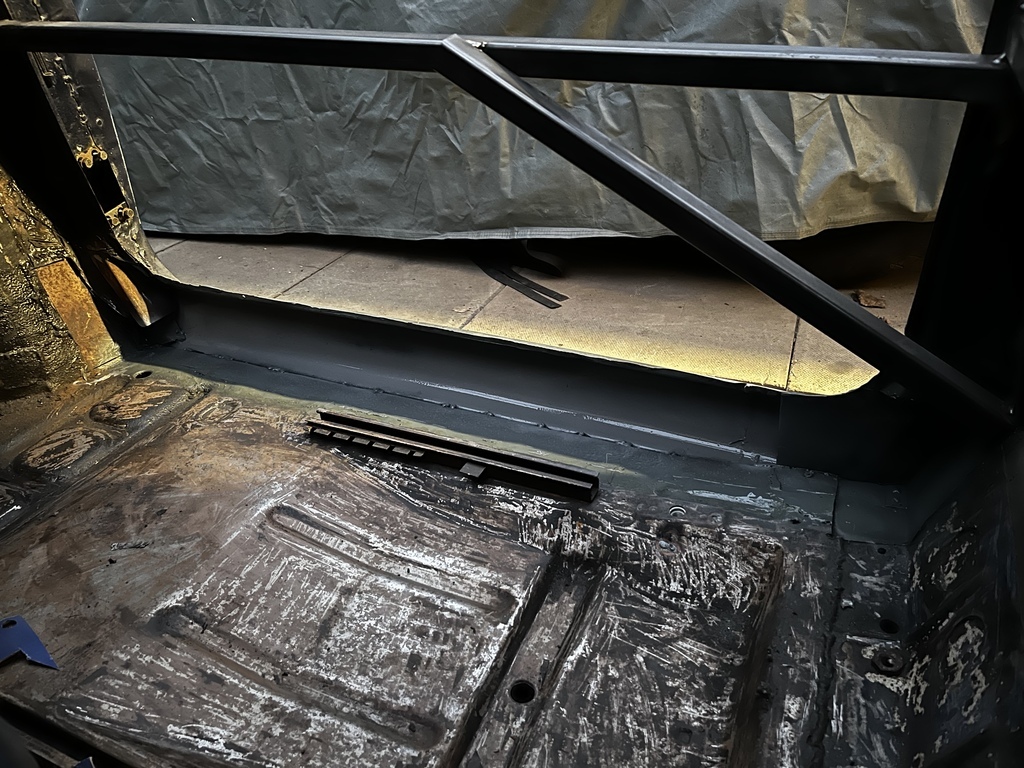

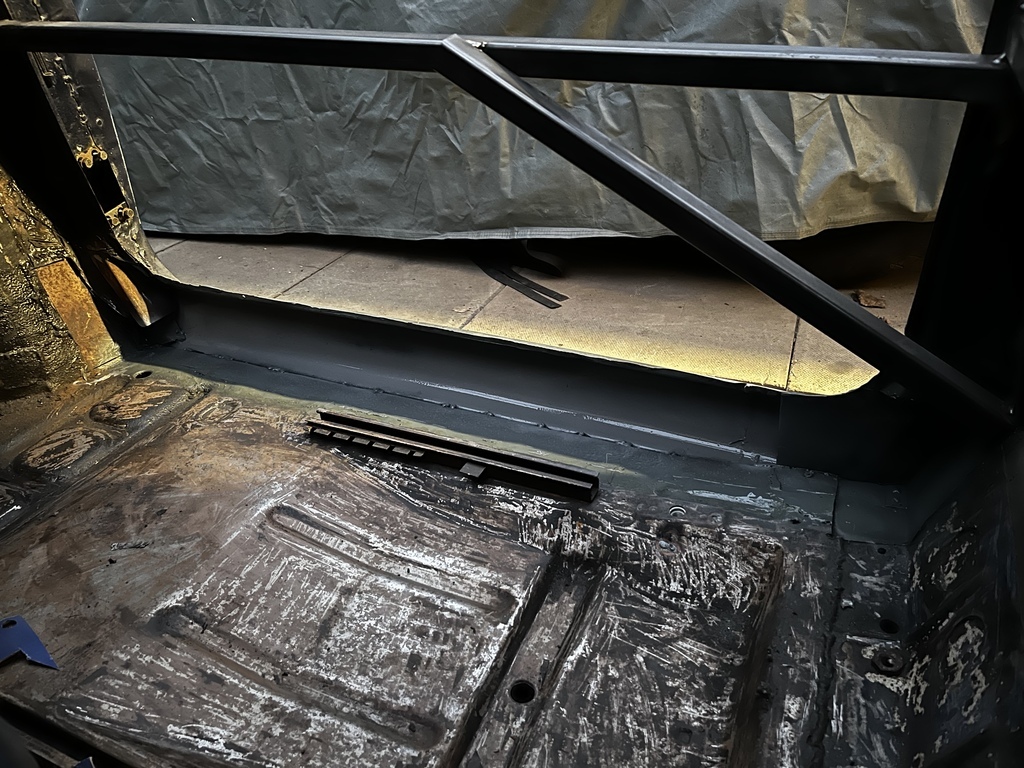

This week, I once again managed a couple of hours on Saturday afternoon working on the car.  As mentioned in the last update, I had two small jobs to finish off on the drivers rear quarter. Firstly I needed to weld in the lifting support bracket, behind the end of the sill. I had bought repair panels for this, so it was pretty straight forward, and can be seen now taking the weight of the car.  The second job was to make a closing panel for the gap between the rear of the wheel arch and the engine bay. On this point I failed, as I had underestimated how much sheet steel I had left. But I did get a card template made, and will order some more steel on Monday.  As this was my one chance to work on the car for the week, I wasn’t going to let the lack of steel stop me in my tracks there, I had plenty of grinding discs so I knew I could start cutting out the next area of concern! That next problem area is the sill. The outer sills have been replaced, and poorly welded in, but the inner sills have been extensively patched, it’s ugly and it’s been done in a way that retains very little strength, so it had to go. Before I could start chopping the inner sill out, I thought it best to fix the outer sill more securely to the floor pan. A nice line of fresh plug welds along the lower seam should do the job much better than the odd tack along the bottom edge that I had originally found.  Now the real challenge could begin of unpicking the patches and removing the remains of the old inner sill, without cutting into either the floor pan or the outer sill. Removing the inner sill revealed a bunch of rust flakes and crud, but thankfully no more hidden surprises. There were a few more tack welds holding the outer sill in hidden inside here, but I still think it was worth the time to plug weld it properly. After a quick clean up and splash of primer then it didn’t seem so bad.  Lastly for today, I was able to offer up the replacement inner sill. It looks promising to me, and shouldn’t need too much work to get it fitting on there nicely.  So a good couple of hours of progress, and hopefully next time I’m out there I can wrap up both of these little jobs  |

| |

Last Edit: Mar 5, 2022 22:31:30 GMT by goldnrust

|

|

|

|

|

|

|

"The pressing for the bottom edge of the door frame is nowhere near where mine is, but it lines up nicely on the inner arch, jacking point and rear seam" it's the old tooling they make the pressings with. They just don't care. It's a whole different discussion , but i rather pay good money for good pressings than less for curse word ones. it's all about price these days , not quality. really bothers me. I saved up all NOS panels over the last 25 years if i found them on the bay of e ,and i have a good selection at home now, so i can buy , build and restore my dream version ( Giannini ) or a Steyr Puch. Just have to buy some time on ebay...... Have you already checked the A pillars were the doors hang? Terrible rustspot and not available as a repairpannel.... epic build and slightly jealous of your build! keep up te good work! bookmarked. Its not necessarily about price in the way that you are suggesting, as the tooling wears the panels become less accurate but the cost of a new press tool for the relativly small volume isn't cost effective.

I don't know how much this panel costs but if it was 10 times the price to cover the cost of a new press tool for a small volume part, would that be something people would pay rather than make adjustments to what is currently available? Personally I don't believe it is.

The cost of new tooling is the reason that quite a few panels are made by hand now rather than re pressed (think Jaguar MK2 and Frogeye Sprite wings for example).

|

| |

|

|

|

|

|

|

|

|

Cost of press tools are 50K upwards per set in cast.

They have to make from draw(roughly form panel), bend, re-strike, cut and pierce. Bigger the panel, bigger the tool.

So for small production, they may make resin tools but they can only make 100 panels at most and cost £££, still.

I think you are doing great work, making what available to adjust and fit.

I'm rebuilding 70's mini with BMC panel(expensive but good) is time consuming enough.

Keep up the good work and work away when you can. I have been there with 3 kids, took me over 15 years to get my mini where I was happy enough body wise.

I have started another project mini and this one is more work than I hoped. new floor panel, inner wings, boot floor, heel board, toe board, front panel, front bulkhead.... list goes on!

Good luck and enjoy, when you finish..... you can park your car and look back and think that I made this bad boy!

|

| |

Building roof chopped, screen raked '68 Mini with G13B 1.3 16v Gti engine with LSD, Yamaha R1 carbs. As well as mk1 Suzuki Swift Gti AWD with a turbo.

Drives PHEV Outlander but wishing my mk1 Swift Gti or mk2 CRX Vt were still with me!

|

|

|

|

|

|

|

|

How have I not seen this. Bit of reading to catch up on. Always had a soft spot for them too!

|

| |

|

|

|

|