|

|

|

Oct 26, 2021 15:13:33 GMT

|

Question? Are you adding in bolt in facility or keeping it? - just wondering why you wouldn't just weld in the cage? if ita ever to be usee in competition he cage must be fixed in the manner it was designed, otherwise its original certificate is invalid and the cage will be looked at as a custom item, which will be assesed using latest regulations. unlikely it would pass, but an old cage qith a suitable cert is fine, unless specifically banned |

| |

|

|

|

|

scdan4

Part of things

Posts: 39

|

|

Oct 26, 2021 19:01:44 GMT

|

Question? Are you adding in bolt in facility or keeping it? - just wondering why you wouldn't just weld in the cage? Cage will be bolt in / removable when done. It's just a case of working with what's there and trying to make it right really rather than a masterplan. Welded front on a bolt on back looks a bit gash imo. I'm aware that it's not the fastest or easiest way, but I'm learning, it keeps me out of trouble and there's no rush. |

| |

|

|

scdan4

Part of things

Posts: 39

|

|

Oct 26, 2021 19:03:42 GMT

|

great progress so far, you are doing the 205 proud Thanks, just chipping away at it. |

| |

|

|

scdan4

Part of things

Posts: 39

|

|

Oct 26, 2021 19:06:26 GMT

|

Question? Are you adding in bolt in facility or keeping it? - just wondering why you wouldn't just weld in the cage? if ita ever to be usee in competition he cage must be fixed in the manner it was designed, otherwise its original certificate is invalid and the cage will be looked at as a custom item, which will be assesed using latest regulations. unlikely it would pass, but an old cage qith a suitable cert is fine, unless specifically banned Absolutely no plans to go near competition, but do plan to use it on track so am keen to get it in as properly /sturdily as possible, just in case. That's why I've hopefully overengineered the bolt bases. |

| |

|

|

|

|

|

Oct 26, 2021 21:17:48 GMT

|

|

Loving the build.

You may find that the shell will twist around the bolt in cage if it isn't a good fit. My friends 205 did the same thing back in the day.

|

| |

|

|

|

|

|

Oct 26, 2021 22:39:53 GMT

|

|

I did not find that to be the case with my safety devices bolt in cage. A not very scientific test of jacking the car up awkwardly from one corner and seeing if the doors actually still shut. (they didnt before the cage was fitted, but did perfectly afterwards)

Edit, on a side note I currently have an OMP cage which has the exact same sleeve tube and cross bolt setup for the join between rear roll hoop and A pillar bars. If that gives any credence to the identity of yours

|

| |

Last Edit: Oct 26, 2021 22:47:39 GMT by darrenh

|

|

|

|

|

Oct 28, 2021 11:34:15 GMT

|

|

Are you planning to race this car?

I hate to say it after you've welded them in, but the regs require the entire mounting foot to be min 3mm steel.. You'll have some trouble with that 1.5mm if you ever decide to compete with it.

EDIT: Didn't realise there was another page of replies! It's up to you, but I would recommend re-doing the feet out of 3mm while it's not too late.

|

| |

|

|

|

|

|

Oct 28, 2021 17:02:02 GMT

|

Are you planning to race this car? I hate to say it after you've welded them in, but the regs require the entire mounting foot to be min 3mm steel.. You'll have some trouble with that 1.5mm if you ever decide to compete with it. EDIT: Didn't realise there was another page of replies! It's up to you, but I would recommend re-doing the feet out of 3mm while it's not too late. Can you crack on with an update your 205 gti project please? Looking forward to some more news from that one! |

| |

|

|

scdan4

Part of things

Posts: 39

|

|

Oct 29, 2021 14:38:40 GMT

|

Are you planning to race this car? I hate to say it after you've welded them in, but the regs require the entire mounting foot to be min 3mm steel.. You'll have some trouble with that 1.5mm if you ever decide to compete with it. EDIT: Didn't realise there was another page of replies! It's up to you, but I would recommend re-doing the feet out of 3mm while it's not too late. I've no plans on competing in it, it's purely for fun. Were I to change my mind then it would relatively easy to overplate the existing in 3mm now it's all a flat, accessible, strong base to work from. There'd be a host of other stuff too no doubt as seats etc would need to be in date, stuff needs lockwired, all sorts of aggro down that route imo. Pragmatically, considering it's all attached to about 0.8mm Peugeot steel its more than strong enough for me to feel safe blatting around a few tracks in it. And yesterday the kindly neighbour used his big boys welder to put the feet on the roll cage properly for me  So when I escaped work nice and early I popped that into the car and bolted it down (with cheap cheese bolts that wont be staying)  And it still fits and it fits really nicely now in my opinion. I've got the tube for the door bars, but seems little point cutting them yet as it really will just be in the way  Pleased with that. I'm quite tall and want to be able to see past it. Next logical step is to do the cross bracing which would finish off the cage stage completely, but I want to know where / how the seat rails need to be so it all looks nice. I can't find any seats. I want pair of lightweight, preferably carbon just out of date race seats which although a bit 'moon on a stick-ey' would normally be achievable if you wandered round the paddock and called 'dibs' but as no one has been racing there's a complete dearth of any quality seats available. Soon, there will be a glut and if 2022 race seasons are all greenlighted hopefully that will be in the spring. So no seats mean the next job is engine out. Unpicked the wiring harness which is just an unspeakable mess, but still spent the time labelling what was what even though it's surely destined for the bin. Took the throttle bodies off and had a good look  Closer, poor focus, sorry   and it looks good to me. Very good in fact. No signs of corrosion anywhere, including the open pair. No sign of dirt of carbon anywhere either. And are those bronze(?) valve guides normal? Ditto the complete lack of flashing or casting steps. And I'm not sure if you can see it in the curse word photo but I think that the valve seats look remachined, or at least the head behind them does. This bodes well. |

| |

|

|

|

|

|

Oct 29, 2021 17:54:27 GMT

|

|

They are probably 3 angle seats as standard so that is what you might see. Regarding the seats, some have had a 3 year extension on expiration but I’m not sure from what date the extension kicks in.

|

| |

|

|

|

|

|

|

|

Oct 31, 2021 11:09:35 GMT

|

|

That engine looks in lovely condition. Bronze valve guides are standard I think?

|

| |

|

|

scdan4

Part of things

Posts: 39

|

|

|

|

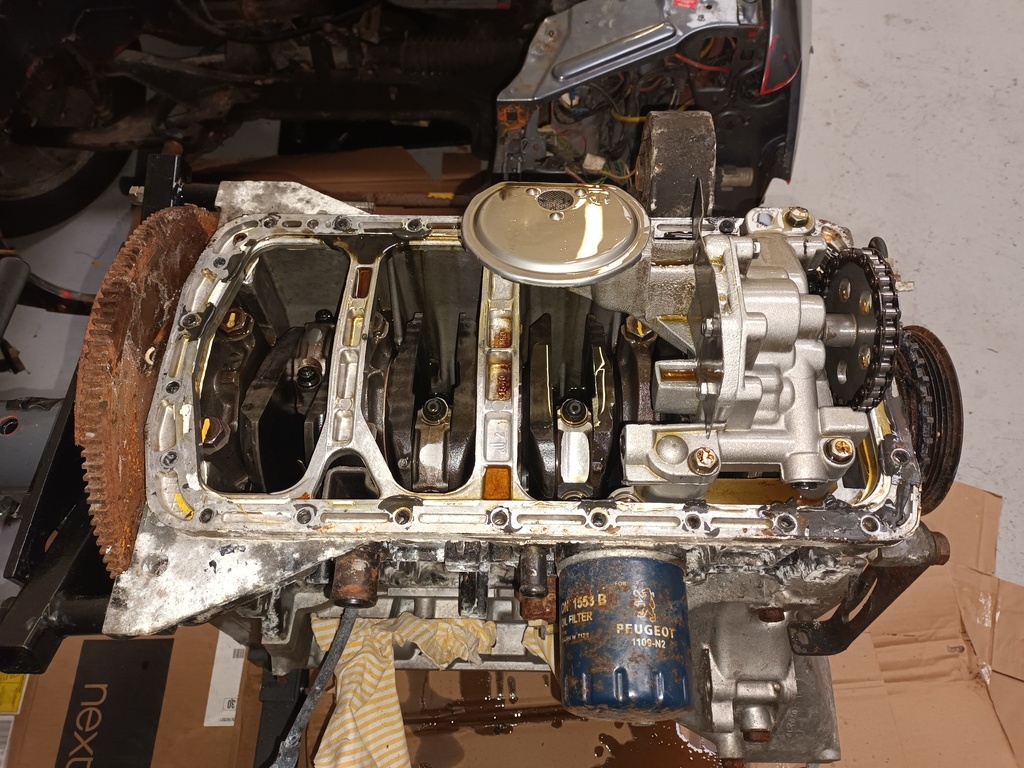

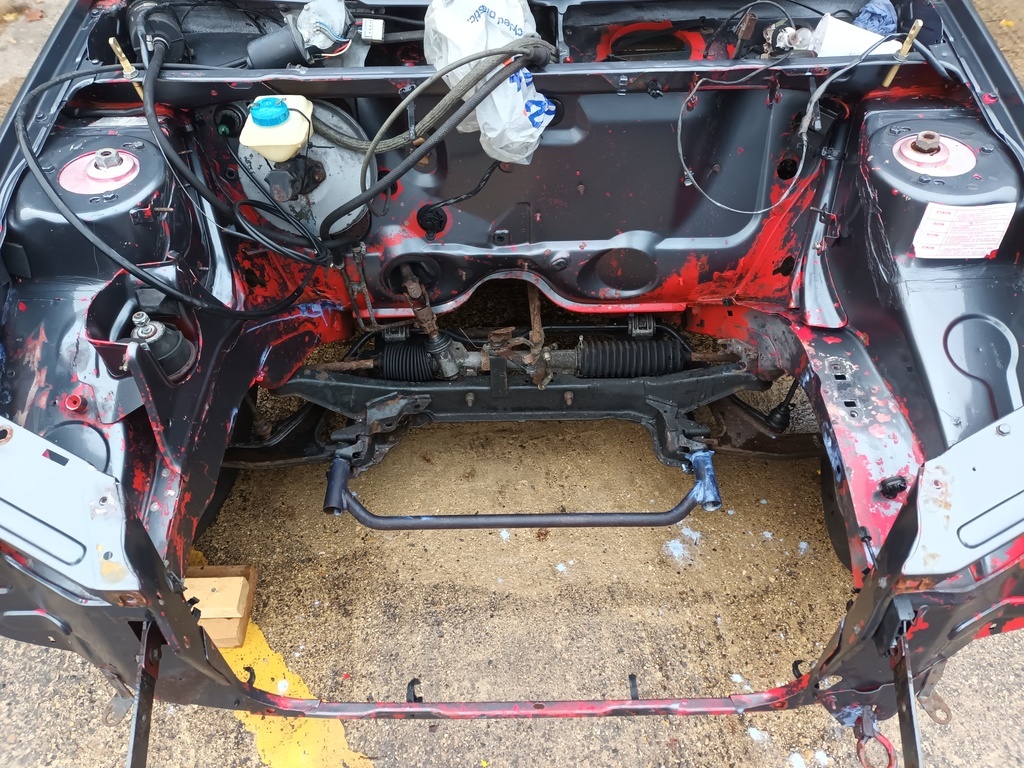

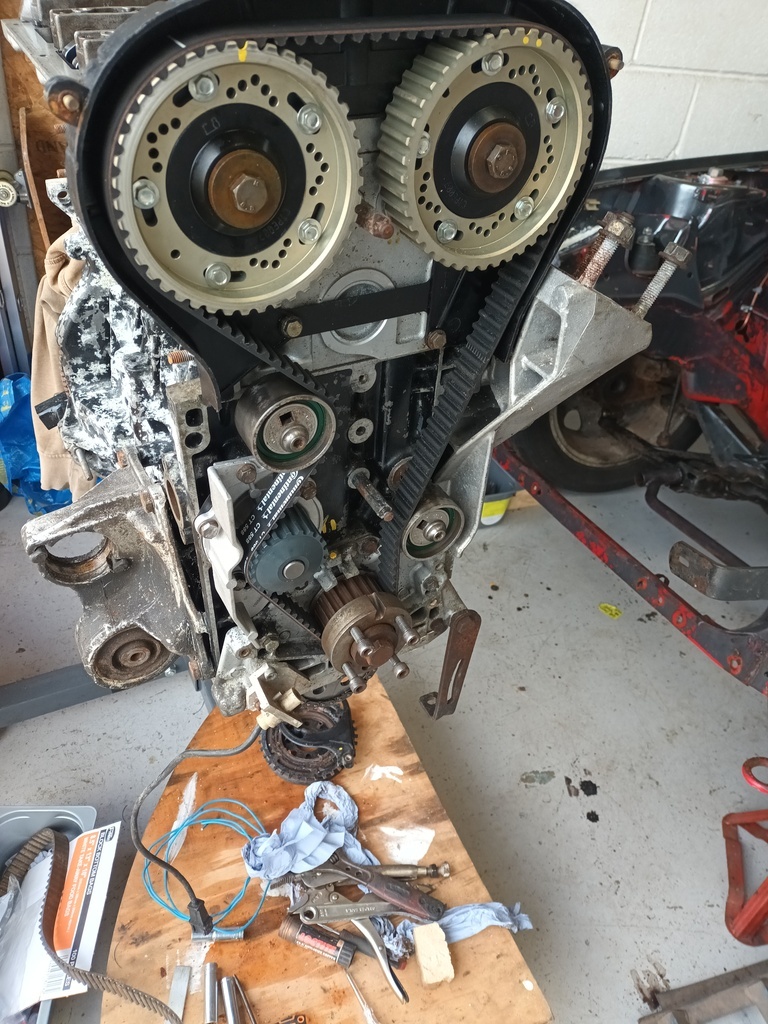

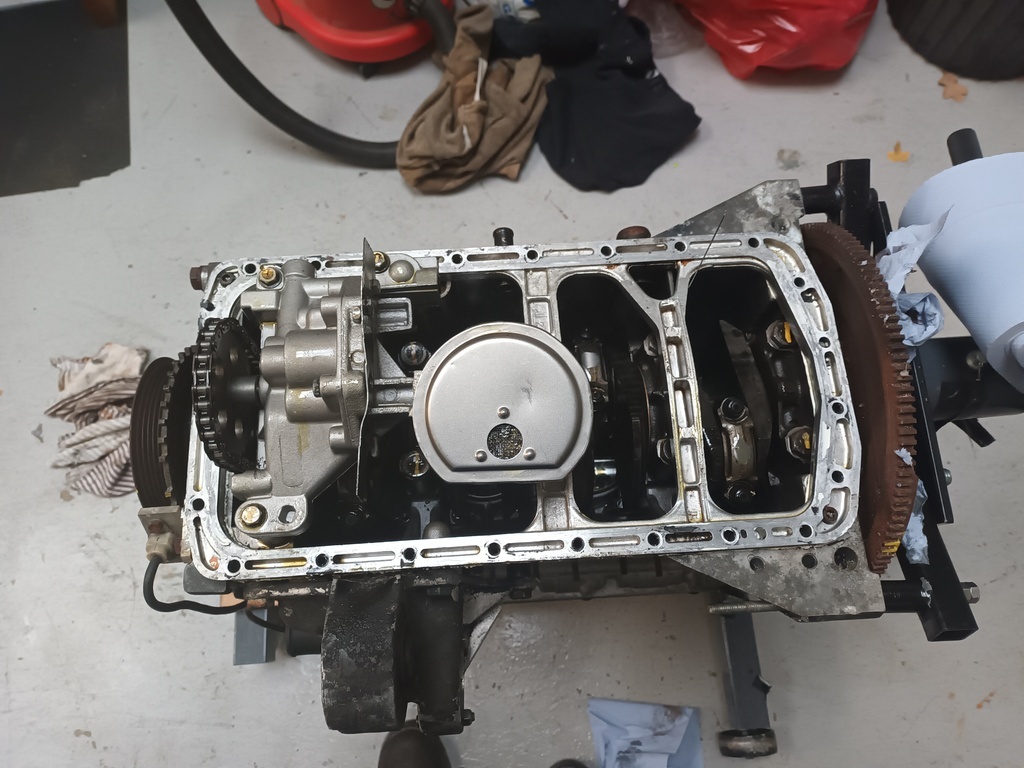

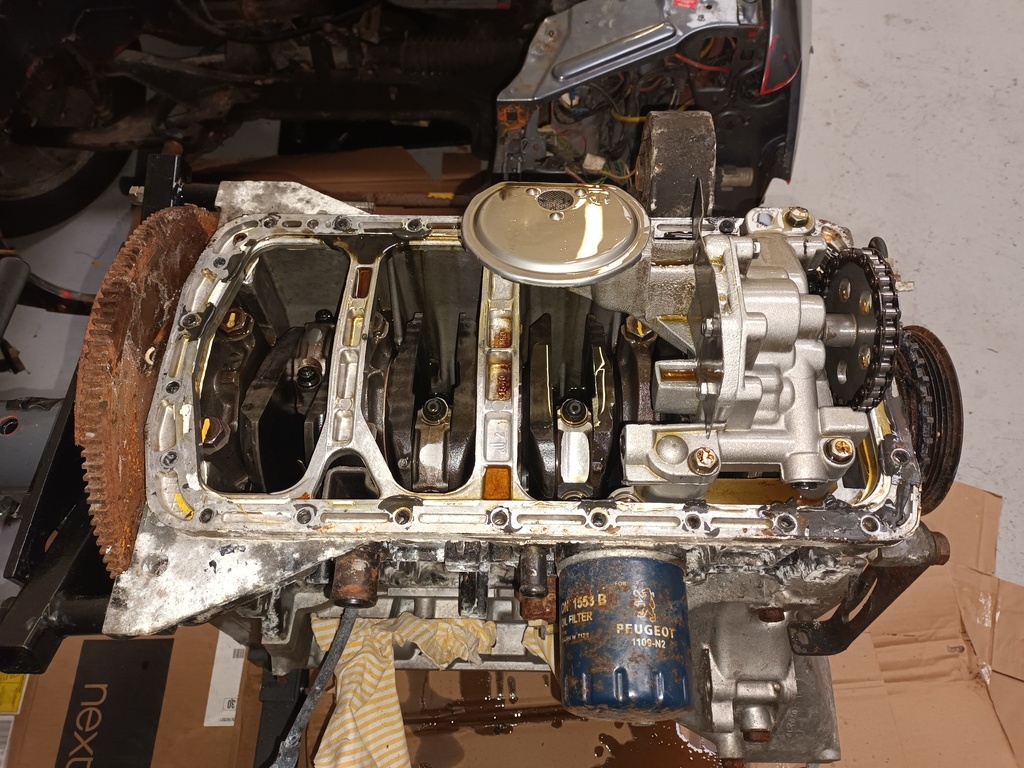

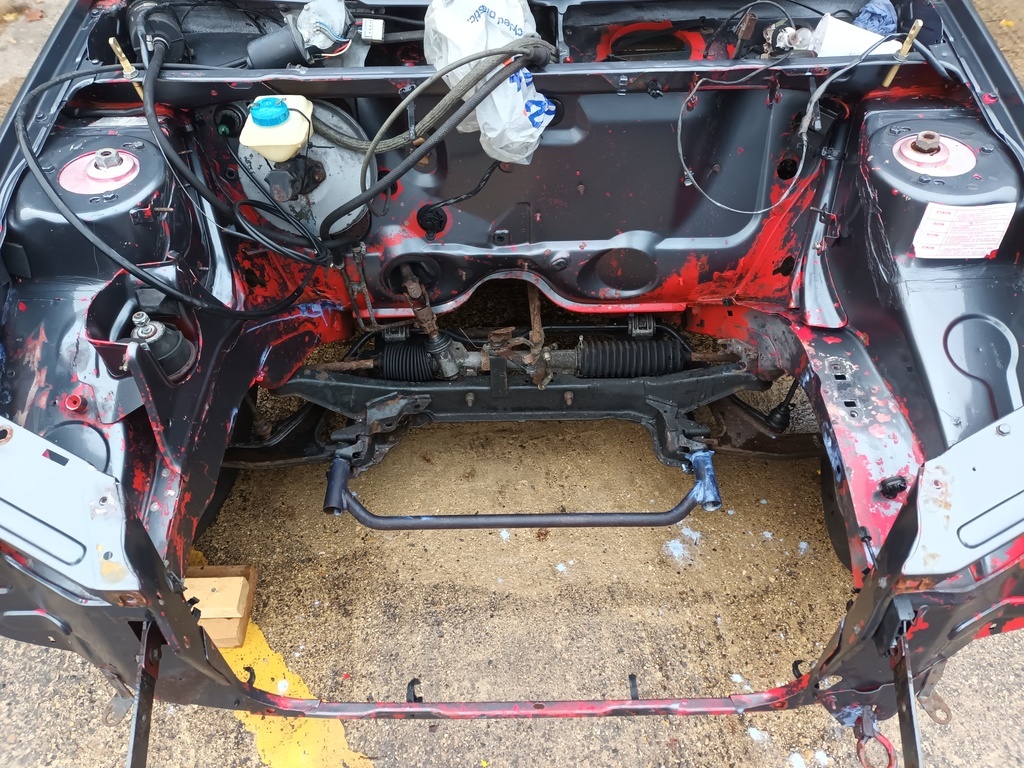

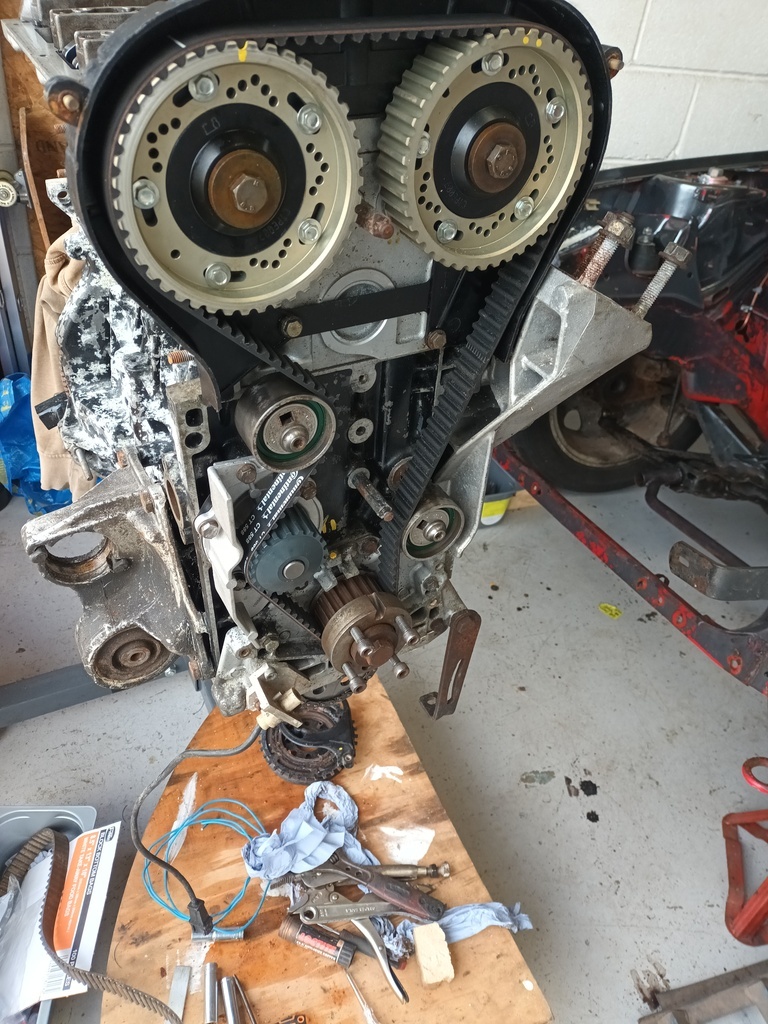

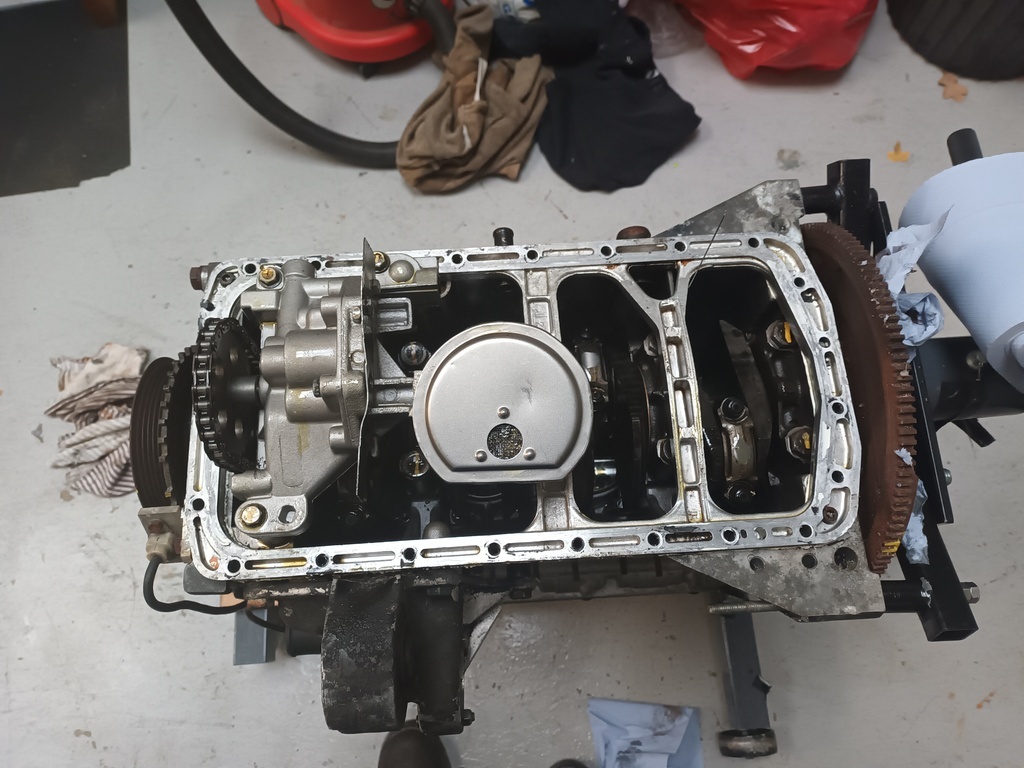

Engine fell out. Lovely and easy and light compared to the volvo diesel lump I was playing with last.  Revealing a tubular exhaust fannimold. braaap. Number one on the list of "things to remember to fit before putting the engine back in"  I then split the gearbox off and discovered a well appointed comfy little nest in the bell housing  Everything rubber on the car has been nibbled by the mice, including the driveshaft gators - those splits are not from aging but are rodent holes  Put it on the stand and took the cam cover off. I was genuinely nervous about this bit as if it had been damp all that time....  It's all good. Its better than good, it's cock on. The littlest corrosion on the spray bar and that's it. Camshafts, buckets, everything else all great mate. Looking verging on unused. Properly pleased with that.   Fancy cams at that. Timing belt looks in remarkably usable condition, camshaft sprockets look fancy  Cat cams were a thing, apparently. Man that knows says their factory burned down and they never started up again. Waterways are gunky but nothing catastrophic   Then flipped it over to look at the bottom end. (I love engine stands  and pulled the sump off  Revealing a lot of silicone sealant in all the bolt holes on and a welded in baffle arrangement with trapdoor.  Looks healthy. Crank webs possibly look like they've been sharpened up.  Turned it the right way up, put a socket on the crank nut and turned it over by hand. Lovely. I'm well happy with that, it's a healthy engine and probably then some. The head can stay on, the crank can stay in. That's great mate. Made a shopping list and put it tidy away.  |

| |

|

|

scdan4

Part of things

Posts: 39

|

|

Nov 28, 2021 15:56:46 GMT

|

Jetwashed a fair bit of paint off the engine bay  Found some sexy harnesses  Bought a bumper box of bits  Made the sump a bit easier on the eye  Locked the cams in a totally professional manner  Grimm  curse word.  Lovely.  Made me a gasket.   Why wont any of my new shiny bolts fit? M7. Thanks peugeot.  Cleaned gallons of silicon from both sides of the sump spacer  and temporarily reinstalled with new gaskets,  but more M7 bolt hideousness in the form of the sump fixings  Means we now wait for the postie, again.  M7? I ask you, what question was that the answer to?! |

| |

|

|

Potter

Part of things

'E who dares wins,eh Rodders??!

'E who dares wins,eh Rodders??!

Posts: 304

|

|

Nov 28, 2021 16:42:34 GMT

|

|

Cool little project you've got there. Looking forward to more progress!

|

| |

More cars than sense or money!🙄

|

|