|

|

|

Jan 13, 2021 21:57:19 GMT

|

|

I thought Christ they have gone up!, then I realised I use the smaller cylinder which is £70 but holds a lot less gas, still lasts a reasonable time though.

and yes I have left it turned on and wasted a cylinder as well.

|

| |

|

|

|

|

Norman

Part of things

Posts: 449

|

|

Jan 15, 2021 19:14:50 GMT

|

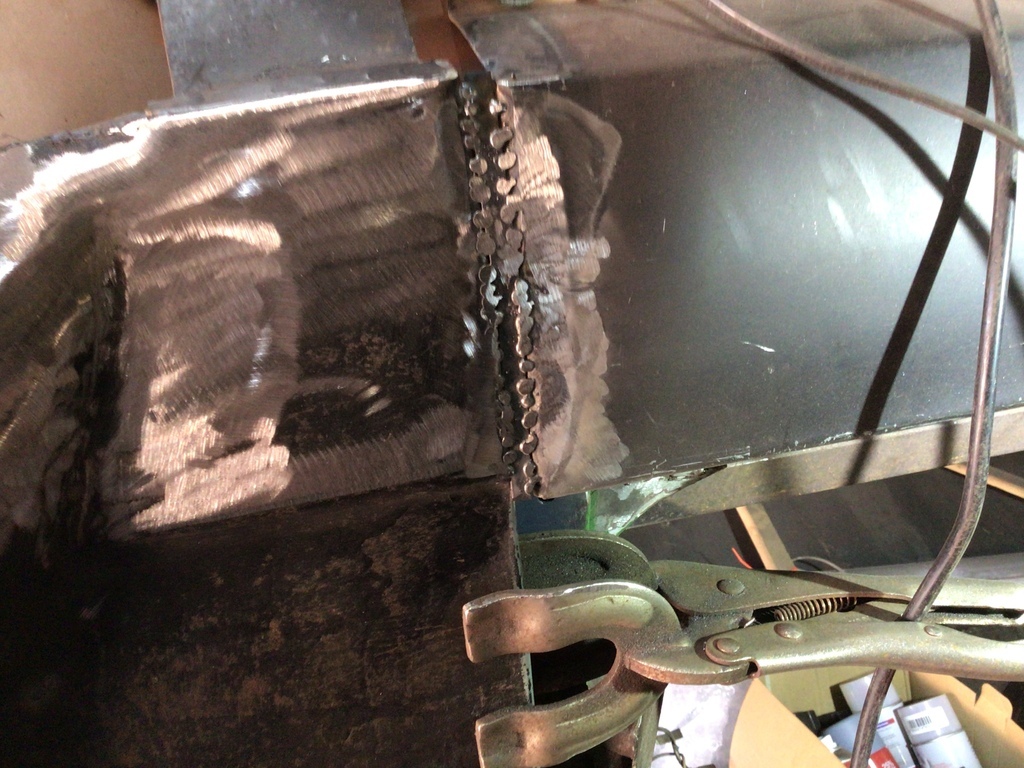

Here are a few pictures of the latest work. I didn’t get much done as i keep getting distracted with other stuff in the garage. The first pic shows the chassis leg which had a bink in it. This is it with a piece cut out to allow me to hammer it back into shape.  I have treated the area with hydrate 80 and weld through primer. I also closed it back in and ground the welds back and fired some primer on it.    This is the next area to be tackled, i have cut the rust out and will treat the area with hydrate 80. I previously mentioned the car had been accident damaged so i will need to do more hammer work on the front valence to make it straighter. Once i have done that i will fabricate a piece to fit between the valence and wheel tub.  That’s it for now folks, i will try and do some more over the weekend if it’s not too cold, it was freezing today so had to have some heat on! Please feel free to comment etc, all the best, Norman. |

| |

|

|

eternaloptimist

Posted a lot

Too many projects, not enough time or space...

Too many projects, not enough time or space...

Posts: 2,578

|

|

|

|

|

Looking good Norman.

|

| |

XC70, VW split screen crew cab, Standard Ten

|

|

|

|

|

Jan 16, 2021 22:44:35 GMT

|

Great to see updates on this  |

| |

|

|

|

|

auswol

Part of things

Posts: 21

|

|

|

|

|

Great to see more work being done on this, I always enjoy your updates.

|

| |

|

|

Donald

East of England

Posts: 133

|

|

|

|

|

Really enjoying reading this thread and seeing how you are getting on with it.

I will hopefully be making a start on my 1962 Vogue in the not too distant future.

I think a new bottle of gas, goggles and cutting discs need to go on the shopping list !

|

| |

|

|

Norman

Part of things

Posts: 449

|

|

Jan 18, 2021 18:30:37 GMT

|

|

|

| |

Last Edit: Jan 18, 2021 18:35:09 GMT by Norman

|

|

|

|

|

Jan 18, 2021 20:15:31 GMT

|

Just found this thread & read through it in one hit! Wow there must be more weld than original car now!! Top marks for doing this - all the people who say why bother will never know the immense satisfaction of doing this sort of work. Welding tip,get yourself a decent earth clamp. That pressed tin thing is rubbish. A decent earth clamp will improve your welds. R Tech are a top company for welding bits, reasonable costs too. earth clampOr get a longer cable with the clamp attached (need to cut the euro connector off) Earth clamp & cable |

| |

|

|

Norman

Part of things

Posts: 449

|

|

Jan 18, 2021 21:04:13 GMT

|

|

Hi, thanks for the tip. I have got a better welding clamp similar to the one linked, unfortunately with arthritis in my fingers I can’t squeeze the damn thing. Maybe I should have some weetabix! Thanks for the encouragement also, sometimes i look at it and think what am i doing. I had lost my way for a few weeks but i have decided to push on and get it done. Love the thread on your own car, it must give you great satisfaction. All the best, Norman.

|

| |

|

|

|

|

|

|

|

Jan 19, 2021 12:54:38 GMT

|

|

If you have problems with arthritis you could make a clamp up using a smallish G cramp. Not as good as the linked one as that has copper/brass mating surfaces but it would still contact better and be easier on your hands.

Yes, sometimes it's hard to keep the mojo going - my build took 25 years!!! but it's worth it in the end.

Chin up on bad days - every bit of progress is a bit nearer the end.

|

| |

|

|

Norman

Part of things

Posts: 449

|

|

Jan 21, 2021 19:13:16 GMT

|

Another wee bit done today, it had been snowing here overnight and the garage was cold, anyhow if you keep moving the cold isn’t too bad. I am attempting to make the wheel tub good to the wheel arch. I needed to curve the metal in two/three directions so there wasn’t much chance of that. I tried to shape the metal to do this in one piece but that wasn’t happening. I decided to fit it in smaller pieces and it looks ok and i have tacked it to the wheel arch profile. I have minimised the distortion by cooling the welds with compressed air. Here are a couple of pictures of the progress.   I have this area to do tomorrow, i need to tie a couple of areas in as i go.  The area between the repair panel and the wheel arch will need tidying, I don’t know whether to smear some body filler in there or rely on seam sealer, what do you guys think? That it for today, another exciting episode tomorrow if it’s not too blooming cold. As usual feel free to comment etc. All the best and stay safe, Norman |

| |

Last Edit: Jan 21, 2021 19:16:21 GMT by Norman

|

|

eternaloptimist

Posted a lot

Too many projects, not enough time or space...

Too many projects, not enough time or space...

Posts: 2,578

|

|

Jan 21, 2021 19:53:31 GMT

|

|

I’d use seam sealer, less likely to crack.

|

| |

XC70, VW split screen crew cab, Standard Ten

|

|

|

|

|

Jan 21, 2021 20:23:25 GMT

|

|

if it's prone to movement or the gap is more than 2-3mm I'd use Tiger Seal (or other name brand PU adhesive) as it sticks forever and is flexible.

|

| |

|

|

Norman

Part of things

Posts: 449

|

|

Jan 21, 2021 20:30:14 GMT

|

|

Hi guys, Thanks for the advice, it shouldn’t move as it tacked in and the gap is no more than 1 or 2mm. I am a while from doing it so will check out suggestions.

|

| |

|

|

|

|

|

Jan 21, 2021 20:30:21 GMT

|

|

As above use a seam sealer, most fillers absorb water if the paint is breached or it cracks and will cause all your good work to rot away again.

|

| |

|

|

|

|

|

Jan 21, 2021 21:14:37 GMT

|

|

great work as always norman keep it up

|

| |

|

|

|

|

|

Jan 21, 2021 21:33:04 GMT

|

|

Keep up the good work Norman. It looks like it’s coming on great from here.

Another vote for seam sealer over filler, and preferably tiger seal if you can get it - it’s good stuff!

|

| |

|

|

Norman

Part of things

Posts: 449

|

|

Jan 25, 2021 19:01:15 GMT

|

|

|

| |

Last Edit: Jan 25, 2021 19:02:49 GMT by Norman

|

|

|

|

|

Jan 25, 2021 20:54:28 GMT

|

|

send me on your address ill send ye a good earth strap

|

| |

|

|

|

|