The Herald has been annoying me, taking up space in the garage when I want to work on another project plus generally not running. Tried everything I could think of to get it running again and was out of ideas.

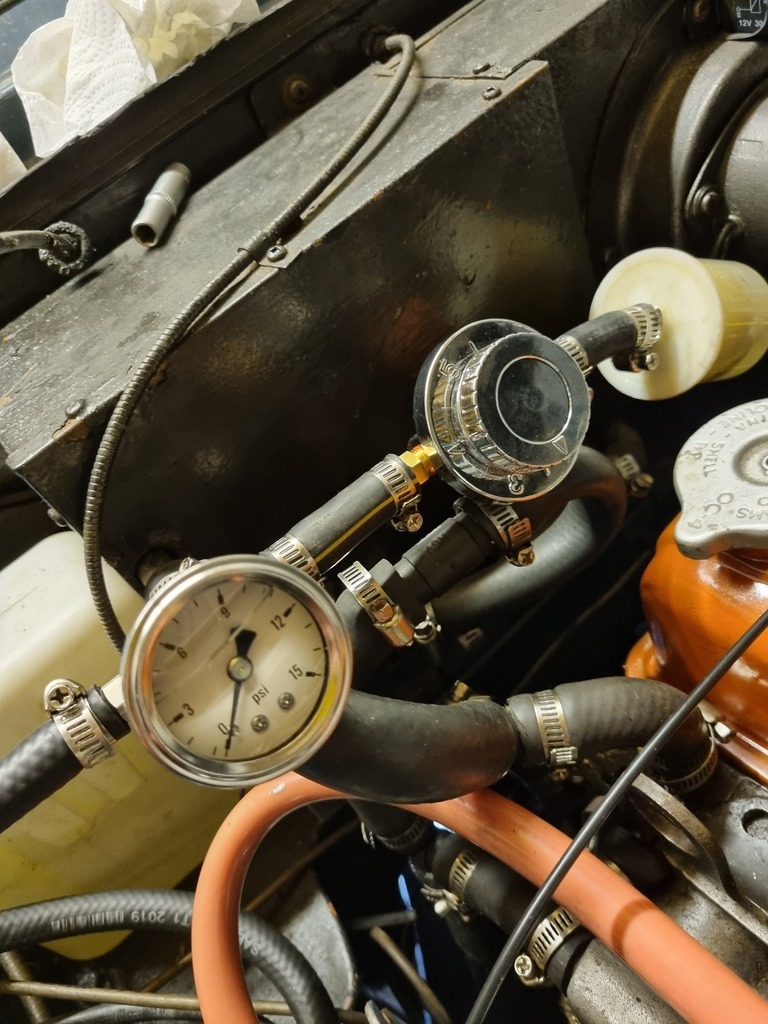

Called a mobile carb tuner to the house and we pushed the car out the garage. I'm sat in the car to hit the brakes, which I do, except the pedal goes to the floor. Ol Harold rolls down into the back of the turner's van... Fml

Only broke a reflector and a slight bump on his bumper, not a great start to the day though. He took it in good spirits, gave him a wedge of money for the damage though, already turned into an expensive visit and we've not turned a key.

Anyway got it running on full choke, and he sprays brake cleaner on the exhaust manifold join and revs rise and you can see bubbles. I'm so irritated with myself, I knew how to do that and have previously checked it in this way, just totally forgot to do that check. Amateur hour, I was pretty embarrassed, should have been the first thing I looked at.

Anyway he got it running despite the manifold leak and went for a spin around the block (it's flat and very quiet, plus got some braking once I pumped). The diff makes no noise and it ran well so I think the diff rebuild is a success!

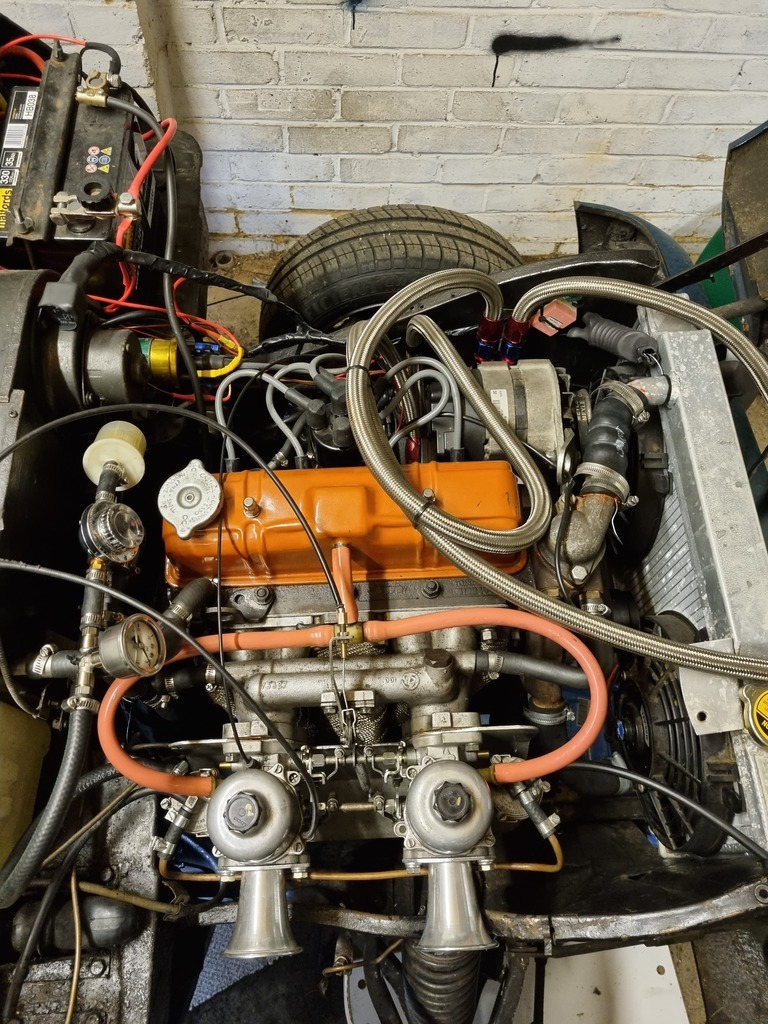

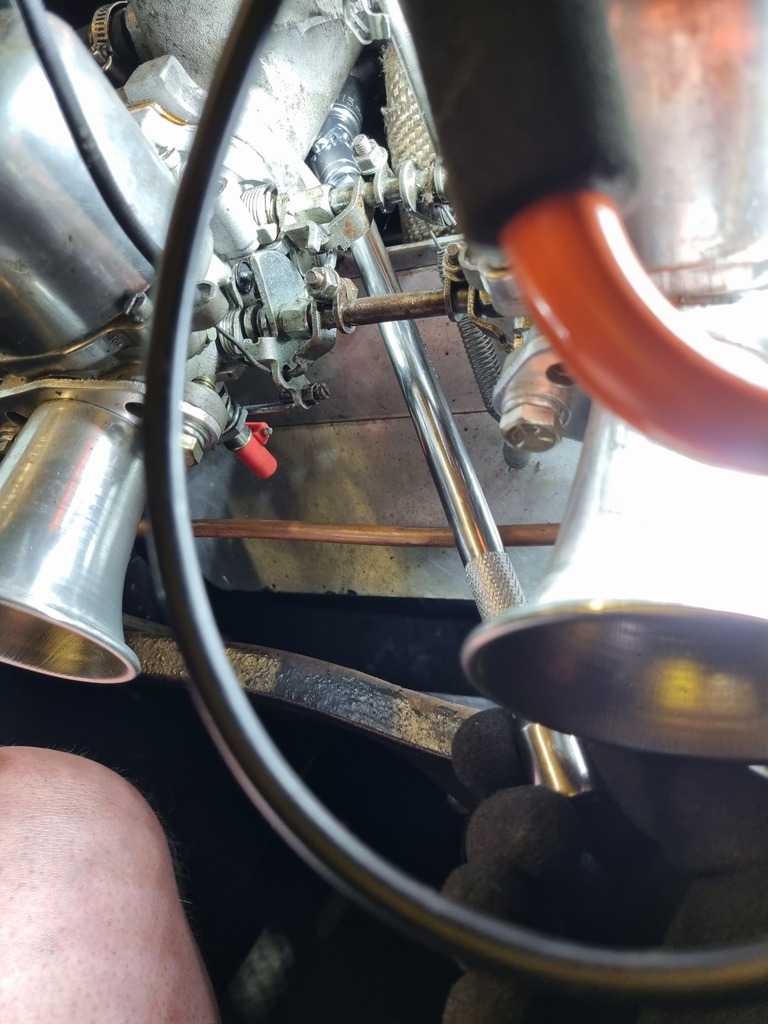

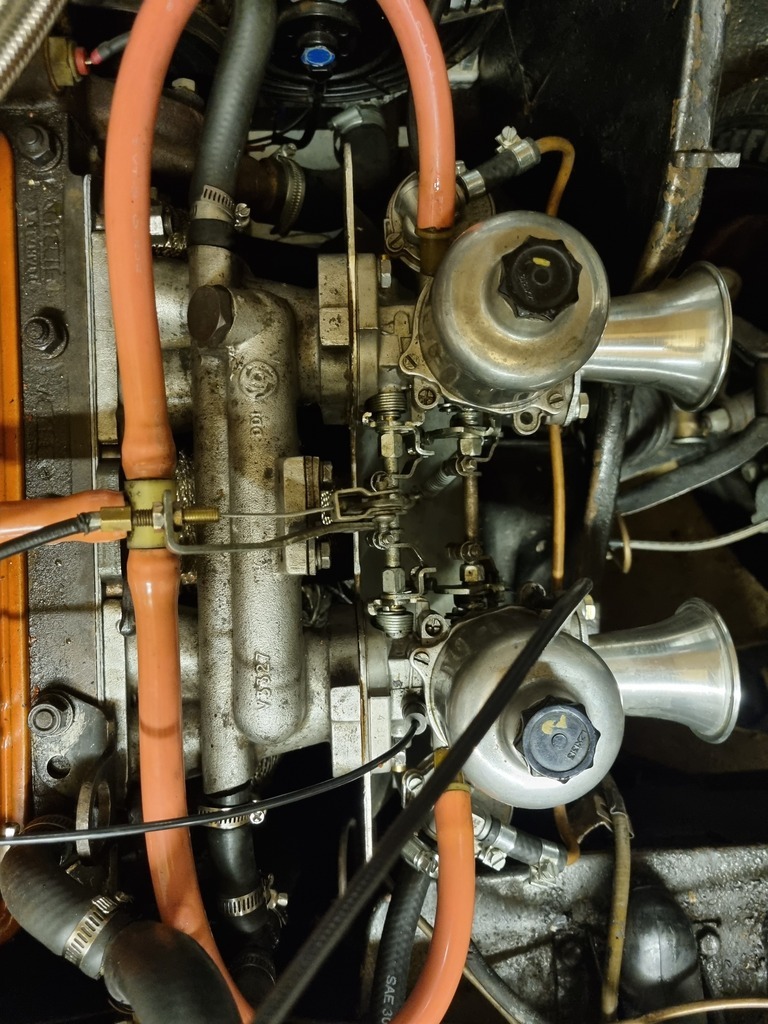

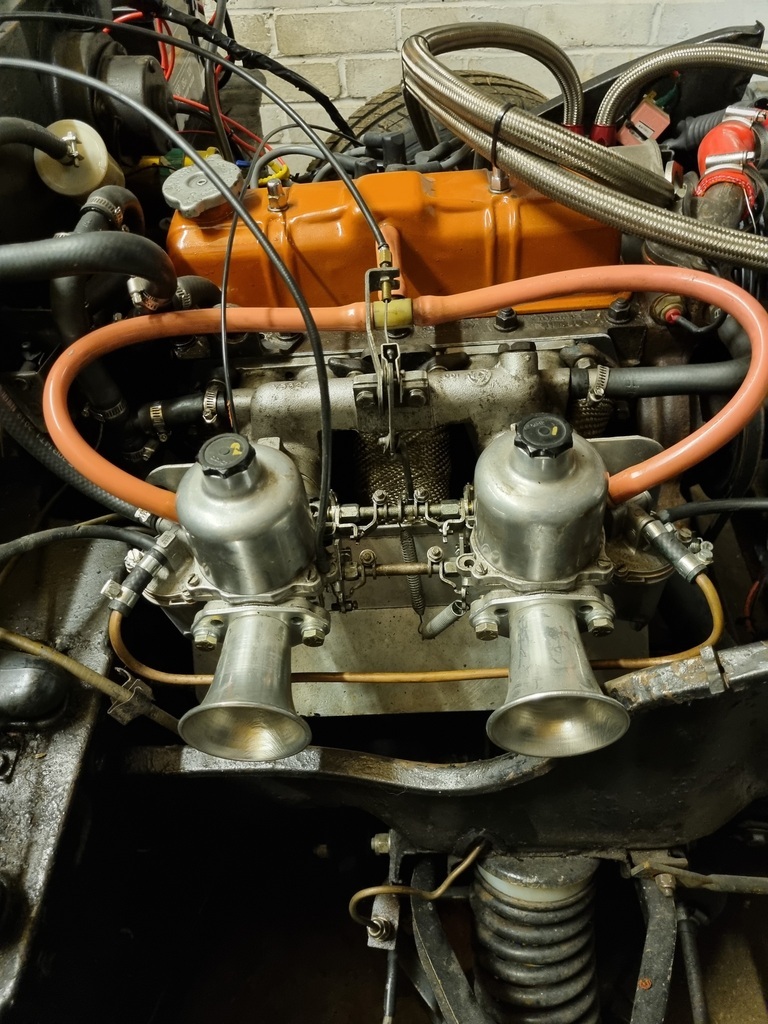

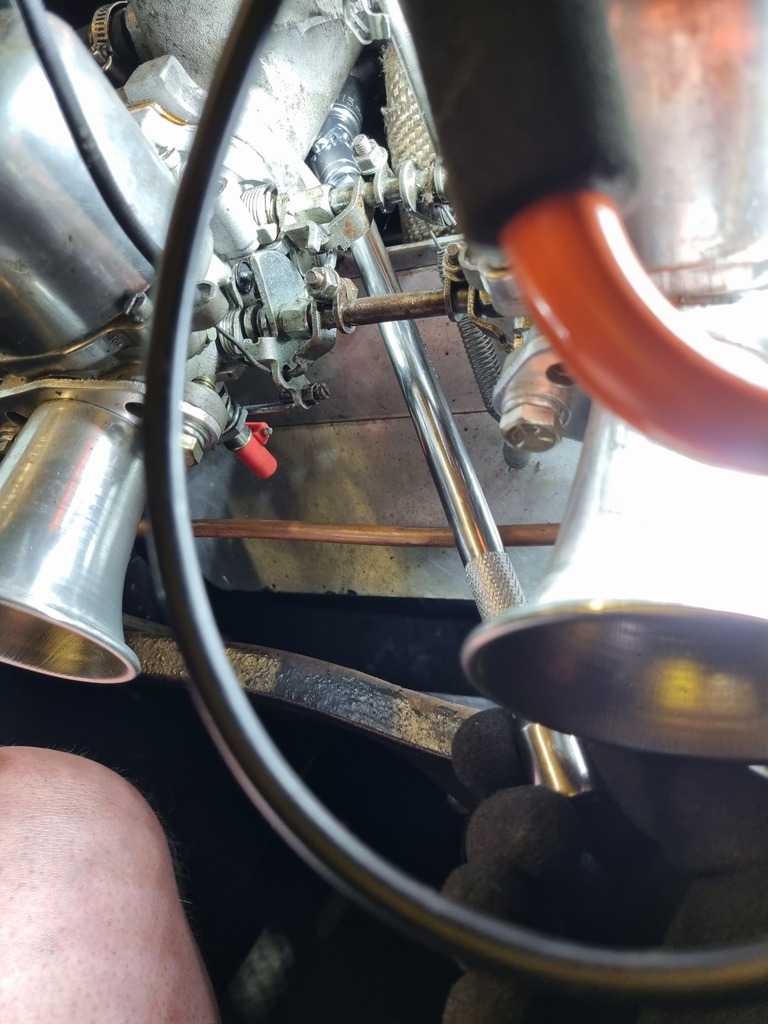

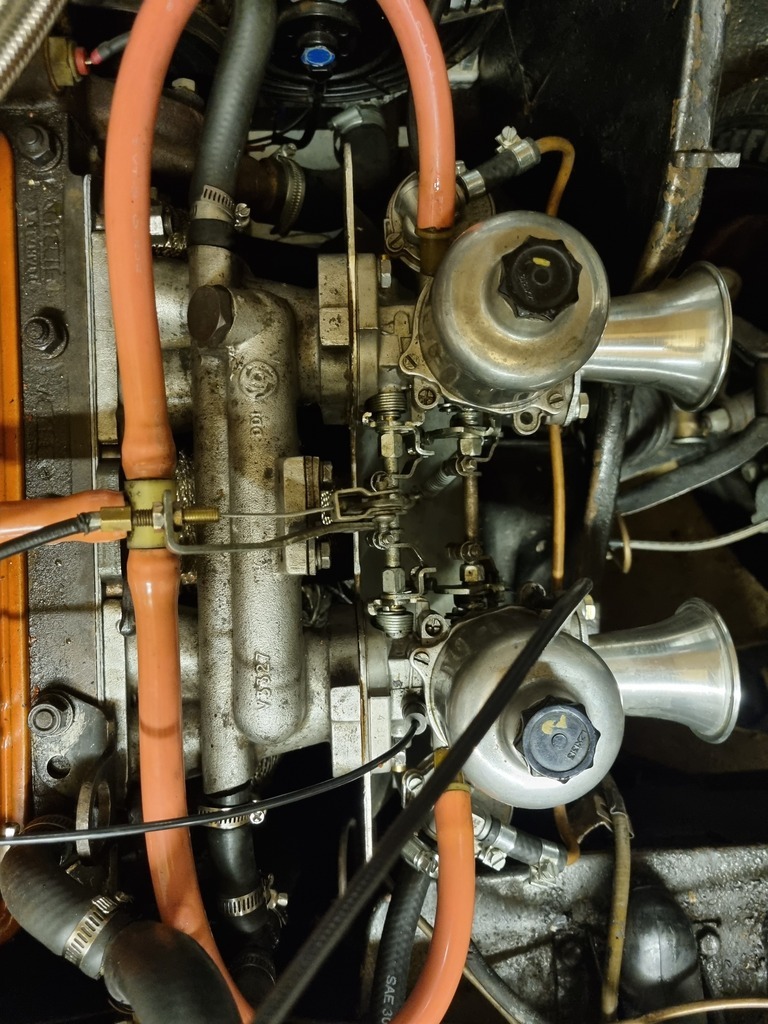

Have spent a few hours each night taking the carbs and exhaust manifold off, cleaning up the surfaces and getting rid of the old gasket.

Pretty satisfying job, this must be the 4th or 5th time I've done it and only now getting the hang of the bottom back bolt that is a pig to reach. Finally got some angles for my socket set.

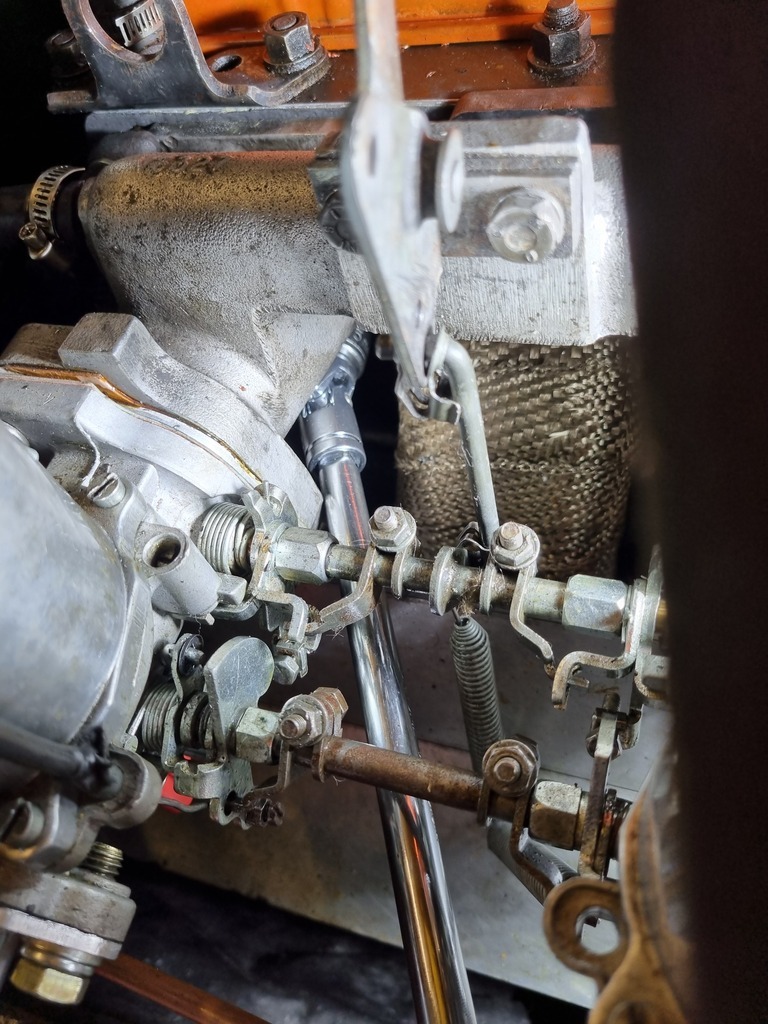

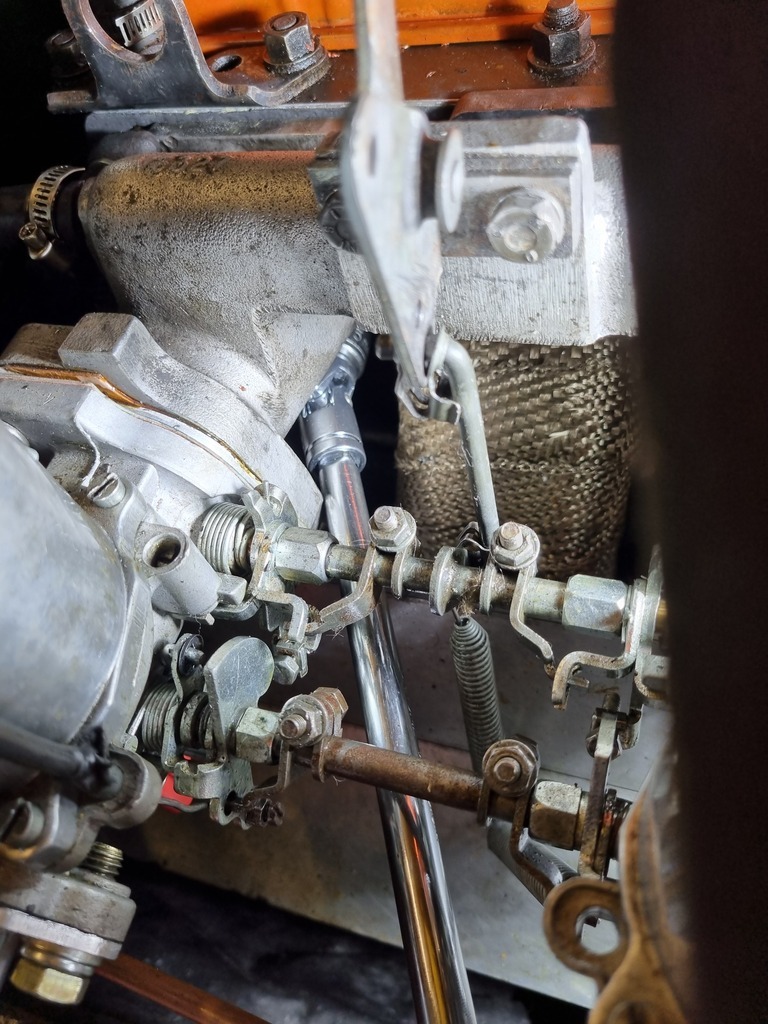

It had pointed to a bigger problem though, I always seem to end up with a leaky exhaust gasket particularly since I put the aftermarket 421 manifold on. More reading seems to indicate that the exhaust may not be particularly well made and not a flat surface.

Tbh I just could not be @rsed to take the exhaust apart, it lazy but the car is so low that raising it in a jack means driving onto wood chocks first, but it won't drive as I've taken the manifold off.

So Ive used 2 gaskets, one thick metal one (metal on each side with compressible stuff in between) and one card one. Put the metal one facing the head and card facing the exhaust.

Seems to be mixed opinions on doing this, some say it just increases the points of failure but other triumph owners have solved their leaks with it and done long distances.

So far my attempts haven't succeeded so I reckon s0d it I'll give it a try. I had both gaskets already in the garage. They're basically consumables for me these days 😂.

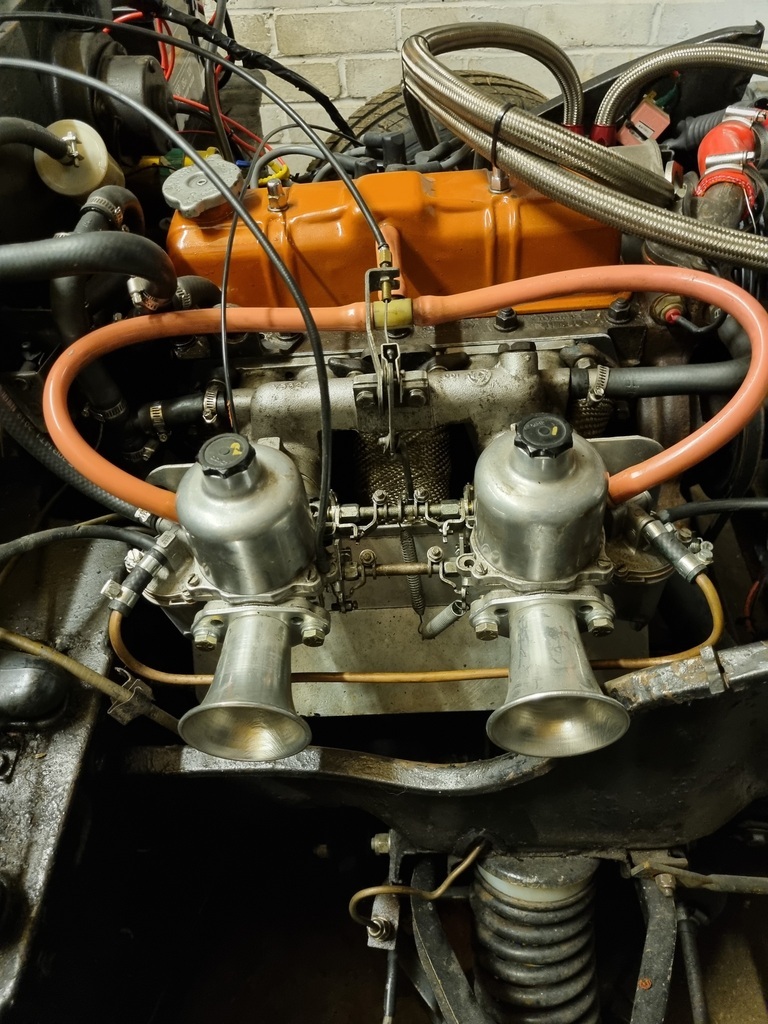

Everything is now bolted together and looking tidy.

Next job is to bleed the brakes, sitting obviously hasn't done them any favours.

Have also been talking to a couple of local businesses to get a custom exhaust done. My home made side exit looks cool and I always wanted a car with a side exit, but the reality is it's so ridiculously loud, meaning I can't really tune it on my drive or the neighbours will lose their minds, and it's pretty anti social.

About £550 gets something made but finding a time slot is hard and taking a day off to get an exhaust done while we've got a new baby isn't really viable.

Considering trying to make another one but use mild steel instead of stainless so my local garage can weld it for me one mocked up.

I need more ground clearance as the exhaust Bottoms out basically on any bump and I don't want it raise it. It'll mean using a slightly smaller bore, maybe going down to 1 3/4" instead of 2" which doesn't currently quite fit in the tunnel/chassic gap.

It'd be cheaper if I could try and fit a spitfire exhaust to it but I'm not sure a spitfire exhaust will fit the Herald as I believe the chassis is a little different (not certain though)?

I'll probably need to cut out the spare wheel well to make room for the box and to give more ground clearance (which is fine by me, not like this car will ever be returned to standard 😂).

Called a mobile carb tuner to the house and we pushed the car out the garage. I'm sat in the car to hit the brakes, which I do, except the pedal goes to the floor. Ol Harold rolls down into the back of the turner's van... Fml

Only broke a reflector and a slight bump on his bumper, not a great start to the day though. He took it in good spirits, gave him a wedge of money for the damage though, already turned into an expensive visit and we've not turned a key.

Anyway got it running on full choke, and he sprays brake cleaner on the exhaust manifold join and revs rise and you can see bubbles. I'm so irritated with myself, I knew how to do that and have previously checked it in this way, just totally forgot to do that check. Amateur hour, I was pretty embarrassed, should have been the first thing I looked at.

Anyway he got it running despite the manifold leak and went for a spin around the block (it's flat and very quiet, plus got some braking once I pumped). The diff makes no noise and it ran well so I think the diff rebuild is a success!

Have spent a few hours each night taking the carbs and exhaust manifold off, cleaning up the surfaces and getting rid of the old gasket.

Pretty satisfying job, this must be the 4th or 5th time I've done it and only now getting the hang of the bottom back bolt that is a pig to reach. Finally got some angles for my socket set.

It had pointed to a bigger problem though, I always seem to end up with a leaky exhaust gasket particularly since I put the aftermarket 421 manifold on. More reading seems to indicate that the exhaust may not be particularly well made and not a flat surface.

Tbh I just could not be @rsed to take the exhaust apart, it lazy but the car is so low that raising it in a jack means driving onto wood chocks first, but it won't drive as I've taken the manifold off.

So Ive used 2 gaskets, one thick metal one (metal on each side with compressible stuff in between) and one card one. Put the metal one facing the head and card facing the exhaust.

Seems to be mixed opinions on doing this, some say it just increases the points of failure but other triumph owners have solved their leaks with it and done long distances.

So far my attempts haven't succeeded so I reckon s0d it I'll give it a try. I had both gaskets already in the garage. They're basically consumables for me these days 😂.

Everything is now bolted together and looking tidy.

Next job is to bleed the brakes, sitting obviously hasn't done them any favours.

Have also been talking to a couple of local businesses to get a custom exhaust done. My home made side exit looks cool and I always wanted a car with a side exit, but the reality is it's so ridiculously loud, meaning I can't really tune it on my drive or the neighbours will lose their minds, and it's pretty anti social.

About £550 gets something made but finding a time slot is hard and taking a day off to get an exhaust done while we've got a new baby isn't really viable.

Considering trying to make another one but use mild steel instead of stainless so my local garage can weld it for me one mocked up.

I need more ground clearance as the exhaust Bottoms out basically on any bump and I don't want it raise it. It'll mean using a slightly smaller bore, maybe going down to 1 3/4" instead of 2" which doesn't currently quite fit in the tunnel/chassic gap.

It'd be cheaper if I could try and fit a spitfire exhaust to it but I'm not sure a spitfire exhaust will fit the Herald as I believe the chassis is a little different (not certain though)?

I'll probably need to cut out the spare wheel well to make room for the box and to give more ground clearance (which is fine by me, not like this car will ever be returned to standard 😂).