lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

May 25, 2020 17:29:48 GMT

|

My door seals turned up so I set about fitting them. The old seals were knackered, shrinking at the corners and falling apart. The original seals had a hard 90 degree mitred corner as per the drivers side below. You can see where they're pulling away from the bodywork due to shrinkage. You can buy door seal kits for Avengers with this corner present, but they're £120 or so which sounds like a lot of money for some bits of rubber to me. Instead I bought some generic door seal of the same type from Woolies for about half the price. I originally intended to cut a 45 degree corner on each end myself and then glue them together to make this corner. However, it doesn't cut very well and tends to roll away from the knife, leaving a slightly scruffy 45 degree edge. So I scrapped that idea and tried tightly bending the seals around the 90 degree corner. It seems to have worked ok and there are no gaps around the edge. I'll keep an eye on it and make sure it doesn't leak in the rain. I really compressed the seals hard along their entire length while fitting, so any shrinkage would have to be immense before it starts coming away from the body.

I also remade the piece of trim behind the seatbelt in black vinyl. The original red stuff has gone rock hard and shrunk, and doesn't match my black interior (car used to have full red interior). I also refitted the door cards and gave them a clean. However, when I went to close the back door it initially wouldn't close. The new seal being much thicker than the flattened old one was grabbing on the door at the hinge end and getting nipped against the B-post. I thought I might have to find some smaller seals, but thankfully lubing it up with talc and it operates properly with a firm-ish push. It should get better once it compresses a little over time. Oh and I refitted the mirror.

|

| |

|

|

|

|

|

|

|

|

|

Huh. Your pit makes more sense how you did it now. Nice. Car is looking good! I like those speakers in the pockets. Cool detail.  |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

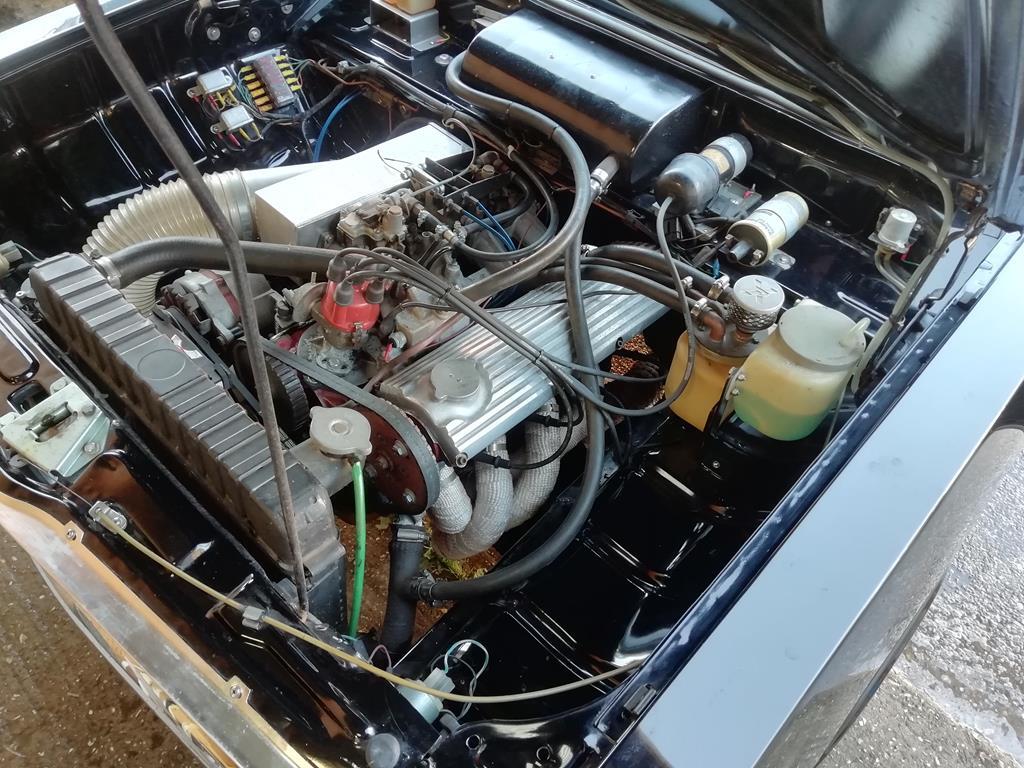

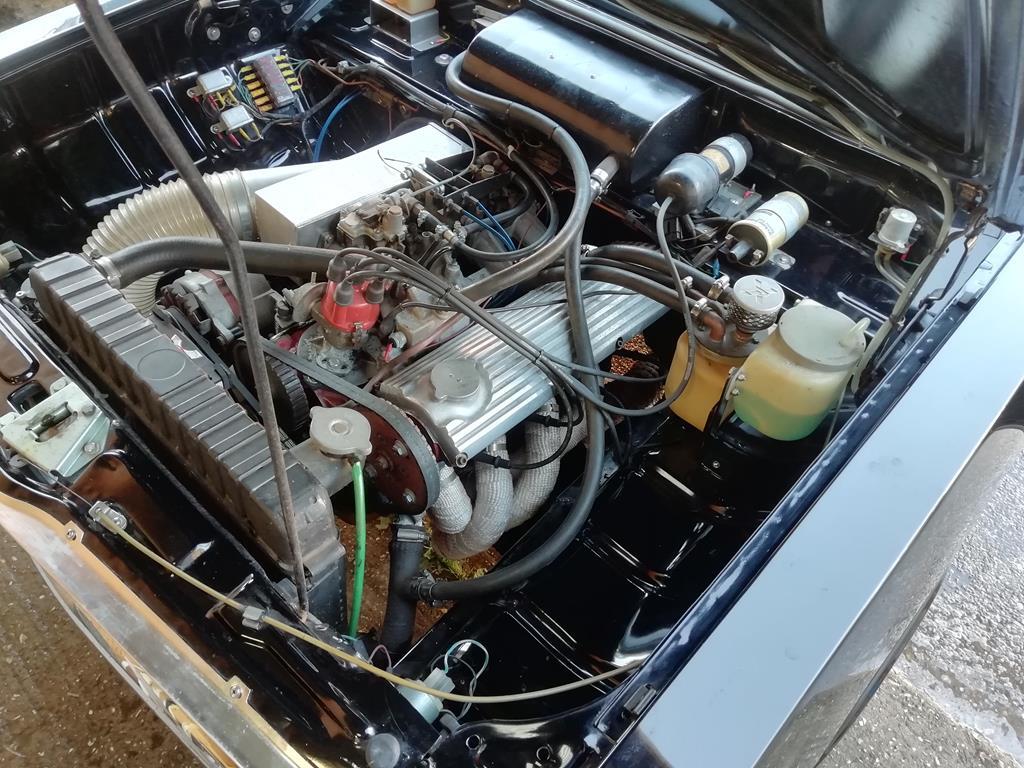

I had a bit of mechanical work to do for a change today. The car has had an annoying ticking sound for a little while which has got progressively worse. I drove it last week for the first time in a while and it sounds terrible. I suspected this was either a leaking manifold gasket or the exhaust manifold itself. With a pipe in the ear it became clear that cylinder 4 was the culprit. So this afternoon was spent taking things apart. It used to be a 15 minute job to get the manifolds off when the car had a single carb. It probably took 2.5hrs today with all the extra stuff that has to come off.  IMG_20200601_154921 IMG_20200601_154921 by Chris Witkowski, on Flickr  IMG_20200601_162025 IMG_20200601_162025 by Chris Witkowski, on Flickr  IMG_20200601_162014 IMG_20200601_162014 by Chris Witkowski, on Flickr Cylinder 4 has clearly been leaking quite badly. Unfortunately the face of the flange is now a bit ropey around there, so I think I'll need to face it to get a good seal. I'm also tempted to buy some copper sheet and make my own gasket from it rather than use the standard Sunbeam gasket. On the plus side, my inlet valves are spotless.  IMG_20200601_162852 IMG_20200601_162852 by Chris Witkowski, on Flickr  IMG_20200601_162912 IMG_20200601_162912 by Chris Witkowski, on Flickr |

| |

|

|

|

|

|

|

|

These Vauxhall slant 4 engines can be a right pain to get the manifolds to seal, the standard gasket is a piece of tin with a bit of a bead formed into it, ive used a thin wipe of silicone sealer on the mating faces with no gasket, that was 10yrs ago and still good!  |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

|

Good to know. You do have one advantage with the slant 4 being a crossflow head. The Avenger uses a common stepped washer type arrangement to secure both manifolds. It's a bit curse word, but OK on n/a cars. I think with the high pressure in the exhaust manifold it's just too much for the standard gasket.

I think copper is probably my best bet, as well as ensuring the flanges are flat. It's now such a pain to remove that I want to get it right 1st time!

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

Hillman Avenger TurboDarkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

Looks like No.4 will always be the weak link only having the two clamp points where all the others effectively have three. - Add to that the clamping line is offset to the top of the port. The lower part of No.4 flange could do with a support fence to help prevent it warping.

|

| |

Last Edit: Jun 1, 2020 18:38:01 GMT by Darkspeed

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

|

What do you mean by a support fence? I agree number 4 would be much better with a 3rd clamp point.

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

Hillman Avenger TurboDarkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

Excuse the dire bit of paint freehanding - hopefully its enough - A bit of 4 or 5mm strip say 1/2" or more deep following the shape of the flange providing a deeper beam section to assist in keeping that area of the flange flat between the two bolt holes.  |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

I see what you're saying. I think I might try and weld an additional bit of plate on the end of the flange as below. There's an area directly below on the block which I can drill and tap, and then use a bridge style clamp on that part of the manifold. |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

The manifold was bowed around cylinder 4 as you can see.  IMG_20200602_115846 IMG_20200602_115846 by Chris Witkowski, on Flickr I decided to slit the manifold between the ports to try and avoid this happening in future. I then spent many many hours with a file trying to get the face flat and free of pitting. It's not perfectly flat across the 4 sections, but each section itself is flat. I will bolt it to the head and check that it pulls down before proceeding. I'm reluctant to plane off any more as the flange is already on the thin side.

If all else fails I do have a spare thicker flange which I can use. I also welded the section of plate onto cylinder 4. Today I'll trim it down so it's a bit more aesthetic. It's going to be used for an additional fastening which I'll make. |

| |

|

|

|

|

|

|

|

|

|

|

It looks from the pics like the Rootes engineers didn't do you any favors with that design; too few fasteners, too far from the ports. John

|

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

|

It's certainly not ideal John. I also have an adjustable turbo support underneath which basically carries the weight of the turbo (see pics in posts above). I did have it set up before so that it was pushing upwards a bit (ie taking the full weight of the turbo). I wonder if I should slacken it off slightly to put more pressure on the bottom half of the manifold flange where there are no fasteners.

|

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

This is the bracket I made to provide additional clamping to no.4 exhaust port. It's not totally ideal as the bolt is a bit too low so can't provide as much clamping leverage as I'd like. It should be better than nothing though.  IMG_20200604_145142 IMG_20200604_145142 by Chris Witkowski, on Flickr  IMG_20200604_124353 IMG_20200604_124353 by Chris Witkowski, on Flickr I didn't take any more photo's but everything is back together now. I used a gasket for the lower performance Avengers which has smaller ports but is a multi layer job with composite and metal. I had to open the ports out a little to match the Ti head, but I think this type of gasket will perform better than the composite one I removed. I need to take it for a run next and check it's not still leaking. |

| |

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

Hillman Avenger Turbostealthstylz

@stealthstylz

Club Retro Rides Member 174

|

|

|

|

What does the block look like behind where you've fitted the additional clamp? Could you put a pivot piece behind the clamp anywhere?

|

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

It looks like this...

You can see where I've done a curse word job of centralising the hole on that block of metal. The clamp bridges between the outermost part of the 'block' on the block and the manifold flange. It will provide some clamping force but it would be better if the bolt hole could be closer to the manifold.

I have a few other ideas if it doesn't work, but it's hard to explain them without diagrams.

|

| |

|

|

|

|

|

|

|

A gusset running along the outside edge of that should add a decent bit of stiffness to the new wavy bit. Something like this.  |

| |

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

Hillman Avenger Turbostealthstylz

@stealthstylz

Club Retro Rides Member 174

|

|

|

I was thinking more a free floating clamp like this. It's same idea to what we use for clamping stuff to a magnetic bed when it has to be sat on bars for clearance.  |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

A gusset running along the outside edge of that should add a decent bit of stiffness to the new wavy bit. Something like this.  I was tempted to put in a gusset but I convinced myself that the metal is thick enough as it is. I'd like to be able to use a bigger bolt or stud so I can really clamp it down. It's only 5/16unf at the moment. I'm a little worried it will crack the block section though. Stealthstylz, that diagram is how it is currently unless I'm missing something. |

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

|

|

| |

Last Edit: Jun 6, 2020 10:41:35 GMT by lebowski

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

Hillman Avenger Turbostealthstylz

@stealthstylz

Club Retro Rides Member 174

|

|

|

A gusset running along the outside edge of that should add a decent bit of stiffness to the new wavy bit. Something like this.  I was tempted to put in a gusset but I convinced myself that the metal is thick enough as it is. I'd like to be able to use a bigger bolt or stud so I can really clamp it down. It's only 5/16unf at the moment. I'm a little worried it will crack the block section though. Stealthstylz, that diagram is how it is currently unless I'm missing something. It might be lol, looked like you'd welded the clamp to the manifold on my phone but can't quite tell now. These are the type of clamps we use which I was trying to draw, can't even find a photo of them set up.  |

| |

|

|

|

|