The story so far...

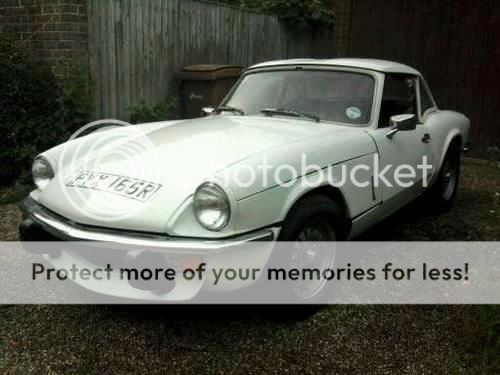

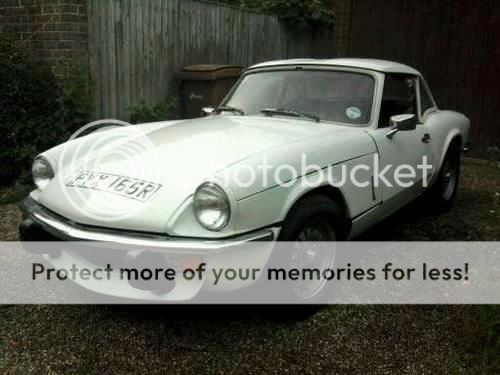

I bought my 1976 Spitfire 1500 in November 2011 in the knowledge that it needed a 'little bit of work', the engine was blowing out a cloud of blue smoke (which turned out to be worn cylinder bores and rings) and the bodywork was a bit tatty. However, in my youthful naivety I didn't appreciate the amount of rust and bodged repairs that had been carried out by previous owners (more about that later!). I had the engine out and got the block rebored, cylinder head skimmed with new valve guides and rebuilt the whole thing with new pistons, bearings, seals etc. This was my first engine rebuild so there was a steep learning curve, however the simple engine proved easy to work on!

Unfortunately, in 2012, after about 2000 miles of driving with the rebuilt engine...disaster! I noticed the coolant was beginning to disappear at an increasing speed and gunk was building up on the underside of the oil filler cap and in the breather hoses. My first thought was that the head gasket may have sprung a leak, so I replaced it to find it had not solved the problem. I really didn't want to strip the engine down again, however one day I checked the oil level and there was gunk on the dipstick. Now something really had to be done!

I pulled the engine and stripped it down again to investigate the issue. There were no obvious signs of a leak, so I sat the block on a bench and filled the jacket with coolant. After several minutes water started weeping from a hairline crack between the water jacket and the crankcase, so the block was now scrap! I had not had any overheating issues so I am not sure what could have caused the block to crack. Rather than trying to source a used engine for rebuild, I got a rebuilt short engine from Canley Classics for a good price and swapped over everything from the old engine.

While the engine was out I decided to investigate the bodywork further as I was not sure it would pass an MOT with the rust and bodged repairs on the cills. Unfortunately I cant find any pictures from this stage of the build, however there were bodges on top of bodges on top of rusted original parts all over the place! A great example was the drivers side rear wing next to the B pillar, where rather than cut out the original panel and weld in a repair panel, a PO had welded the repair panel over the top of filler and the original rusty panel. To make things worse, the same repair had been carried out a further time, with another repair panel welded over the top of more filler and the previous repair panel. When I cut this piece out it weighed an absolute ton! This should give a good idea of the levels of bodgery I was faced with.

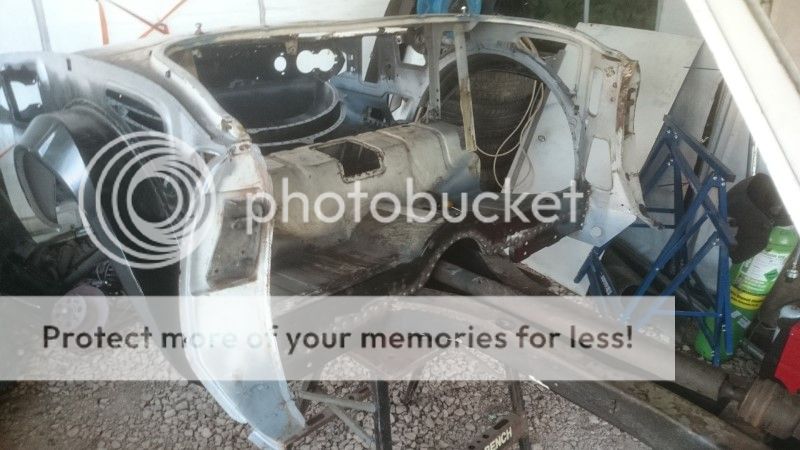

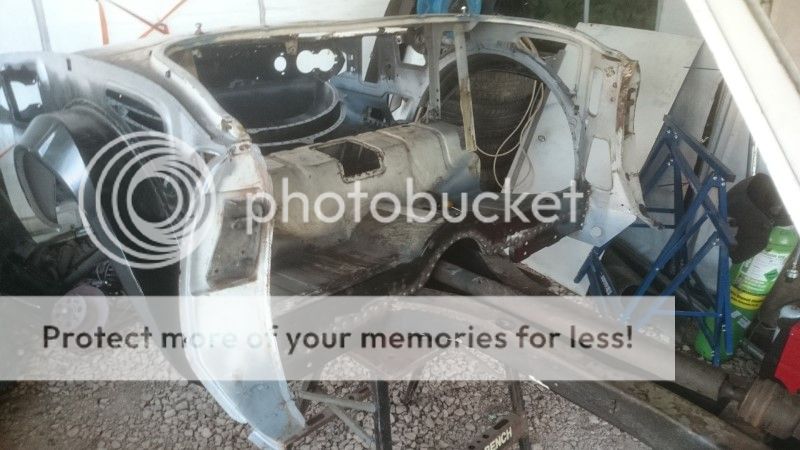

In the end I decided it would be easier to strip the body of all the rusted/bodged panels and start again. The boot floor, rear valance, lower B pillars, inner rear quarter panels and outer arches were replaced first, with all the floors, cills and rear arches removed. A new heelboard and cross member were welded in as the originals were shot. I would have been better off finding a good body tub to start with!

The next thing to go in were the new floors with the original tunnel welded on.

Next the new inner cills and inner A pillar sections went in with the bonnet, hardtop and doors used to correctly position the bulkhead and get the gaps right.

After that, it was time to weld the bulkhead and windscreen section back onto the body. New outer cills and rear wings went on as well.

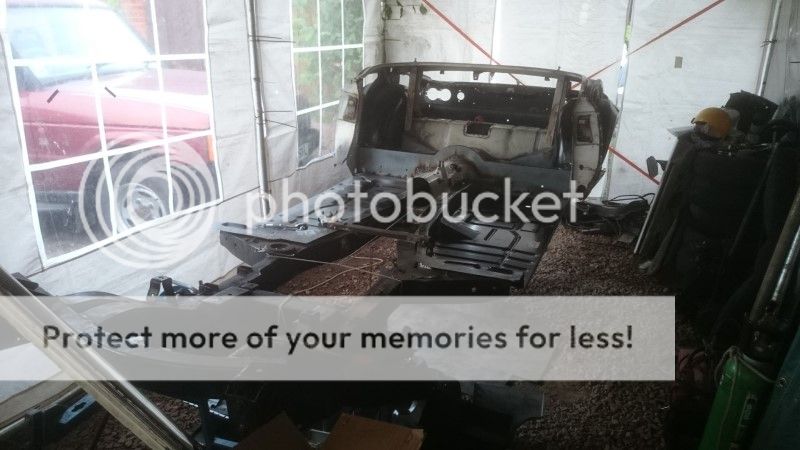

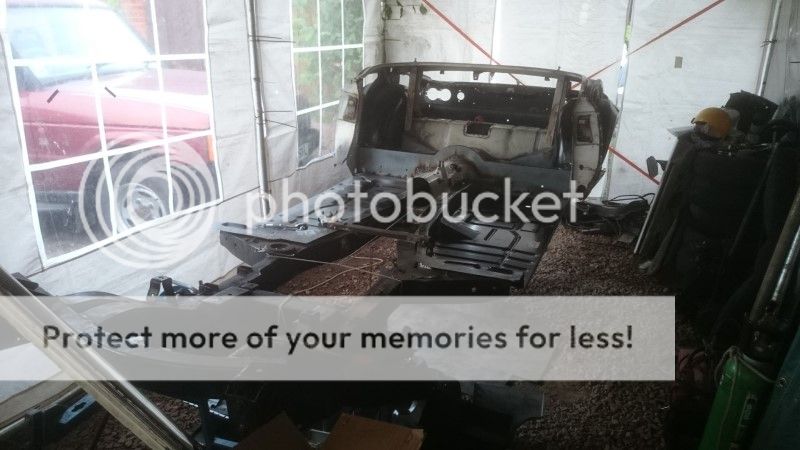

The final piece to go on were the A pillar and cill end finishers. After this the body was set to one side to work on the chassis. I started blasting the chassis at home however I just couldn't do it all in one day and as soon as it was left overnight the damp would rust the surface. I ended up sending it away and getting it blasted and powder coated by a professional!

Looks much better with a decent finish on it! All the suspension parts were also blasted and powder coated ready for building the rolling chassis. Front end suspension and brakes rebuilt with new calipers, discs, pads and stainless steel hoses.

![]()

Rear end rebuilt with new leaf spring, brake parts and reconditioned diff. Uprated wheel studs were added to the front and rear hubs to allow for bigger wheels in the future.

The rebuilt chassis is ready to be reunited with the completed body tub!

They are together at last! However this was not for long as the body was coming off to be blasted.

I should have learned from doing the chassis how labourious blasting is! In the end I gave up and sent it away to be blasted and epoxy primed.

Before and after, blasted and epoxy primed ready for the paint shop!

Off she goes to the paint shop! Unfortunately the car was in the body shop for a lot longer than expected due to staffing issues. it left on the 6th April and didn't

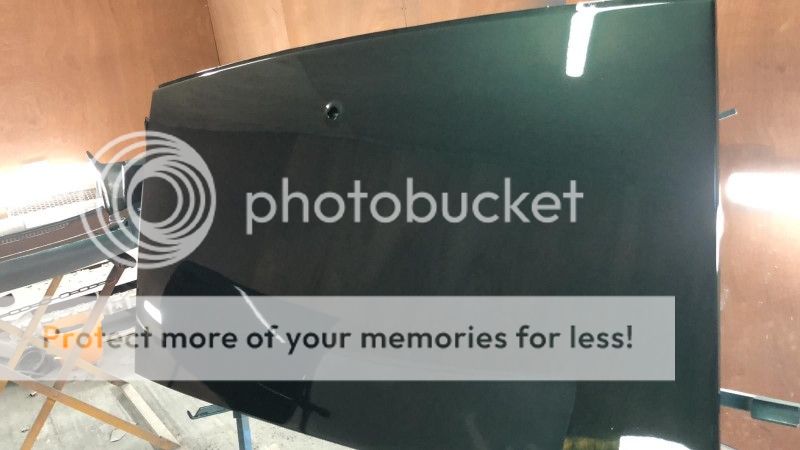

The bonnet and doors needed a fair bit of work to get them smooth enough to paint which is another reason it has taken a while.

The underside was painted with stone-chip, then primed and finally painted with the new body colour. Needless to say it was a great feeling to finally see some fresh paint going on after such a long rebuild!

Next up the lower portions of the cills and rear quarter were painted with stone-chip and then the whole thing primed ready for colour! I was getting very excited by this point to see the final outcome.

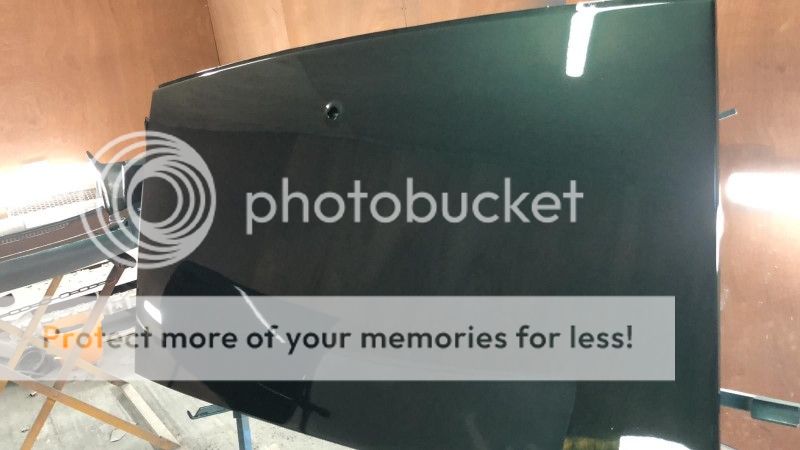

First to get colour coated were the doors and boot lid, and the outcome is better than I had ever hoped for! However, the moment I had really been waiting for was to see the body in colour again. The results speak for themselves!

Just the bonnet, headlamp cowls and front valances left to be painted now, and she should be coming home on Wednesday. Then the fun of reassembly can begin at last!

I Got the call on 7th August that the car was finally on its way home! Here she is all loaded and leaving the paint shop.

And a little while later she was home! Unfortunately I didn't have time to start tinkering that evening so she was tucked away for the night.

I was away at a festival for the rest of the week so I had to wait to get started. I had an extra day booked off on the Monday though so I booked to hire a van with a plan to get the engine back in. Unfortunately the weather was not on my side! so lots of waiting around for the rain to stop. This is the closest the engine has been to the car for 7 years! Whilst waiting around I installed the propshaft and bolted it up to the diff.

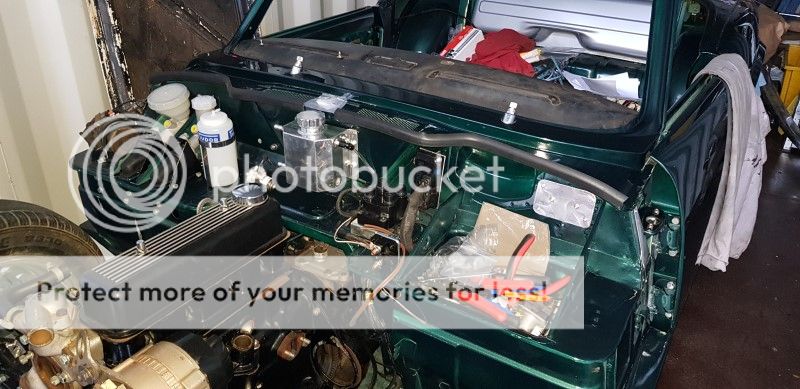

Finally there was a decent break in the weather and I managed to manoeuvre the engine and gearbox into place and reunite it once more! I had read that it is possible to get the engine in and out with the bonnet in place, so rather than damage my new paint trying to remove the bonnet on my own I left it there. Fortunately it was quite straightforward and slotted into place easily.

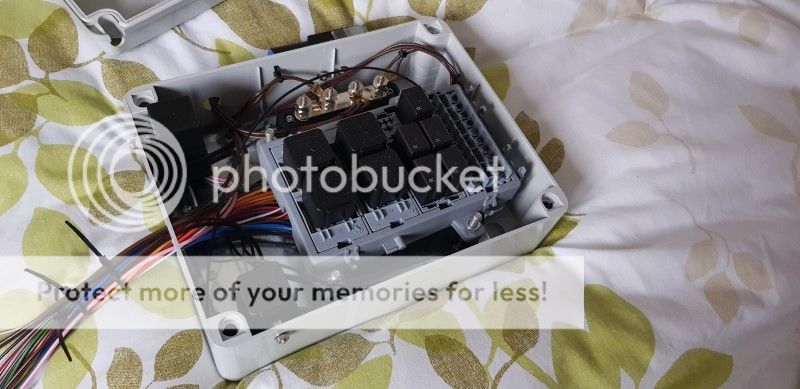

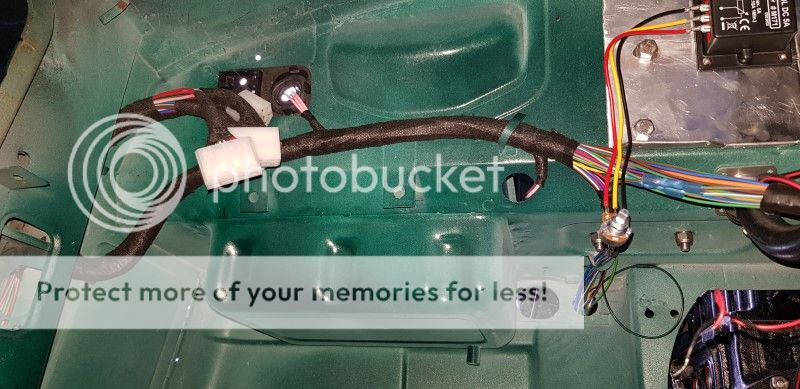

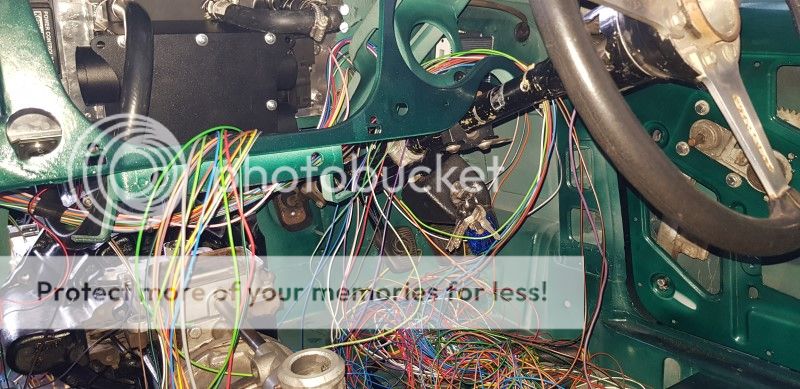

The only problem I have is that the rear gearbox mount doesn't seem to line up with the mounting holes as if the engine is too far forward. I ran out of time to figure that one out so will leave it for another day. Since then I have been rewiring and creating a new heater box assembly which will be posted soon. Thanks for reading!

I bought my 1976 Spitfire 1500 in November 2011 in the knowledge that it needed a 'little bit of work', the engine was blowing out a cloud of blue smoke (which turned out to be worn cylinder bores and rings) and the bodywork was a bit tatty. However, in my youthful naivety I didn't appreciate the amount of rust and bodged repairs that had been carried out by previous owners (more about that later!). I had the engine out and got the block rebored, cylinder head skimmed with new valve guides and rebuilt the whole thing with new pistons, bearings, seals etc. This was my first engine rebuild so there was a steep learning curve, however the simple engine proved easy to work on!

Unfortunately, in 2012, after about 2000 miles of driving with the rebuilt engine...disaster! I noticed the coolant was beginning to disappear at an increasing speed and gunk was building up on the underside of the oil filler cap and in the breather hoses. My first thought was that the head gasket may have sprung a leak, so I replaced it to find it had not solved the problem. I really didn't want to strip the engine down again, however one day I checked the oil level and there was gunk on the dipstick. Now something really had to be done!

I pulled the engine and stripped it down again to investigate the issue. There were no obvious signs of a leak, so I sat the block on a bench and filled the jacket with coolant. After several minutes water started weeping from a hairline crack between the water jacket and the crankcase, so the block was now scrap! I had not had any overheating issues so I am not sure what could have caused the block to crack. Rather than trying to source a used engine for rebuild, I got a rebuilt short engine from Canley Classics for a good price and swapped over everything from the old engine.

While the engine was out I decided to investigate the bodywork further as I was not sure it would pass an MOT with the rust and bodged repairs on the cills. Unfortunately I cant find any pictures from this stage of the build, however there were bodges on top of bodges on top of rusted original parts all over the place! A great example was the drivers side rear wing next to the B pillar, where rather than cut out the original panel and weld in a repair panel, a PO had welded the repair panel over the top of filler and the original rusty panel. To make things worse, the same repair had been carried out a further time, with another repair panel welded over the top of more filler and the previous repair panel. When I cut this piece out it weighed an absolute ton! This should give a good idea of the levels of bodgery I was faced with.

In the end I decided it would be easier to strip the body of all the rusted/bodged panels and start again. The boot floor, rear valance, lower B pillars, inner rear quarter panels and outer arches were replaced first, with all the floors, cills and rear arches removed. A new heelboard and cross member were welded in as the originals were shot. I would have been better off finding a good body tub to start with!

The next thing to go in were the new floors with the original tunnel welded on.

Next the new inner cills and inner A pillar sections went in with the bonnet, hardtop and doors used to correctly position the bulkhead and get the gaps right.

After that, it was time to weld the bulkhead and windscreen section back onto the body. New outer cills and rear wings went on as well.

The final piece to go on were the A pillar and cill end finishers. After this the body was set to one side to work on the chassis. I started blasting the chassis at home however I just couldn't do it all in one day and as soon as it was left overnight the damp would rust the surface. I ended up sending it away and getting it blasted and powder coated by a professional!

Looks much better with a decent finish on it! All the suspension parts were also blasted and powder coated ready for building the rolling chassis. Front end suspension and brakes rebuilt with new calipers, discs, pads and stainless steel hoses.

Rear end rebuilt with new leaf spring, brake parts and reconditioned diff. Uprated wheel studs were added to the front and rear hubs to allow for bigger wheels in the future.

The rebuilt chassis is ready to be reunited with the completed body tub!

They are together at last! However this was not for long as the body was coming off to be blasted.

I should have learned from doing the chassis how labourious blasting is! In the end I gave up and sent it away to be blasted and epoxy primed.

Before and after, blasted and epoxy primed ready for the paint shop!

Off she goes to the paint shop! Unfortunately the car was in the body shop for a lot longer than expected due to staffing issues. it left on the 6th April and didn't

The bonnet and doors needed a fair bit of work to get them smooth enough to paint which is another reason it has taken a while.

The underside was painted with stone-chip, then primed and finally painted with the new body colour. Needless to say it was a great feeling to finally see some fresh paint going on after such a long rebuild!

Next up the lower portions of the cills and rear quarter were painted with stone-chip and then the whole thing primed ready for colour! I was getting very excited by this point to see the final outcome.

First to get colour coated were the doors and boot lid, and the outcome is better than I had ever hoped for! However, the moment I had really been waiting for was to see the body in colour again. The results speak for themselves!

Just the bonnet, headlamp cowls and front valances left to be painted now, and she should be coming home on Wednesday. Then the fun of reassembly can begin at last!

I Got the call on 7th August that the car was finally on its way home! Here she is all loaded and leaving the paint shop.

And a little while later she was home! Unfortunately I didn't have time to start tinkering that evening so she was tucked away for the night.

I was away at a festival for the rest of the week so I had to wait to get started. I had an extra day booked off on the Monday though so I booked to hire a van with a plan to get the engine back in. Unfortunately the weather was not on my side! so lots of waiting around for the rain to stop. This is the closest the engine has been to the car for 7 years! Whilst waiting around I installed the propshaft and bolted it up to the diff.

Finally there was a decent break in the weather and I managed to manoeuvre the engine and gearbox into place and reunite it once more! I had read that it is possible to get the engine in and out with the bonnet in place, so rather than damage my new paint trying to remove the bonnet on my own I left it there. Fortunately it was quite straightforward and slotted into place easily.

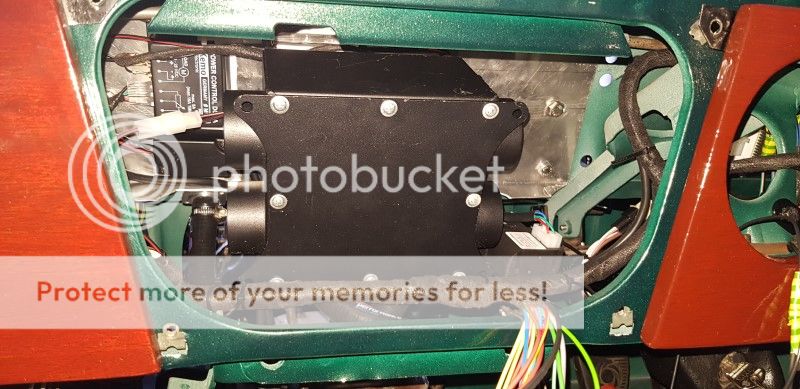

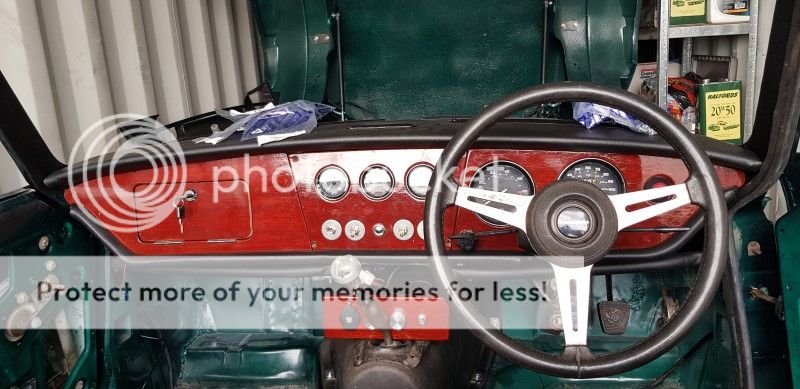

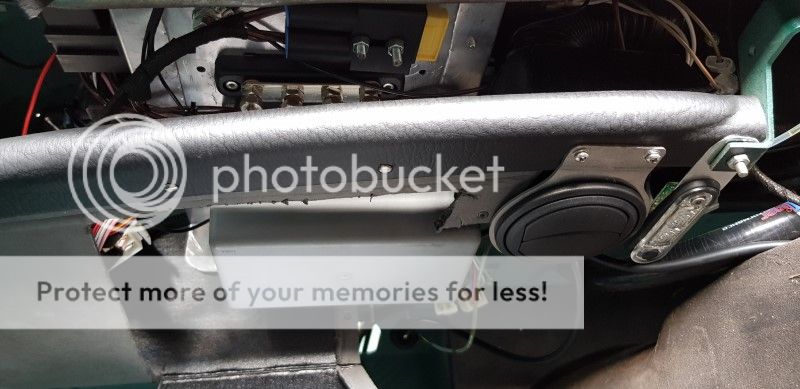

The only problem I have is that the rear gearbox mount doesn't seem to line up with the mounting holes as if the engine is too far forward. I ran out of time to figure that one out so will leave it for another day. Since then I have been rewiring and creating a new heater box assembly which will be posted soon. Thanks for reading!

any idea how much it weighs?

any idea how much it weighs?