|

|

|

|

|

|

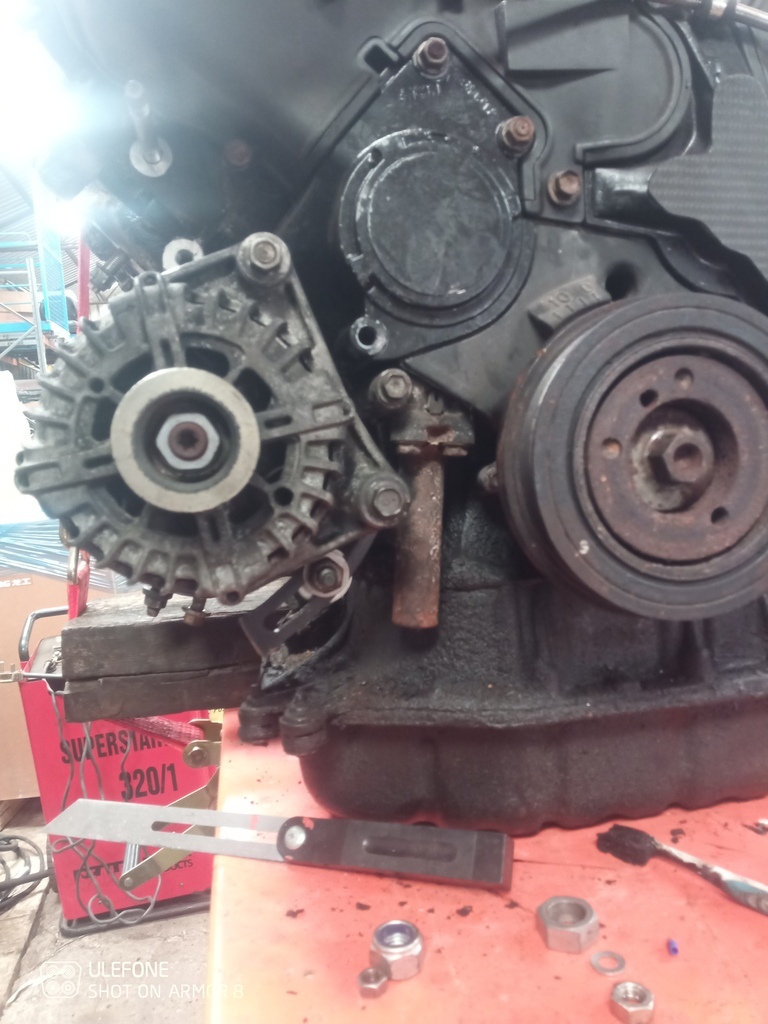

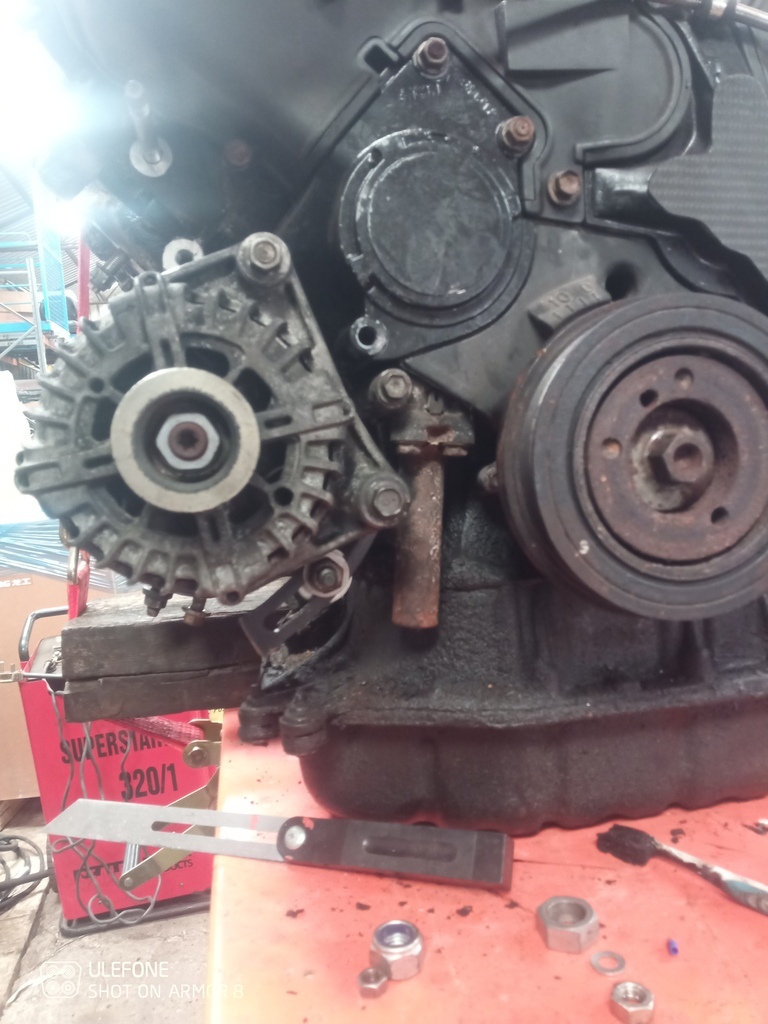

With my set up, at the moment with the standard Lexus alternator, I have to use a tensioner idler as there is not enough room for any adjustment for the alternator, as its close to the chassis. The reason for changing mine, is that I do have a few extra electronics, electric hydraulic power steering pump, two air compressors, electric water pump, a few amps plus all the usual stuff to run. The car doesn’t get used a lot and it is always on a battery conditioner/trickle charger when not in use. there’s alway that thought when everything is on that there might not be enough power to go around, I don’t want to overload the alternator, which could cause more issues. It’s hard enough sorting out the problems that I know about.

Even when the car has been used and it’s gone back in the garage for a sleep, with the battery conditioner on, it does take a while for the conditioner to show the battery is fully charged. It is a good, new, big, Yuasa battery and this is one of reasons that I thought the alternator might not be up to the job. As you would’ve assumed that after a couple of hours of driving the battery should be toppers, and wouldn’t need any additional charging.

anyway, isn’t more better.

|

| |

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

Bit of an update and photo dump of last 2 days progress.. there a bit muddled but you should get the gist. It's slightly more jumbled than my usual jibberish so get ready haha.. Had a few boxes turn up, starting with quite a big one..  Flat pack Manifolds! Excellent  Some very very nice quick release v bands. Twice the price of the usual eBay china specials but a lot better made, and each half of the vband itself has a definite male and female half to make sure it seals and locates! Figured for summat as important as the link pipe pre turbo I didn't want any leaks..  A proper Flexi for the link pipe. Nicer than the woven ones, and smaller. And since we're on a saving space mission figured it would help   And the really important bit. Stainless steel flanges for the manifolds  And a new spigot bearing, which I fitted straight away before I forgot haha  ![]() img.retro-rides.org/i/v/mat88/bba53ee48be1.jpg[/img img.retro-rides.org/i/v/mat88/bba53ee48be1.jpg[/imgFinished off the alternator yesterday.. needed a 25mm and 15mm spacers. Found a lump of stainless bar that looked prime for Job so cracked on and made them.    All finished with proper bolts In place. Seem to have between 745 and 760 mm on the belt so il be able to get a belt easy enough  Got the lower temp thermostat swapped out of my old engine into the new. Also fitted the oil feed and pressure sensor  That brought me roughly up to today.. Made a start on the Manifolds today. There oh see nearly easy to do.. but not quite. The overall length of the bits to make it is 388mm.. the overall length between the holes in the flange are 362mm... In other word I'd got to lose 4mm of each of the joints.. this was going to be fun.. After quite a lot of time (more than il admit).. ended up with this..     Chucked the stainless wire in the mig and set too.. didn't seem to behave how I expected it to.. but after a bit of playing around and a quick tickle with the grinder I've got 1 done! Bolted the flanges together for the welding to stop them warping and it seems to have worked. Still perfectly flat.    Don't get me wrong they would have been nicer if someone with a tig and some ability had done them! But they will work (and look fine wrapped in heatwrap).. There going to work tho, and best of all I've got plenty of clearance now! I couldn't try it on the passenger side. But the drivers side is a mirror image. And I can get 3 inch exhaust under the manifold and above the engine mount! So that looks promising..  Sadly that's it for now. Got to go and collect a load of laminate flooring for the house project (yes it's still ongoing) and Mrs is working all weekend so it's daddy day care til Monday... Fingers crossed il get them finished off next week and look at getting engine back in! Sorry it's a bit jumbled. Cheers |

| |

|

|

|

|

|

|

|

Are diesel alternators still rated ridiculously high because they don't spin them fast enough ? 180A seems quite a lot : 16A to run a V8 (ecu, coils, etc) 20A of lights (headlights, tail, dash, etc) 8A for wipers 8A for heater fan 8A for misc stuff So 60A total assuming you're running it all at the same time. Add 40A for PAS pump so 100A is more than enough. EPAS can peak at up to 80amps on lock or dry steered tho, surely not a bad thing to have more amps output for some headway with charging surely?  Yes, but the battery can supply short duration peak loads so why over-engineer things ? Seems like things are well in hand though. |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

EPAS can peak at up to 80amps on lock or dry steered tho, surely not a bad thing to have more amps output for some headway with charging surely?  Yes, but the battery can supply short duration peak loads so why over-engineer things ? Seems like things are well in hand though. Yeah it's in and should work.. and will leave me with a reserve of juice rather than being borderline.. which is always good! |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 12, 2021 16:59:59 GMT

|

Managed to sneak another hour today. Unfortunately had to go to Birmingham for work and even tho it was only a little job, it's still a 4/5 hour round trip by time I've done.. Had a few bits turn up at work, including a new stainless T4 turbo flange and some new high tensile bolts for the bellhousing (mine were starting to look a bit dog eared from all the times they have been in and out)..  Set to doing the passenger side manifold.. having done one I already knew I could be a bit more generous with the amount I cut off so ended up with this in no time at all.  Then tacked the runners to the flange, before fully welding the runners to each other.. Once I'd fully welded the "log" I then cut the tacks off to clean it up, and clamped the flange to the drivers side one to keep it from warping..  Quick flick round with the flap disc "weld your best and grind the rest"  and I've got two matching manifolds that will work lovely  Now as I said I'm sure they would look nicer if someone had tigged them (my mate who did the old turbo to vband for example).. but this has cost me 11 quid for stainless welding wire, and I've learnt summat. Plus once there heatwrapped you won't see them anyways.. Bear in mind Elate in Australia sell exactly same as what you can see in the pic above, for 480 Australian kangaroo dollars! Plus shipping, import duty, vat and whatever else we get stung for here. These have cost a fraction of that. Offered it up to see what were working with... Yep. That will work!   Whipped the turbo off the old link pipe and had to call it a day. Next step is get the turbo flange tacked in right place with a bracket, then make the link pipe, I'm still aiming for the new exhaust bit to be "finished" this week all being well. Anyways. That's all for now. Cheers |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Member is Online

Club RR Member Number: 77

Member is Online

|

|

Apr 12, 2021 17:25:49 GMT

|

Lovely bit of progress at least  And nowt wrong with log manifolds, that is what Turbo Yoda on the Skid Factory has always done with very good results  What is the plan for the pipe in front of the engine? (And unless you have already bought the wrap, get some of the black stuff. The normal white/cream stuff is an  for showing dirt!) |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 12, 2021 17:44:50 GMT

|

Lovely bit of progress at least  And nowt wrong with log manifolds, that is what Turbo Yoda on the Skid Factory has always done with very good results  What is the plan for the pipe in front of the engine? (And unless you have already bought the wrap, get some of the black stuff. The normal white/cream stuff is an  for showing dirt!) My mate says I remind him of a younger grumpier version of turbo Yoda haha. Difference is he knows what he's doing and I'm winging it 😂 Link pipe will be a similar affair to the old one, but using the nice vbands rather than 2 bolt flanges, and rather than reusing a zafira exhaust, this is all being made from the sch10 stainless same as the logs.. that's tomorrow's job all being well to make a start atleast. I've actually got some 25mm wide "titanium" colour heat wrap on way in hope it's easier to get round the logs, and some 50mm wide for the link pipe. I've also got a load of black I can hopefully reuse from the old exhaust it it's needed. Nothing is white in my world, even just using my tools I have instant black hands haha Cheers for the positive comments, it all helps to keep me motivated haha |

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,239

|

|

Apr 12, 2021 18:55:44 GMT

|

Yeah it's in and should work.. and will leave me with a reserve of juice rather than being borderline.. which is always good! There's an old saying in my line of work, which applies here  "Your better looking at it than looking for it" |

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

Apr 12, 2021 22:49:19 GMT

|

|

The welding on the manifolds looks really good to me, what type of shielding gas do you use to weld stainless?

|

| |

|

|

|

|

|

Apr 13, 2021 11:20:02 GMT

|

The welding on the manifolds looks really good to me, what type of shielding gas do you use to weld stainless? I've always used regular argon/CO2 mix. I think it's the TIG process itself that requires pure argon, and MIG's less fussy. Although saying that I've never done anything that's subject to the sorts of forces and heat expansion a manifold is (and I haven't back-purged before, so I'm probably not the best example to learn from). |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 13, 2021 17:51:36 GMT

|

Yeah it's in and should work.. and will leave me with a reserve of juice rather than being borderline.. which is always good! There's an old saying in my line of work, which applies here  "Your better looking at it than looking for it" Yeah I'd sooner have an abundance of power than run out when I need it most |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 13, 2021 17:52:22 GMT

|

The welding on the manifolds looks really good to me, what type of shielding gas do you use to weld stainless? It looks ok after a tickle with grinder. Aslong as it's strong it doesn't need to be pretty haha |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 13, 2021 17:53:08 GMT

|

|

Also... I'm not sure what your "meant" to use. But I've been using the same argon mix we use for mild at work.. seems to be working this far anyways haha

|

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 13, 2021 17:55:33 GMT

|

The welding on the manifolds looks really good to me, what type of shielding gas do you use to weld stainless? I've always used regular argon/CO2 mix. I think it's the TIG process itself that requires pure argon, and MIG's less fussy. Although saying that I've never done anything that's subject to the sorts of forces and heat expansion a manifold is (and I haven't back-purged before, so I'm probably not the best example to learn from). Don't say stuff like that. Your making it sound like I know what I'm doing and should be welding stuff subject to this level of heat and stresses haha. Saying that it's all been welded with mig set to very lots of amps, there's good penetration (oooh eerrrr) and it seems solid as a rock. I've actually got a decent update coming later if I get half hour without a child round my ankles haha Cheers |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

So the update (that didn't happen last night) haha. Managed to get a fair bit done yesterday. Pictures should explain where I'm up to First job was getting the turbo and flange sat where I needed it so I could make a little bracket to hold the flange in place while I worked. If you remember way back when (seems like a life time ago tbh) I used the old engine crane to hold the turbo and flange. Sat the engine on the trolley and rolled the 2 together. My borrowed engine crane has gone back til I need it again so had to Improvise. Maybe a bit overkill but it worked   And held in place with a little bracket just to hold the flange  Then it was just a simple case of getting two pipes from the manifolds, over the alternator, into the flange. Along with 2 vbands and a flexi. All while keeping enough room to get a 3 inch exhaust down the passenger side. Simple eh  Tbh it took me a fair while to get it something like I'm happy with. But I've got clearance everywhere and it "should" work. The thick wall stainless tube is a lot nicer to weld in the sense it takes plenty of current without going all holy, but there is no movement, it either fits or it doesnt.. and some of my cuts meant it doesn't... Well didn't haha. Anyways less waffle, more out of focus pics..     I've a bit of welding to finish off today, then a bit of grinding to make em prettier haha. Also need to finish off where the pipes join the flange. But just to confirm it will work, that's 3 inch exhaust under the log, above the engine mount. So it "might" work.  Had a critical parcel turn up yesterday... My power steering pump. Looks relatively simple to make work, and it's all in one unit pump, tank, motor everything. High pressure feed, low pressure return couple of wires, bobs your aunties husband!  And where I'm planning on it living, battery is off to the boot and pump can live under bonnet where battery was (tray still needs to come out so will sit lower)  Also grabbed a belt for the alternator on my way home so fingers crossed my measuring is right and it fits.. Anyways. Best crack on with some real work. May get an hour later depending how day pans out. Cheers |

| |

|

|

|

|

|

|

|

|

Bloody hell, that's coming together at a fair old rate!

|

| |

|

|

|

|

|

|

|

|

Can I ask why there's a flexi in the pipe manifold to turbo on the right bank ?

I understand the v-band but ...

|

| |

Last Edit: Apr 14, 2021 9:04:02 GMT by westbay

|

|

|

|

|

|

|

Don't say stuff like that. Your making it sound like I know what I'm doing and should be welding stuff subject to this level of heat and stresses haha. Saying that it's all been welded with mig set to very lots of amps, there's good penetration (oooh eerrrr) and it seems solid as a rock. Cheers I wouldn't sweat it too much. It looks like good thick steel which is positive, and you've chamfered the welds so as you say it should have good penetration. I do know that MIG welds are harder than TIG ones, which makes them more prone to cracking. It's probably worth checking for cracks after running it for a while, but I do wonder how much of the problem is with people trying to save weight and using thin-wall tubing. Can I ask why there's a flexi in the pipe manifold to turbo on the right bank ? I understand the v-band but ... It's to take up the heat expansion in the manifolds, which would otherwise be sandwiched between the two banks. It can move quite a lot with turbo cars, and log manifolds in particular run hot* and don't have much length for taking up that movement within themselves. *That's why they work quite well for turbos. More heat = more energy to spin the turbine. So long as you can control EGTs enough they work better than tubular ones (faster spool). |

| |

|

|

|

|

|

Apr 14, 2021 10:29:03 GMT

|

Ahh! brain in gear now ! thanks  |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Apr 14, 2021 11:23:29 GMT

|

Bloody hell, that's coming together at a fair old rate! I don't mess around when I get time haha. It's getting the time that's the issue. |

| |

|

|

and I've got two matching manifolds that will work lovely

and I've got two matching manifolds that will work lovely

for showing dirt!)

for showing dirt!)