|

|

|

Aug 13, 2020 14:30:45 GMT

|

It's been a good few month since I last updated this post, mostly because the 200E has been on its best behaviour, until yesterday. A few weeks ago I took the 200E to Islington, London N1, on a busy Friday morning. Parking was fun, the 200E just about fitted in the only parking space available for a mile.  I took this arty photo next to an industrial unit, in deepest Slough.  And these two shots inside an old large warehouse located on the outskirts of Thatcham.   It's been very hot and dry lately, hence I've been making regular use of the 200E for both work and pleasure trips. Yesterday, on route from Farnham to Reading, the engine developed a misfire at idle and up to 2,000 revs. The engine bay was bloody hot and I guess the old ignition system developed an issue. I am not a fan of the original design of the HT leads, which are fixed to the top of the engine with plastic trunking. In case the misfire was related to the leads, I removed the trunking and secured the leads away from the cam cover with 3 cable ties.  On route home from Reading the misfire became intermittent rather than constant, so perhaps my assumption about the leads was right. I have ordered new leads, plugs, rotor arm and distributor cap, which I should hopefully be collecting tomorrow. In preparation, I removed everything this afternoon. The distributor cap and rotor arm don't look brilliant.   I replaced the spark plugs some time last year and they're still ok. Although there is evidence of an oil leak, which affects cylinder 3. Cam cover gasket strikes again.  More about the 200E soon, once I sort out the ignition parts. In the meantime, the W123 has passed an MoT, although the steering box needs some more adjustment / overhauling. I did drive it last week, took it to see a client who lives in a proper Berkshire manor. Pretty car next to a pretty house with a pretty sky above.   |

| |

|

|

|

|

|

|

|

Aug 14, 2020 15:26:59 GMT

|

Before removing the old distributor cap and HT leads, I marked where each lead fits on the cap. I thought it would be best if I re-assembled the new parts correctly. I'm clever like that.  I fitted the new plugs, leads, rotor arm and cap. All in, the parts cost me £85. I asked my wife to help me re-fit the leads into the original trunking as I could not manage with just two hands. W124s are brilliantly engineered cars but there are a few design issues that bug me. The HT leads trunking is one of them. The clips used to secure the door cards is definitely another. I digress. I forgot to fit the black plastic cover that slips over the distributor cap. Never mind. With the new parts fitted the engine started up straightaway and idled smoothly. I let it run for a few minutes but couldn't take the car for a drive as there is currently 0.5 tonne of gravel stacked outside my garage, ready for tomorrow's landscaping project. Time and weather permitting I'll test drive the 200E tomorrow. Wish me luck.   |

| |

|

|

|

|

|

Aug 16, 2020 17:45:05 GMT

|

|

I took the 200E for a drive this morning, everything seems to be ok. However, let’s see what happens next time I’m stuck in traffic on a hot day.

|

| |

|

|

|

|

|

Sept 5, 2020 14:36:42 GMT

|

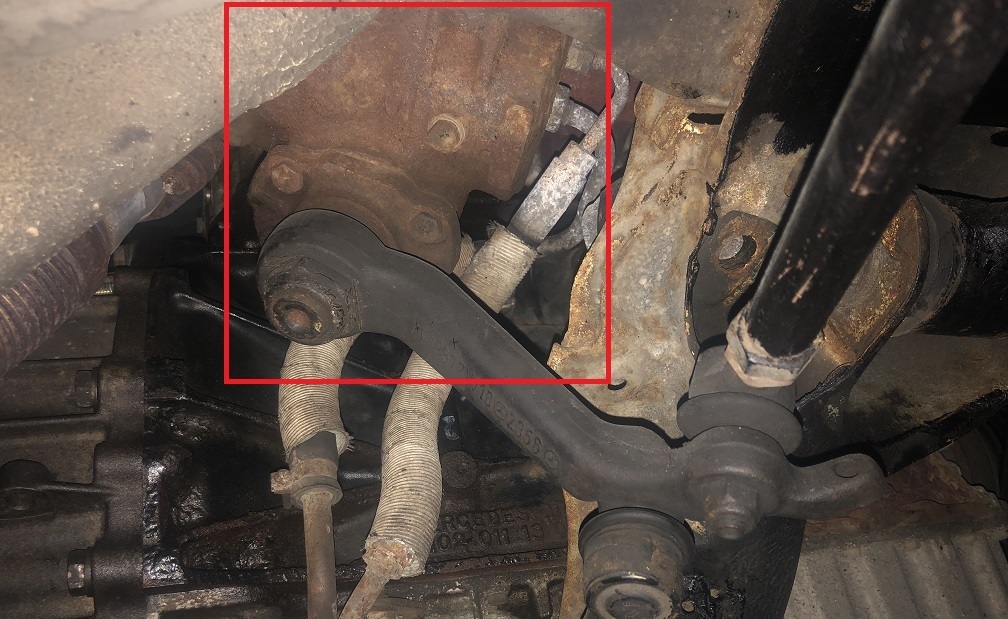

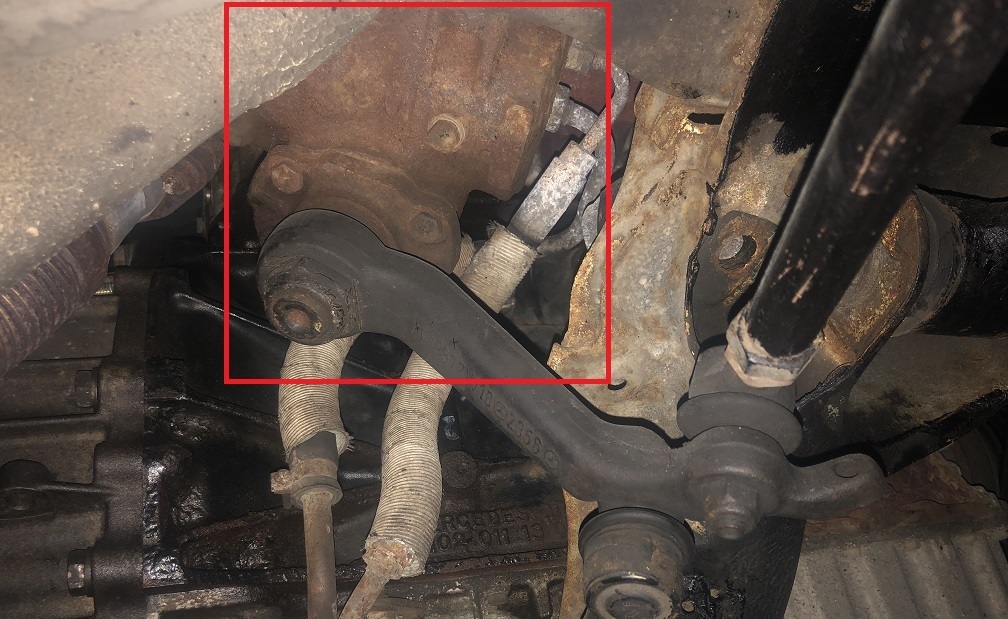

The 200E has been running just fine. The misfire has not returned, however the hot start misfire is still there. This confirms my suspicions that the problem relates to an injector rather than the ignition system. Since passing the MoT, I have not used the W123 due to an ongoing issue with the steering box. The MoT tester, very kindly, passed the steering at the last test but made it clear that attention is needed. There is far too much slack in the system and turning the wheel quickly from left to right and back again causes a worrying clicking sound, which emanates from within the steering box. I found a company in Wakefield, which specialises in overhauling Mercedes steering boxes. They're called Steering Specialists Limited. For £250, which includes courier costs both ways, they will overhaul the steering box, all I had to do is get it off the car. Research on the internet suggests that the task can be made difficult by 35+ year old fixings and a couple of chaps on a Facebook W123 page advised against doing it at home. On a RHD 230E the steering box is visible from the underside but nicely hidden under the exhaust manifold when viewed from the engine bay.   One of the toughest jobs was getting these three bolts out. I've never come across a fixing so rusted and seized.  Anyway, two hours later, I had the steering box out and on my bench. It's a big and heavy old lump! I couldn't get the pitman arm off, a known problem. Hopefully the steering specialist will be able to sort that.  I will update again once I get my hands on the refurbished steering box. |

| |

|

|

|

|

|

Sept 19, 2020 14:37:49 GMT

|

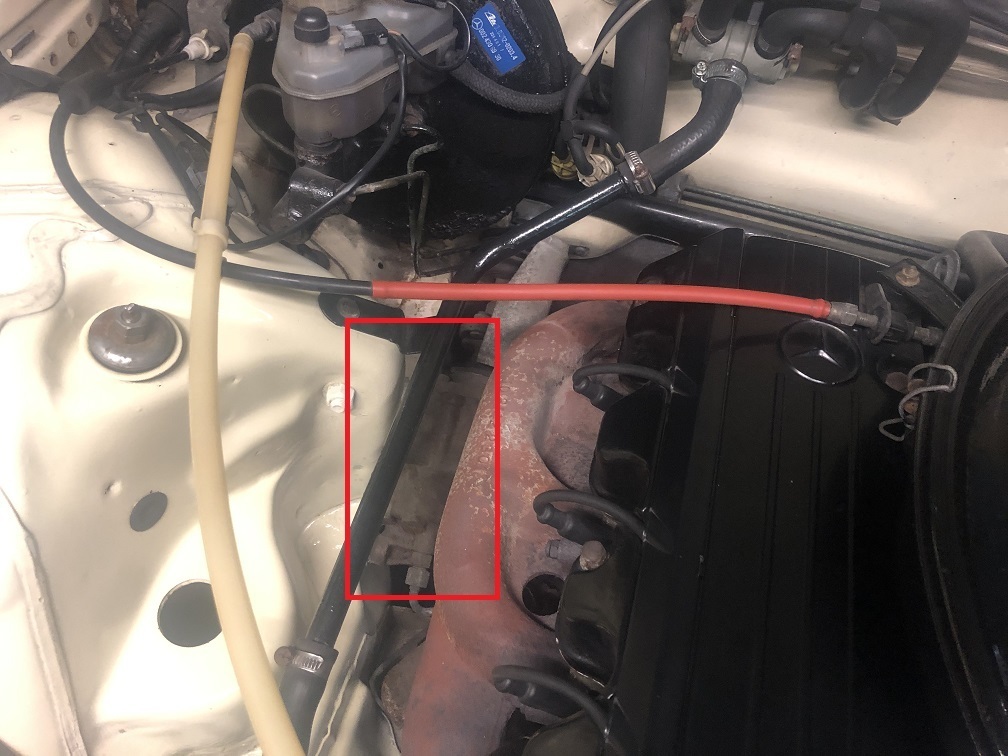

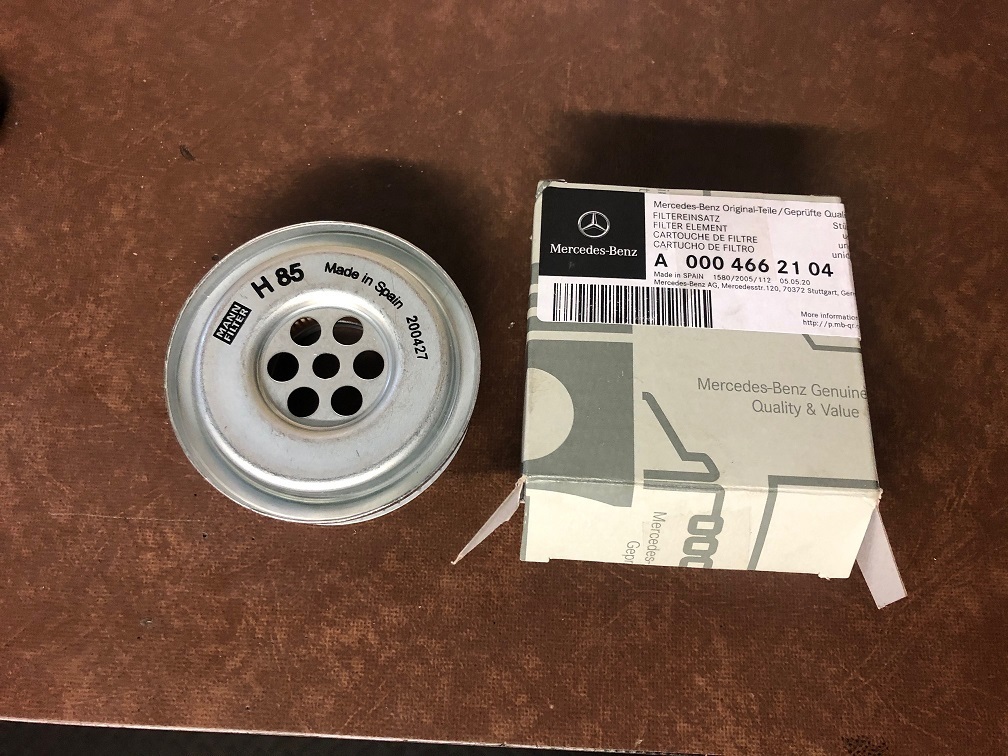

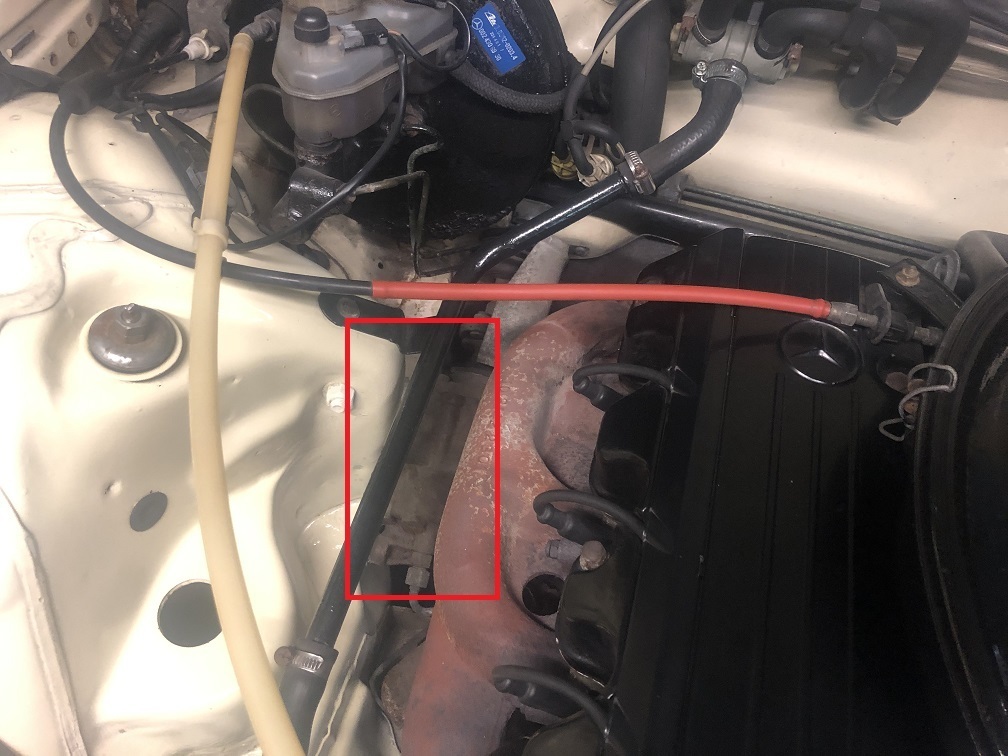

As part of the process of overhauling the steering box I replaced the power steering fluid and filter. I got an original MB filter from my local Mercedes dealer.  Old against new. The power steering fluid has never been renewed or topped up during my ownership (shame on me).  The refurbished steering box arrived (via courier) on Thursday. Apart from being shiny and clean, turning the input shaft revealed significantly less play in the box and a complete absence of alarming clicking sounds.  Despite the relatively small size of the steering box, it's a bloody heavy curse word of a thing. Manhandling it into place from underneath the car and securing the three fixing bolts was a two man job. Actually it was me and my wife that got it back in. Before removing the steering box I forgot to mark up various elements and prior to reinstatement I had to work out at which point the steering box was centralised and align the steering wheel to match, then bolt the two together. I was sure that I got this right, however with everything back together, the first test drive revealed that the steering wheel was approx 60 degrees off centre. Theoretically this should not be an issue, however I have never been able to remove the allen key bolt that secures the steering wheel, which would enable removal and adjustment of the steering wheel location. Despite using my longest power bar and all my strength, I could never shift the bolt.  I had booked the 230E for an appointment at Wheels in Motion in Chesham for a geometry check and adjustment.  I explained the situation to the technician and he agreed that before the geometry could be adjusted, the steering wheel and box need to be aligned. Matey got his power bar out and despite using every Newton that he could exert, the steering wheel bolt would not shift. Then matey brought out his Snap-On electric impact wrench and repeated the exercise. The bolt was loose and off in about 2 seconds. Bingo. With the steering wheel lined up with the steering box, the geometry check and adjustment could begin.  The front wheels had too much toe, which caused excessive wear to the inner sides of the front tyres and made the car nervous in a straight line. The toe was adjusted, however the slight misalignment of the camber and castor (both adjustable on the W123) were left as they were on the basis that all fixings are 35 years old and attempts to release, adjust and re-tighten the fixings could prove to be a nightmare.  On route home from Chesham the steering felt a lot better, especially now that the steering wheel was perfectly straight. One issue that needs attention relates to the adjustment of the steering box. I think that the box has been over adjusted, which causes the steering to bind in the straight ahead position, which makes it very difficult to keep the car driving straight. The steering box adjustment nut is located on top of the box, approx 1/2 an inch below the exhaust manifold. To get to the nut, the engine needs to be lifted off the exhaust manifold. I have everything set up and will adjust the box later this evening / tomorrow morning, once the engine has cooled down. Looks like I'm 95% there. |

| |

Last Edit: Sept 19, 2020 14:42:34 GMT by Peter C

|

|

|

|

|

|

|

Regular readers will know that I've had a long term problem with the 200E's 5 speed manual gearbox. The gearbox would crunch horribly when changing up from 1st to 2nd, unless the process was taken very slowly, preferably with a short pause in neutral but the change was smooth when down changing from 3rd to 2nd. In my opinion this was not a synchromesh related issue but something to do with the selector mechanism. Last year I found a replacement gearbox on EBay, described to be in good condition. I travelled to deepest East Anglia to fetch it (from Buckinghamshire) only to find out upon arrival that the gearbox has been modified. Apparently, the gearbox was mated to a Mercedes V8 engine and fitted to a BMW E30. The bellhousing had an opening cut into it, to accommodate a larger starter motor and the holes for bolts that connect the gearbox to the engine have been enlarged. Despite these issues, the seller claimed that the gearbox was in good working condition. In the end I got the gearbox for free. A couple of weeks ago I decided to clean up the gearbox and find a local mechanic to do a gearbox swap for me. I was quoted £150 for the job, which I thought was reasonable. I delivered the car and replacement gearbox to the mechanic on Tuesday and all being well I should have had it back yesterday. As I am writing this today, clearly things have not gone according to plan. First time the mechanic called me yesterday was to say that the vibration damper on the propshaft is knackered. A Febi replacement soured from the internet costs £60 inc p&p. An original part from my local Mercedes dealer costs £157 plus VAT and would not be with me for 10-12 days. I told the mechanic to leave the damper as it is and crack on with the gearbox swap, on the basis that I will fix the damper myself in due course. Then came the second call. The input shaft on the replacement (modified) gearbox has been machined down by approx 12mm. This was done professionally and without the other gearbox along side it, I had no way of knowing that the replacement gearbox is scrap. Whilst working from home, a quick look on EBay revealed a suitable Buy It Now gearbox for sale in Epsom, only 40 miles away from me. I bought it, the seller's phone number appeared on the screen, I gave him a call and arranged to collect the gearbox within 2 hours. By 5pm, I had delivered the new replacement gearbox to my mechanic. This latest bit of kit was once fitted to a W201 (190E) Mercedes, however to the best of my knowledge, it is the same as gearboxes fitted to W124s. The casing number even starts with 124... The gearbox is filthy but the seller claims that it is in good working condition. I guess time will tell. By placing this gearbox alongside the other two revealed that the flange and doughnut fixed to the output shaft are smaller, however these can be easily swapped. All being well, the 200E will be ready for collection tomorrow. The job will now cost more that £150 but if everything works out, I will have a crunch free transmission. Have some pics.     |

| |

|

|

|

|

|

|

|

Sorry to hear of your tales of gearbox woe. Sometimes throwing money at an issue can solve it and save masses of time too so good on your for just doing it and buying that other one. Hopefully you'll be able to sell the one your bought to at least recoup something. The 123 seems to have built to a spec, rather than a price - just seems to have a depth of engineering most cars lack. I bet it rides well (and perhaps is just a smidgen too slow?) Either way - enjoying your trials and tribulations. And clearly you married the right girl when she's prepared to get stuck in on the car stuff too. Excellent!  |

| |

|

|

|

|

|

|

|

Peter C I love reading about your 2 saloons. I like a Mercedes (I have an SLK as a daily) and particularly like your methodical approach to fixing things. Your two are both lovely motors and a credit to you.

|

| |

|

|

|

|

|

|

|

Sorry to hear of your tales of gearbox woe. Sometimes throwing money at an issue can solve it and save masses of time too so good on your for just doing it and buying that other one. Hopefully you'll be able to sell the one your bought to at least recoup something. The 123 seems to have built to a spec, rather than a price - just seems to have a depth of engineering most cars lack. I bet it rides well (and perhaps is just a smidgen too slow?) Either way - enjoying your trials and tribulations. And clearly you married the right girl when she's prepared to get stuck in on the car stuff too. Excellent!  Thank you for the feedback. When my mechanic told me that the replacement gearbox was no good, I could have told him to re-fit my original one, paid him the agreed £150 and left it at that. Trouble is, I would still have had a car with a defective transmission and I'd be no better off. I was lucky that I found the right gearbox on EBay, for a good price, not far from me and that the seller was a top bloke. See update below, I will keep the replacement gearbox and extract parts to help fix my original gearbox. The W123 is a little more powerful than my 200E and feels it out on the road but only in a straight line. Dynamically, it drives like an old car, with a soft ride and rolly polly handling. |

| |

|

|

|

|

|

|

|

Peter C I love reading about your 2 saloons. I like a Mercedes (I have an SLK as a daily) and particularly like your methodical approach to fixing things. Your two are both lovely motors and a credit to you.  I appreciate the feedback. I enjoy tinkering with my cars and sharing my experiences with others. It's great that at least a few people read and benefit from my updates. I've seen a few SLKs for sale and was almost tempted to buy one, they are such great value for money. Thing is, my penchant is for sedans, not sports cars and I wouldn't be able to share my journeys and experiences with my family. |

| |

|

|

|

|

|

|

|

|

|

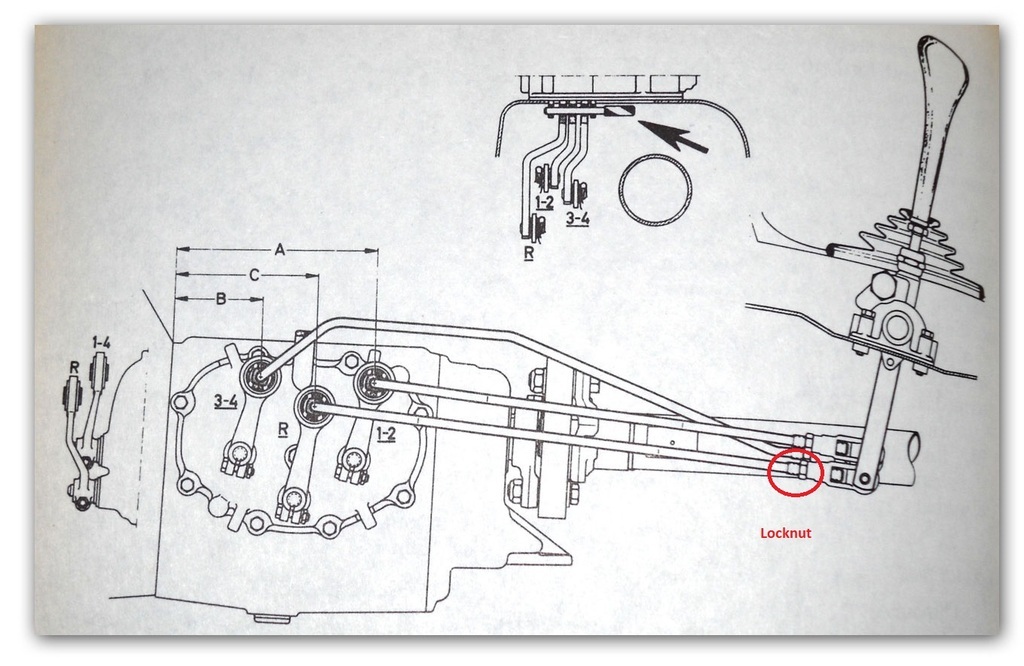

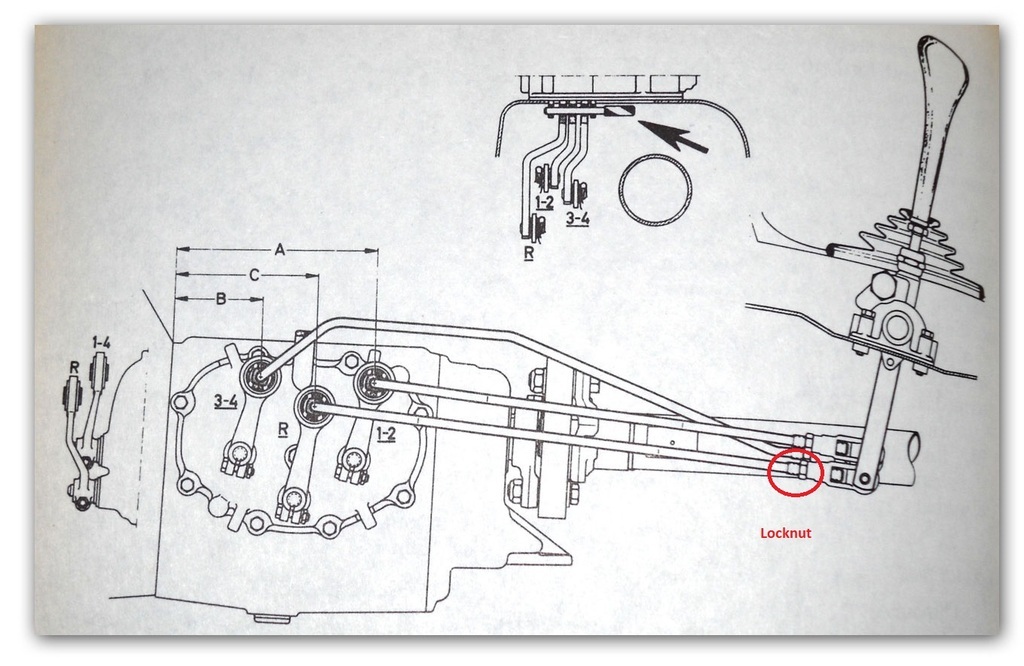

So, on route home yesterday I popped over to see the mechanic. The 200E was still on jacks, the gearbox was in (hoorah!) but the propshaft and exhaust still needed refitting. I was told to come back in an hour.  Just because the gearbox was in, it didn't mean that it would be any good. I returned to collect the 200E at 5:45pm, suitably dressed in case I was going to get dirty. With everything reassembled, we pulled the 200E out of the workshop and the mechanic asked me to start the engine and select all gears. Whilst I could get 3rd, 4th, 5th and reverse, the gearstick would not move across to the left of the gate to enable selection of 1st and 2nd gears. The first two gears could only be selected if I pushed the gearstick forward by approx 5mm, then to the left but even then the movement was very clunky. Getting the gearstick back to the central position took a lot of wiggling. We concluded that the rod that links the gearstick mechanism to the selector lever on the gearbox needed adjustment. The rod has a locknut, which, once released, allows the rod to be lengthened or shortened.  Following a little trial and error, the mechanic got the length of the rod just right and with everything reassembled I could easily select all gears. By then it was dark and cold and I decided to put the other two gearboxes and left over parts in the boot and drive home.  I reversed out of the mechanic's yard and onto the road. With the original (faulty) gearbox fitted, I often had problems selecting 1st gear from standstill and there was no way I could get the 'box into 1st gear if the car was moving. To my immense satisfaction, 1st gear went straight in, then 2nd, then 3rd, then 4th and 5th. No crunching, no whining, no rumbling, I finally had a fully functioning gearbox. The first replacement gearbox did not cost me anything and truth be told I enjoyed my journey to East Anglia to collect it. The second gearbox cost me £95 and less than £10 in diesel to collect it from Epsom. I agreed to pay the mechanic £150 to swap the gearboxes over, however in the end I gave him £200 to cover the additional buggeration factor. I'm a happy man. The first replacement gearbox is scrap. It's been modified and its condition remains unknown. However, rather than throwing it away, I propose to open it up and see how the internal bits compare with those in my original gearbox. If I am lucky, it might be possible to salvage something from the replacement gearbox and fix the original one, but that's something that I propose to leave for another day. |

| |

Last Edit: Oct 10, 2020 5:48:17 GMT by Peter C

|

|

|

|

|

Oct 10, 2020 10:59:50 GMT

|

|

Good to hear about the box. You should invest in a Delrin gear linkage bush kit as that would transform gear selection. Keep up the good work.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

Oct 27, 2020 15:05:28 GMT

|

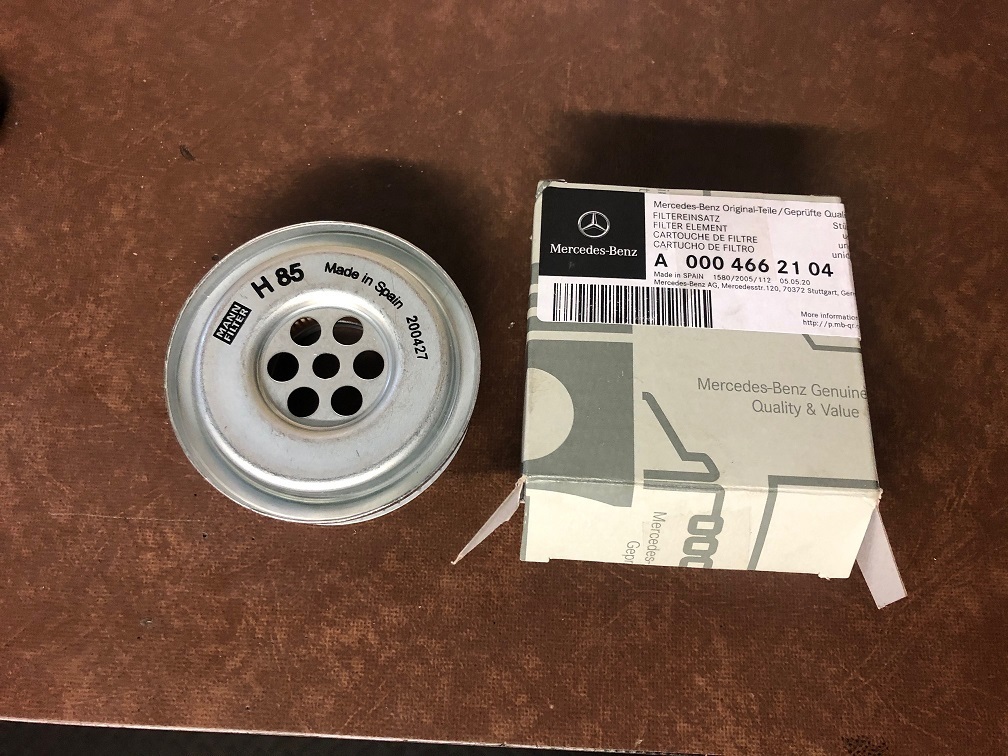

According to a classic car magazine that shall remain nameless, certain old Mercedes steering boxes feature a drain plug, which allows hassle free PAS oil changes. Sadly, my W124 does not benefit from this feature. Over the past few weeks, on numerous occasions I syphoned out fluid from the PAS reservoir and re-filled it with fresh ATF. The trouble is that every time I do this, I only get to change approx 50% of the fluid that is in the PAS system, with the other 50% left in the pipes and steering box. I managed to drain, refill and mix approx 600mm of fresh ATF.  Earlier today I syphoned out the contents of one more reservoir.  This time I also removed the PAS reservoir filter and got as much oil out as possible.  I bought a genuine MB (made by Mann) PAS reservoir filter.  I fitted the new filter and topped up the PAS reservoir with fresh ATF. I reckon that approx 75% of the oil is now new, which is not ideal, however I do not want to start removing the PAS pipes and attempt to drain more oil and in the process disturb or damage something that will cause more problems in the future.  |

| |

|

|

|

|

|

Oct 27, 2020 21:41:07 GMT

|

|

The method you're using is fine for changing the PAS fluid. What I do is suck the reservoir, refill and start the engine and turn the st.wheel from lock to lock about four times and syphon the reservoir again. Do the same again in 12 months and that should be it for a few years.

I suspect the correct method is to drain from the return line (low pressure) but being candid I'm adverse to disconnecting old hydraulic hoses/pipes.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

Oct 28, 2020 13:10:44 GMT

|

|

Great thread. Nice cars.

Best way to bleed the PAS is, as mentioned above, disconnect the return and redirect it to a catch pail/bucket. Then, with engine running, keep topping up the reservoir with fresh fluid whilst gently turning the wheel lock to lock until it all runs lovely and clear red with no bubbles, then connect it all back up. Viola.

Usually easier with two persons (one on the steering wheel & one at the reservoir) with the front end on axle stands. Do not let the reservoir run dry or the car roll back off the stands whatever else happens!!!

Done a few now, first one was a bit twitchy, but much easier now I know whats what.

Have fun 😀

|

| |

|

|

|

|

|

|

|

|

Thank you for the advice gents.

As I've said, I know how to drain all the PAS oil from the system but that is something I'd rather not get involved with right now. I have managed to replace a large proportion of the oil and I have also fitted the new filter. Fingers crossed, the PAS system will be happy for the foreseeable future.

|

| |

|

|

|

|

|

|

|

It's been a good few month since I last updated this post...   Glad you updated as I had not spotted your thread. Hat off to you sir for keeping two old Mercedes still rolling and in fine fettle. I do miss my W123. Should not have sold it. I was stupid. Here it was...   Keep up the good work. |

| |

|

|

|

|

|

|

|

11 years ago today I bought my W123. Happy anniversary old friend.  |

| |

|

|

|

|

|

Nov 13, 2020 15:58:13 GMT

|

Right, as matters stand, my daily for the past 3 years Hyundai Tucson has gone back to the leasing company, the Audi TT that I bought and turned out to be a giant defective disappointment has been returned to the dealer I bought it from and my next lease car, a Kia Xceed, is not due to be delivered until the end of the month. This leaves me with the 200E, which is now being used for daily duties, with the W123 on stand-by, although technically I'd rather walk 25 miles to a work appointment than drive the W123 in the wet. Some cars are meant to be driven but not my W123. The exhaust on the 200E is 29.5 years old and during my ownership the rear box has received at least three coats of silver Hammerite.  I noticed earlier this week that the exhaust has started to blow. I jacked the car up and investigated.  A little prodding revealed a rotten back box, where the tailpipe joins the box.  I am now actively looking into purchase a new centre and rear box, however getting the right parts may not be easy. As a short term repair, I bought a tin of this stuff.  Bearing in mind that all I am doing is sealing up holes in the tailpipe to box joint, hopefully the repair will last a couple of weeks. The tailpipe is quite short and it doesn't weigh much, so hopefully the remaining metal plus my repair will be strong enough to prevent it from falling off. The putty is good for 160 deg C, which is a lot more than the temperature of a fully warmed up back box. Once mixed with hardener, the putty had the consistency of chocolate sauce and is not the easiest product to apply. The repair is not pretty but having left it for an hour to harden, I can confirm that it feels solid as a rock and the exhaust is no longer blowing.  |

| |

|

|

|

|