|

|

|

|

|

Hi folks Sorry for the lack of updates - my father has been ill with cancer and passed away this month, so family matters have taken precedence. On a more cheerful note, my cousin is getting married this September in Cambridgeshire, and I have offered to drive her to the church in the jag. So I thought I ought to give it a bit of a check over and bring it up to scratch. So I've made a list of stuff to do - and thought I would start with the tyres as they were on the car when I bought it in 2012. They look fine, but having heard of horror stories of aging tyres giving out on the motorway, I thought I had better check the date stamps - the front tyres have some numbers (0404) and (1305) both of which could be the date stamp - suggesting I think either 2004 or 2005 production dates. The back tyres have no numbers which I can see which look like date stamps - any bright ideas? As the fronts seem to be over 10 years old I think I am looking at changing all four. A wise decision and one that I would wholly endorse - From much previous experience I can recommend the excellent guys at Longstone Tyres who really do know what they are talking about when it comes to supplying & fitting tyres to classic cars - although they are a couple of hundred miles from me - they normally ship to me the following day of the order and my local tyre centre fit them for a small fee longstonetyres.co.uk/ |

| |

Last Edit: Jul 7, 2019 19:20:30 GMT by Deleted

|

|

|

|

|

|

|

|

|

|

So sorry to hear about your loss. Yes those tyres are old the first number is that week number of the year and the second is the year .

|

| |

|

|

|

|

|

Oct 14, 2019 13:03:09 GMT

|

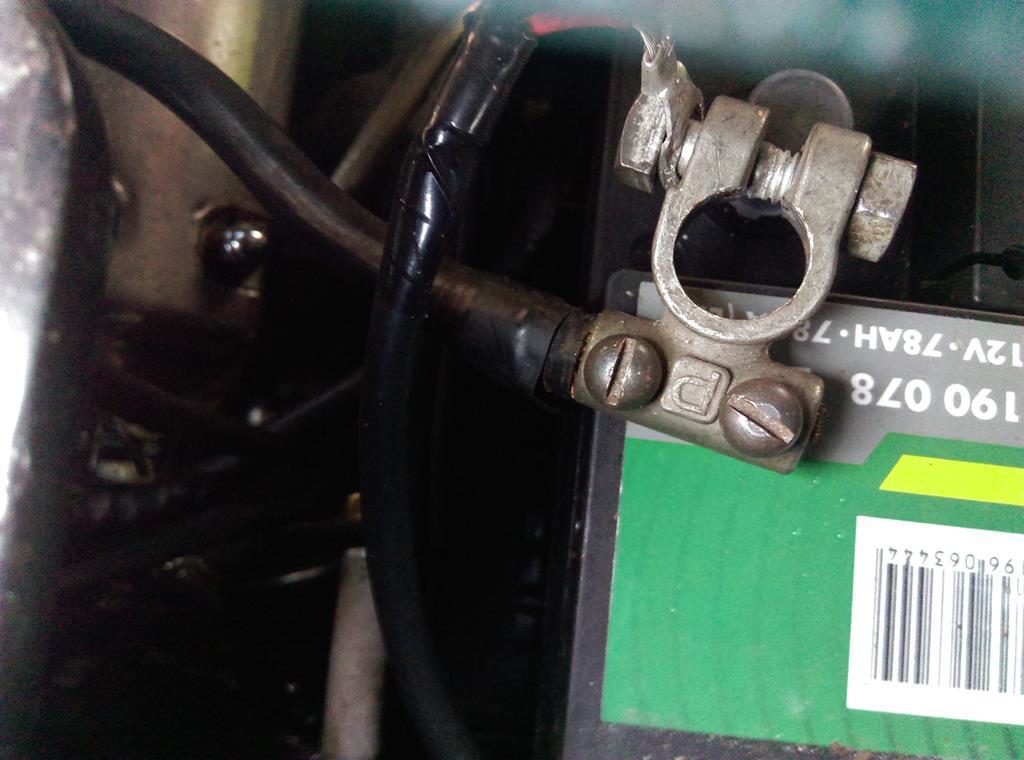

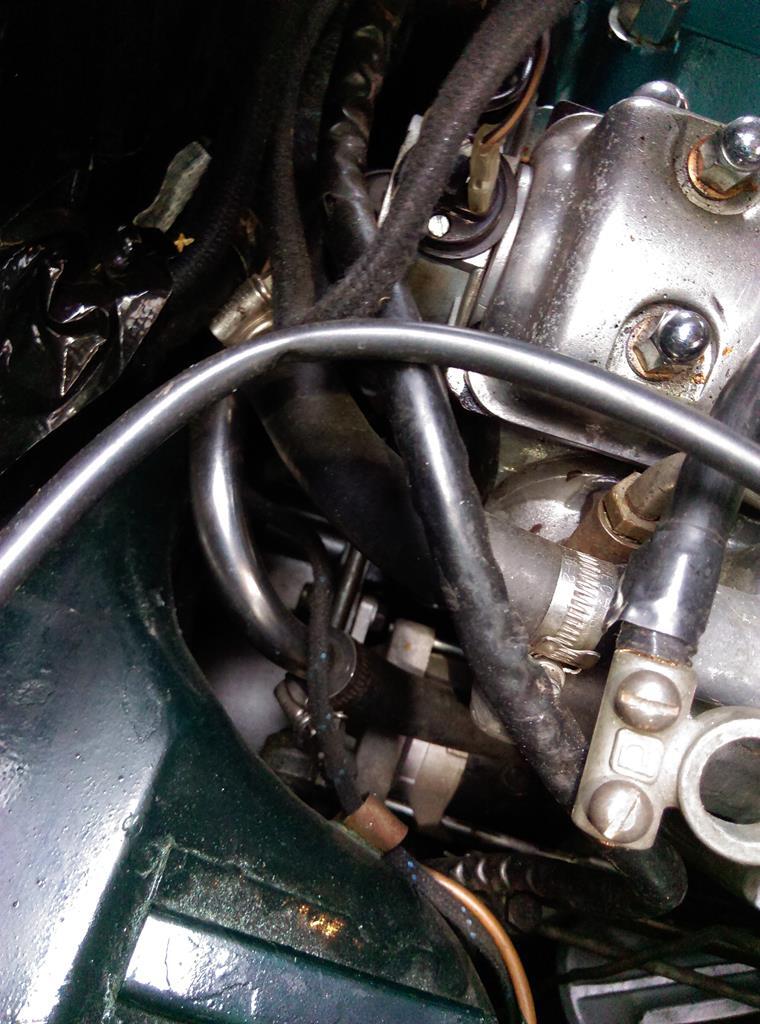

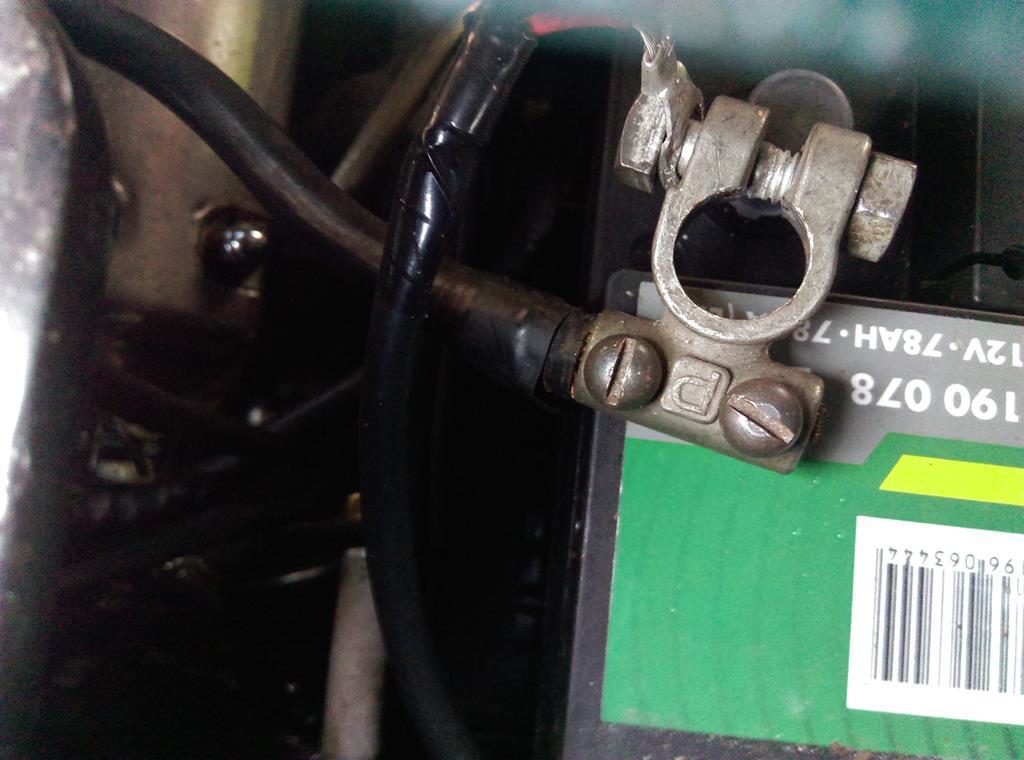

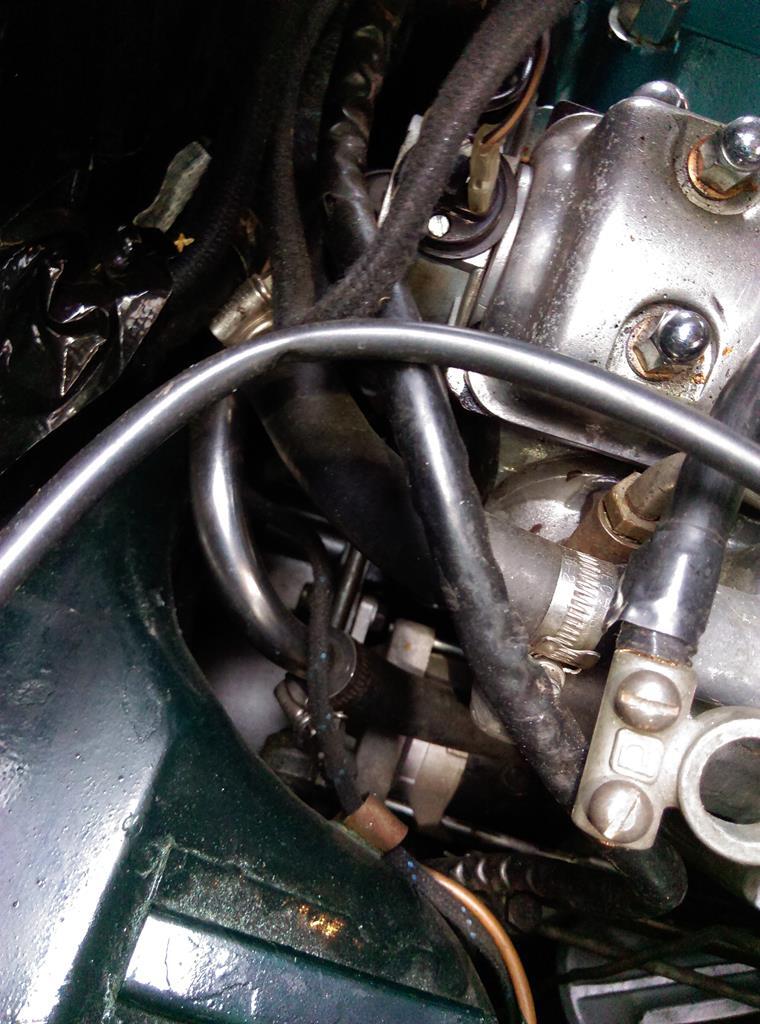

It's been a while - been putting the Jag to use - went to Goodwood Revival and used it as a wedding car for my cousin's wedding. So, having driven it to Suffolk and back without any hitch, I decided to drive it work while the weather was vaguely dry. All is well until I start it to come home, whereupon it graunches a bit and then has a constant rubbing noise. Hmmmm....sounds like the starter motor has worked loose. Last Friday evening while SWMBO was out running, I thought I would check to see what was what. Now, the Mk2 Jaguar is possibly the most awkward and inaccessible cars to work on, so I peered into the depths of the engine bay to try and see if the starter motor was indeed loose.  Can you see it? No? Its the thing to the right of the wiring loom with two long thin bolts - the photo is taken later once I had removed the battery. Well, I poked it with a stick and the starter moved, so I figured, yes it's loose! Last Saturday as it was raining so no gardening chores were possible, I blagged some time in the garage to sort it out. In the meantime the rubbing noise had got worse so I didn't want to drive it, so pushed it far enough to get the jack in and jack up the front.  Removed the front wheel and slid underneath to see if I could reach the starter from there:  Hmmm - not really - can you see it? Its above the curvy bit of rusty steel! Easy! So, there is no room for a spanner, but two ratchets, with various lengths of extension bar and long reach sockets I managed to tighten it up enough to start the car without it rubbing on the flywheel, but not after dropping the ratchet on my head and swearing. A lot. Lunch hour over now - so more later. |

| |

Old Fords never die they just go sideways

|

|

|

|

|

Oct 14, 2019 14:35:01 GMT

|

|

Mk2's are terrible to do anything around the bell housing unless you have access to a ramp or a two poster, axle stands and trolley jack just don't cut it for ease of access or safety as the car is so dam heavy.

Well done not an easy job to do on a garage floor lets hope it stays there now.

|

| |

|

|

|

|

|

Oct 14, 2019 18:09:02 GMT

|

Next installment! So having got the bottom bolt of the starter tightened up, I figured I needed to also tighten the top one, on the basis that both must have been loose in order for the starter motor to be wobbling about. Refer to uncle Haynes for guidance:- 1. Disconnect the power supply to the starter motor. 2. Push the two front seats back as far as they will go and remove the seat bases. 3. Unscrew the gear lever knob. 4. Unscrew the knurled knob which secures the centre console. 5. Pull the centre console up and back. 6. Remove the side panel concealing the radio gubbins (I'm paraphrasing) 7. Disconnect the heater pipe. 8. Pull back the carpet 9. Find a circular access hole and unscrew it. 10. Gain access to the rear nut on the starter motor..... Really! So, probably best to turn the car round as the garage isn't the biggest, and tightening one bolt seemed to have secured the starter enough to stop it rubbing on the flywheel.  Actually, it wasn't as bad as it sounds - the seat bases just pull off. But the aftermarket seat belt stalks got in the way of the centre console sliding "up and back" so off they came - then the console won't clear the seat back, but it came out enough to get to the rest.  Well, this circular access hole.....  Can you see it?  There it is - I was kind of expecting something you could swing a spanner in, but hey it is a Mk2 Jag! Peering down from the top of through the gap between the scuttle and the bonnet - I could see precisely nothing.  So out came the battery.  Now, I could see the top bolt - and see I needed to access the nut via an extension bar from inside the car. Pushing the bonnet up as far as it would go and propping it on a bit of wood meant I could squeeze my arm down between the scuttle and the bonnet I could just about get a spanner on the top bolt - what you do if you don't have skinny arms I know not! Time for tea - back later  |

| |

Old Fords never die they just go sideways

|

|

|

|

|

Oct 14, 2019 19:10:34 GMT

|

Having established that my arms aren't six foot long and double jointed, I recruited SWMBO to help, turning the ratchet while I held the spanner. All is well and tightened up. Lets chuck the battery in and check it starts - yup, it starts but with a constant grinding noise. A bit of background to my particular Mk2 - it was built in South Africa as an automatic, and imported to the UK and probably at the same time given a quick tart up and converted hastily to manual overdrive. The XK engine was used in many different cars, and the parts to do the manual conversion can come from many different sources, and there are some combinations of bell housing, engine, gearbox and starter which don't quite line up - guess what my car has just such a combination. So the starter has to be spaced off the mounting flange by about 1.5mm in order to mesh correctly with the ring gear. I wondered what that odd shaped washer on the garage floor was.  Yup it was one of the spacer washers used to align the starter! So the starter needed loosening off and the washers inserting - good job I tried to start it before putting it all back together! So, loosen off the bolts and realise I only had one washer - so into the stash of random nuts, bolts and washers and actually found one of the right size (usually I have to do a ten mile round trip to buy such things!) out with the grinder and cut a slot out. Slot in the washers, what a pain in the fox picture that was - then with the assistance of SWMBO bolt it all up again and.... It only works! Interior back in and we are good to go. And this is what it looks like when it is all primped up for wedding duties.  |

| |

Old Fords never die they just go sideways

|

|

|

|

|

Oct 14, 2019 19:11:52 GMT

|

Mk2's are terrible to do anything around the bell housing unless you have access to a ramp or a two poster, axle stands and trolley jack just don't cut it for ease of access or safety as the car is so dam heavy. Well done not an easy job to do on a garage floor lets hope it stays there now. I hope so too - I've got heavy duty axle stands and jack, but would much prefer to do it on a ramp! |

| |

Old Fords never die they just go sideways

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,889

|

|

Oct 14, 2019 21:07:19 GMT

|

Ah-ha, so that explains what that hole is for in my Daimler 250! You think it's fun with a straight 6 in that bay you should try working round a v8 in the same space, haha. That said, the starter on the v8 is actually on the other side of the engine and relatively easily accessed, it's just everything else that's impossible... Lovely colour on this Mk2, looks great in the sun in that last photo.  |

| |

|

|

|

|

|

Nov 22, 2020 17:48:22 GMT

|

It's time for the annual Jag service! Well, not a full service, just changing the oil and filter- exciting stuff!  So did I learn anything from last time - well I put the oil drain tray well over to one side and not under the oil plug. Carefully undid the drain plug and watch the oil squirt half way across the garage missing the tray completely!  So far so good. Took the oil filter housing off and spilt more oil on the floor! One thing I did remember from last time was the importance of getting the o-ring to seat correctly in the oil pump housing so it doesn't leak everywhere! Only minor problem was the new o-ring was much fatter than the slot it goes into and wouldn't sit in place - the old one was much thinner and was still in usable condition so that went back in. Put a bit of oil in the filter housing and popped it back on - so far so good. Measured out six litres of oil and filled up the engine checking for drips - all good. Oil seems to be registering on the dip stick so back on the ground for a fire up. Fired her up - got some oil pressure - checked underneath and no oil p1ssing everywhere like last year - excellent! Check the dipstick - oil is just barely registering on the bottom - so put some more oil in, check - repeat etc etc. Got up to 7.5litres of oil which is supposed to be the capacity of the engine, and still it is only up to the minimum mark on the dipstick - put a bit more oil in, check the dipstick - and something drops on the ground under the car with a cheerful metallic tinkle. I peer under the car - what's that black tube? Ah - the dip stick tube has only gone and snapped off where it goes into the engine! Damn and blast!  As is typical of the jag the dip, stick tube is singularly inaccessible - behind the exhaust manifold (why, given that all the early XK engine cars had cast two part manifolds of more or less the same design couldn't they have moved the dipstick hole a little further back to be easier to get to?).  It's down there in the dark! The tube has snapped off flush with the casting, so I can't see any way of getting the remains out without risking getting debris in the engine. So it might be a job for the professionals. I also noticed that the oil pump housing where the oil filter goes on has a dent in it- I wonder if there is a more modern oil pump with a spin on oil filter which is a bolt on swap (XJ6 perhaps) - anyone know? cheers Cortinaman |

| |

Old Fords never die they just go sideways

|

|

|

|

|

Nov 22, 2020 18:39:45 GMT

|

|

Don't know what it's like getting the sump off a mk2 if you can you can probably drift the stub out from underneath.

Another option might be to screw a large self tapper in and pull it out with a slide hammer.m

|

| |

|

|

|

|

|

|

|

Nov 23, 2020 13:37:48 GMT

|

Don't know what it's like getting the sump off a mk2 if you can you can probably drift the stub out from underneath. Another option might be to screw a large self tapper in and pull it out with a slide hammer.m If its anything like every other job on a Mk2 it will be a pain in the ar$e! Good idea with the self tapper and slide hammer. |

| |

Old Fords never die they just go sideways

|

|

|

|

|

Nov 28, 2020 17:04:01 GMT

|

As I was in the garage looking for Cortina wheels I thought I would see if I could get my head round dealing with the snapped dipstick tube with a little more light. Well here it is:  See the little orangey coloured ring - that's it - well hidden behind the rear exhaust manifold. A bit of web research suggests a 3/8 or 10mm tap could cut a thread for a bolt to be wound into it which might be better than a self tapper, but first I have to get the manifold off as there is no way of gaining access with it in place. Might have to wait until Christmas! cheers Cortinaman |

| |

Old Fords never die they just go sideways

|

|

|

|

|

|

|

See the little orangey coloured ring - that's it - well hidden behind the rear exhaust manifold. A bit of web research suggests a 3/8 or 10mm tap could cut a thread for a bolt to be wound into it which might be better than a self tapper, but first I have to get the manifold off as there is no way of gaining access with it in place. Might have to wait until Christmas! cheers Cortinaman So I'm not the only one where a simple oil and filter change goes to rat-poo then? I've got something blocking the sump drain, although I originally thought the oil had finished draining. Then filled up with 5.5L (it takes 6.6L with the filter, which I'd prefilled), dipped it and it's miles up the stick. Drop the plug again and only drips. So now it sits, with probably 7 or 8 litres of oil in it until my vacuum oil drainer arrives. Then sump off.  Bolt sounds a good method, just stuff plenty of grease in the hole to catch any swarf. |

| |

|

|

|

|

|

Nov 29, 2020 17:08:20 GMT

|

To be honest georgeb pretty much anything I do to that car goes to sh*t of some sort! Good point on the swarf and grease. Good luck with the P38 oil change v2. Cortinaman |

| |

Old Fords never die they just go sideways

|

|

|

|

|

|

|

|

So, the excitement continues - I had a crack at getting the manifold off yesterday to get at the remains of the tube, but ended up not being able to get to to the manifold nuts with any sort of sensible tool! So I have admitted defeat and spoken to my friendly local mechanic, to see if he can help me out - he can but not until January (which is fine as I don't tend to use the Jag when the roads are salted). But he did ask that I source the parts needed, including the dipstick tube.

It is not something that is remanufactured and stocked by any of the major Jag spares suppliers, but it is just a steel tube with a funnel, so shouldn't be hard to remanufacture. I've spent this morning looking for suppliers of 7/16 OD mild steel tube (which is what I have measured the tube as) and so far drawn a blank. The closest I have come is European Tubes in Wigan who could sell be a 5.8m length at £59 +VAT + shipping. My local specialist metal stockist don't have any tube of the right diameter but did suggest machining down a larger diameter tube - which is always an option if I can find someone with a lathe.

Any thoughts on steel suppliers I might try? Cheers folks

Cortinaman

|

| |

Old Fords never die they just go sideways

|

|

|

|

|

|

|

Just a thought - have you tried contacting a Jaguar specialist? They quite often have various s/h spares on the shelf. A friend of mine works at the firm below - very friendly service. They specialise in older Jags and may be able to offer some advice or may have the part on the shelf. suffolkclassicservices.com/ 01728 745055. |

| |

|

|

|

|

|

|

|

Just a thought - have you tried contacting a Jaguar specialist? They quite often have various s/h spares on the shelf. A friend of mine works at the firm below - very friendly service. They specialise in older Jags and may be able to offer some advice or may have the part on the shelf. suffolkclassicservices.com/ 01728 745055. Thanks mrbounce - I'll give them a try. |

| |

Old Fords never die they just go sideways

|

|

|

|

|

Dec 15, 2020 14:01:12 GMT

|

A quick update. Having tried to source some suitable diameter tube to recreate the dipstick tube - with no results (apart from being able to buy 5m of 3/8 OD tube for £50 + VAT + shipping, to get the 6" length I actually need), I took mrbounce advice and tried a jag specialist. Ken Jenkins ( ukjag.co.uk ) came up trumps with a tube from one of many engines he has lying around. Phoned on Thursday - arrived on Monday.  Also ordered studs, gasket and new nuts for when the manifold comes off from SNG Barratt.  Looks like I've got everything I need, and my mate's garage should be able to do the work in January (unless I manage to find a way to get the manifold nuts undone in the meantime!) |

| |

Last Edit: Dec 15, 2020 14:01:43 GMT by cortinaman

Old Fords never die they just go sideways

|

|

|

|

|

Dec 15, 2020 14:12:39 GMT

|

Fantastic! This is what I love about this place - advice everywhere. I get so many tips and ideas from other peoples' threads I am so glad I could give something back!  Good luck getting it sorted  |

| |

|

|

|

|

|

Dec 15, 2020 14:27:56 GMT

|

Fantastic! This is what I love about this place - advice everywhere. I get so many tips and ideas from other peoples' threads I am so glad I could give something back!  Good luck getting it sorted  It's amazing how sometimes you miss the blindingly obvious, so all advice is good! I must confess I had assumed (on the basis of no science whatsoever) that I stood no chance of getting a replacement, that I didn't even bother looking beyond an ebay search, and I was amazed when the first place I tried knew exactly what I was talking about and actually had one!  |

| |

Old Fords never die they just go sideways

|

|

|

|

It's down there in the dark!

It's down there in the dark!