|

|

|

Feb 17, 2020 12:12:22 GMT

|

|

ive converted a few single sockets to double sockets in houses like these, chain drilling, chiselling, fitting the double back boxes.

have to agree on the granite like strength cinder blocks back then, by comparison the new breeze blocks you can literally gouge with a screw driver like flower arranging "oasis"

|

| |

Last Edit: Feb 17, 2020 12:15:05 GMT by darrenh

|

|

|

|

|

|

|

Feb 19, 2020 22:11:50 GMT

|

ive converted a few single sockets to double sockets in houses like these, chain drilling, chiselling, fitting the double back boxes. have to agree on the granite like strength cinder blocks back then, by comparison the new breeze blocks you can literally gouge with a screw driver like flower arranging "oasis" When I've done it here I've used an air hammer. You barely touch the block but the thousands of tiny blows reduce it to powder without damaging the bits you want to leave alone. It does a really accurate job. My air hammer exhausts the air out of the front so it actually cleans the opening as it goes. And the bad news... It's a quite unbelievably dirty way to do it. Dust goes everywhere and I wind up looking like a reject from the Black And White Minstrels Show. Even for the most anti health and safety person a damn good mask and goggles is essential. |

| |

|

|

|

|

|

Apr 23, 2020 10:22:03 GMT

|

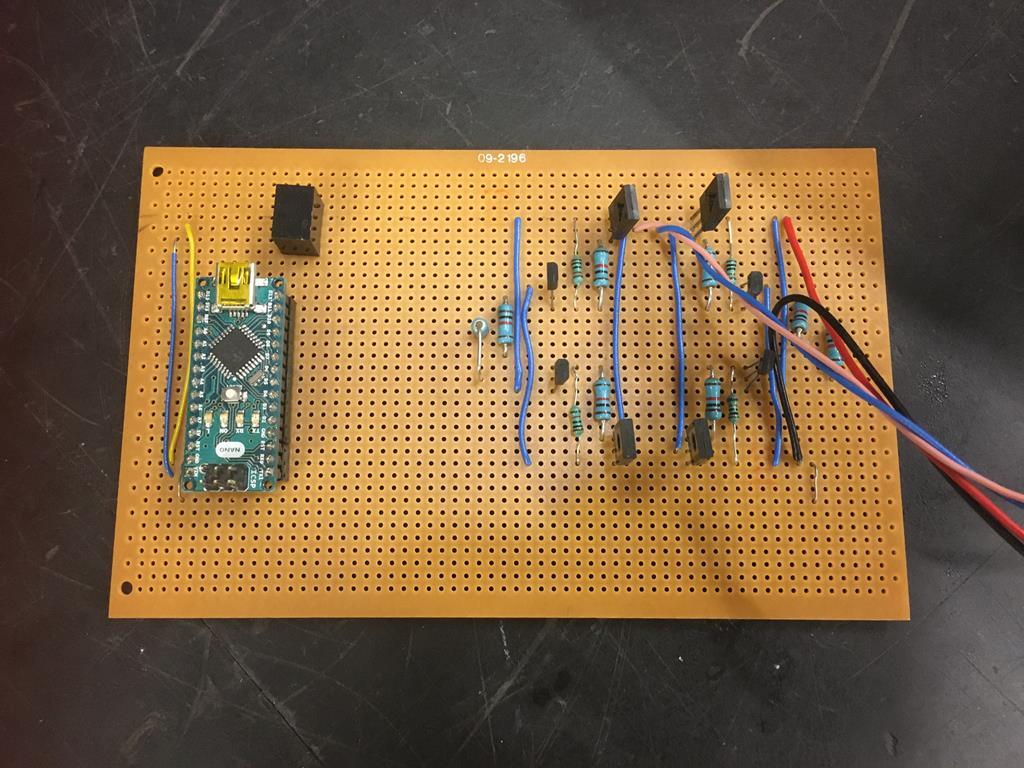

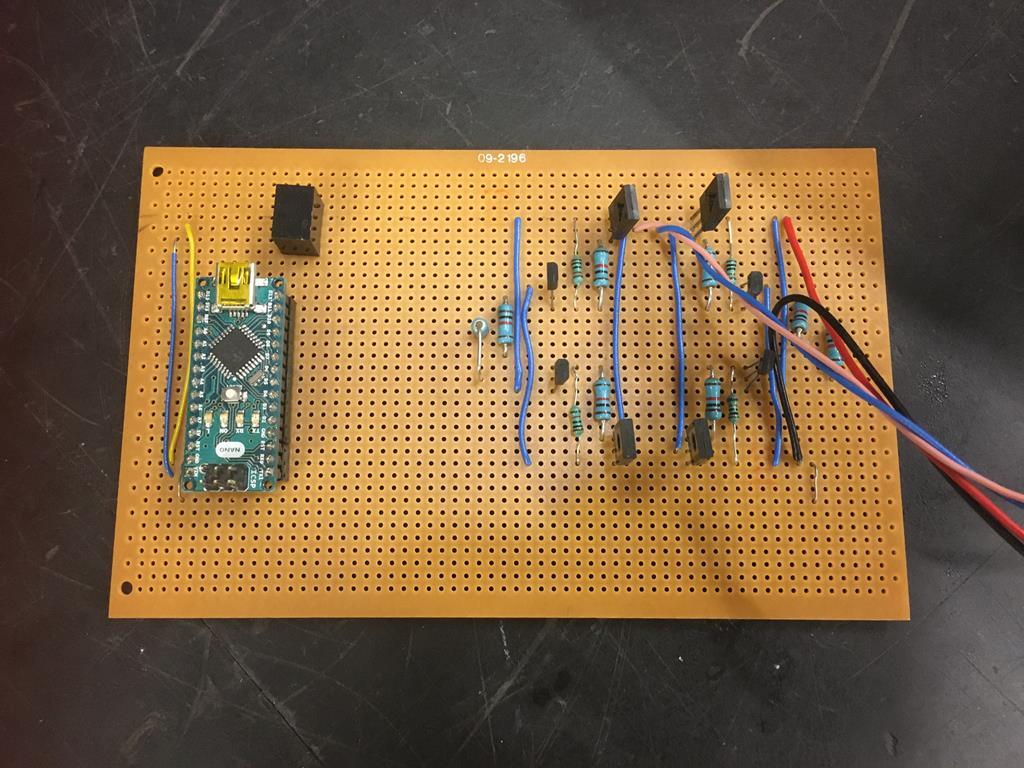

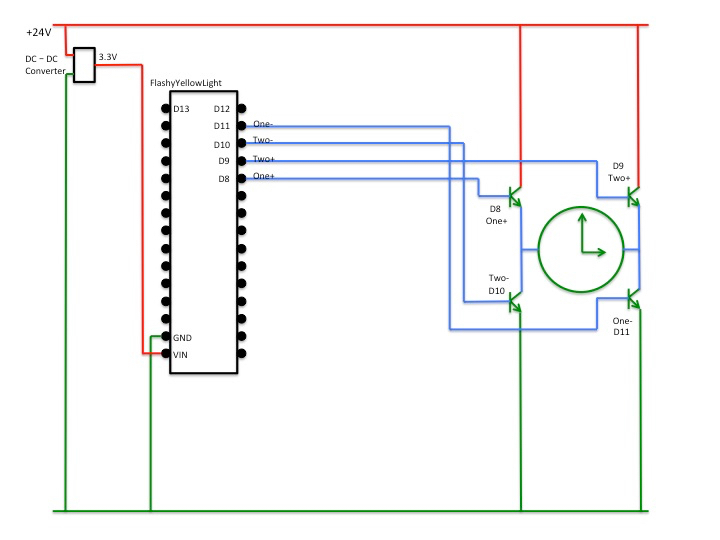

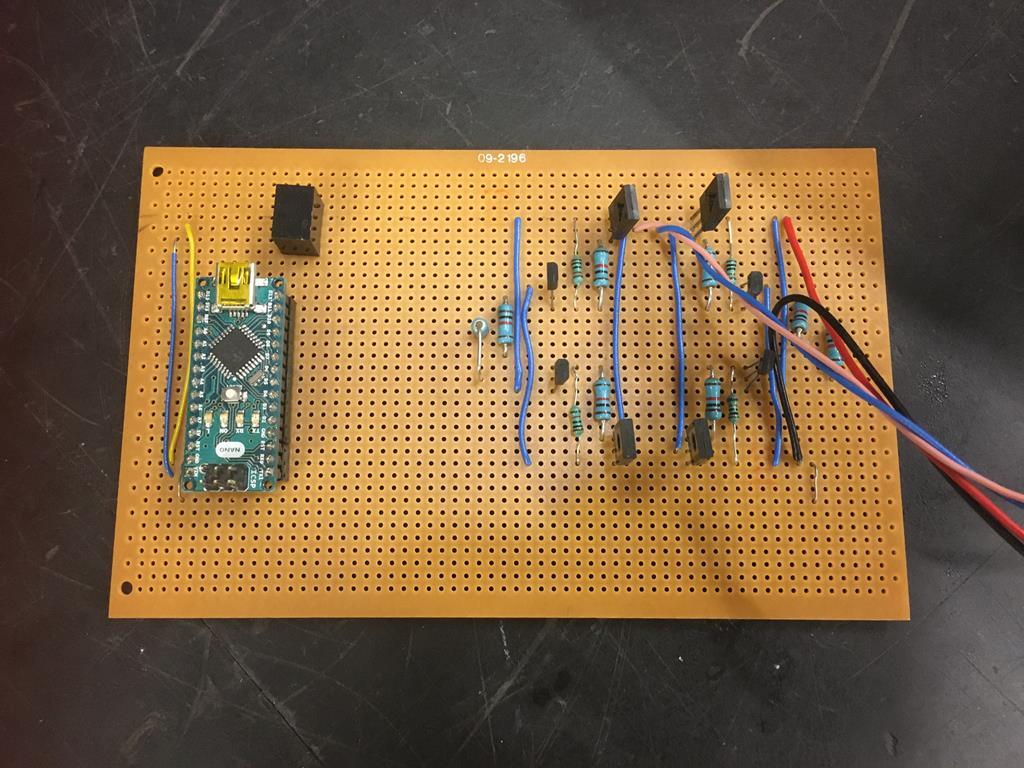

My employer seems to think I’m important enough to go to work during the lockdown. Most of the time I’ve been working from home but I’ve had to go in a couple of times. I’m not sure what’s worse, going into London or working from home. Anyway, last time I was in I pinched the big clock. Or at least part of it. Here’s the big clock…   The history is that it was on the wall of our control room until it was eventually removed from service. Somebody rescued it and when I joined it was stored in a cupboard. Some years later we moved building and, again, it was rescued and wound up in storage. Sadly, not well enough stored. It was face up and somebody put something on top of it. It no longer has any glass in it. Well, a few fragments behind the hazard tape. So I’d never seen it working and couldn’t because it’s a “loop clock” and needs a master clock to drive it. The new building doesn’t have a master clock capable of driving it so I was doomed to never see it running. Or was I? So when I did night shifts I did sneak away and make a driver circuit.   The thing on the left is an Arduino micro computer, actually this is an Arduino Nano. That will do the ticking for me. And on the right is the driver circuit. This isn’t going to keep time very well. The Arduino just counts to 1000nS and then ticks the clock. But it’s entirely dependant on the accuracy of the crystal on the Arduino and that’s not one intended for timekeeping. Added to which I’d need to calculate the amount of time the code takes to run and remove it from the 1000nS. And that’s potentially tricky because I’m programming it in some language that is then compiled into machine code for the chip. I don’t know what the compiler actually creates so I don’t accurately know how long it takes to run. I could use an on board timer to interrupt the chip every second and get round that problem but I’m still limited by the accuracy of the crystal on the board. It really needs locking to a reference source. Well, I’m supposed to be working from home. And it’s sort of work… Isn’t it? Maybe we won’t tell the boss though. |

| |

|

|

|

|

|

Apr 23, 2020 10:37:48 GMT

|

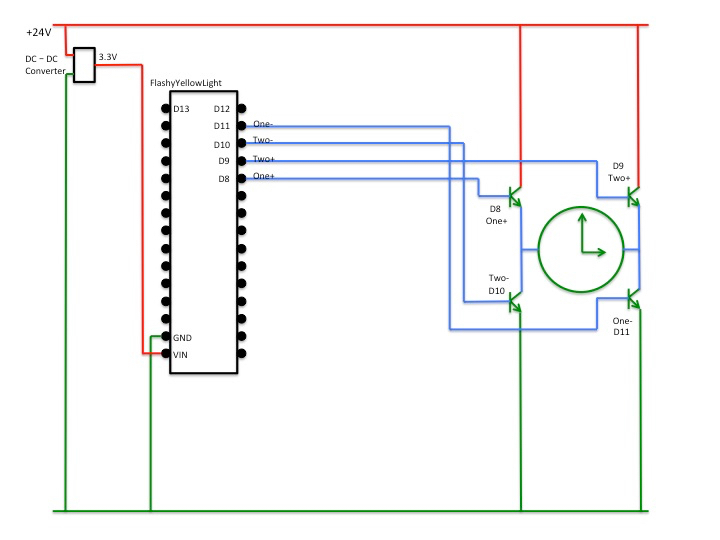

I didn’t want to take the whole clock home. It’s too big and heavy. So I stripped the mech out of the face and just brought that home. The first job was that when some muffin dropped something through the glass it bent the hands.   So they were very gently straightened. My next job was that having left the face at work I needed something to mount the movement in. So I found am old piece of steel in the garage, actually the side off an old computer, and marked it up.   Then mounted the hands and marked up a few numbers of interest.   As you can see the old clock was huge and I had to offset the movement near the top to stop the hands hitting the bottom. Right, who’s up for a bit of electronics then? The clock has two wires on the ‘motor’. It needs current to flow through it in one direction for one second and then the other direction for the next second. Each passage of current spins the motor a quarter of a turn and advances the second hand one second. So actually the clock is fed with a reversing square wave with a frequency of 0.5Hz. Interestingly if you got the wires the wrong way round on the motor the clock would always be one second out and you couldn’t get it right. The driver is a bit more complex than the diagram but works like this.   The four transistors (D8 to 11) work like switches. The Arduino turns them on and off. If I turn on D8 and D11 current flows through the clock from left to right and the second hand moves forwards one second. Then I turn D8 and D11 off and turn on D9 and D10. Current flows the other way and the second hand advances another second. Clearly if you turn on D8 and D10 at the same time (or D9 and D11) you short out the power supply and it all goes off with a bang. There is nothing to protect you from doing that. It’s all in the programming of the Arduino to make sure that doesn’t happen. So. Does it work? See for yourself. As you can see from the video after a couple of days it started misbehaving. This is longer than the movement has run for 30 years so I thought I was going to have to strip it and rebuild it. Luckily it was just the second hand that had come slightly loose on it’s spindle. |

| |

Last Edit: Apr 23, 2020 10:41:29 GMT by Sweetpea

|

|

|

|

|

Apr 23, 2020 10:51:21 GMT

|

|

Strangely satisfying.

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,361

Club RR Member Number: 64

|

|

Apr 23, 2020 11:11:00 GMT

|

|

Very cool.

I would have used a radio controlled movement. I've rescued a couple of nice looking clocks that way. Compared to this though, it's clearly cheating and I'll have to try harder.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Apr 23, 2020 16:54:59 GMT

|

|

Thanks chaps!

Glen, I'd get lynched if I changed the movement in this old thing! The other thing is that the hands are huge and it would need a pretty big movement to drive them.

I've used MSF radio movements around the house a few times. I've got one in the clock in garage, it's great and works really well. However the plan for this clock is that it'll live in the workshop at work. That's in a building with lots of rebar in it and three floors underground. MSF hasn't a hope!

In the next exciting instalment I'll explain how I'm going to give it some sort of reference to lock to. As it stands in the video the Arduino isn't a good time keeping source so it won't keep good time.

|

| |

|

|

|

|

|

Apr 23, 2020 16:56:42 GMT

|

My employer seems to think I’m important enough to go to work during the lockdown. Most of the time I’ve been working from home but I’ve had to go in a couple of times. I’m not sure what’s worse, going into London or working from home. Anyway, last time I was in I pinched the big clock. Or at least part of it. Here’s the big clock…   The history is that it was on the wall of our control room until it was eventually removed from service. Somebody rescued it and when I joined it was stored in a cupboard. Some years later we moved building and, again, it was rescued and wound up in storage. Sadly, not well enough stored. It was face up and somebody put something on top of it. It no longer has any glass in it. Well, a few fragments behind the hazard tape. So I’d never seen it working and couldn’t because it’s a “loop clock” and needs a master clock to drive it. The new building doesn’t have a master clock capable of driving it so I was doomed to never see it running. Or was I? So when I did night shifts I did sneak away and make a driver circuit.   The thing on the left is an Arduino micro computer, actually this is an Arduino Nano. That will do the ticking for me. And on the right is the driver circuit. This isn’t going to keep time very well. The Arduino just counts to 1000nS and then ticks the clock. But it’s entirely dependant on the accuracy of the crystal on the Arduino and that’s not one intended for timekeeping. Added to which I’d need to calculate the amount of time the code takes to run and remove it from the 1000nS. And that’s potentially tricky because I’m programming it in some language that is then compiled into machine code for the chip. I don’t know what the compiler actually creates so I don’t accurately know how long it takes to run. I could use an on board timer to interrupt the chip every second and get round that problem but I’m still limited by the accuracy of the crystal on the board. It really needs locking to a reference source. Well, I’m supposed to be working from home. And it’s sort of work… Isn’t it? Maybe we won’t tell the boss though. You lost me after ‘big clock’ 🤔 I should say I’m impressed tho’ 👍 |

| |

|

|

|

|

|

Apr 23, 2020 19:13:08 GMT

|

James - Thanks - You reminded me that we also own such a thing as a impulse clock - probably a bit older than one in your pics  It carries GPO initials (General Post Office) and a King George crest so it probably dates to the late 30's / early 40's - purchased by SWMBO about 20 years ago at a auction for not a lot of money - its just shy of 24" diameter - I should say that its a former impulse clock has its now powered by a modern movement via a 1.5v battery - until your post today I had all of forgotten about it - its been on the top of a wardrobe gathering dust since we moved here 6 years ago - now dusted off - cleaned up - new battery fitted and hung in the kitchen has of this evening |

| |

Last Edit: Apr 23, 2020 19:14:00 GMT by Deleted

|

|

|

|

|

Apr 23, 2020 19:52:06 GMT

|

|

Hi Chris,

That's really nice. Shame it doesn't have the original movement but it's better on the wall and working with a modern one than in a skip with the original one.

It sits nicely in the room too. Very nice indeed.

Interestingly (well its interesting to me but that might just prove I'm a boring git).. Interestingly, I know pretty accurately when ours was made. Gent was bought by Chloride in 1981 and sold again in '82. So some time in that year.

|

| |

|

|

|

|

|

|

|

Apr 23, 2020 19:58:18 GMT

|

Hi Chris, That's really nice. Shame it doesn't have the original movement but it's better on the wall and working with a modern one than in a skip with the original one. It sits nicely in the room too. Very nice indeed. Interestingly (well its interesting to me but that might just prove I'm a boring git).. Interestingly, I know pretty accurately when ours was made. Gent was bought by Chloride in 1981 and sold again in '82. So some time in that year. James - I have kept the original movement and made sure that it could always be reconverted - just at the time we acquired it could I hell get anyone to build me a signal impulse generator for it - original clocks of this size sell for daft money in todays markets - I think ours has cost about £40 to date |

| |

Last Edit: Apr 23, 2020 19:59:42 GMT by Deleted

|

|

|

|

|

Apr 23, 2020 21:01:17 GMT

|

Chris, you've got my address. Feel free to post it to me and I'll see if I can get it running if you want. Can't promise how quickly though. Better yet, take some close up photos of it. Some movements can be driven by relatively off the shelf units these days. It cropped up in a thread recently. I'll see if I can find it. Found it... Another old clock |

| |

Last Edit: Apr 23, 2020 21:04:59 GMT by Sweetpea

|

|

|

|

|

|

|

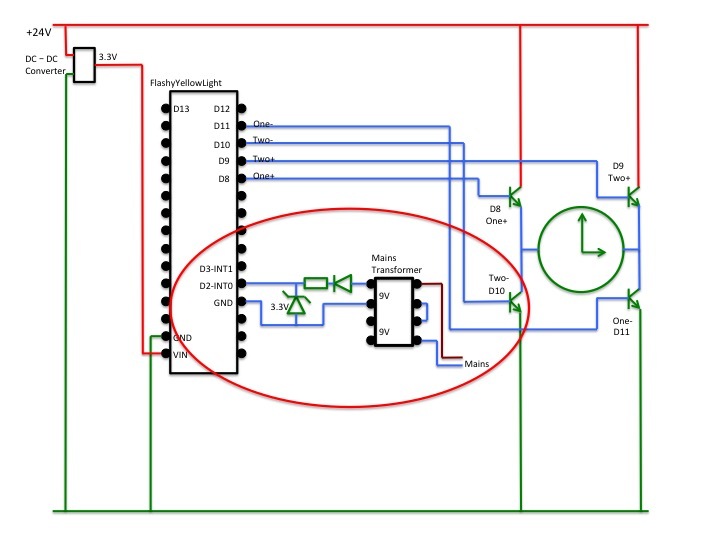

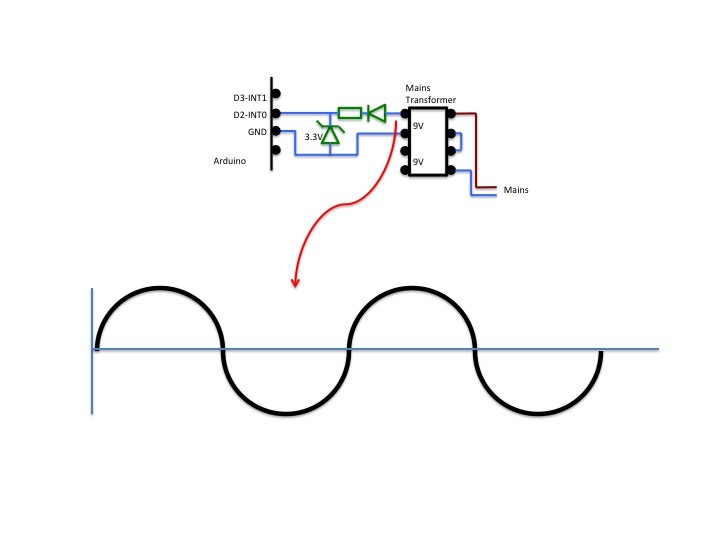

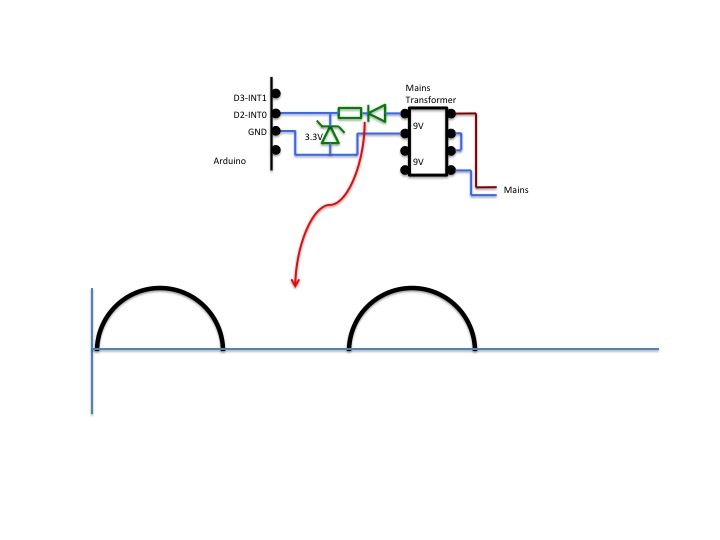

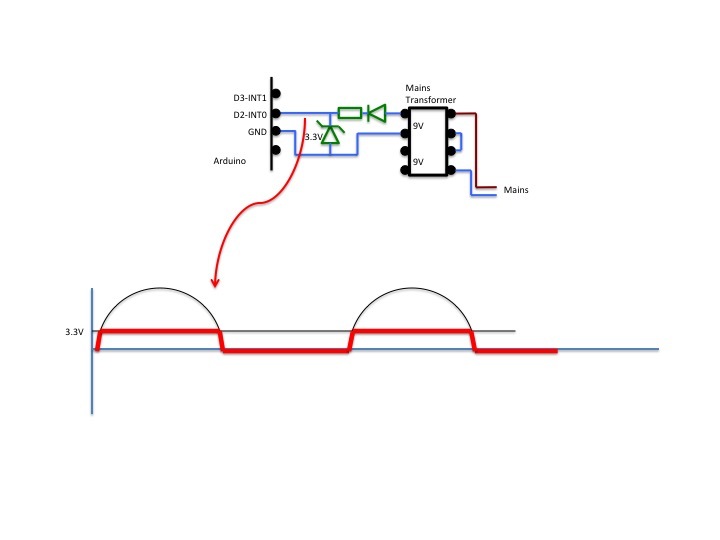

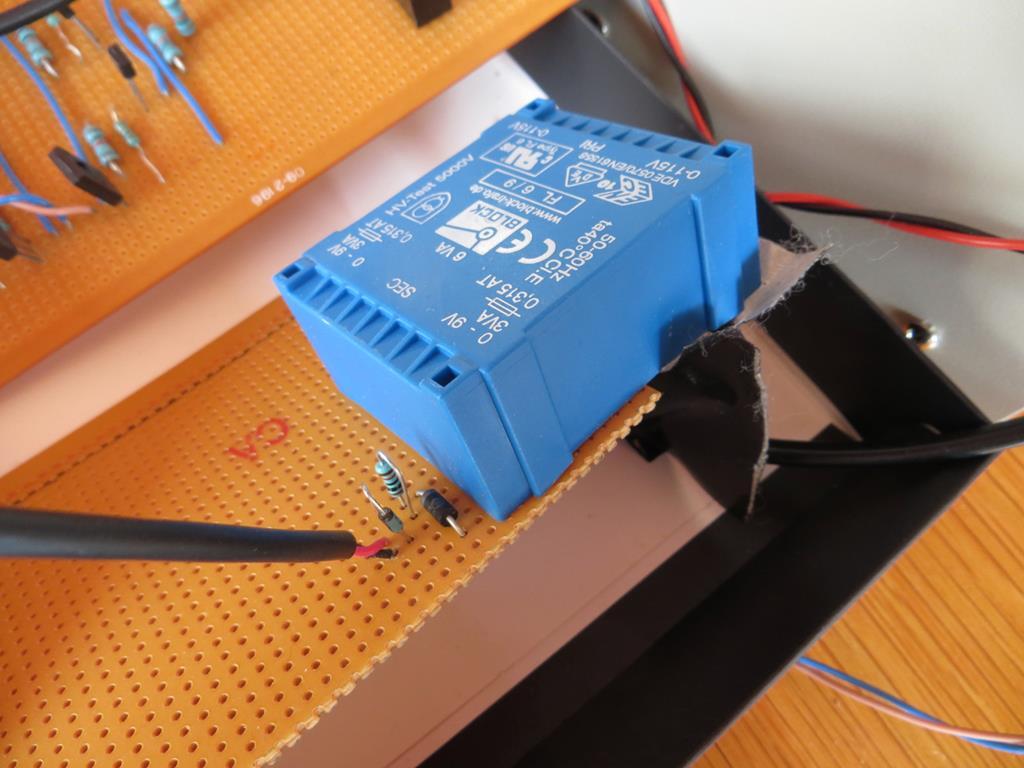

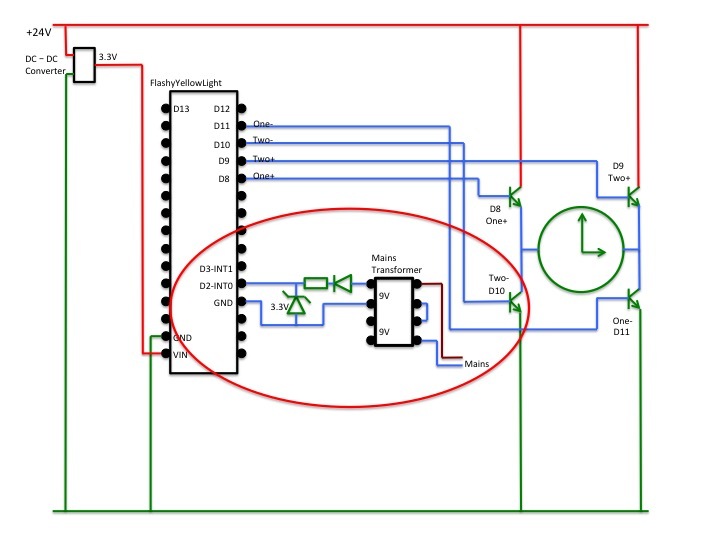

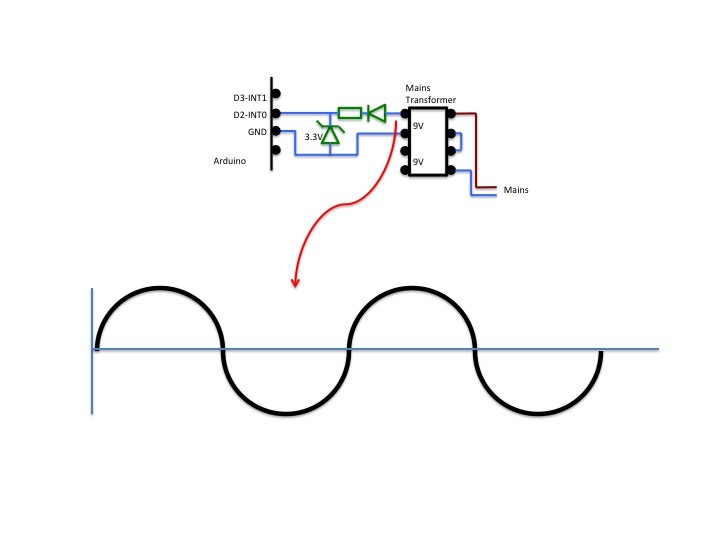

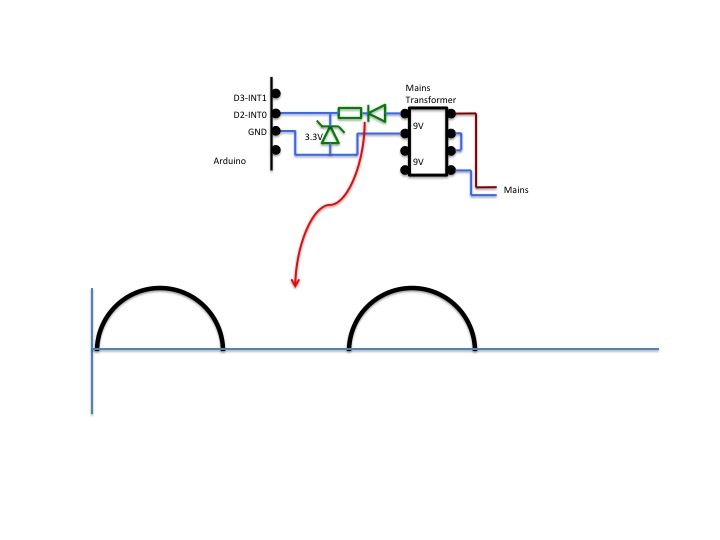

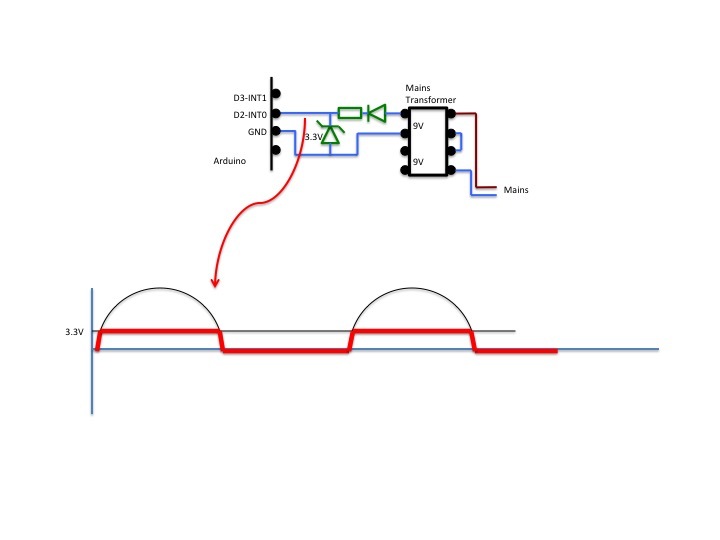

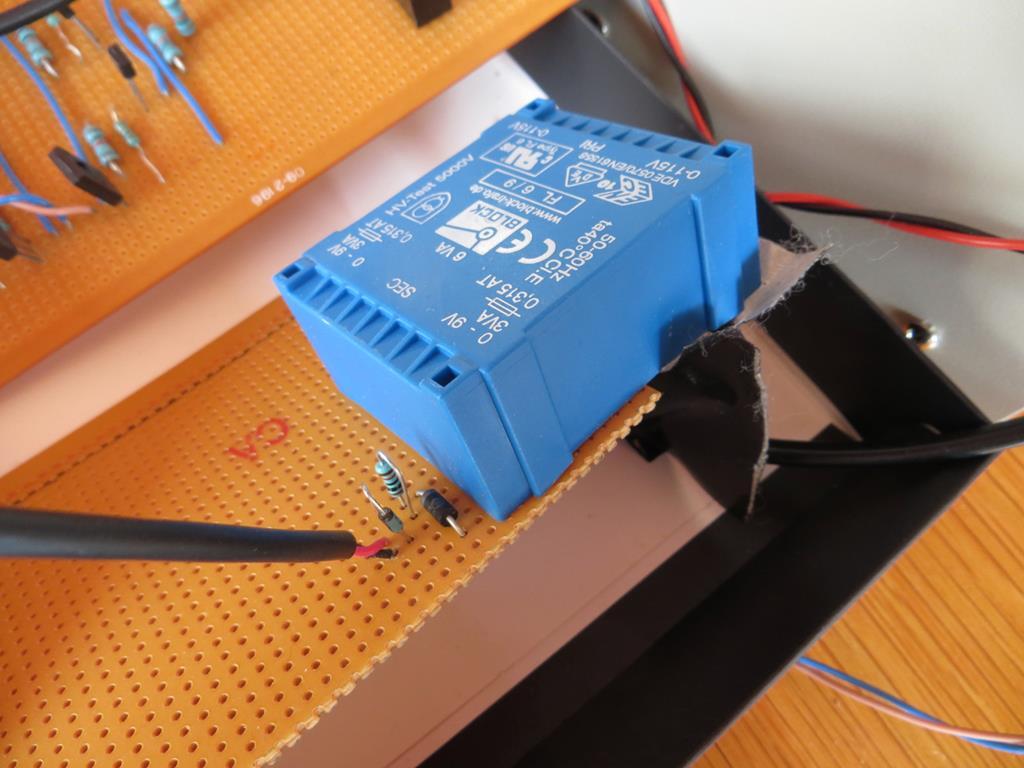

I’ve said that it’s running on the Arduino’s crystal and that I haven’t taken into account the amount of time the program takes to run so it won’t be accurately timed. It really needs some sort of time reference to follow. So what are we going use then? Well we have a few options. We have a few flavours of digital time code at work so one of those would be a possibility. NTP (a computer time signal carried over networks) is another possibility. Both of these ideas have problems though. The biggest one is the complexity of programming the Arduino to read and understand them. Secondly, they tell the Arduino what the time is. This would be great if the Arduino had any idea where the hands were pointing. But it doesn’t and it has no way of finding out. So the one massive advantage of time code - that the clock could set itself - won’t work, and given the complexity involved it’s just not worth the bother. I’m planning to leave the option open though. There is a much more simple and effective reference. And it’s available everywhere. It’s the mains. It’s a very stable 50 cycles per second and synchronous clocks already use it to keep time. All I need to do is have the Arduino count 50 cycles of mains and then advance the clock one second. Easy peasy lemon squeezy! Obviously you can’t just stick the mains into a microprocessor. Well, you can if you want to turn it into a small smoke generator. Briefly. But if you want it to survive it needs something like a 3.3V square wave rather than a 240V sine wave. That’s going to need some really clever electronics involving Schmitt Triggers or Monostable Oscillators or something. Or, maybe, just something really quick and dirty. Quick and dirty? Hello, yes, did somebody want me!? We need to add this it to our circuit.   So. We take the mains into a transformer. That reduces the voltage and makes it safe for us humans if not for the Arduino. Out of the transformer we get a low voltage sine wave.   Safe but unhelpful. I think the mains transformer is a 9V one. Still far to much to stuff up the Arduino. The pointy green component next to the transformer is a diode. It only passes current in one direction so it effectively throws away the bottom half of the wave form.   Ok… Then the clever bit. The other pointy thing with ears and the word “3.3V” next to it is a Zener diode. It too conducts in the forward direction but that’s not what it’s here for. It’s other trick is that when the voltage in the other direction reaches 3.3V it clamps and holds at that level.   The wasted tops of the sine wave are lost across the resistor - the oblong box in the diagram. What we wind up with is the red line on the diagram above. It’s close to a 3.3V square wave at 50Hz. It’s got slightly squint leading and trailing edges and the mark / space ratio isn’t quite right, but it’s close enough for me and the Arduino. And it didn’t involve anything with impressing sounding names like Schmitt Trigger or Monostable Oscillator. The Arduino is set to ‘interrupt’ when it sees a rising edge on pin D2. The interrupt causes it to stop what ever it was doing and run the interrupt routine. That counts 50 edges and then ticks the clock along one second. Another 50 interrupts and it tocks. Here is a photo of the actual circuit.   Yeah, I know, it looks a bit, er, ropey and, er, lethal. But all the mains bits are well covered behind heat shrink. The sticky tape is just there to stop the heat shrink getting disturbed. Once it’s all proven to work it’ll get rebuilt into a proper box. Does it keep proper time now? Ah… There’s a story behind that question. |

| |

|

|

|

|

|

|

|

|

TELL US THE STORY!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Thanks for explaining all the eletrickery. I hate the stuff personally so I'm always impressed when someone really knows how to wrangle it... Like watching a cowboy riding lightning.

|

| |

|

|

|

|

|

|

|

|

You're welcome!

I know electronics is a bit of a tricky subject 'cos you largely either know it or you don't. There is no way I'm going to teach people on here either. And most people here won't care. But you never know, if people find it an interesting read then that makes worth writing. And if it sparks an interest in anybody then that's better yet.

I'll write something up... And then I'm off to the garage to deal with a pile of fragmented plastic off my car.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,889

|

|

|

|

|

You know if you're enjoying this little clock circuitry, you'd have some serious fun if you built a Megasquirt/Speeduino for the Mr2. All of this kinda input and output signal conditioning stuff, with the added bonus of making the car fast in the process!

Cool project with the clock by the way. All making sense, it's amazing how much of the old electronic A-level is still hiding in the back of my mind somewhere!

|

| |

|

|

|

|

|

Apr 25, 2020 10:35:55 GMT

|

The question of how well it keeps time is dependant on two things. 1, How stable the 50hz mains actually is. Common knowledge is that it’s stable over a 24 hour period but that it drifts a bit during the day. 2, Did I actually get the coding of the Arduino right. If I messed up anywhere it’ll drift over a period of days. So I set it against a quartz kitchen clock that’s been doing its stuff reliably for years.   This one! I set them the same and let them run. Yeah, my old loop clock appeared to be utterly hopeless. Within a couple of hours it was about 30 seconds ahead. Bumhats. Over the next day or two I wasn’t really sure what it was doing. It appeared to run slowly during the day and catch up during the night. That could be what the mains does but I really didn’t know. And I was a bit surprised that it was varying so much. After a couple of days there was evidence that it was a couple of minutes different but I really wasn’t sure. You’d think that comparing one clock against another would be easy but because the hands on the loop clock had come loose I couldn’t really tell what it was doing. And then I realised that the kitchen clock wasn’t all it could be either. At one point the second hand was on the top of the minute and the minute hand was exactly half way between two minutes. So I knew it was on the minute but not sure which one. So I stopped it, tightened the hands, and set both clocks against my laptop. Now, my laptop takes NTP (Network Time Protocol) from the internet. It should know what the time is. And because it’s a digital display you don’t have the wobbly hands problem. Where does this put us. Well of course the quartz kitchen clock would be bob on. Er no! It’s bl00dy hopeless. It gains and looses and is currently about 2 mins behind. Any wonder I couldn’t work out what the loop clock was up to when the one I was checking against can’t keep time. My clock. Well over a few hours it appeared to get about 20 secs behind. I’m not sure what happened there. It’s possible my laptop hadn’t set its self and was a bit off. But ever since then the loop clock has kept pace very nicely. It drifts about 10 seconds fairly randomly which is what I’d expect the mains to do. I’m a happy chappy! It’s interesting - humans relationship with time. I work in an industry where we need to know the time to the second. And that has to be accurate across the building hence we used a master clock system. But the reality is that the kitchen clock has probably been all over the place for years and I never noticed. The clock on the microwave is useless but you don’t really notice it until it move than 5 mins out. So although we want to know the time to the second, actually things can be way off and you don’t see it. In the hall is a long case clock. I think it dates from about 1850 and probably started life in a little village in North Yorkshire. It keeps time to about a minute a week which is pretty impressive and I set it each week when I wind it up. But in 1850 what did they set it against? Probably the clock in the village church. But what did they set that against? Ultimately, probably, by observing the sun. So our ‘need’ for accurate time is a relatively new thing. The railways get blamed for it but even after that if you were a farmer in a little village and weren’t fussed about the train, why would you care what the time is? So how did we become so obsessed by what time it is? Next job, ‘cos we ain’t finished yet, oh no… Next job is to alter the coding in the Arduino to make it work in a slightly different way. But that, my dear friends, is for another day. |

| |

|

|

|

|

|

Apr 25, 2020 10:46:56 GMT

|

You know if you're enjoying this little clock circuitry, you'd have some serious fun if you built a Megasquirt/Speeduino for the Mr2. All of this kinda input and output signal conditioning stuff, with the added bonus of making the car fast in the process! Cool project with the clock by the way. All making sense, it's amazing how much of the old electronic A-level is still hiding in the back of my mind somewhere! Somebody on the Mk1 forum did do that. I don't think it was a Megasquirt but something similar. Toyota altered the mapping, in particular the ignition timing of the later MK1B cars. We suspect it was to do with the introduction of unleaded petrol but no nobody actually knows. They also altered the crank journal sizes, fuel injectors, and a few other things at the same time. The result is that a 4AGE from a MK1A MR2 or Corolla AE86 will scream to nearly 8000 revs like your bum is on fire and, subjectively, the later cars felt a little breathless at high revs. So this chap programmed a late engine with the maps from an early one and it apparently went like stink. Probably no faster but felt more lively and fun to drive. |

| |

Last Edit: Apr 25, 2020 10:49:32 GMT by Sweetpea

|

|

The Doctor

Club Retro Rides Member

Posts: 3,449

Club RR Member Number: 48

|

|

Apr 25, 2020 17:28:50 GMT

|

. In the hall is a long case clock. I think it dates from about 1850 and probably started life in a little village in North Yorkshire. It keeps time to about a minute a week which is pretty impressive and I set it each week when I wind it up. That is impressive! My main clock is a windup clock from my grandparents, so early 1900s. It runs 15 minutes fast the first week, then falls behind in the second and just as it's back on time, it stops because it needs to be rewound! Bang on running 2 weeks. Most of the time it stops within the same hour it did 2 weeks before!  |

| |

|

|

|

|

|

Apr 25, 2020 18:49:02 GMT

|

|

There’s a wall to the front of my house, no matter what clock is put on it, it’ll run about 10 minutes fast after a day or two, and stay there. Take it off that wall and it keeps time fine, this happens whether it’s a battery or clockwork one, and I’ve tried with different clocks and the same thing occurs 🤔

|

| |

|

|

|

|