I had some time off from work today, so I finally got around to servicing my auto transmission.

Hey, here's a car I haven't worked on in a while. Cant let the Vitesse have all the fun now can we?

I purchased all the parts to service my auto a while ago, including the fluid, but have put it off. Rimmers doesn't have a lot of the parts available anymore, but because Rover used a standard old GM auto, I was able to order parts for a GM TH-180 (Turbo-Hydramatic 180) which was used in heaps of different cars, even the old Commodores. I ordered the gaskets from a place in the states called Makco but there are heaps of places that can supply these parts.

In regards to which oil to use, there is HEAPS of discussion on it, but I chose to use a Semi-Synthetic Dexron compatible Penrite "Multi-Vehicle' ATF-MHP. This meets the requirements for the fluid type, but has the added advantage of being a semi-synthetic. I didn't want to go for a full synthetic because I'm not flushing the trans so would be mixing synthetic oil with whatever is already in there. Not keen.

Obviously the first step in this game is the first step in most games.... jack the car up. Thankfully the EFI is at standard height and doesn't need any special work to get it in the air.

Once in the air it was obvious why she smoked like crazy when sitting for a few days. The trans was leaking badly onto the RH exhaust pipe.

The oil, as oil does, had travelled everywhere on the underside of the car. Makes a good rust preventative though I guess.

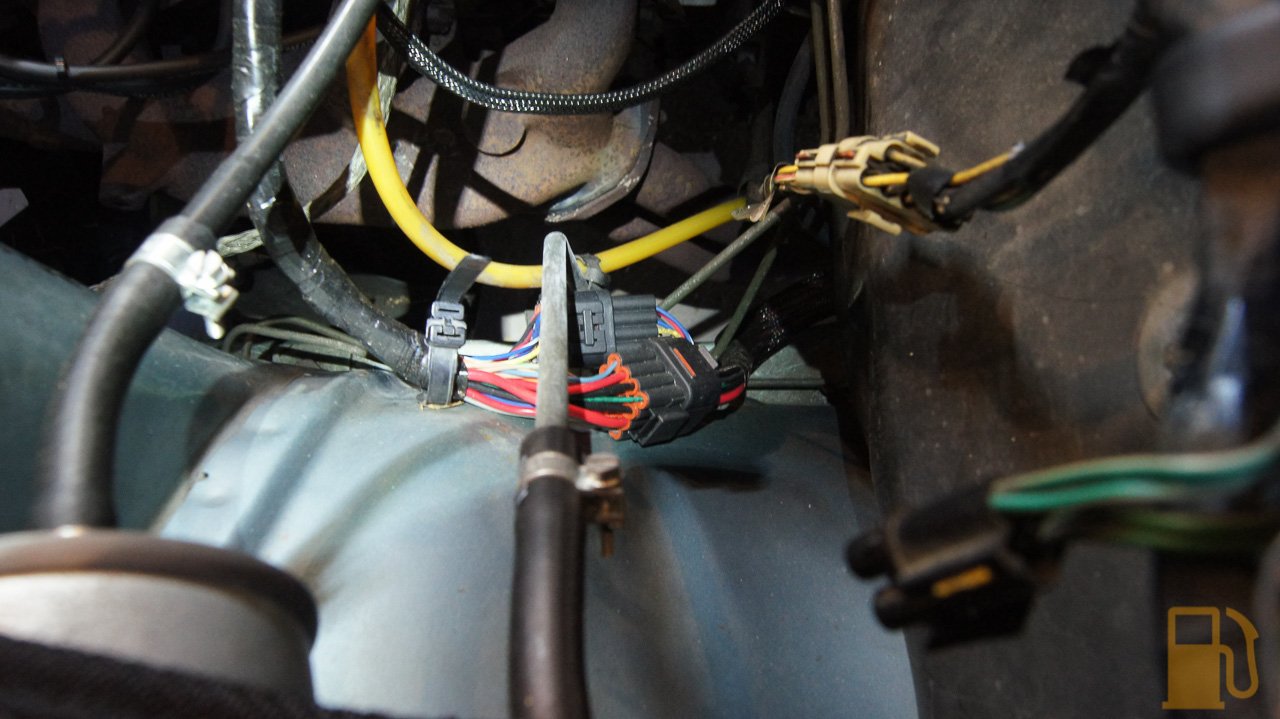

Looking around I could see oil traces coming from two main places; the dipstick tube seal and the inhibitor switch. Both are common areas to leak from, so I pre-ordered the seals required to try to fix them.

It also appeared to be leaking from the oil pan gasket itself. No surprise really as most of the bolts at the rear of the pan were barely finger tight. I know the torque setting is low on these, but that's just being silly. I'm not sure when the trans was last serviced, but it had been worked on at some point in the past.

The GM trans of this era doesn't have a drain plug in the pan, so the only way to drain the trans is to make a mess. This was my first time working on an auto without a drain plug, so I wasn't so sure what I was in for. I loosened off all the 1/2" pan bolts, more so on the side that the exhaust wasn't hard up against, with the rear ones looser than the front ones so that the pan would drop at the rear. After breaking the sealant seal on the pan, it all started to dribble out, and most of it ended up in the drain pan I had placed under it.

When that stopped dripping I removed the rest of the bolts whilst supporting the pan with my other hand, and when it came free I just tipped it straight into the drain pan. No mess, no fuss. It probably did help though that the oil level was low.... It should have drained about 2.8L, but only 2L came out.

![]() tasteslikepetrol.net/wp-content/uploads/2017/12/DSC01672.jpg

tasteslikepetrol.net/wp-content/uploads/2017/12/DSC01672.jpg![]()

The fluid color was dark, but still had a definite redness to it. It didn't smell burnt, and no worrying chunks or anything were found in the pan.

I was under the impression that most auto pans had magnets in them to collect the metal particles in the oil. There was no magnet in my pan, and the bottom of the pan and filter were covered in a fine layer of sludge.

I thoroughly cleaned the pan, making sure there were no traces of oil, sludge or old gasket.

With the pan off I could see the valve body and filter. It all looked pretty clean in there, and although I don't really know much about what I was looking at, it all looked like I feel it should

The old filter got removed. This is held in place with three 1/2" bolts and then it just comes free. Apparently they can be cleaned and reused, as they are just a mesh filter, but a new one was cheap enough that it wasnt worth cleaning. I picked up a replacement gasket for the filter too.

There was some confusion when ordering the gasket for the filter, as the parts book and Rimmers show a different style gasket to the one supplied by Makco. I ended up ordering both so I could replace it with similar to what came off.

This is what the book shows

And the gasket that came off (and what Makco supplied)

I refit the square type, just to stick with what was already working before.

Next up was to remove the dipstick tube and replace the seal. There were two different kinds of seal that I came across, so once again I ordered both. It turns out that the type used on the SD1 GM180 was the Top-Hat style

Interestingly, the one removed from the car was smooth inside and out, whilst the replacement was ribbed inside and out. I used a thin smear of sealant on the end of the dipstick tube where it fits into the seal just to ensure it doesn't leak.

Getting the dipstick tube in and out is a job that I wouldn't wish on anyone. It is a damn nightmare of a thing. This is what I have named the "curse word Bolt"

It's the only bolt holding the tube in place, but it's almost impossible to work with. It's a 9/16" head, but you cannot get a ratchet on it, and can only barely get a spanner on it to turn it 1/8th of a turn at a time. Getting it out wasn't the worst thing in the world, but getting it back in was terrible and took far too long and used up my daily quota for swearing. I even enlisted the help of my lovely wife as no matter what I did I just couldn't get the bolt hole in the block to line up with the bracket on the tube. We got there in the end, but my god what a curse word of a job. One other tip I will say, is that a 14mm ratchet spanner is very close in size to a 9/16" spanner... this makes tightening the long bolt up a lot quicker, but no less painful.

After that fiasco I cleaned the old gasket off and refit the pan with a new cork gasket which I installed with a thin smear of sealant on both sides and torqued all the bolts up to their super low setting of 9NM.

The inhibitor switch was the last part to get some special treatment. This was easier to work with, but was soaked in oil.

A while ago when I was bored I reconditioned a spare switch I had. The GM180 switches are NLA now, so I couldn't get a new one. They are common for wearing out and either not allowing starting when in park, or the reverse lights not working. My reverse lights don't work, so I hoped that reconditioning and replacing my switch might fix this (sadly it didn't, so I need to look elsewhere).

This is the GM180 switch. Nothing fancy.

Mine was sealed, and the clips broken. I used a sharp blade to open the two halves

The contacts weren't looking good

Its a fairly simple device. On the bottom housing there are three contact sets. Park, Reverse and Neutral. Sprung pins in the moving insert bridge the terminals when the selector is moved

Both the contacts and the pins had heavy wear, and were badly oxidized. I cleaned up the terminals with some fine sandpaper

Half and half

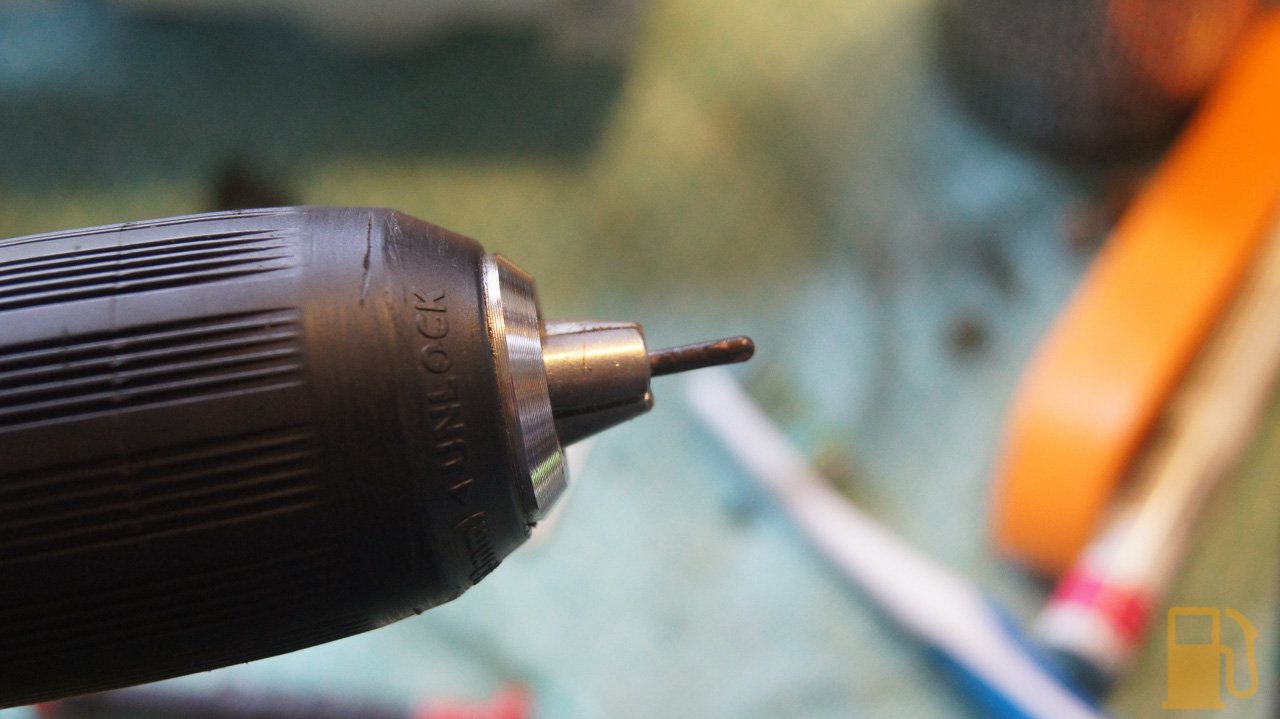

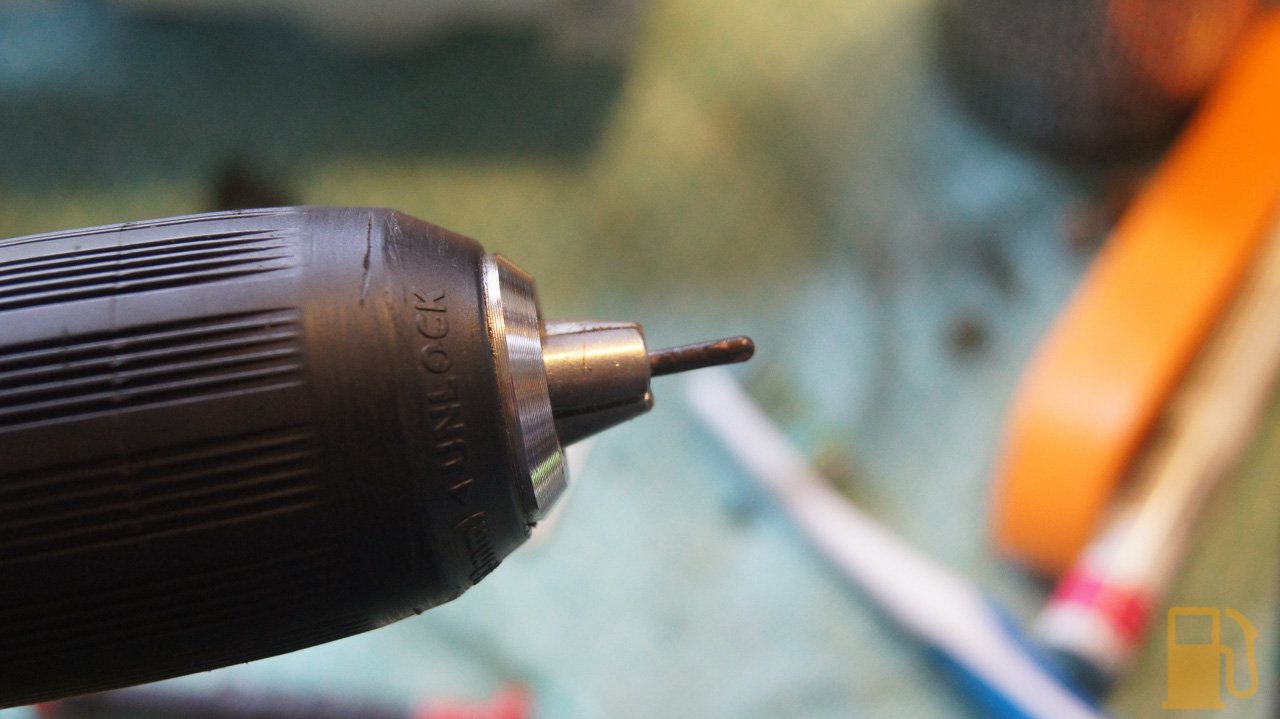

I got a bit more fancy for the pins. I carefully removed them and spun them up in a drill and used some fine sandpaper to clean them

Everything got a good helping of dielectric grease and reassembled. I used a thin bead of superglue to re-assemble the switch. The replacement switch does everything it should, except the reverse lights still don't work. Oh well, at least I know it should be a reliable starter.

One of the biggest reasons for me to do all this work (other than to fix the leaks) was to have a known quantity of oil in the pan. Since getting the car I haven't been able to get a clear reading on the dip stick, even after adding oil to the trans. Obviously now I know it was low, but since I know how much oil went in, I can monitor it correctly.

I poured in 2.1L, and then as per the instructions I started the engine up and ran it through the gears three times. With the engine running, and in Park, I checked the oil level. It needed to be above the triangle on the back of the dipstick. It's hard to see but the oil level is below the Min mark, but is above the triangle on the rear of the dipstick. This is good.

The new fluid was a lovely rich cherry red

I took her for a drive to warm the fluids up, and burn off the oil and brake clean from the exhaust (boy does it smoke), and upon my return I once again cycled the gears and with the engine running I checked the fluid level. Now it should read between the two Min-Max marks; to which it was a little low, so I added another couple of hundred ml of oil which brings it to bang on.

I'm not 100% certain this will fix all the leaks from the trans; they are well-known for leaking from new and being impossible to fix due to bad design, but hopefully this slows it down and reduces how much oil is ending up on the pipe. This also allows me to correctly monitor the oil level now.

So how did the test drive go? Well, the trans is quieter, smoother and shifts better. It was already pretty good by 1980s standards in my opinion, but now it shifts like a trans made some time in the late 90s. Smooth and almost unnoticeable shifting.

Now to put more rego on, and take for more hoons before its WOF expires again next month.

Hey, here's a car I haven't worked on in a while. Cant let the Vitesse have all the fun now can we?

I purchased all the parts to service my auto a while ago, including the fluid, but have put it off. Rimmers doesn't have a lot of the parts available anymore, but because Rover used a standard old GM auto, I was able to order parts for a GM TH-180 (Turbo-Hydramatic 180) which was used in heaps of different cars, even the old Commodores. I ordered the gaskets from a place in the states called Makco but there are heaps of places that can supply these parts.

In regards to which oil to use, there is HEAPS of discussion on it, but I chose to use a Semi-Synthetic Dexron compatible Penrite "Multi-Vehicle' ATF-MHP. This meets the requirements for the fluid type, but has the added advantage of being a semi-synthetic. I didn't want to go for a full synthetic because I'm not flushing the trans so would be mixing synthetic oil with whatever is already in there. Not keen.

Obviously the first step in this game is the first step in most games.... jack the car up. Thankfully the EFI is at standard height and doesn't need any special work to get it in the air.

Once in the air it was obvious why she smoked like crazy when sitting for a few days. The trans was leaking badly onto the RH exhaust pipe.

The oil, as oil does, had travelled everywhere on the underside of the car. Makes a good rust preventative though I guess.

Looking around I could see oil traces coming from two main places; the dipstick tube seal and the inhibitor switch. Both are common areas to leak from, so I pre-ordered the seals required to try to fix them.

It also appeared to be leaking from the oil pan gasket itself. No surprise really as most of the bolts at the rear of the pan were barely finger tight. I know the torque setting is low on these, but that's just being silly. I'm not sure when the trans was last serviced, but it had been worked on at some point in the past.

The GM trans of this era doesn't have a drain plug in the pan, so the only way to drain the trans is to make a mess. This was my first time working on an auto without a drain plug, so I wasn't so sure what I was in for. I loosened off all the 1/2" pan bolts, more so on the side that the exhaust wasn't hard up against, with the rear ones looser than the front ones so that the pan would drop at the rear. After breaking the sealant seal on the pan, it all started to dribble out, and most of it ended up in the drain pan I had placed under it.

When that stopped dripping I removed the rest of the bolts whilst supporting the pan with my other hand, and when it came free I just tipped it straight into the drain pan. No mess, no fuss. It probably did help though that the oil level was low.... It should have drained about 2.8L, but only 2L came out.

The fluid color was dark, but still had a definite redness to it. It didn't smell burnt, and no worrying chunks or anything were found in the pan.

I was under the impression that most auto pans had magnets in them to collect the metal particles in the oil. There was no magnet in my pan, and the bottom of the pan and filter were covered in a fine layer of sludge.

I thoroughly cleaned the pan, making sure there were no traces of oil, sludge or old gasket.

With the pan off I could see the valve body and filter. It all looked pretty clean in there, and although I don't really know much about what I was looking at, it all looked like I feel it should

The old filter got removed. This is held in place with three 1/2" bolts and then it just comes free. Apparently they can be cleaned and reused, as they are just a mesh filter, but a new one was cheap enough that it wasnt worth cleaning. I picked up a replacement gasket for the filter too.

There was some confusion when ordering the gasket for the filter, as the parts book and Rimmers show a different style gasket to the one supplied by Makco. I ended up ordering both so I could replace it with similar to what came off.

This is what the book shows

And the gasket that came off (and what Makco supplied)

I refit the square type, just to stick with what was already working before.

Next up was to remove the dipstick tube and replace the seal. There were two different kinds of seal that I came across, so once again I ordered both. It turns out that the type used on the SD1 GM180 was the Top-Hat style

Interestingly, the one removed from the car was smooth inside and out, whilst the replacement was ribbed inside and out. I used a thin smear of sealant on the end of the dipstick tube where it fits into the seal just to ensure it doesn't leak.

Getting the dipstick tube in and out is a job that I wouldn't wish on anyone. It is a damn nightmare of a thing. This is what I have named the "curse word Bolt"

It's the only bolt holding the tube in place, but it's almost impossible to work with. It's a 9/16" head, but you cannot get a ratchet on it, and can only barely get a spanner on it to turn it 1/8th of a turn at a time. Getting it out wasn't the worst thing in the world, but getting it back in was terrible and took far too long and used up my daily quota for swearing. I even enlisted the help of my lovely wife as no matter what I did I just couldn't get the bolt hole in the block to line up with the bracket on the tube. We got there in the end, but my god what a curse word of a job. One other tip I will say, is that a 14mm ratchet spanner is very close in size to a 9/16" spanner... this makes tightening the long bolt up a lot quicker, but no less painful.

After that fiasco I cleaned the old gasket off and refit the pan with a new cork gasket which I installed with a thin smear of sealant on both sides and torqued all the bolts up to their super low setting of 9NM.

The inhibitor switch was the last part to get some special treatment. This was easier to work with, but was soaked in oil.

A while ago when I was bored I reconditioned a spare switch I had. The GM180 switches are NLA now, so I couldn't get a new one. They are common for wearing out and either not allowing starting when in park, or the reverse lights not working. My reverse lights don't work, so I hoped that reconditioning and replacing my switch might fix this (sadly it didn't, so I need to look elsewhere).

This is the GM180 switch. Nothing fancy.

Mine was sealed, and the clips broken. I used a sharp blade to open the two halves

The contacts weren't looking good

Its a fairly simple device. On the bottom housing there are three contact sets. Park, Reverse and Neutral. Sprung pins in the moving insert bridge the terminals when the selector is moved

Both the contacts and the pins had heavy wear, and were badly oxidized. I cleaned up the terminals with some fine sandpaper

Half and half

I got a bit more fancy for the pins. I carefully removed them and spun them up in a drill and used some fine sandpaper to clean them

Everything got a good helping of dielectric grease and reassembled. I used a thin bead of superglue to re-assemble the switch. The replacement switch does everything it should, except the reverse lights still don't work. Oh well, at least I know it should be a reliable starter.

One of the biggest reasons for me to do all this work (other than to fix the leaks) was to have a known quantity of oil in the pan. Since getting the car I haven't been able to get a clear reading on the dip stick, even after adding oil to the trans. Obviously now I know it was low, but since I know how much oil went in, I can monitor it correctly.

I poured in 2.1L, and then as per the instructions I started the engine up and ran it through the gears three times. With the engine running, and in Park, I checked the oil level. It needed to be above the triangle on the back of the dipstick. It's hard to see but the oil level is below the Min mark, but is above the triangle on the rear of the dipstick. This is good.

The new fluid was a lovely rich cherry red

I took her for a drive to warm the fluids up, and burn off the oil and brake clean from the exhaust (boy does it smoke), and upon my return I once again cycled the gears and with the engine running I checked the fluid level. Now it should read between the two Min-Max marks; to which it was a little low, so I added another couple of hundred ml of oil which brings it to bang on.

I'm not 100% certain this will fix all the leaks from the trans; they are well-known for leaking from new and being impossible to fix due to bad design, but hopefully this slows it down and reduces how much oil is ending up on the pipe. This also allows me to correctly monitor the oil level now.

So how did the test drive go? Well, the trans is quieter, smoother and shifts better. It was already pretty good by 1980s standards in my opinion, but now it shifts like a trans made some time in the late 90s. Smooth and almost unnoticeable shifting.

Now to put more rego on, and take for more hoons before its WOF expires again next month.