Not much done since last update what with having a cold then having the flu and don't forget the nice cold weather outside, with it being so cold and wet outside I decided that the wiring could wait until it gets a bit warmer ( probably next year ) and have started on the interior trim repair's.

First thing was to tackle was the damaged and cracked dashboard crash padding.

P1010151a by karl stroud, on Flickr

P1010151a by karl stroud, on Flickr

P1010150a by karl stroud, on Flickr

P1010150a by karl stroud, on Flickr

The loose plastic was first removed and the foam underneath ground down slightly, then all the cracks were ground right down with a die grinder.

P1010152a by karl stroud, on Flickr

P1010152a by karl stroud, on Flickr

Next polyurethane was melted into all the damaged area's with a plastic welder then flatted of to just below the level of the plastic finish with a power file.

P1010153a by karl stroud, on Flickr

P1010153a by karl stroud, on Flickr

P1010154a by karl stroud, on Flickr

P1010154a by karl stroud, on Flickr

This was then filled with flexible filler ( the type used for repairing bumpers ) and then sanded by hand to the same shape as the original finish.

P1010155a by karl stroud, on Flickr

P1010155a by karl stroud, on Flickr

P1010156a by karl stroud, on Flickr

P1010156a by karl stroud, on Flickr

P1010157a by karl stroud, on Flickr

P1010157a by karl stroud, on Flickr

P1010158a by karl stroud, on Flickr

P1010158a by karl stroud, on Flickr

P1010160a by karl stroud, on Flickr

P1010160a by karl stroud, on Flickr

This will get painted with texture paint at the same time as the other parts are done. The interior trim parts still to repair are, both door trims ( one very badly damaged and both slightly warped ), rear b-post to rear wheel arch plastic cover ( just needs covering in texture paint as all the texture has rubbed off ), rear shelf plastic trims ( same as the plastic covers ).

On another note I have started sorting out parts for the engine. I have bought the cylinder heads, but I did the one thing I said not to do I bought them with all valves in ( they were a silly cheap price with all the valves in ). I am now in the process of pulling them apart to double check valve fit, clean any casting flash off them with a die grinder and get rid of any sharp edge's and radius oil drain back holes.

P1010162a by karl stroud, on Flickr

P1010162a by karl stroud, on Flickr

P1010163a by karl stroud, on Flickr

P1010163a by karl stroud, on Flickr

P1010164a by karl stroud, on Flickr

P1010164a by karl stroud, on Flickr

P1010165a by karl stroud, on Flickr

P1010165a by karl stroud, on Flickr

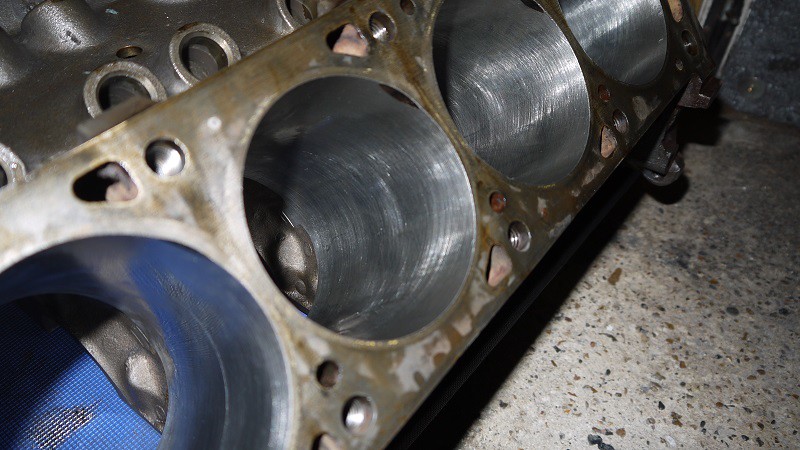

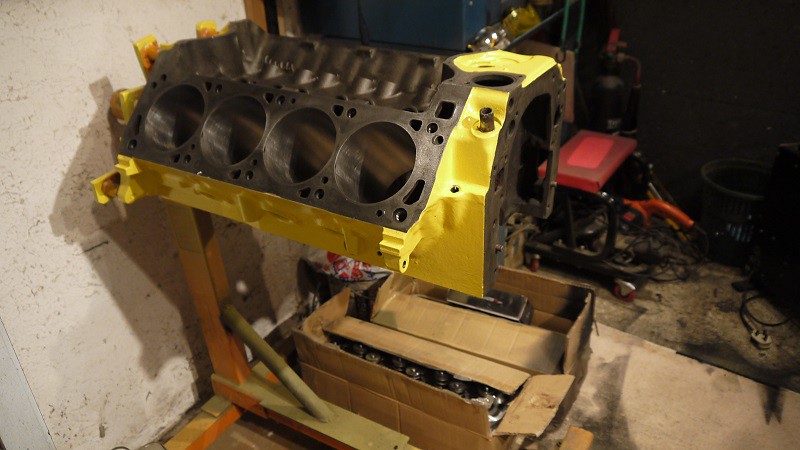

Also the engine block is now with the machine shop to be re-bored. I have decided to fit hypereutectic pistons made by speed-pro ( H555cp ) and plasma-moly rings ( r-9903 ), when the block is back I will be ordering a set of eagle con rods ( 5780f3d ) to complete the bottom end build.

Next I have got to choose what camshaft to use, these are the spec's of the ones I am looking at :

Lunati 30320511 ( old code 411a1lun )

In Ex

Duration 272 / 282

Duration @ 0.050 238 / 248

Lift ( gross ) 0.558 / 0.580

Lash 0.018 / 0.020

Valve opening BTDC 28 / 77 BBDC

Valve closing ABDC 64 / 25 ATDC

Overlap 53

LSA 112

RPM 2500 - 6500

Schneider cams 256-64f 254-74f

In Ex In Ex

Duration 256 / 264 264 / 274

Duration @ 0.050 212 / 224 224 / 230

Lift ( gross ) 0.502 / 0.519 0.519 / 0.532

Lash 0.012 / 0.014 0.014 / 0.014

Valve opening BTDC 20 / 68 BBDC BTDC 24 / 73 BBDC

Valve closing ABDC 56 / 16 ATDC ABDC 60 / 21 ATDC

Overlap 36 45

LSA 112 112

RPM 1500 - 5500 2000 - 6000

Howards cams 232342-10

In Ex

Duration 258 / 258

Duration @ 0.050 230 / 230

Lift ( gross ) 0.554 / 0.554

Lash 0.022 / 0.022

Valve opening BTDC 23 / 63 BBDC

Valve closing ABDC 55 / 15 ATDC

Overlap 38

LSA 110

RPM 2000 - 6200

Comp cams 270s 282s

In Ex In Ex

Duration 270 / 270 282 / 282

Duration @ 0.050 224 / 224 236 / 236

Lift ( gross ) 0.540 / 0.540 0.570 / 0.570

Lash 0.022 / 0.022 0.022 / 0.022

Valve opening BTDC 29 / 69 BBDC BTDC 35 / 75 BBDC

Valve closing ABDC 61 / 21 ATDC ABDC 67 / 27 BBDC

Overlap 60 62

LSA 110 110

RPM 1800 - 5800 2000 - 6000

At the moment I am leaning towards the Lunati cam as I have been told that a split pattern cam with a wide LSA and low overlap will suit my heads the best and give me the good vacuum at idle to work my power brakes and maintain low speed drivability, but if I do not go for this cam it will probably be the Schneider 254-74f cam as I have also been told that it is best to have the exhaust valve opening at around 80 BBDC because the later you open the exhaust valve the more it causes high RPM to drop off.

I will also be changing the toque converter to a higher stall to match whichever cam I fit and I will also be changing the rear axle ratio to suit as well.

If anybody has any feed back on these cams or know of any other mechanical flat tappet cams I have overlooked please let me know.

. The reason I am quite concerned about this is that the Cleveland is a thin wall casting and they also sometimes suffered core shift when casting, but the guy doing my machine work is sure that there is enough metal there to machine. Oh well time will tell, we will wait and see.

. The reason I am quite concerned about this is that the Cleveland is a thin wall casting and they also sometimes suffered core shift when casting, but the guy doing my machine work is sure that there is enough metal there to machine. Oh well time will tell, we will wait and see.