|

|

|

Mar 16, 2017 17:58:10 GMT

|

WOW Ive always wanted a Mach1 ever since a watched Clarkson drive a green one on old top gear way with Don Henlys Boys of summer playing in the back ground, Hats off to you for getting one and kudos to the top notch work bringing it back to its former glory, bookmarked, cant wait to see this all up and running  |

| |

|

|

|

|

|

|

|

Mar 16, 2017 18:03:43 GMT

|

|

Jump to 4:36 to see the MACH1

|

| |

|

|

|

|

|

Mar 16, 2017 18:12:41 GMT

|

|

I love a Mach 1! Definitely following this lovely motor!

|

| |

|

|

|

|

|

Mar 16, 2017 19:11:32 GMT

|

|

keep up the good work, I'm doing a 72 Sprint myself.

|

| |

|

|

|

|

|

Mar 16, 2017 20:10:05 GMT

|

|

outdoor resto and paint job takes some real cajones !

|

| |

|

|

|

|

|

Mar 17, 2017 21:55:32 GMT

|

Many thanks for the comments.

To answer a few questions, yep it was painted outside I just had to make sure my neighbours were not in ( I did not think that they wanted yellow cars as well ) and that there was a lack of wind, as it was I got a little overspray on the spitty ( it went on my new soft top, doh! ).

Nope this car will not be making it to the gathering this year as I still have the interior, the wiring, the front suspension and the engine to sort out yet.

I hope to keep the roof without anything on it just like it came from the factory, about the only mod which is happening on the outside is that I am going to fit a factory rear spoiler as mine was not ordered with one from new. It will be getting its side stripes back at some time in the future but only when I am happy with the finish of the paintwork as I have not got around to mopping it yet.

As to the engine I have big plans for that as the engine needs a rebore and a total rebuild. I Have already had the crank ground, straightened and tuftrided, next job to be done will be to have it rebored then fitted with sealed power pistons, then have ARP bolts fitted to the conrods then have them re circled, then I will grind off any casting flashes and get them at all the same weight, I will do the same with the pistons if needed. The main bolts will also be replaced with ARP bolts, next job on the block will be sorting the oil system, to do this I will be fitting restrictors in the cam oilways ( as they get far to much oil flow ) and I will also be sleeving the lifter bores as this is where the Cleveland block tends to lose most of its oil and then I will blue print the oil pump. I have not decided on what cam to fit yet but it will be a mechanical cam not hydraulic but I don't know if its worth the added expense of roller tappets over flat tappet at this time. The other thing I have yet to decide on is what to do over the heads, I can either have my existing heads worked on ( new valves, new guides, new inserts, ported then machined to take roller rockers ) but this might be pointless as they have a bad chamber design ( apparently prone to pinking ) or to invest in a set aftermarket heads like trickflow or AFD. Externally I already have a set of headers and twin 2.5 inch exhaust system which I will be reusing, on the induction side of things I plan on having a carb manifold modified to take injectors and EFI hardware and I will be using an old holly dominator as a throttle body, by doing this I can keep the semi stock look of the engine externally and also use the ram air intake setup, and the ignition will be done by coilpacks. Most of the work on the engine will not be done this year as at the moment the car itself ( bodywork and interior) is eating most of my cash.

There are lots of other little mods I will be doing to the car but I will leave posting about them till I do them. |

| |

71 ford mustang being restored

71 triumph spitfire 3.5 v8

88 bmw e32 735 --SOLD--

|

|

andyw

North East

Posts: 238

|

|

Mar 17, 2017 23:01:57 GMT

|

|

Fantastic work

|

| |

|

|

|

|

|

|

|

|

My dad had a 1972 Mach 1 for years, it was black with flames when he bought it, but he resprayed it signal red not long after! We went everywhere in that car, I loved it and will own one myself one day.....

As for your induction idea, have you considered the FiTech units that are now available? Looks similar to a holley but is fuel injection. Might save you a whole heap of cash...

|

| |

|

|

|

|

|

Mar 19, 2017 23:09:28 GMT

|

|

Before you buy any parts or start to build your engine get a clear goal of what you want as in power and manners as you can't always have both and getting it wrong can get very costly and frustrating .

Nothing wrong with 2v heads (similar design to a pinto) my friend you will have no trouble with pinking that's just low grade petrol in the states, it is possible to use a 4v exhaust valve and definitely change all to 1 piece stainless. Oiling mods choose one or the other you won't need both or any unless you are constantly reeving the nuts of it( they are not as bad as made out) nor is blue printing the pump needed for a road car(stick with a standard pump).Cam choice can have a knock on effect and lead to a lot of extra spend ie high stall convertor and gear change and I personally wouldn't recommend using a solid lifter cam for a road car and stick with hydraulic ( less adjustments and longer wear).I recommend buying your cam as a kit with springs roller, rockers etc that way all matches and leave the push rods till you have finished machining and built her up then you can check the length properly'

After market heads may need different intake and headers so worth checking before buying, it is far to easy to get confused with Clevelands with so much info and a lot of it is really for those at the top end and even they can't agree.Might actually be worth pricing an engine from the states.

I hope I don't come across as being negative or a smart ass just trying to help as your work on a driveway puts me to shame.

|

| |

Last Edit: Mar 19, 2017 23:12:47 GMT by slow2learn: didn't mean to give myself a thumbs up (what a dumbass)

|

|

|

|

|

Mar 19, 2017 23:14:52 GMT

|

|

Sorry meant to ask did you put in sub frame connectors ?

|

| |

|

|

|

|

|

|

|

|

|

|

I have put in sub frame connectors ( made my own ) and I will be cross bracing the underside when the engine, exhaust and prop shaft are in, as for the engine any advice is welcome, as you have said, info concerning the Cleveland is a bit of a mine field. As for the oil system mods I am looking at all my options.

Camshaft wise I am looking at something streetable ( not to mad, from somebody like comp cams or lunati ) with a touch of lope at idle and I will be fitting a new high stall torque to match the cam and possibly, depending on the cams specs a new rear axle CROWN wheel and pinion. The reason that I am persevering with this engine as it is a numbers matching engine for the car, the only problem is that sometime in the past the engine has been abused and this has caused a lot of wear internally ( 15+ thou on the cylinder bores, lifter bores slightly scored, crank journals badly scored, oil ways full of muck and the rocker assembly totally worn out ) so a lot needs to be repaired, modified and replaced before it can be run again.

As to the question about the holley system I have looked at these combined throttle body systems but I want to go fully sequential as I have done on my v8 spitfire using a megasquirt ecu as I am comfortable with this setup and it can be modified very easily.

|

| |

71 ford mustang being restored

71 triumph spitfire 3.5 v8

88 bmw e32 735 --SOLD--

|

|

|

|

|

Mar 22, 2017 14:20:46 GMT

|

|

Nice job.

Regarding the engine as mentioned above I wouldn't use a mechanical cam if its mainly a street engine. My old engine ran 12.9 1/4 mile with open chamber 2v heads with 4v exhaust valves , mild hydraulic cam & a Weiand X-Celerator intake. I have never done the oiling system mods and never had any issues but i only turn my engine to 6000 rpm. Clevelands can have heating problems when overbored more than 30 thou as many suffer from core shift.

Also beware of the cooling system. Some aftermarket water pumps block the warm up cooling system circuit dead heading the system and letting the water boil in the heads before the stat opens. You must also run the correct stat which blocks the bypass circuit when the engine is up to temperature. Many places sell you a Windsor thermostat which is incorrect.

I currently run a 351 with a comp cams roller hydraulic CHN alloy 3v heads & CHN intake manifold and a demon carb. It's quite streetable except for fuel consumption.

|

| |

|

|

|

|

|

Mar 31, 2017 22:29:21 GMT

|

Well got the weather for doing a few more jobs on the mustang, so onwards we go.

First of all I managed to fit the new door rubbers to the doors and door frames and managed to fit the new door locks and handles ( without making the lock explode like I did with the original locks ), then I managed to fit the doors ( fitting was easy adjusting the door gaps a complete pain ) and got the wings back on with all of there mounting hardware, then came the fun job of aligning wings to the doors and bonnet ( 2 hours of backwards and forwarding of panels until right ).

Next job done was to temp fit the quarter windows, this was a completely horrible job because the new window felts must of been made by someone who was drunk as the clips had been put in all the wrong places and the felts did not match the body line, on top of all this the screws supplied where as strong as soft cheese. So as it was it took me all day to fit the quarter windows ( as it is the windows have got to come out again to do the sound proofing ) and I still have the front window felts to look forward to yet.

A couple of other small jobs done as well, I have got the headlamp brackets back in, the bumper mounts temp fitted and lastly I have fitted the Hood ram air scoops. The next jobs on the list while the weather is good is to get the windscreen out and see how bad the crack is in it and to see if I need to order a new screen, start putting in the sound proofing, fit the door glass and waxoil the car. If the weather turns nasty again I can get on with modifying and restoring the front suspension so I can get that fitted and get the shocks ordered.

P1000963a by karl stroud, on Flickr P1000963a by karl stroud, on Flickr

P1000964a by karl stroud, on Flickr P1000964a by karl stroud, on Flickr

P1000965a by karl stroud, on Flickr P1000965a by karl stroud, on Flickr

P1000966a by karl stroud, on Flickr P1000966a by karl stroud, on Flickr

P1000967a by karl stroud, on Flickr P1000967a by karl stroud, on Flickr

P1000968a by karl stroud, on Flickr P1000968a by karl stroud, on Flickr

|

| |

Last Edit: Sept 9, 2017 1:35:26 GMT by kusanagi

71 ford mustang being restored

71 triumph spitfire 3.5 v8

88 bmw e32 735 --SOLD--

|

|

|

|

|

|

|

Well I dug my windscreen out and its had it, over the winter it looks like the frost got into screen between the laminate and has caused a large crack right through the middle of the screen  , so that's another thing I will have to replace. , so that's another thing I will have to replace.

On to other jobs, I have finished reinforcing the suspension arms got them painted and fitted all the ball joints and new upper and lower inner bushes and are now fitted to the car, I have also temp fitted my front hubs so when I have finished fitting all the suspension I can get it off axle stand and on to its wheels for the first time in 7 years ( the hubs might be changed as I have not decided on the front brake setup yet ). Also fixed was the front bump stop mounts, they where that rotten you could fit your hand through the middle of them.

The next jobs to do are either finish reconditioning the shocks and springs and then fit them or it will be to finish fitting the sound proofing to the doors so that I can fit the door glass. Some other jobs which have to be done are to recondition the steering arms and to make a set of rose jointed strut rods to replace the bent ones which I currently have.

P1000945a by karl stroud, on Flickr P1000945a by karl stroud, on Flickr

P1000947a by karl stroud, on Flickr P1000947a by karl stroud, on Flickr

P1000946a by karl stroud, on Flickr P1000946a by karl stroud, on Flickr

P1000959a by karl stroud, on Flickr P1000959a by karl stroud, on Flickr

P1000960a by karl stroud, on Flickr P1000960a by karl stroud, on Flickr

P1000962a by karl stroud, on Flickr P1000962a by karl stroud, on Flickr

P1000971a by karl stroud, on Flickr P1000971a by karl stroud, on Flickr

P1000970a by karl stroud, on Flickr P1000970a by karl stroud, on Flickr

P1000972a by karl stroud, on Flickr P1000972a by karl stroud, on Flickr

P1000973a by karl stroud, on Flickr P1000973a by karl stroud, on Flickr

P1000974a by karl stroud, on Flickr P1000974a by karl stroud, on Flickr

P1000975a by karl stroud, on Flickr P1000975a by karl stroud, on Flickr

|

| |

Last Edit: Sept 9, 2017 1:44:07 GMT by kusanagi

71 ford mustang being restored

71 triumph spitfire 3.5 v8

88 bmw e32 735 --SOLD--

|

|

|

|

|

|

|

|

Great progress! It's looking excellent.

|

| |

'84 308 GTS /// '88 528e /// '88 M5 /// '89 944 Turbo /// '98 E430

|

|

|

|

|

Apr 21, 2017 22:34:01 GMT

|

The new screen has finally been ordered but will take about six weeks to get here, so for now I have put the cracked screen in place to keep the weather out of the car ( great stuff duct tape ), also the headliner and all the bits for it have been ordered but that should be here in about three weeks and I have also ordered the final bits for the suspension, a 1 1/8" front sway bar kit and a set of KYB rear shocks, again I should have them in about three weeks, this should give me the time to build the new adjustable stay bars ( the originals are bent as were the lower track control arms, possibly one of the earlier owners may have been doing jumps in the car or something like it ).

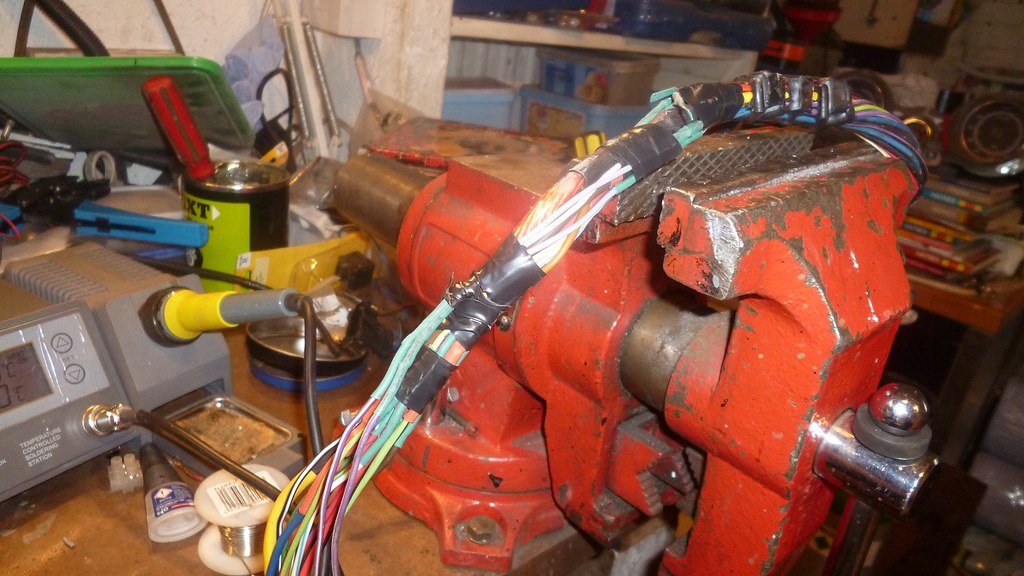

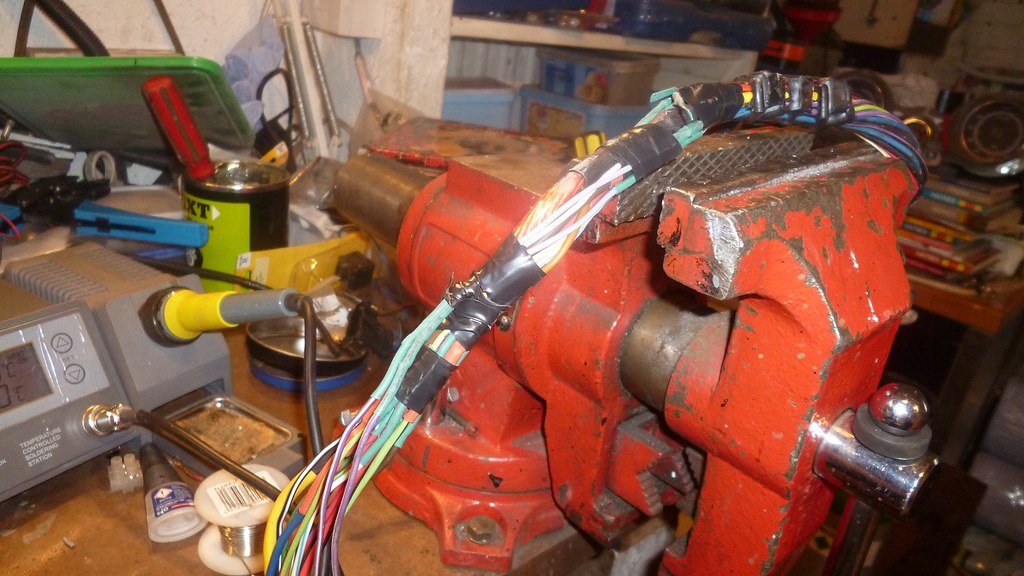

With the screen wedged in place to keep the weather out I have started putting the sound proofing in, both doors have been done internally as have the areas under the rear quarter windows and also done is the bulkhead ( all areas described have been done with a sound dampener then a 10mm foam rubber sheet ), I have also fitted the reconditioned heater setup and reconditioned pedals and steering support. The dash assembly as it being metal was also treated with sound dampener, then the wiring was fitted and cushioned with foam to stop vibration ( hopefully doing these jobs will make the car a bit more civilised ). The dash frame was then fitted, the only problem I had with doing this was that when I started fitting up the passenger side ducting one of the plastic mounts for the vent broke off  , so this meant that all the ducting and vents had to come out again ( not an easy job with the dash in ). The part which broke has broken before and was fixed with a two part plastic epoxy but it looks like that was not any use for this type of plastic, so to that end I have ordered a plastic welding kit ( gas soldering iron type ) to have a go at fixing it, I will also use this kit if it works to fix my grill assembly as that is also cracked and broken. , so this meant that all the ducting and vents had to come out again ( not an easy job with the dash in ). The part which broke has broken before and was fixed with a two part plastic epoxy but it looks like that was not any use for this type of plastic, so to that end I have ordered a plastic welding kit ( gas soldering iron type ) to have a go at fixing it, I will also use this kit if it works to fix my grill assembly as that is also cracked and broken. The other job on the car I have been doing is sorting the engine bay loom out as it is a mess, first of all it is covered in scotch clips  and has lots of cracks in the insulation of some wires, the other fault is just where the loom comes through the bulkhead there was a big lump in the loom which should not be there, so the loom tape was removed and revealed a nightmare of bad wiring as at sometime in the past someone had damaged the loom in the engine bay and decided to replace it, the only problems with doing this is that A. they did not use a mach one loom so this means that the ammeter did not work and there was no wiring for the grill marker lamps ( this explains the scotch clips ) and B. they only twisted the wires together then taped them up, no soldering and no crimp joints this includes the main power feed for the cars wiring ( this now explains why the car kept blowing fuses and the intermittent electrical problems ). and has lots of cracks in the insulation of some wires, the other fault is just where the loom comes through the bulkhead there was a big lump in the loom which should not be there, so the loom tape was removed and revealed a nightmare of bad wiring as at sometime in the past someone had damaged the loom in the engine bay and decided to replace it, the only problems with doing this is that A. they did not use a mach one loom so this means that the ammeter did not work and there was no wiring for the grill marker lamps ( this explains the scotch clips ) and B. they only twisted the wires together then taped them up, no soldering and no crimp joints this includes the main power feed for the cars wiring ( this now explains why the car kept blowing fuses and the intermittent electrical problems ). What was worse was oil had got inside the electrical tape so this was a fire waiting to happen, so now the wires have been repaired, soldered and covered in heat shrink. I have also put the wire back for the grill marker lights and have modified the lighting circuit to take relays for the main and dipped lights and horn. This will get wrapped in loom tape when I get some more wiring to finish the relay circuits.

P1000982a by karl stroud, on Flickr P1000982a by karl stroud, on Flickr

P1000983a by karl stroud, on Flickr P1000983a by karl stroud, on Flickr

P1000988a by karl stroud, on Flickr P1000988a by karl stroud, on Flickr

P1000991a by karl stroud, on Flickr P1000991a by karl stroud, on Flickr

P1000992a by karl stroud, on Flickr P1000992a by karl stroud, on Flickr

P1000984a by karl stroud, on Flickr P1000984a by karl stroud, on Flickr

P1000985a by karl stroud, on Flickr P1000985a by karl stroud, on Flickr

P1000989a by karl stroud, on Flickr P1000989a by karl stroud, on Flickr

P1000990a by karl stroud, on Flickr P1000990a by karl stroud, on Flickr

|

| |

Last Edit: Sept 9, 2017 1:50:40 GMT by kusanagi

71 ford mustang being restored

71 triumph spitfire 3.5 v8

88 bmw e32 735 --SOLD--

|

|

onlyv8

Part of things

Posts: 28

|

|

|

|

|

Great work, hats off to you doing all this outside. Can't be easy.

Good luck with it.

|

| |

|

|

|

|

|

May 12, 2017 22:09:13 GMT

|

Well its about time for another update on the money pit. I have finished designing and making my stay bars and have now fitted them, the reason I have replaced the original bars was that they where bent like a banana and even if I bought new replacement bars I was still stuck with using a rubber bush to locate the lower track control arm at least with the new arms the track control arm is kept in place with rod ends.

P1000993a by karl stroud, on Flickr P1000993a by karl stroud, on Flickr

P1000994a by karl stroud, on Flickr P1000994a by karl stroud, on Flickr

P1000995a by karl stroud, on Flickr P1000995a by karl stroud, on Flickr

P1000996a by karl stroud, on Flickr P1000996a by karl stroud, on Flickr

P1000997a by karl stroud, on Flickr P1000997a by karl stroud, on Flickr

P1000998a by karl stroud, on Flickr P1000998a by karl stroud, on Flickr

P1000999a by karl stroud, on Flickr P1000999a by karl stroud, on Flickr

P1010001a by karl stroud, on Flickr P1010001a by karl stroud, on Flickr

P1010008a by karl stroud, on Flickr P1010008a by karl stroud, on Flickr

P1010009a by karl stroud, on Flickr P1010009a by karl stroud, on Flickr

P1010010a by karl stroud, on Flickr P1010010a by karl stroud, on Flickr

P1010011a by karl stroud, on Flickr P1010011a by karl stroud, on Flickr

I have also got around to reconditioning and fitting my rear lights.

P1010003a by karl stroud, on Flickr P1010003a by karl stroud, on Flickr

P1010004a by karl stroud, on Flickr P1010004a by karl stroud, on Flickr

P1010005a by karl stroud, on Flickr P1010005a by karl stroud, on Flickr

The next job I have sorted out is the prop shaft, this has been cleaned and repainted and has new U joints fitted the gearbox has been fitted to the car as well but upon fitting the prop shaft to the car a problem has developed. The problem is that the rear u joint does not fit the differential flange, the correct part was ordered and the box is correct but the part in the box is wrong. The way that the u joint is wrong is that the car has a 1310 BC ( Big Cap ) flange fitted to the differential this means that the prop requires a 1 1/16 " cap the diff requires a 1 1/8 " cap with both measuring across the caps 3 7/32 ". The u joint supplied in the box had both caps measuring at 1 1/16 " ( the same as the front u joint ) so this means that I have to try and get the correct part sent to me and the prop shaft will have to come out again to have the correct u joint fitted, the only good thing is that as the gear box is in the car I can get the cooling lines run.

P1010012a by karl stroud, on Flickr P1010012a by karl stroud, on Flickr

I have also started to fit some more of the sound proofing in readiness for my headlining ( the roof and rear quarters ) and will be fitting the sound proofing to the boot area soon, then I can get to fitting the swirl pot and fuel pumps.

P1010013a by karl stroud, on Flickr P1010013a by karl stroud, on Flickr

P1010014a by karl stroud, on Flickr P1010014a by karl stroud, on Flickr

The next major job to get done while I am waiting for my suspension parts to arrive will be to recondition, repaint and fit a new ignition lock to my steering column then fit that to the car.

|

| |

Last Edit: Sept 9, 2017 2:05:11 GMT by kusanagi

71 ford mustang being restored

71 triumph spitfire 3.5 v8

88 bmw e32 735 --SOLD--

|

|

|

|

|

May 13, 2017 10:47:45 GMT

|

Love this. When I was a teenager there was one in Clacton (Orange with black) which I fell in love with. Sadly, being 14 when this picture was taken I never got to buy it  My dad would not buy it for me either. Parents can be so cruel...  |

| |

Last Edit: May 13, 2017 10:52:54 GMT by mrbounce

|

|

luckyseven

Posted a lot

Owning sneering dismissive pedantry since 1970

Owning sneering dismissive pedantry since 1970

Posts: 3,839

Club RR Member Number: 45

|

1971 mustang mach1luckyseven

@luckyseven

Club Retro Rides Member 45

|

May 13, 2017 11:23:51 GMT

|

Just stumbled across this thread. Dunno why everyone keeps going on about how amazing you are for doing this out on the driveway  ....cos I couldn't manage one tenth of this level of excellence in a fully-equipped climate-controlled workshop  Superb work, humbling. Having just had to sort hateful mutilation on my own wiring loom, I feel the pain. Someone else's historic wiring bodges are my personal worst nightmare |

| |

|

|

|

|

, so that's another thing I will have to replace.

, so that's another thing I will have to replace.

, so this meant that all the ducting and vents had to come out again ( not an easy job with the dash in ). The part which broke has broken before and was fixed with a two part plastic epoxy but it looks like that was not any use for this type of plastic, so to that end I have ordered a plastic welding kit ( gas soldering iron type ) to have a go at fixing it, I will also use this kit if it works to fix my grill assembly as that is also cracked and broken.

, so this meant that all the ducting and vents had to come out again ( not an easy job with the dash in ). The part which broke has broken before and was fixed with a two part plastic epoxy but it looks like that was not any use for this type of plastic, so to that end I have ordered a plastic welding kit ( gas soldering iron type ) to have a go at fixing it, I will also use this kit if it works to fix my grill assembly as that is also cracked and broken. and has lots of cracks in the insulation of some wires, the other fault is just where the loom comes through the bulkhead there was a big lump in the loom which should not be there, so the loom tape was removed and revealed a nightmare of bad wiring as at sometime in the past someone had damaged the loom in the engine bay and decided to replace it, the only problems with doing this is that A. they did not use a mach one loom so this means that the ammeter did not work and there was no wiring for the grill marker lamps ( this explains the scotch clips ) and B. they only twisted the wires together then taped them up, no soldering and no crimp joints this includes the main power feed for the cars wiring ( this now explains why the car kept blowing fuses and the intermittent electrical problems ).

and has lots of cracks in the insulation of some wires, the other fault is just where the loom comes through the bulkhead there was a big lump in the loom which should not be there, so the loom tape was removed and revealed a nightmare of bad wiring as at sometime in the past someone had damaged the loom in the engine bay and decided to replace it, the only problems with doing this is that A. they did not use a mach one loom so this means that the ammeter did not work and there was no wiring for the grill marker lamps ( this explains the scotch clips ) and B. they only twisted the wires together then taped them up, no soldering and no crimp joints this includes the main power feed for the cars wiring ( this now explains why the car kept blowing fuses and the intermittent electrical problems ).

....cos I couldn't manage one tenth of this level of excellence in a fully-equipped climate-controlled workshop

....cos I couldn't manage one tenth of this level of excellence in a fully-equipped climate-controlled workshop  Superb work, humbling.

Superb work, humbling.