Cool, thanks for the recommendation, I'll have to see how close to the coast we stick. West coast is definitely on my list of places to visit!

I actually managed to get out the last two days and do a half decent stint on the car!

Job number one, clean up the scuttle area. Before (you can see the patched up battery tray which was the first bit of welding I did on this before I started this thread, it was a bit more of a rush job as it was before I'd given up on getting the car straight back on the road:

After:

I'd trimmed a bit much out of the inner wing's box section to make way for the cage. I thought it would work well to patch this in with a bit of a spreader plate rather than just a flush fitted section, a decisions made in no way by how much easier it would be to do... honestly... Anyway, although I didn't get any photos that show it, there's also a plate closing the vertical face into the bottom of this one:

Before:

After:

I also cleaned up some surface rust on the passenger side engine mount and stitch welded it. I'll be running quite firm polyurethane mounts, so I thought this might be a good idea. Although that said, like a lot of stuff on this shell Porsche's design seems spot on and I'm sure it would have been fine. I really am impressed by the way they put these shells together; everywhere I'd usually want to improve on the thing's already designed in a way where there's no real improvement to be had, it's almost spoiling my fun! I though I may as well stitch this while I was there though, no harm in belt and braces. Not the neatest welds sadly as it was impossible to get all the seam sealer out of the joints they should clean up fine though:

I though I may as well stitch this while I was there though, no harm in belt and braces. Not the neatest welds sadly as it was impossible to get all the seam sealer out of the joints they should clean up fine though:

Next up I wanted to add some strength to the rear shock mounts as I'll be using coilovers and being about a 0.6:1 motion ratio the coilovers end up with some pretty firm rates. I'd deliberately brought the cage's rear legs down onto the boot floor directly above the shock mounts so it was an easy task of bridging the gap between the shock's bracket and the floor above it.

Before (other than some cleaning up):

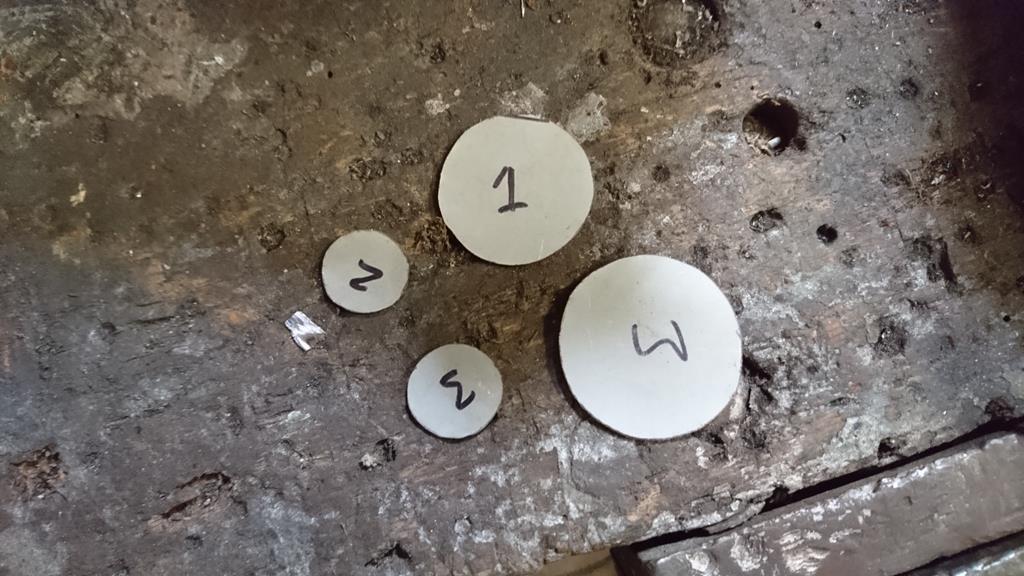

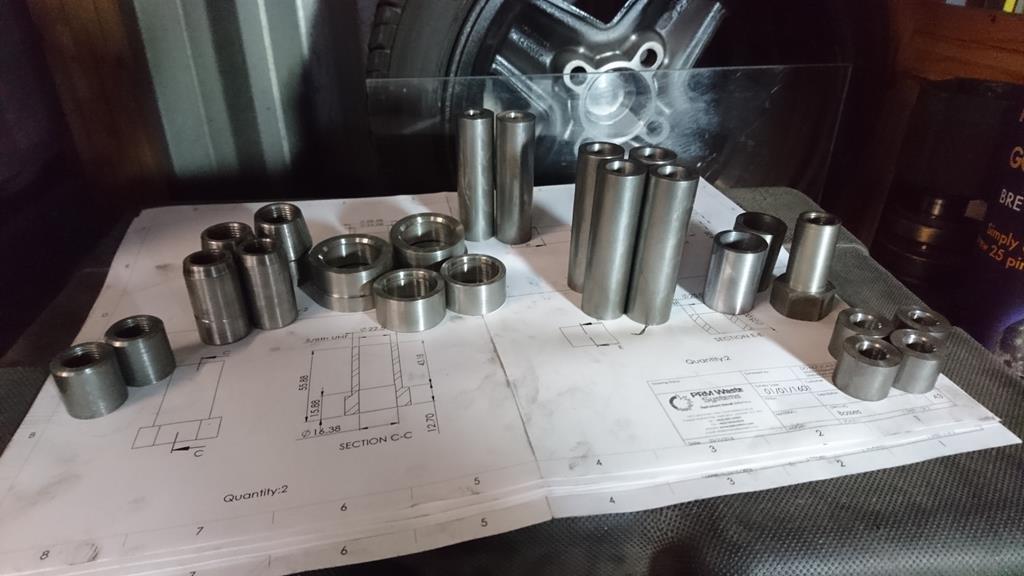

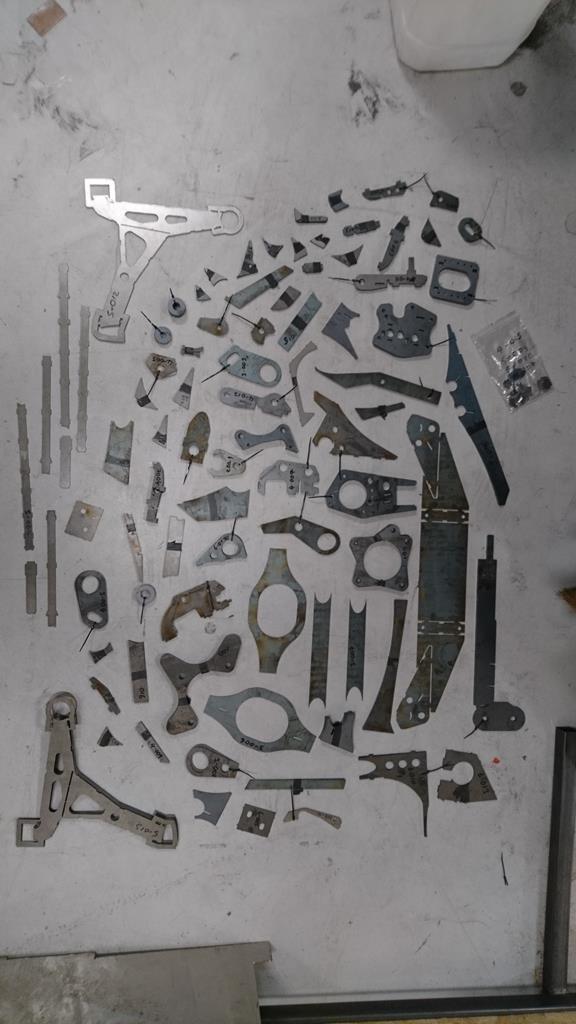

Some 3mm plate cut out and bent:

In Place:

Hot-metal glue-gun'd:

A friend had commented on a bit of cut-up pedalbox that was in my 'offcuts' bin looking too good to scrap and it got me thinking that actually it's a ready-made start to hydraulic handbrake, so I cleaned up the cut edges and trimmed off any unnecessary bits:

Just need to work out where's best to fit it so I can make a handle to suit and some mounts.

I actually managed to get out the last two days and do a half decent stint on the car!

Job number one, clean up the scuttle area. Before (you can see the patched up battery tray which was the first bit of welding I did on this before I started this thread, it was a bit more of a rush job as it was before I'd given up on getting the car straight back on the road:

After:

I'd trimmed a bit much out of the inner wing's box section to make way for the cage. I thought it would work well to patch this in with a bit of a spreader plate rather than just a flush fitted section, a decisions made in no way by how much easier it would be to do... honestly... Anyway, although I didn't get any photos that show it, there's also a plate closing the vertical face into the bottom of this one:

Before:

After:

I also cleaned up some surface rust on the passenger side engine mount and stitch welded it. I'll be running quite firm polyurethane mounts, so I thought this might be a good idea. Although that said, like a lot of stuff on this shell Porsche's design seems spot on and I'm sure it would have been fine. I really am impressed by the way they put these shells together; everywhere I'd usually want to improve on the thing's already designed in a way where there's no real improvement to be had, it's almost spoiling my fun!

I though I may as well stitch this while I was there though, no harm in belt and braces. Not the neatest welds sadly as it was impossible to get all the seam sealer out of the joints they should clean up fine though:

I though I may as well stitch this while I was there though, no harm in belt and braces. Not the neatest welds sadly as it was impossible to get all the seam sealer out of the joints they should clean up fine though:

Next up I wanted to add some strength to the rear shock mounts as I'll be using coilovers and being about a 0.6:1 motion ratio the coilovers end up with some pretty firm rates. I'd deliberately brought the cage's rear legs down onto the boot floor directly above the shock mounts so it was an easy task of bridging the gap between the shock's bracket and the floor above it.

Before (other than some cleaning up):

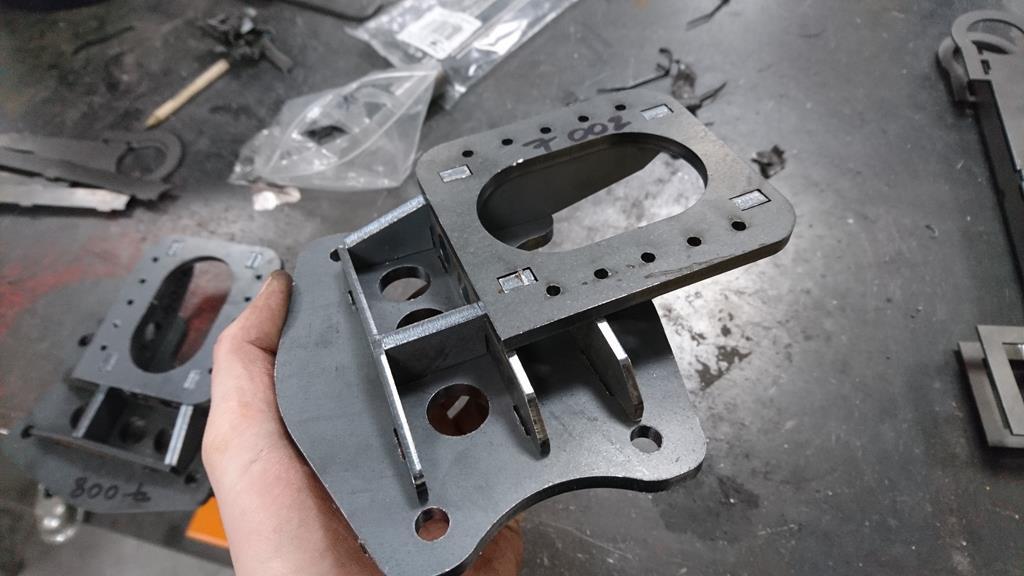

Some 3mm plate cut out and bent:

In Place:

Hot-metal glue-gun'd:

A friend had commented on a bit of cut-up pedalbox that was in my 'offcuts' bin looking too good to scrap and it got me thinking that actually it's a ready-made start to hydraulic handbrake, so I cleaned up the cut edges and trimmed off any unnecessary bits:

Just need to work out where's best to fit it so I can make a handle to suit and some mounts.