|

|

|

Feb 26, 2023 17:46:01 GMT

|

I’d wanted to finish the bulkhead before putting the car back on the rotisserie, but the stars didn’t align for folding the aluminum so on the rotisserie it went. Remember the link boxes?  The keener eyed amongst you might have thought “how is that idiot going to fit the bottom axle links with those tubes welded in there?” Well my intention was always to cut them out after the link boxes were welded in to reduce the risk of things moving. It would be a simple job of cutting them out with the grinder  Or not, as a new disc wasn’t big enough to cut all the way through 😩. So I brought out the big guns  The tubes gave in  And after a tickle with the new power file  The link boxes hang down from the floor so are a bit vulnerable. So I needed some skidage. So I made a template and folded a bit of 1,6mm steel - the wrong way. No worries I’ll just put it on the other side as it should be a mirror image. No. The floor is different the other side so the exhaust box can sit higher up. So I trimmed and trimmed the bit until it fitted. Luckily the cardboard template I made was somehow miles to big so there was plenty of meat left to adapt it. Got them welded on   This left a gap between the skidage and the bottom of the link box.   So I welded some bits in and ground them off   And added a bit of primer  So next I turned my attention to one of the turrets that I hadn’t trimmed down  Cut, welded and part ground back  Because even though I have a new power file, I’ve got no belts. I know I had 2 but I’ve put them down and can’t find them. |

| |

|

|

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

Feb 26, 2023 17:52:13 GMT

|

|

Liked, not for the progress, but for the reassurance that I’m not the only one who has things he put down a nanosecond ago and then can’t find.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Feb 26, 2023 18:08:11 GMT

|

|

Nice skiddies, dude.

|

| |

|

|

|

|

|

Feb 26, 2023 19:23:59 GMT

|

Liked, not for the progress, but for the reassurance that I’m not the only one who has things he put down a nanosecond ago and then can’t find. I’m useless Glen. I loose everything. Being an untidy worker realty doesn’t help. |

| |

|

|

|

|

|

Feb 26, 2023 19:25:18 GMT

|

Cheers Teaboy. Nobody has ever complimented me on my skiddies before |

| |

Last Edit: Feb 26, 2023 19:25:35 GMT by jonsey

|

|

|

|

|

|

|

I’ve had a delivery of sanding belts so I could crack on with finishing off the turrets. As I had welded the turrets from inside the car, when I trimmed the excess material off in the wheel arch, an unwelded line was left. So I welded it.  Then ground back  And then a bit of primer added  The other side needed the same once cut back  So I started welding and then the welder started playing up. Everything looked ok but the gas was only pretending to work as when I looked at the gauge it read 0. It was giving a burst of gas but then dropping off. Luckily the place I buy the gas from was open until 3pm so I managed to get it sorted so I could finish off. While I was there I decided to go for a 30liitre(?) bottle instead of the 20 I usually get.  So i finished the welding (no pic) and ground it all back  An added a bit of primer to that side too  At this point some of our Shepherd hut guests turned up so I couldn’t make any more noise, but I’d done what I needed to do noise wise. I can’t remember if I said, but I’d bought a sheet of 1.2mm aluminum to skin the bulkhead. I needed to cut it to size and put a fold in it. As my guillotine is hand operated and I’m useless at cutting straight lines with it, and I don’t have a folder, I went to see my neighbour with the Historic Escort as he has a big folder and a 4’ guillotine. The trip up the road resulted in this  I had to put another small fold in the bottom but as it was only a few degrees I did it with some scrap in the vice  It goes here  I’ve had to put some notches in the bottom to clear the link boxes and some welds and it looks messy. I’m going to weld a bit of steel behind there so I can just cut the notches square. Hopefully I’ll get that sorted tomorrow and get the aluminum riveted in |

| |

|

|

|

|

|

|

|

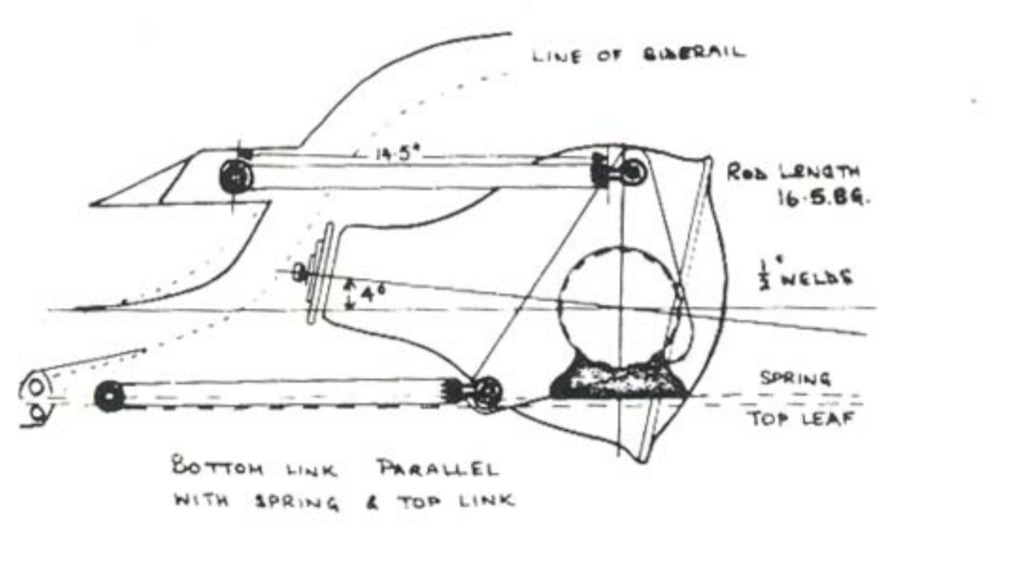

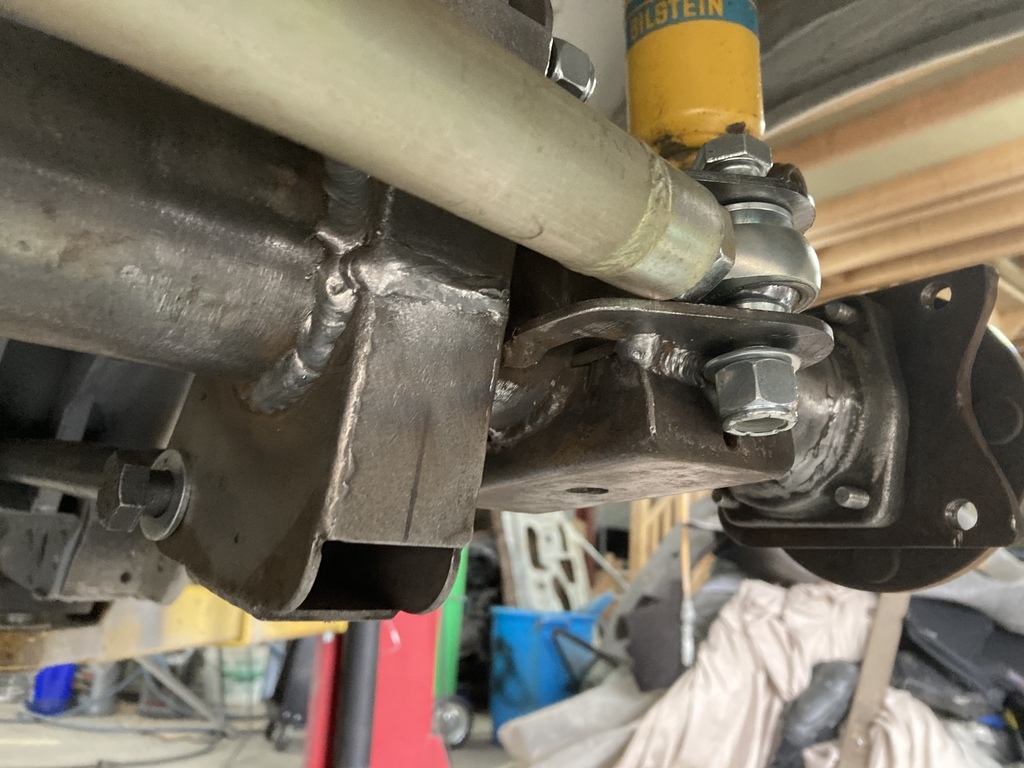

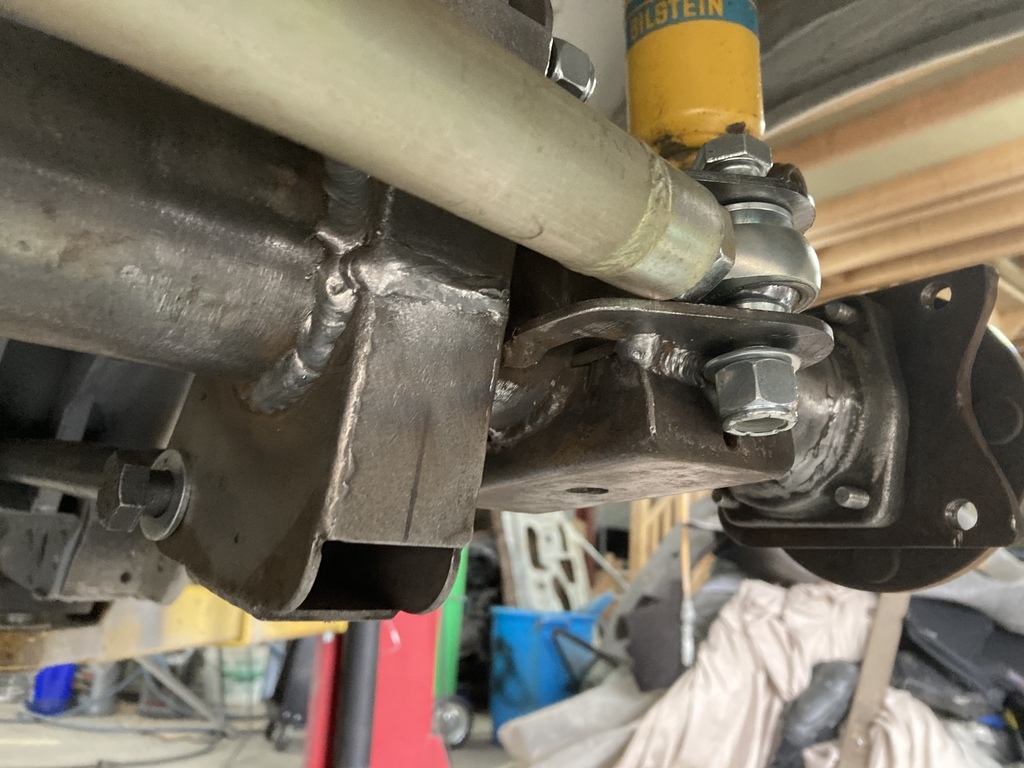

I was late out the garage today because I lay in bed until nearly 10am and then had a fry up. After that I went out the garage and met the lady who’s bought the field next door so ended up talking for ages. Those are my excuses for not getting much done out of the way. So i primered the turrets after sanding the flash rust off, I welded the little plates on the bottom that I mentioned yesterday and I’ve now noticed I took no photos of any of this. Anyway, the paint needed to dry so I went over my brothers and gave him a hand to put the axle back on his rally car. On my return I riveted the aluminum on   Blingy or what? It will be painted. Other than riveting the cover back on over the fuel filler pipe (it will need a little mod), this marks the end of the turret / link box work (it seems to have gone on a bit). Well nearly. I still have to fit these to the axle.  Obviously they can’t just slide on as hubs and spring platforms are in the way so I cut them in half  The axle looks like this  So I cut the remaining brake pipe clip off and the redundant tramp bar brackets  I ground all the welds off but no photo. And then got the brackets tacked back together on the axle  Both sides  I could not weld them fully as the instructions I have say to mount the axle to the car on its slipper springs and link bars on and then load the car until the slipper spring is parallel to the link bars. But I don’t have any slipper springs, only conventional “eye” springs. I’m sure there must be a known angle out there to weld them on in relation to the diff flange, so I’ve asked the question on a FB group. There’s plenty of companies out there selling pre-made axles so someone must know. |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

|

|

I lay in bed until nearly 10am and then had a fry up. That sounds like the perfect morning!  |

| |

|

|

|

|

|

|

|

I lay in bed until nearly 10am and then had a fry up. That sounds like the perfect morning!  it was pretty good Mr T |

| |

|

|

|

|

|

|

|

So I thought I’d go out the garage and connect the axle and link bars up. A nice easy job that shouldn’t take long. 4 links  And fitted  Balls. The link bars are 15.25” long. They should be 14.5”  So I cut the ends off,  Machined the pipe off in the lathe and refitted   That’s better |

| |

|

|

|

|

|

|

|

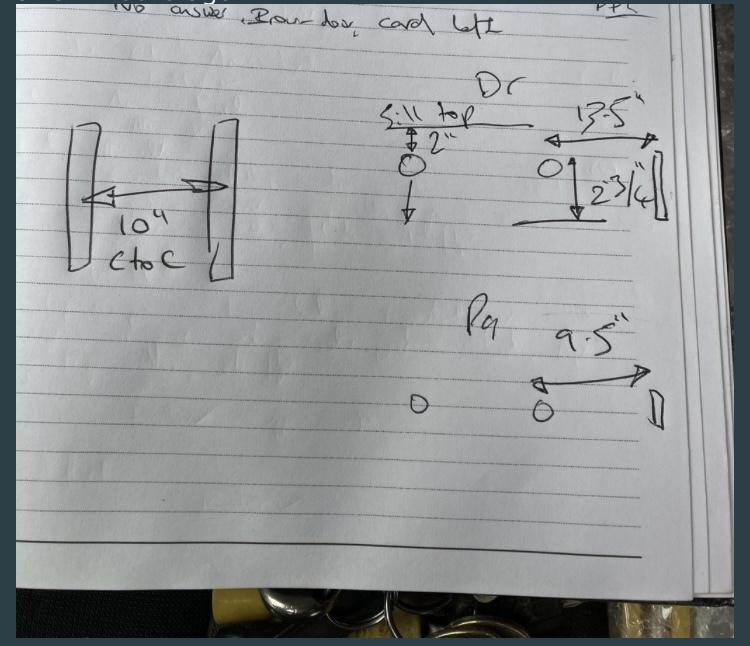

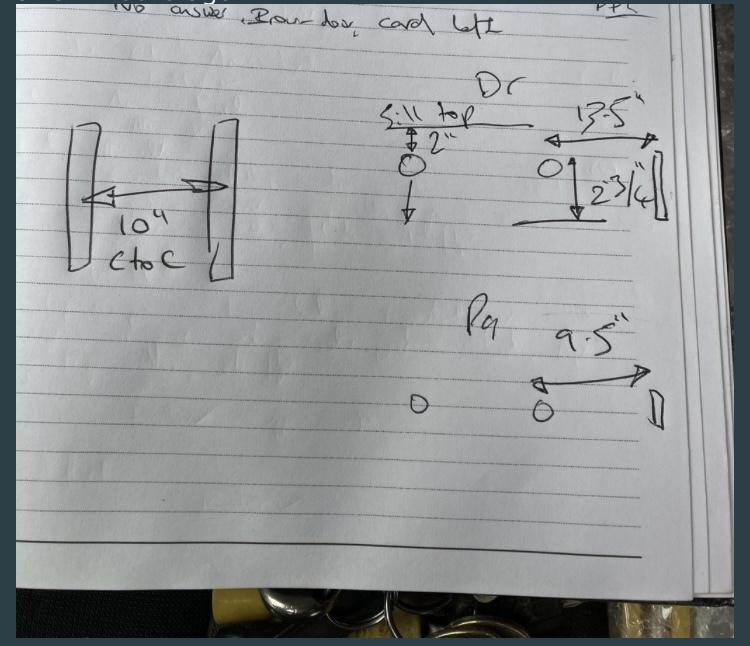

I was on call last night. When I awoke this morning, Mrs Jonsey asked what shift I was on, so I replied, days. Then I thought for a second or two and realised I’d booked the day off as Jones Junior ( the elder) had booked his driving test for today. He then managed to get an earlier test last week (he passed by the way👏), but I’d forgotten to cancel the holiday. So I had the day off when I thought I was going to work!! Best feeling ever. I could now go straight out the garage and make a chunk of progress but Mrs Jonsey had other plans and I ended up driving to Cardiff and going to Ikea. To make matters worse their cafe was closed so no meat balls for me😩. On our return a headed straight out the garage, cut down the link bars for the other side and welded the threaded ends back on. I’d turned the welder up to 11 as I don’t want these coming loose but the welding had distorted the threads. I went over my brothers and retapped them and cleaned up the thread on the rose joint the had been damaged when I found the distortion problem out. Ta da  Next I need to weld the brackets to the axle at the same centers as the link boxes on the shell. In order to mark where to weld I needed to measure the width of the pigs head. This is the only method I could come up with.  The panhard rod axle bracket was in the way of where the link bracket need to go so I trimmed it down. The panhard bracket was welded on back to front so it would miss the caliper, now it was in the way again  The keener eyed amongst you may noice I stupidly cut into the axle doing this. I will repair it before the bracket is welded. I dropped the shell down onto some axle stands so next time I’m out the garage I can load up the boot to ride height and tack the brackets on  |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

|

|

It all looks fantastic and you even manage to sound like you know what you are doing.  Oh, have you checked that the diff is actually in the centre of the axle before you use that as a datum? |

| |

|

|

|

|

|

|

|

It all looks fantastic and you even manage to sound like you know what you are doing.  Oh, have you checked that the diff is actually in the centre of the axle before you use that as a datum? It’s all smoke and mirrors Teaboy. I rally am making this sh1t up as I go along. I’m sure it is central, but will be measuring from both ends before welding. I wanted to get it all done today but ran out of time as it was the mother-in-law’s birthday and I was ordered vacate the garage |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

|

|

I wanted to get it all done today but ran out of time as it was the mother-in-law’s birthday and I was ordered vacate the garage They keep making us to do things! Ikea and M-I-L, you might have been better off at work today...  |

| |

|

|

|

|

|

|

|

I wanted to get it all done today but ran out of time as it was the mother-in-law’s birthday and I was ordered vacate the garage They keep making us to do things! Ikea and M-I-L, you might have been better off at work today...  Nah. I’m never better off in work 😁 |

| |

|

|

|

|

|

Mar 11, 2023 16:50:45 GMT

|

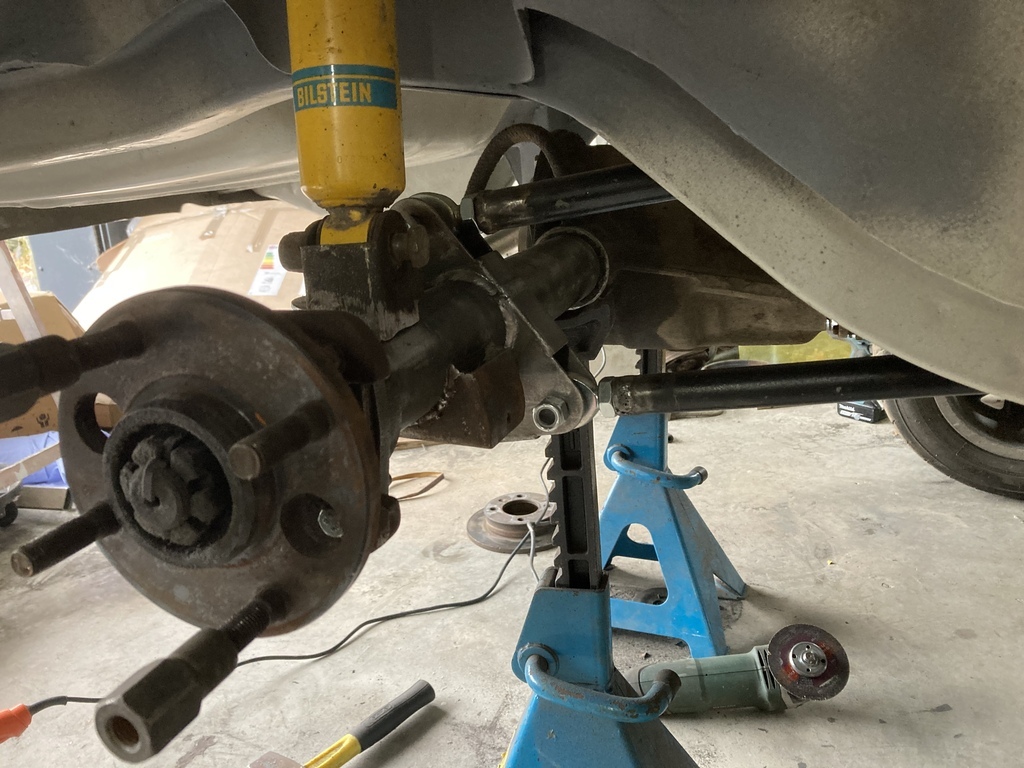

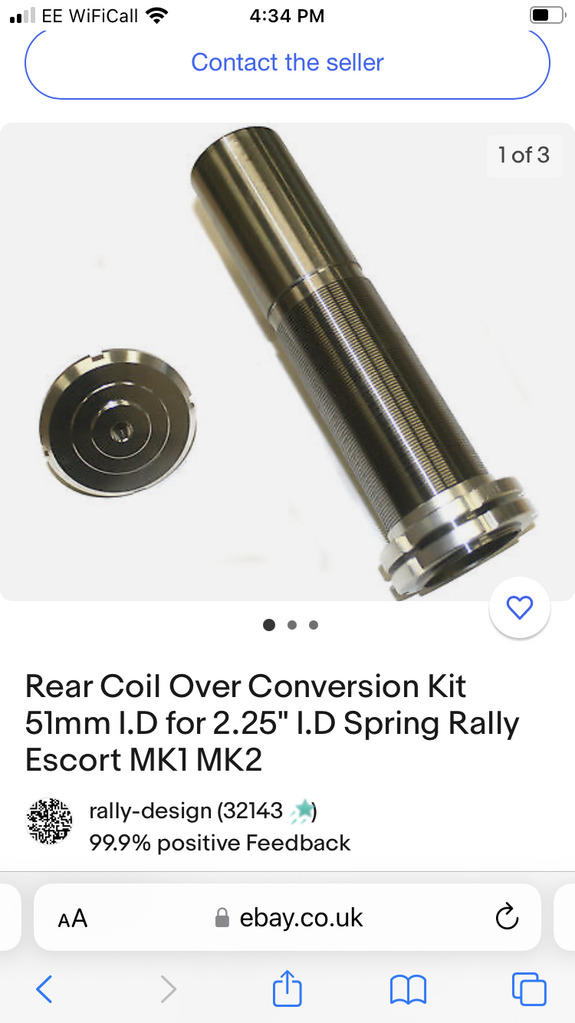

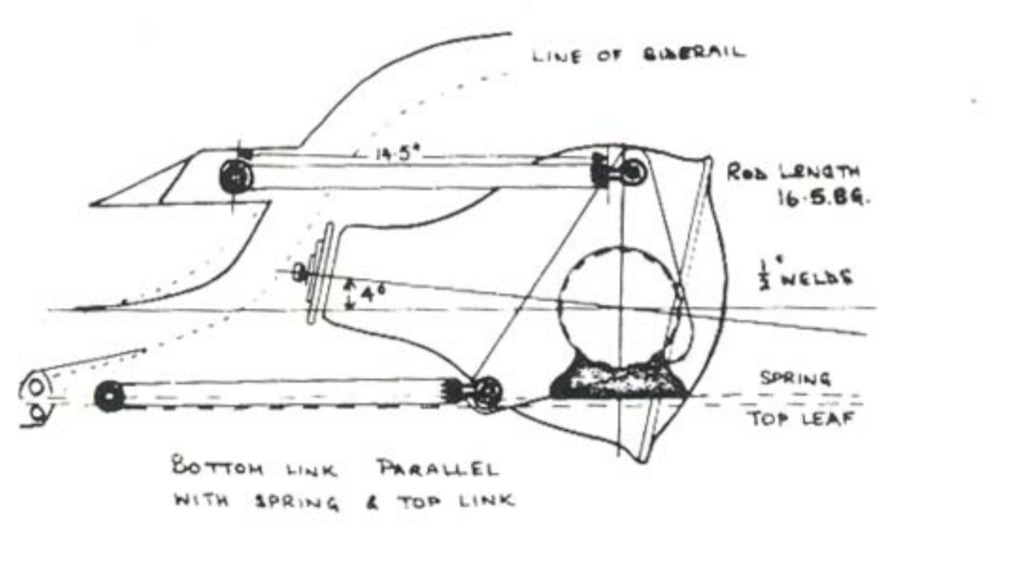

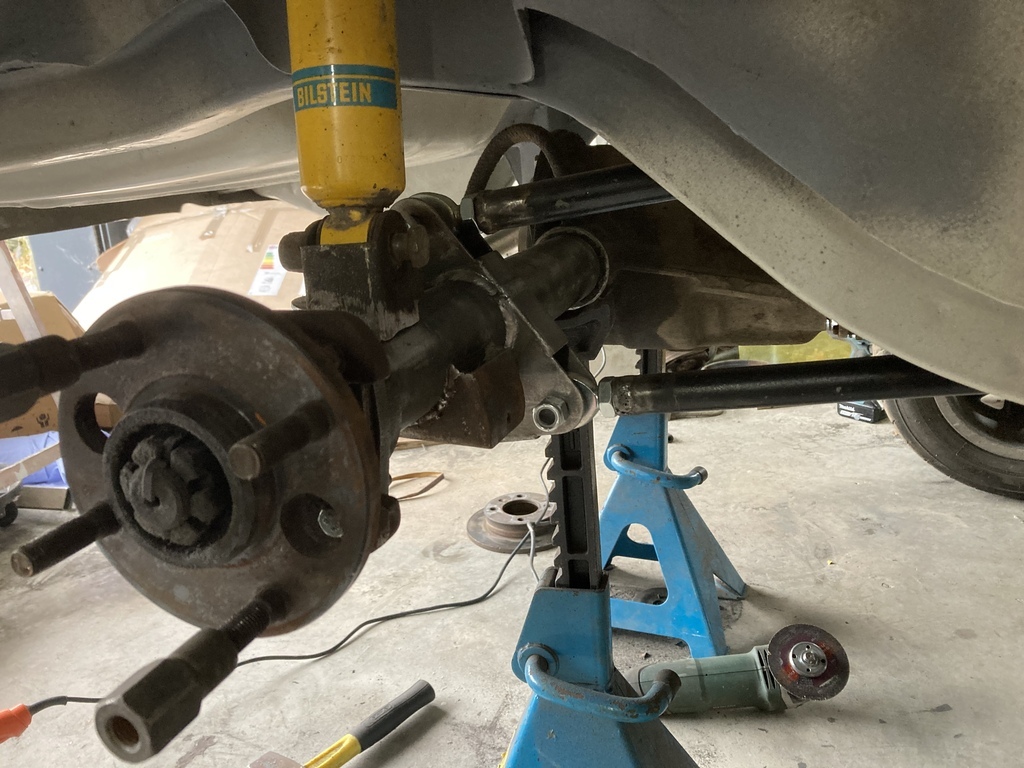

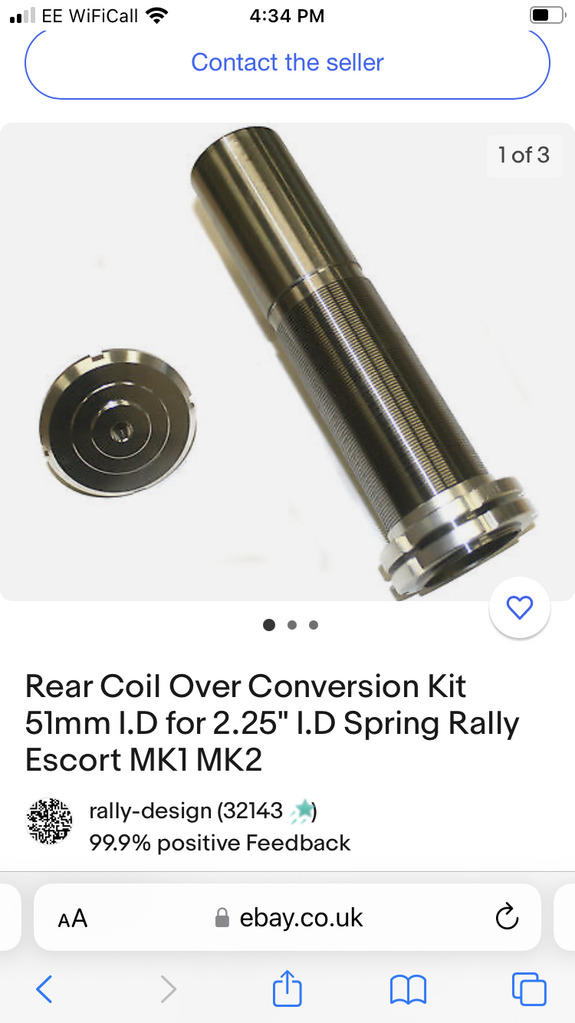

I was on call yesterday. Normally I put a couple of hours in before work but yesterday when I looked out the window, it was windy and cold. So I sat in the house and watched the telly. Today it was wet and cold but I wasn’t going to have to go to work so I got some work done. As per Teaboy’s suggestion I checked if the pigs head was in the centre of the axle. Indeed it was. I got Jones Junior (the elder) to stand in the boot with a load of wheels to achieve ride height. With the leaf springs still bolted on, the suspension will bind as normally a mk1 Escort runs slipper springs with the 4link These springs don’t have an eye on the front, they are flat and slide in a PTFE bush that allows the spring to just take load and not locate the axle. I don’t have any of these so I just took the front bolt out to allow movement and stop binding. So I tacked the axle brackets on ( no photo). I then turned the welder up to twelvty and welded them on     When I fitted the new brake set up on the back a couple of years ago, I cut the old caliper brackets off enough so the new set up worked but did not tidy it up as the axle didn’t come off the car   So I then spent what seemed like hours grinding the rest off    With the springs still off I fitted the axle to the car with the 4 links and the panhard rod. I also sat the shocks on top of the axle    Another issue of fitting the panhard rod axle bracket back to front, is it now contacts the rod😩  A bit of clearancing with the power file sorted that (no photo). I have 3 options in which to run the rear suspension. 1. Slipper springs as described above 2 Standard leaf springs but only using the top link as a tramp bar (this was my original plan as it’s the least cost option to get me up and running). 3. Remove the leave springs altogether and fit coil overs. No.3 is the best option but as I showed a few weeks ago I’m limited for space in the wheel tub due to wide wheels and a narrowed axle. To check this I’m going to borrow a set of coil overs from my nephew and see if I stand a chance of getting them to clear the wheel and tub. If I get the desired clearance I can than by a pair of these that will fit over the shocks I have  Whilst watching a YouTube vid from 4 years ago of someone fitting bubble arches to an Escort wing yesterday, I thought how familiar the arch he cut out looked  There the one I bought last summer to fit the steel arches   Fancy that. |

| |

|

|

|

|

|

Mar 11, 2023 23:11:19 GMT

|

|

Top fab work on the axle......just check when you welded all the brackets on the axle, it hasn't bent the tube, its quite easy to straighten. Any plans to fit a toe correction kit while you're upgrading the axle?

|

| |

|

|

|

|

|

|

|

Top fab work on the axle......just check when you welded all the brackets on the axle, it hasn't bent the tube, its quite easy to straighten. Any plans to fit a toe correction kit while you're upgrading the axle? Thanks generalstirlingprice. My brother has a 4 wheel alignment kit so I’ll be able to check if it ha bent. If it has I’ll run a couple of welds down it to pull it back. I doubt I’ll fit the toe correction kit - I doubt I’d notice if a wheel fell off never mind any difference in toe in. |

| |

|

|

|

|

|

Mar 12, 2023 18:03:07 GMT

|

My nephew was supposed to take the coilover shocks off his Viva ( they’re only on loose) and take them to the motorkhana today for me to pick up. He text me early doors to say he’d forgotten them so that put the mockers on me finishing the axle. So I needed to find something else to sort. It wasn’t hard to find something as I have a complete car to build. So seat rails it was  I’d tacked the plates to the car on the driver side sometime last summer. I’d since had the car blasted and sprayed in epoxy. The MIG really doesn’t like the epoxy so I needed to remove it where I was going to weld. It was easier to do with the plates removed so that’s what I did.  After a quick tickle with the power file I welded the plates on to the car and welded the bars to the bolt on plates  I put a bit of primer on too  I put one of the old seats on just to try  Those with a good memory will remember I had the seat mount dimensions from a car built by a well known Escort rally car builder  These are from a mk2 Escort. They are a bit roomier inside than a mk1. The passenger seat was sited 4” further back than the driver seat in the mk2 but I was a bit concerned I’d have issues as new seats are over 100mm wider than the Sparco Sprint seats that I used to run. So I fitted the rear roll cage to see what room I did or didn’t have  I decided to play it safe and put the passenger seat 2” behind the driver seat. I tacked the plates to the car, and the bolt on plates to the pipes. I ballsed up the tunnel side as I forgot I was only going 2” further back and started fitting one of the plates 4” back. I now have a hole to weld.  I’ll weld them next time. I put the old seats in just to “see”  |

| |

|

|

|

|

|

Mar 13, 2023 15:18:23 GMT

|

|

could you convert your leaf springs to slippers by cutting a bit of the front eye off and flattening the rest and just buy the slippers for the front mount?

|

| |

|

|