|

|

|

Jul 17, 2022 17:41:57 GMT

|

I went for a run in the Cortina early this morning before it got too hot. Took a few turns to get it going as it’s not been used for ages. Once going though it seemed to go really well. I managed to blag some more steel so I started making the new chassis rail.   To fold the steel I scored it with the grinder so it bent easier where I wanted it to, and then I welded up the score line. Welded in the bumper iron tubes   And welded it on with the amps cranked up to ensure good glueing, whilst trying to my set fire to everything in the engine bay.   I then made the vertical internal strengthener  And welded it into the chassis rail  I just need to add the lower strengthener tomorrow and the lower inner wing can be remade and fitted. |

| |

|

|

|

|

|

|

|

|

|

|

Phew!

I don't check in for a little while and you've practically welded in a new car!

Cracking progress!

Hope the spicy cough isn't slowing you down too much!

|

| |

|

|

|

|

|

|

|

Phew! I don't check in for a little while and you've practically welded in a new car! Cracking progress! Hope the spicy cough isn't slowing you down too much! Thanks Varelse. It’s progressed quickly now I’m in the groove. I had a couple of days where I felt rough but a lot better now. But can’t go back to work until I’ve had two clear tests. |

| |

Last Edit: Jul 18, 2022 13:50:18 GMT by jonsey

|

|

|

|

|

Jul 18, 2022 18:30:36 GMT

|

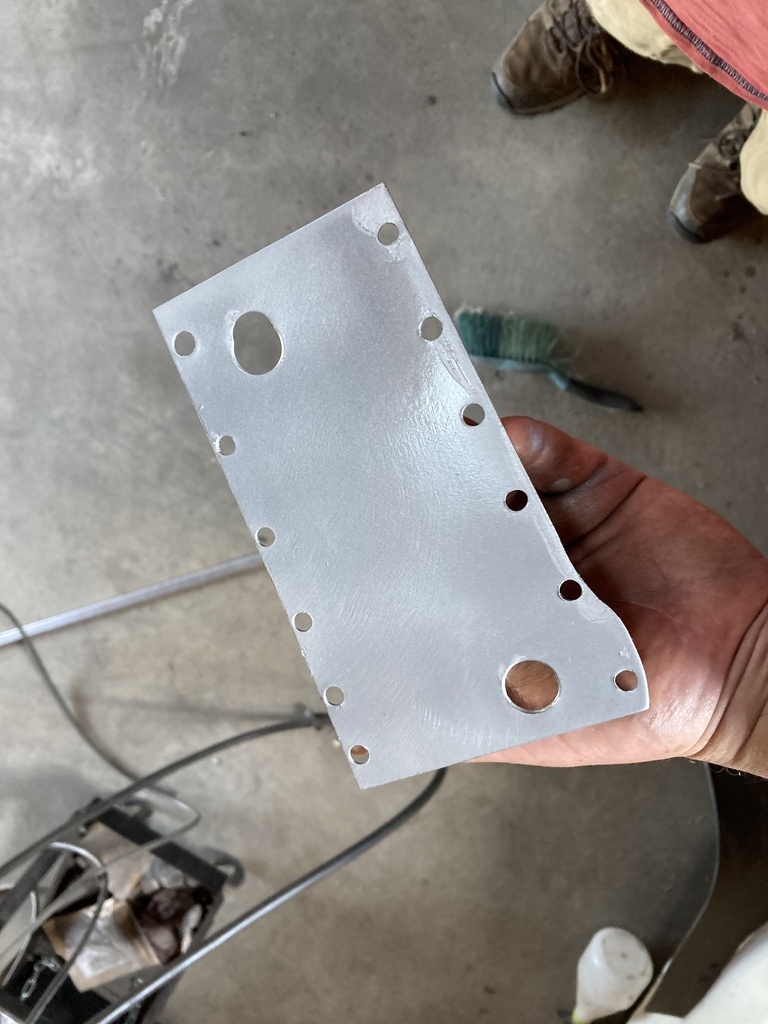

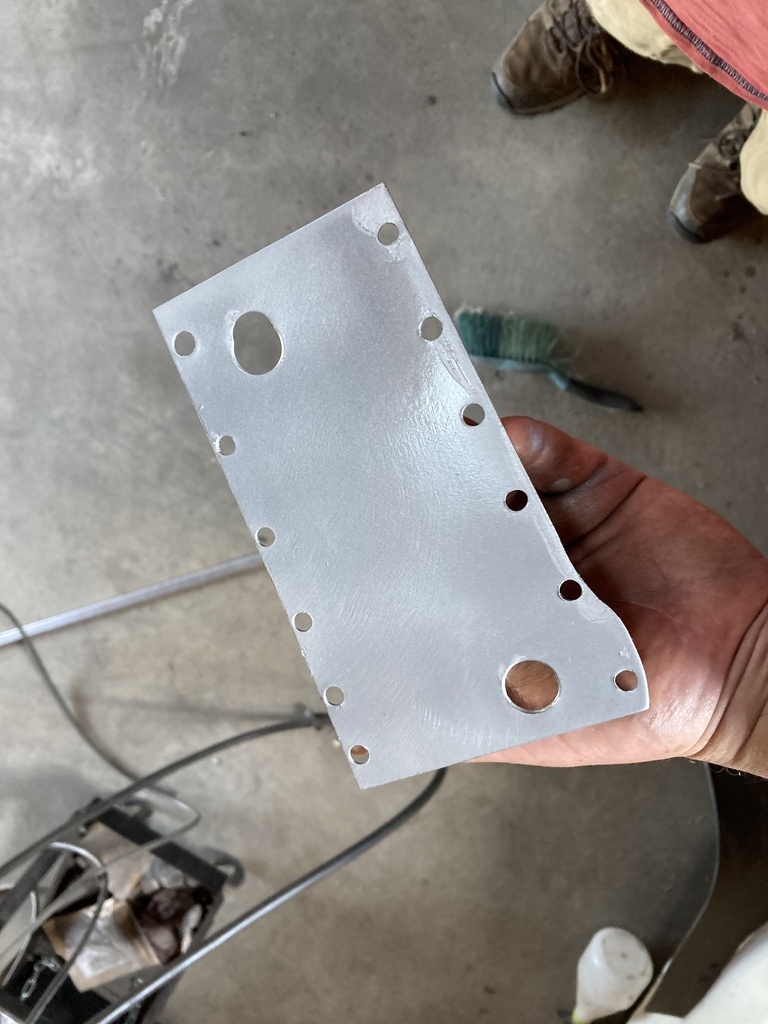

I will be returning to work tomorrow so progress will slow from now on😩. My goal for today was to finish the welding on the passenger side chassis rail/inner wing. I hadn’t planned on grinding it all back today as we had some guests coming early. First up was the bottom of the internal strengthener. Made a bit.  And welded it in  Next was the bumper bracket strengthener. My eyecrometer was off marking one of the holes.  And welded it on  And ground it off  Last up was the bottom of the inner wing. Was going to make it in 2 bits. I made the rearmost section first and welded it on (no photo). On making the front section I made a couple of school boy errors. First was making it to small so the very front couple of inches will be a 3rd section. The second was the stupidest one. The first thing they taught is in metal work in school was always use a mole grips to hold your work piece when using the pillar drill. Even when I was drilling it I new I shouldn’t have been doing it freestyle. And then it caught.  I have a couple of small superficial cuts on the palm of my hand, the spinning metal tried,quite successfully, to pull all the inside of my middle finger out. Luckily, Mrs Jonsey is a nurse and bandaged it up. I have full movement so all ok there, but it’s made a right mess. I was then banned from going back out the garage. For about an hour anyway. She even stood in front of the kitchen door stopping me from passing. After me moping around like a Russian bear chained in a cage, she finally relented and let me passed. I welded on the front (now the middle section) and that was me done for the day.  Stuff the front section, it can wait until the weekend. |

| |

|

|

|

|

|

Jul 18, 2022 18:52:30 GMT

|

|

Not for nothing is it said we put our blood, sweat, and tears into these things...hope your recovery is swift and relatively pain-free!

|

| |

|

|

|

|

|

Jul 18, 2022 19:20:33 GMT

|

Not for nothing is it said we put our blood, sweat, and tears into these things...hope your recovery is swift and relatively pain-free! Me too 😁 |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,360

Club RR Member Number: 64

Member is Online

|

|

|

|

|

Ouch.

We never learn do we?

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

Ouch. We never learn do we? I’m too stupid to learn Glen. I’ll probably do it again. |

| |

|

|

|

|

|

|

|

|

Ahhh yes…..

I may have been hit three times by the same piece of metal in my drill press, also same story, thankfully it was all blunt force to bruises mostly.

It would have been really funny if you managed to set that bandage alight while welding……

The Bear would certainly not be dancing then, or would he.

I have managed to set myself alight, welding upside down under a race car dash, my mates stood there laughing, watching till I felt the heat.

Brilliant repairs as usual.

You really do it well.

|

| |

|

|

|

|

|

Jul 19, 2022 15:56:44 GMT

|

Ahhh yes….. I may have been hit three times by the same piece of metal in my drill press, also same story, thankfully it was all blunt force to bruises mostly. It would have been really funny if you managed to set that bandage alight while welding…… The Bear would certainly not be dancing then, or would he. I have managed to set myself alight, welding upside down under a race car dash, my mates stood there laughing, watching till I felt the heat. Brilliant repairs as usual. You really do it well. Thanks for the compliment Grizz. I’m no expert. Just gleaning knowledge from others such as Tonybmw and the library of YouTube. I’m yet to set myself on fire but the cars not finished yet. |

| |

|

|

|

|

|

Jul 21, 2022 17:42:47 GMT

|

Not progress, but the new front panel has turned up. On a mk1 the front panel can pretty much only fit in one place. I just need to finish the very bottom of the inner wings and put a flange on there to weld the panel to. I’m hoping to borrow my brother’s spot welder to do this.    Finger is still in bits but no pain though, which is a bit worrying, so I’ll leave it until the weekend before I play again |

| |

|

|

|

|

|

Jul 22, 2022 17:02:37 GMT

|

I was on a training course today that finished early so I thought I’d go out the garage. Inner wing ground down and lower strut tower welded back on  Tower ground off and stitch welded too  End of the inner wing where the front valance butts up to welded on and a flange for spot welding added   Other side flange added   And a shot of the passenger side inner wing ground off  I also welded up some small tears in the other flanges ready for welding the front panel on. |

| |

|

|

|

|

|

Jul 23, 2022 17:32:05 GMT

|

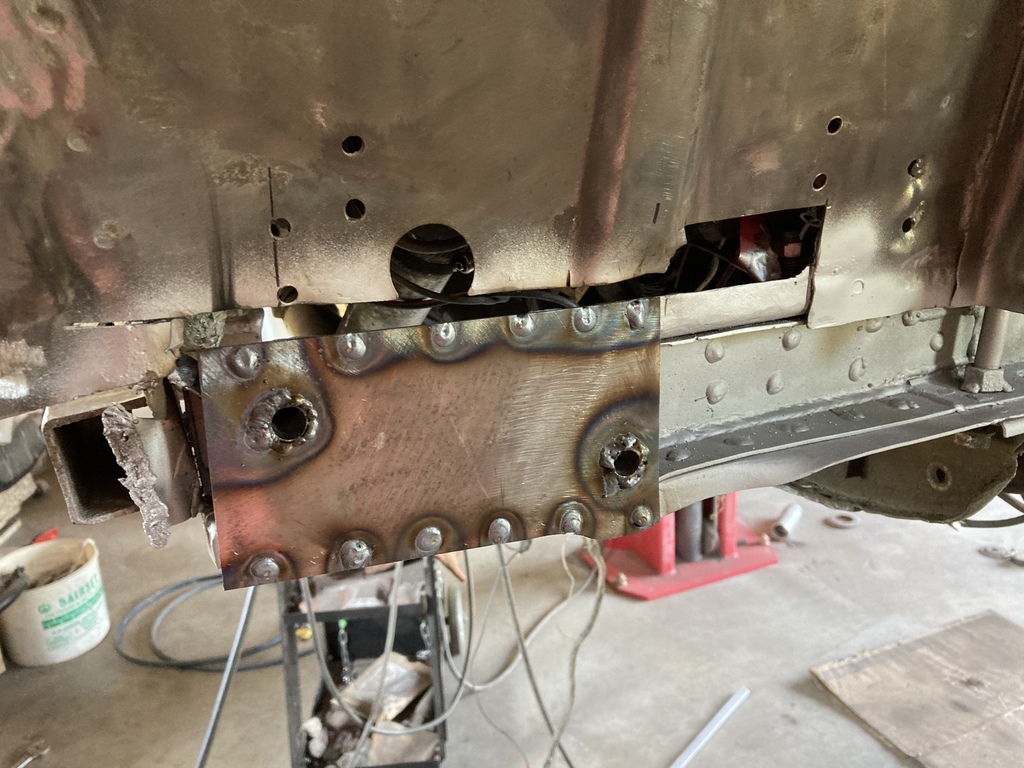

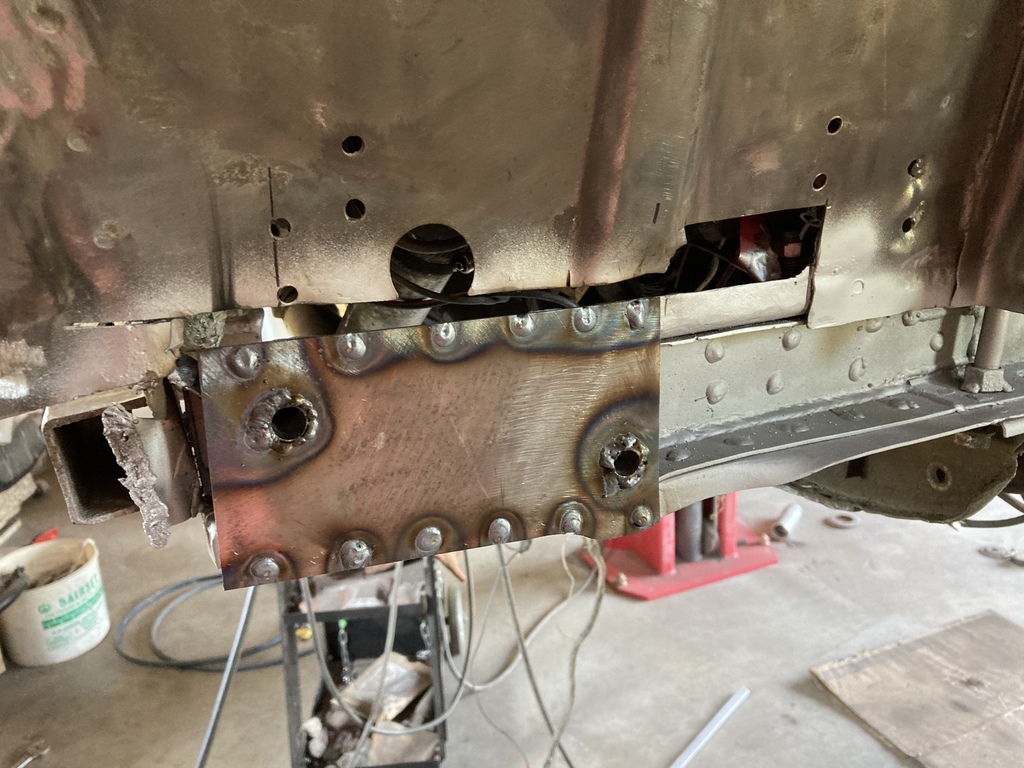

Had a big tidy up in the garage today. I was looking for the Escort’s old front calipers to lend to my brother. I couldn’t find them anywhere. It’s like they’ve evaporated. At least the garage is a bit tidier. So a few days ago I spotted this rust bubble.  There’s two rust bubbles so worth investigating as the chassis rail is usually rotten behind. So out with the grinder.  Bit of a mishap there. But no baby ducks (or fingers) were harmed so we’re all good. It is a pain to get tools in there but eventually it was all cut out.  Amazingly the chassis wasn’t rotten behind. There a small hole where I ripped a spot weld out with a chisel but I welded that up.  I’ll have a go of making a replacement tomorrow. |

| |

Last Edit: Jul 23, 2022 17:33:13 GMT by jonsey

|

|

|

|

|

Jul 24, 2022 14:35:12 GMT

|

|

|

| |

|

|

|

|

|

Jul 31, 2022 17:06:33 GMT

|

So I made a washer.  And welded it on (we’ll gloss over the fact I forgot to pull the bush out and melted it a bit)  And ground the whole bracket off  I then spent an our grinding welds on the floor. Even though it’s n the 2 poster, it’s still a pain.   I then cut out a section of the radiator panel. The air filter sits behind here and I thought it could do with some cooler air as currently it’s drawing air from behind the radiator. Before  After  My nephew then came up to take some of his Astra stuff from my garage. Yay. I was then thinking about what a pain it was going to be to remove all the paint and surface rust from the underneath. My neck was in bits after just an hour standing underneath. I have a rotisserie from when I did the Cortina. This would make it a lot easier. Except the engine is still in the car. (In the voice from Sponge Bob) 1 HOUR LATER   There were a couple of casualties. I forget to take the fuel pipes loose so had to cut them both as they are copper and now mangled. And one of the lambda plugs caught on something so the cables ripped out - not that I use the lambdas, but they should go back in once I find out which order. I may get the shell shot blast depending on price as it’s a lot less work and will cost a small fortune in discs etc. This fit a cage and go stage rallying as crept into a lot bigger job pretty quickly. |

| |

Last Edit: Jul 31, 2022 21:58:50 GMT by jonsey

|

|

glenanderson

Club Retro Rides Member

Posts: 4,360

Club RR Member Number: 64

Member is Online

|

|

Jul 31, 2022 20:52:10 GMT

|

|

How’s the hand?

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Jul 31, 2022 21:57:43 GMT

|

It’s healing really good, Glen. Thanks for asking. I think my finger is about 5mm wider than it once was though |

| |

|

|

16grit

Part of things

Posts: 215

|

|

Jul 31, 2022 22:39:18 GMT

|

This fit a cage and go stage rallying as crept into a lot bigger job pretty quickly. Standing by for pics of unwrapping packages with 4 link kits and slipper springs and all the rest ...... |

| |

|

|

|

|

|

Jul 31, 2022 22:50:34 GMT

|

This fit a cage and go stage rallying as crept into a lot bigger job pretty quickly. Standing by for pics of unwrapping packages with 4 link kits and slipper springs and all the rest ...... Lol. I have toyed with the idea of fitting link boxes and panhard rod mount while it is in pieces, but it handles and grips pretty good as it is. It’s not to late. We’ll see. I don’t know. Perhaps. I’ll keep mulling it over |

| |

|

|

|

|

|

|

|

I had some time before work so I took the axle off.   Next I dug out the rotisserie. I bought it as a kit and welded it together (badly). It’s for a Mk2 Cortina, but with a couple of holes drilled in the bumper iron connection point I had the front frame on.  The rear mounting points were to far from the bumper holes just to redrill so I welded a bit of steel to extend the mounts so the rear frame was also sorted.  I can’t spin it around yet as the inside is still full of bits and bobs and there is 3/4” of a tank of super unleaded in the tank that I need to drain. One issue I have is taking it to the blaster. I’d hoped to take it on the rotisserie but the whole thing is 17’ long and my trailer bed is only 13’. I think I’ll have to take it there with the shell sat on some tires and then put it back on the rotisserie when there. |

| |

|

|