|

|

|

Sept 18, 2020 6:17:00 GMT

|

|

With shell pulling out of LPG in the Uk the nearest filing station is 18 miles away in the opposite direction to work. Also it's not that bad on fuel anyway, on a run it will do close to 30 mpg.

A further plus is with the tow bar which currently supports the filler and protects the lpg pipes it will take approx 100kg or 10% of the weight out and remove a restriction from the intake so should give a noticible performance improvement.

|

| |

|

|

|

|

|

|

|

Sept 18, 2020 9:59:04 GMT

|

|

Really enjoy your posts - and the effort and love and problem solving (why don't they teach problem solving in school but I digress - it forms most of what we all do at work....).

I'd sell the elan if you were thinking of down sizing - it's the car that holds the most value (I think) out of all your cars (but the range rover has value too of course).

Prices of them (elan's) are up too.

Love the colour of the TR7 too. And of course - that rover v8 is based on a buick engine (I think - wasn't it licensed by BL back in the late 60's?) so good thinking about going to rock auto.

|

| |

|

|

|

|

|

Sept 18, 2020 14:47:20 GMT

|

|

I've just been for a 60 mile blast in the TR can't beat a V8 with minimal silencing and the roof down on a sunny day!

It's one thing the lockdown has shown me, when I drove 15 miles to work every day the range rover got used all winter and the the others all summer, but this year I have driven the Lotus a total of 20 miles. Thinking ahead to my plan to retire in 4 years time I can't see it getting any use then either.

The Mazda does everything it does without the worry of breaking some ridiculously expensive part and I would be happy to go anywhere in Europe in it which can't really be said about the elan, the TR has far more modifying potential and the Range Rover can't be beaten for moving stuff or use in foul weather, on the other hand I can't think of any thing else to spend the cash on and I really hate the messing around and idiots when trying to sell a car.

That said my lad is very keen on a Defender, and we would then need the space, all in all though I will probably wait until life is back to normal before doing anything I might later regret.

|

| |

|

|

|

|

|

Sept 18, 2020 14:56:28 GMT

|

I understand that seller dread. But perhaps there are other ways? For example; collectingcars.com/ some of the prices on there (and I've not heard any bad stories about buyers reneging) are pretty punchy imo. The one thing I come back to about the elan is that the people that yearn for one are getting older and some are dying (sorry). They are being replaced by stuff from the 80's/90's now. It's why, in my opinion, the market not to be in right now is old motorbikes (30/40/50/60's stuff) - again the market is moving on as the people that coveted them are literally dying or retiring and new generation yearn to relive their youth - which are not those era of bike. My uncle has just sold all 14 of his pre-war and 50's cafe racer bikes (and bought diving gear with the proceeds!!) I'm not saying that he's right and I'm right but I agreed with his rationale for selling (even if I can't understand his new-found passion for diving). It's a good time to be selling (buoyant market, people have money and have had time to consider what they want, following a period of enforced/restriction) and importantly - you're not under pressure. Pressure of circumstance leads to price pressure on the sale imo. Most people are so rarely able to choose when to sell. Food for thought anyway. Perhaps a different perspective on the sale might help (sell this and I can achieve the next good thing) or give it to someone else for a commission so it's them having to deal with the buyers. There's always an opportunity cost - sell it yourself and save money, technically, on the sale but have to deal with buyers or spend some money (akin to a new RR gearbox perhaps) and let someone else deal with them. |

| |

|

|

|

|

|

Sept 20, 2020 21:06:10 GMT

|

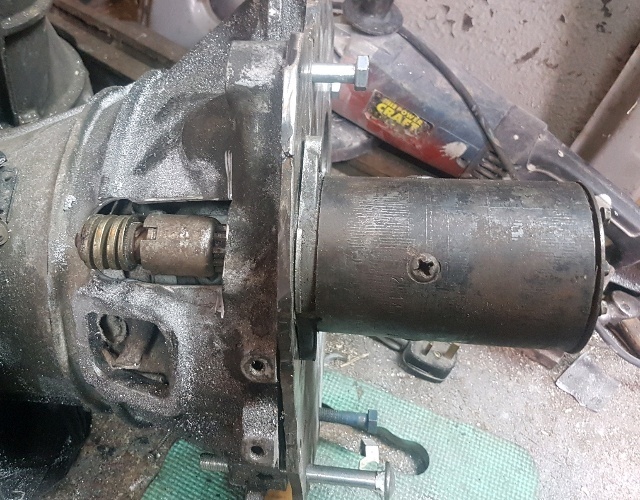

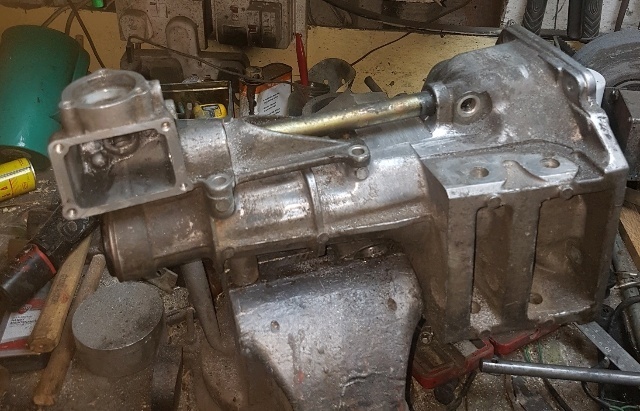

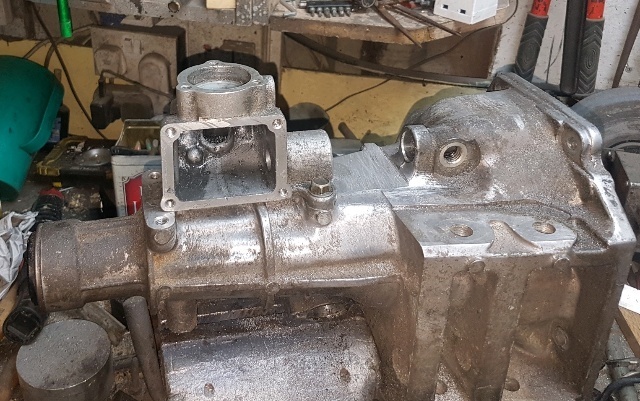

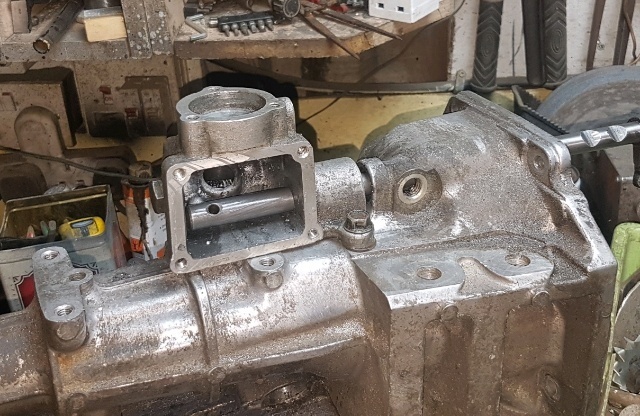

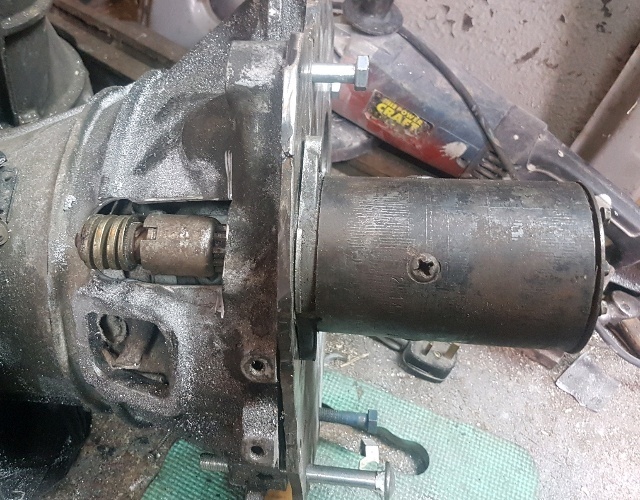

Over the last couple of days I have resurected something I started 2 or 3 years ago. Making a MX5 gearbox fit in the minor. When I tried last time I used a marina backplate and flywheel because this easily accomodated the mx5 clutch disc, problem is the starter motor wants to occupy the same place as the chassis leg.  So I have now decided to go with the minor starter position.  With this it looks like it will fit ok, need to do the following - find out if a 200mm mx5 clutch will fit under the 1098 clutch cover - cut the bell housing to clear the steering rack and starter pinion - make a CSC installation - move the gearstick forward - Make a gearbox mounting - modify gearbox cover to give clearance - sort out a prop shaft. The biggest sticking point will be if the clutch disc doesen't fit. |

| |

Last Edit: Sept 20, 2020 21:18:11 GMT by kevins

|

|

|

|

|

Sept 21, 2020 18:52:06 GMT

|

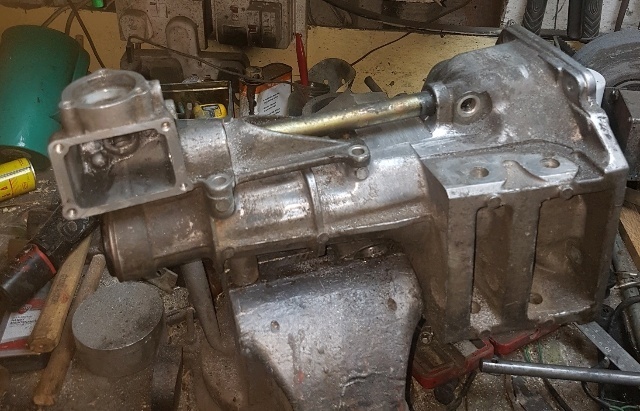

Popped out at lunch time to gather parts from the lock up, Range rover usefull as ever, but I also had to start up and move the Lotus, must go and use it hor a few days if nothing else just to use fuel up so I can store it for the winter with fresh.  So what did I get - The original mk1 mx5 box with the wrong area of the bell housing cut out. - 1098 minor flywheel - 1098 minor backplate  I was also looking for a stater but I think that may be in the loft atic. So the plan is to move the mk1 gearshift approx 7" forward then fit the extension housing to the mk2 box, it looks like it will fit! Then I can put the mk1 box back in storage to clear some space. Looking at the flywheel I am hopefull I can just squeeze the 200mm mx5 clutch plate in it will overhang the egde of the pressure plate a little though. |

| |

|

|

|

|

|

Sept 22, 2020 18:10:55 GMT

|

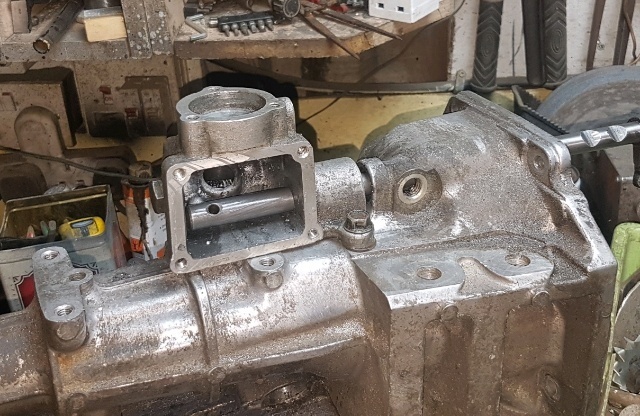

Took the tail housings off both boxes today.  6 bolts and off it lifts, fitting the mk1 tail housing to the mk2 box is a bit more involved than I hoped the arm on the end of the shift rod is longer on the mk1.  But fortunatelly all you need to do is swap the forks on the end of the selector rods.  Drifted the roll pins out and over they swapped, put the mk2 housing on the mk1 box and it all works fine. Indide of box is pretty clean.  Took the oil guide out and now ready to drill and tap it to move the shifter forward. Hopefully get this done and it back together tomorrow.  |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Sept 23, 2020 13:42:57 GMT

|

|

Love a bit of home engineering!

|

| |

|

|

|

|

|

Sept 23, 2020 20:18:16 GMT

|

Some more today, firstly finaly had a go at the hood frame on the mx5, ever since we have had it has dipped across the top of the drivers side window and catches on the seatbelt tower when you close it from the passenger side. Looking at it it was noticible the bent bar which goes up the inside of the b pillar was a different shape on the drivers side. The outward bend at the top was too sharp, you can't get it appart so some lateral thinking was needed after a lot of thinking I came up with this  Clamped it across the bend with the fork on the inside and leg on the oustide of the bend and lo and behold it worked, the bend opened up and the frame now fits properly.  Next back onto the gearbox. This is the standard shifter position.  Cutting the front off of the shifter housing just in front of the rear fixing.  And then bolting the rear holes to the front bosses moves it forward 103mm.  But to put it in the same place as the minor it needed to further.  After some work with a file on top of the housing.  And shim I had this.  I used a straight edge off the 2 original bosses and the shaft to get it right. Next up is the shaft, the hole in the end the dowel pin goes through needed to move forward 156mm and remain in exactly the same alignment. So I took a piece of square bar and drilled 2 holes 156 mm appart using the pillar drill.  Then aligned one hole with the original hole in the shift rod using a drill bit and welded a nut beside it  Then moved the rod up to the other hole using the drill bit to the left of the picture to align it again and clamped the shaft against the nut.  Drilled through the hole on the vice to give a perfectly aligned hole.  Coutersunk the holes slightly and cut it off, then a trial fit of the selector.  Put it all together for a trial. (drill bit replacing roll pin as it is a pig to get out)  And to my suprise I have all 5 forward and reverse gears. Next up was a bracket to support the rear of the shifter.  Still need to shorten the shifter rod tube and get some sort of sealer (no gaskets) but I'm almost there. While I was at it I also cut some of the mounting for the mx5 ppf frame away as this is where the gearbox mount needs to go to align with the x member, on second thoughts though I may just add a second x member further back using the 2 threaded holes where there is more space.  |

| |

Last Edit: Sept 23, 2020 20:24:54 GMT by kevins

|

|

|

|

|

Sept 24, 2020 18:15:41 GMT

|

Been to work today so no fiddling at lunchtime, did get an hour after work though, cut the shift rod tube down, and slipped it over a bit of 13mm pipe then welded it back together.   Painted it and the bracket up.  Can't put it all together because I have dropped a ball, the 7.5mm one which goes in the shift housing, 10 replacement ones are on their way. And the KA passed its mot, after the hego failed I was worried about emissions but it sailed through with 0.0 co and 10ppm hc. |

| |

Last Edit: Sept 24, 2020 18:20:34 GMT by kevins

|

|

|

|

|

Sept 26, 2020 18:32:58 GMT

|

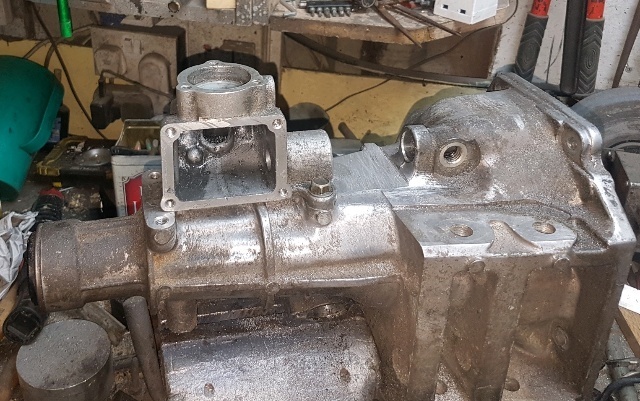

While I'm waiting for the ball to arrive so I can reassemble the rear of the box I returned to the front. Cut out tapered and welded some plate in to cover the missing areas.    This is the mazda plate vs the std one.  Then cleaned up the starter hole with a file through the original plate so it fitted.   Cut just enough of the bell housing away to clear it.  Eventually I will make a steel panel to go over the area and the redundant clutch arm hole then bolt or rivet it in place. Also had a try to see how the slitting disc cuts a clutch lining, the answer is quite easily and cleanly, which means I may be able to cut 5mm off the outside of the mazda clutch with it mounted on the lathe if it won't fit under the minor cover |

| |

Last Edit: Sept 26, 2020 21:01:10 GMT by kevins

|

|

|

|

|

Sept 26, 2020 18:42:55 GMT

|

|

Clever Clever stuff.

|

| |

|

|

|

|

|

|

|

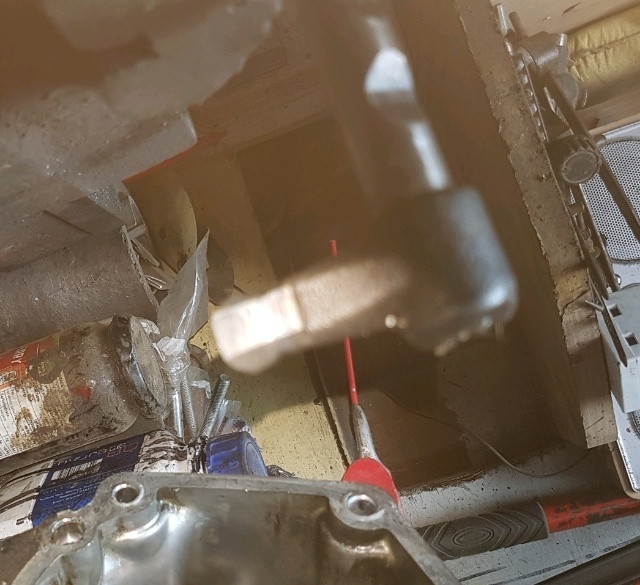

Only few odds and ends on the cars in the last few days, changed the oil presure switch on the Range rover, ever since I fitted a new one after I broke the original the light has flickered at idle in drive when hot, looking into it there are 2 switches one at 10 psi and the other 5, I had the 10 so it now has the 5 psi one. Then in all the rain we have had in the last few days the TR passenger footwell has got rather wet (after fixing the hood frame the drivers side is dry). Pulling the speaker grille off the cause became obvious.   It's dripping from the door glass hitting the back of the speaker then running through the now detached cone and inside the car, taking the speaker out has stopped the leak and a bit of research shows they are supposed to have plastic rain sheilds , I'll put it back in with a piece of polythene over the top . Cars now sitting with a dehumidifier on the passenger seat. Also got this out and washed it, now Andrew has passed his test we've insured it for him, he's off to collect a 60's roof rack for it this week and we need to wax it underneath before he uses it too much in the rain but otherwise it's ready to go. B The main thing I have done though is clear up the workshop, first step was to clear out the pit, quite a bit of junk a few things like the cement mixer and ďollies which are staying and this.  An old land rover petrol 2.25 which ran ok but had quite a thirst for oil. Stck it on ebay and it went for 100 notes in a couple of hours, I was contemplating sending it for scrap! There is now enough space in the pit for my next job which is to put the compressors down there. |

| |

Last Edit: Oct 4, 2020 18:12:26 GMT by kevins

|

|

|

|

|

|

|

Glued the mx5 speaker cone back together and then glued some polythene on the back as a sheild.  It seems to sound Ok still as well, definitely not buying any new ones until I'm sure they are staying dry, The other side isn't leaking but I will take them out and do the same for good measure sometime this week. A good little job to do for a break between meetings. The 1.6 MX5 clutch for the minor gearbox conversion arrived today. The 200mm disc won't fit under the minor cover, this is it on the flywheel.  and this is the mx5 cover on the minor flywheel.  It is only 3mm too big, so it looks like the solution is to file the holes into slots, drill and tap the flywheel for the mx5 cover and then skim 3mm off the outside of the cover on the lathe. filed one hole in 3mm  plenty of room for a cap head bolt still. Another solution would be a hi torque starter which comes in from the front but thats £220. |

| |

|

|

|

|

|

|

|

|

I have a random pile of HiFi stuff, amp, speakers etc.

Was destined for the Blazer, never fitted.

Yours if you need it.

|

| |

|

|

|

|

|

|

|

|

Once you make that gearbox fit you could mass produce them and sell them 👍

|

| |

|

|

|

|

|

|

|

I have a random pile of HiFi stuff, amp, speakers etc. Was destined for the Blazer, never fitted. Yours if you need it. Thanks, I'll see how it goes, It's never going to be great as there is a fair bit of background noise (4000rpm at 70mph). Posted by tineca2 hours ago Once you make that gearbox fit you could mass produce them and sell them 👍 I don't think I can be bothered with manufacturing a full kit but I plan to get the backplate scanned so I could get some more laser cut if there is interest and perhaps provide plans / instructions for those who want to fit one for the rest. |

| |

|

|

|

|

|

|

|

Drilled and tapped the flywheel today.  Seems pretty central, less tha.05 mm variance in the overhang. Just need the proper bolts to turn up now then I will mount the whole lot on the lathe and skim the outside of the cover down to remove the overhang. |

| |

|

|

|

|

|

|

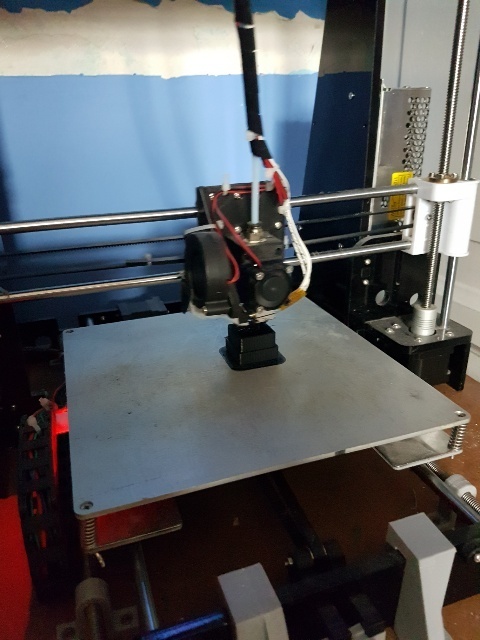

|

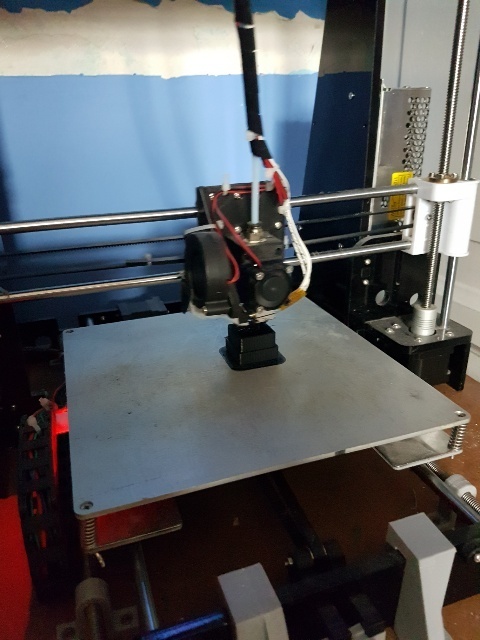

Been doing some odd jobs the last couple of days. Glued polythene covers to both door speakers on the mx5, in all the rain we've had in the last couple of days it's stayed bone dry inside. My wife wants heated seats in it which actually make lot of sense if you use a convertible in the colder weather. So we purchased a kit, so far I have soldered the wiring for it up wrapped it in self amalamating tape and put it all in, need to make a bezel to mount the swi tch in the cubby below the radio (more 3d printing) And then take the seats appart to fit the pads (drivers cover needs to come off to fix a split anyway).  Then I 3d printed one of the parts I drew up a couple of weeks ago, it's the bezel to go around the thermostst I added to the range rover for the A/C. Being printed.  Pulled off the printer.  Cleaned the support structure off.  Painted with stone chilp and the symbols with acrylic.  Then in the car.  Just need to print the knob and blanking covers now. |

| |

Last Edit: Oct 8, 2020 18:56:58 GMT by kevins

|

|

|

|

|

Oct 16, 2020 18:21:06 GMT

|

Been having problems with the 3D printer so not much progress on that front, Andrew's going to take a look at it later, he thinks it might be something in the settings on my laptop, we'll try something we know did print OK from his and work from there. Andrew has started using the minor, missed all the gadgets on our new fiesta at first (started reversing listening for the parking sensor!) but after a few miles reckons it is pretty easy to drive.  |

| |

Last Edit: Oct 16, 2020 18:27:06 GMT by kevins

|

|