|

|

|

|

|

|

Time to postulate and muse:

I am now in the fortunate position of having the following axles built and ready to use;

3.9 Quaiffe, drums

4.4 Plate diff, drums

5.1 Plate diff, discs 180 calipers

So I had a thought about being able to swap between them to experiment or for different events, but it's a pain with the brakes and the hand brake etc.

Then I thought, if I take the drums off the axles and fit each with identical brackets to the 5.1 then I could easily swap axles and keep the brake system intact. The brackets are flat shaped pieces of steel, I can easily replicate these, which just leaves the hand brake arrangement.

That then means I reckon I can swap an axle in 30 mins on my own, shorter with help.

The prep to make this happen is actually small, the only thing I do not know is the hand brake arrangement but it's been done before so I just need to ask the right questions!

|

| |

|

|

|

|

|

|

|

|

|

Fuel pump and fuel sender all done. I also found an exhaust mount rubber that had torn so I made a stronger version and refitted. So far so good. I have some new Bilstien inserts that I have had on the shelf since the sick pretender gave them in part payment for the engine failure. These are 280/150 and will replace some very tired 250/80. The new inserts have bump stops with them so I fitted these in and left the springs off so I could do a manual check of the bump steer and other front geometry bits and bobs. I have hit a snag in that the bump stop becomes active at normal static height for me! Not too much of an issue for the checking because I can take them off to get full travel whilst doing the checking BUT If I put them back in and fit the springs and refit to the car it means the 225lb spring will get a rising rate 'extra spring' as the bump stop compresses. They are already beginning to compress at standard ride height for me so I am in a bit of a quandary what to do? If I take them off at least I know what the spring rate is and feel the difference just from the new damper rate but I won't have a bump stop. If I leave them on I am unsure as to the effect of the rising rate will cause? Any one got any thoughts?  |

| |

|

|

|

|

|

|

|

|

They are the Bilstien supplied items and actually take up about half the total travel. I guess this is for heavy rally cars etc.

I was a bit surprised myself actually that the bump stops came into play so soon. I will do some proper measurements next weekend and from that I can work out what to do with them. I am thinking that I might shorten them slightly and then they can add rate as the car rolls.

|

| |

|

|

|

|

|

|

|

|

Unblocking the drains this morning did not take quite as long as i thought so had a spare moment to go into the garage before leaving for work.

Struts back off, bump stops out. Bump stops are 82.5mm and total travel is 165mm, so as can be seen they are half the total travel.

Back on with the strut and measure the bump steer.

Not the result i was expecting:

There is a linear response which is good but a big response!

It goes from toe in to toe out as the wheel rises. This means the rack is far enough back but not high enough!!! I can't get the rack any higher so to compensate i can move the TCA inner mount down one hole and start again. This will also lower the RCH but at least it goes the right way!

Something for when i get home again.

|

| |

|

|

|

|

|

|

|

|

I have just had a thought.

If i need to raise the rack position, the same can be achieved by lowering the track rod end on the steering arm.

That would negate having to make a new part for the base of the steering coloumn too. And it means i am only changing one thing at a time.

I wonder if the jointed steering track rod ends can be shimed down. Phone call needed.

Some time later.............

Phone call made, i can do this but of course i need to parallel the taper in the steering arm so i can shim the track rod end up and down. Not something i can do with the kit in the garage but easy enough for a proper engineering place to take out to 0.5".

|

| |

|

|

|

|

|

|

|

|

Jim, the rack needs to go up - I was not expecting that- not by much but up all the same and only if I really want to eradicate the bump steer. The bump steer is linear and for a road car it could be argued that it would induce stability, but all the same I shall try minimise as much as possible. Although I have plenty of upwards adjustment on the rack mounts there is the unfortunate case of an engine in the way. Due to the engine being lower and the suspension (as a whole) being higher relative to the shell.

I have plenty of downwards adjustment but wish to keep the TCA mount as per standard geometry for the near future to see what the increase in damper rate has done.

|

| |

|

|

|

|

|

|

|

|

Its been nagging me all week but i think the rack actually needs to go down. Brain fart in reading Staniforths book.

|

| |

|

|

|

|

|

|

|

I have bought the car a little present:  I have been away a lot with work and i thought the car might be feeling left out. These are Pipercross full radius and tapered ram pipes and others that have used them have reported a small increase in power - so all good. The filter though was a real curse word to fit as i have very little room between the carbs and the inner wing. And these Pipercross filters need room to fit.   Back too the issue of the bump stop on the front. As can be seen below the bump stop is 80mm long and the full travel is 165mm. My car sits at 100mm which means there is 20mm of compression before the bump stop starts to affect the spring rate. I can either take off a further 20mm of the bump stop or leave them but i have not decided yet as i need to think about the spring rate of them.  |

| |

|

|

|

|

|

|

|

|

I have considered changing over to throttle bodies but have decided to stay with the modified Webers as it looks right.

|

| |

|

|

|

|

|

|

|

|

I rang Bilstien and the bump stop rubbers are sold at a length that is too long for most applications and they expect them to be cut down. Most rally cars run two sections.

I guess if you had to run a standard spring then the bump stop could be used to add spring rate.

I suspect I may cut mine down to two segments. Only one is needed to protect the damper apparently.

|

| |

|

|

|

|

|

|

|

|

|

|

I also spent the day with the front steering and after a lot of faffing I can say the rack needs to go up. Up further than I have room so it's back to the rose jointed track rod ends I guess.

|

| |

|

|

|

|

|

|

|

So i got the steering arms bcd from being parallel bored:  And a trial fit:  The new adjusters make adjusting the tracking very easy and quick now. After a bit more of taking off, putting on, level the steering rack, set the tracking, adjust height shims, check bump steer, change shims, set tracking, check bump steer i finally got to a value that i was happy with. More to the truth i was due to meet my wife in the pub and needed to finish…….. The final value was 0.43mm of toe out with 25mm of suspension travel. It started out with nearly 9mm!!! All i need to do is put it all back together and make some proper shims and then i am ready to tackle the next job, which is setting the corner weights. That should be fun as i have never done it before. |

| |

|

|

|

|

|

|

|

|

I have just weighed my car as part of doing the corner weights and it comes out at almost exactly 850kg with 20 litres on board as well. Only thing missing is me sat in it.

I am very pleased with that! :-)

Oh, and a 58/42% split front/rear.

|

| |

|

|

|

|

|

|

|

|

The car has been lightened by:

Fibreglass bonnet

Fibreglass boot (original spoiler and that is heavy)

Perspex rear window.

Each door has had metal removed all the way around until it's just a skeleton, all door locking furniture removed except external door handle but all lightened, all glass winding removed, the window divider removed so that a single piece of Perspex sits in each door.

All fixings and fittings are aluminium apart from the door lock!

Internal door pull release is now 9/0.30mm wire.

No internal carpets, sound deadening or trim except dash and head lining.

Anything left has been reworked to be lighter.

New fibre dash I the new year as well I hope.

|

| |

|

|

|

|

|

|

|

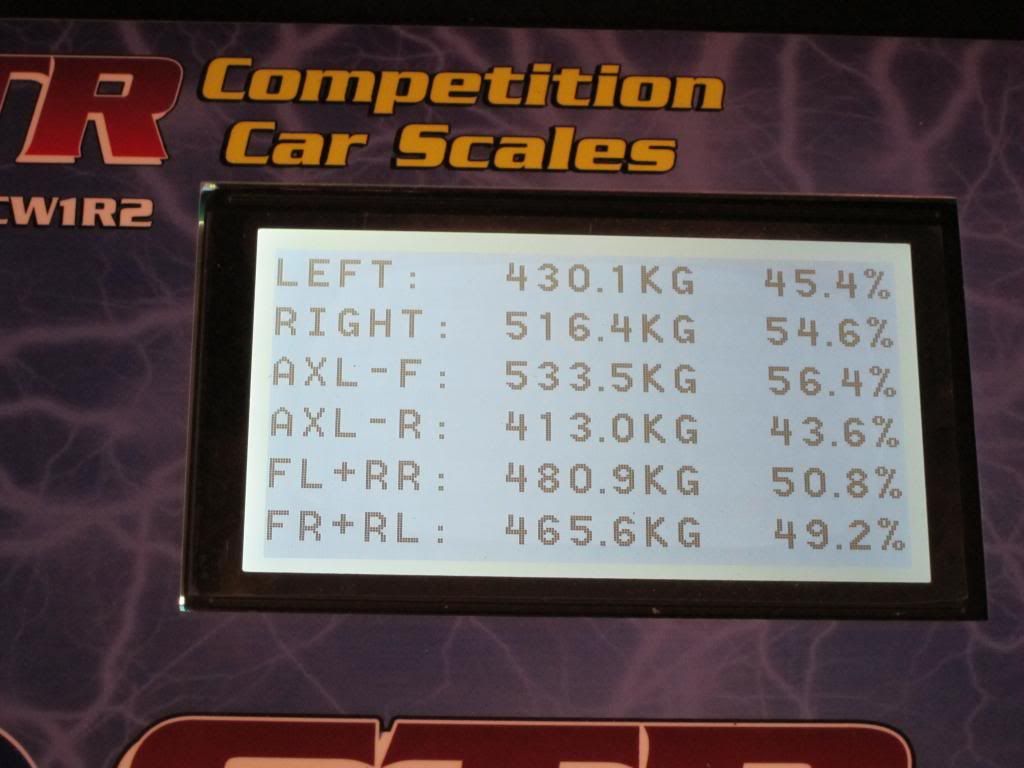

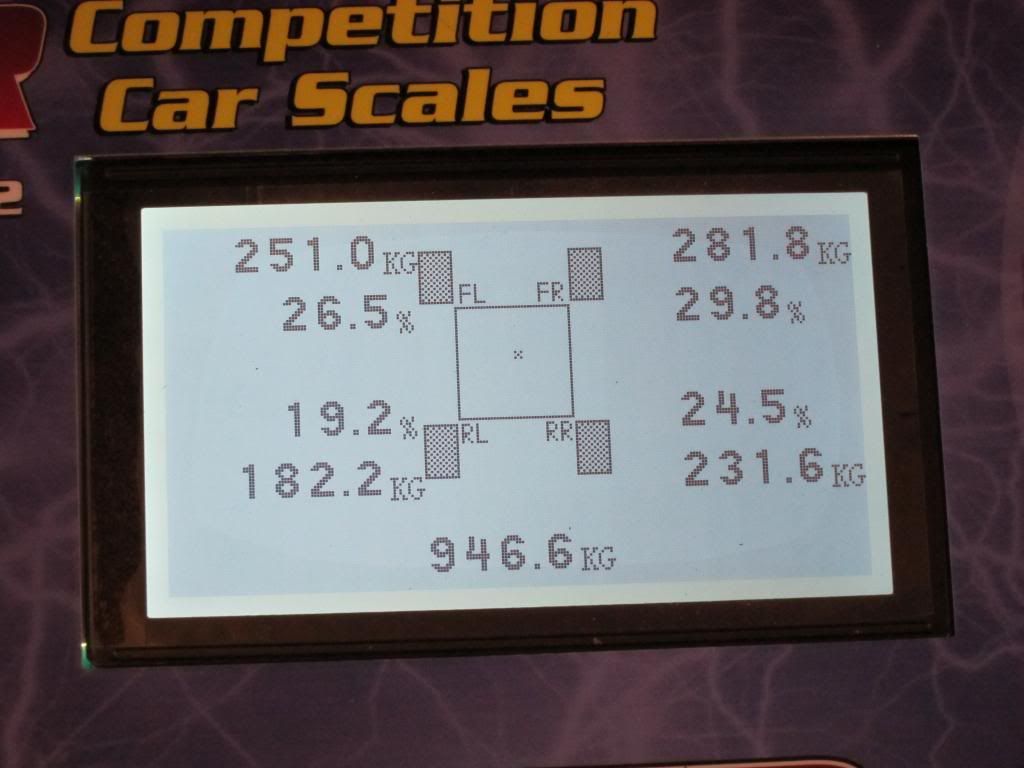

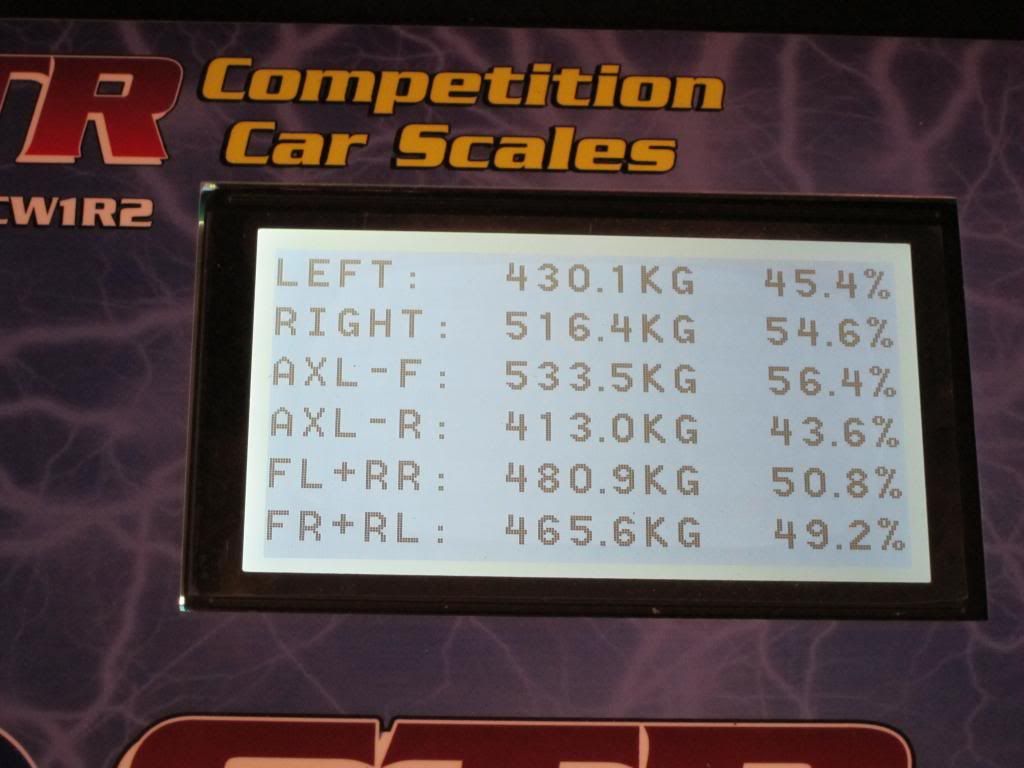

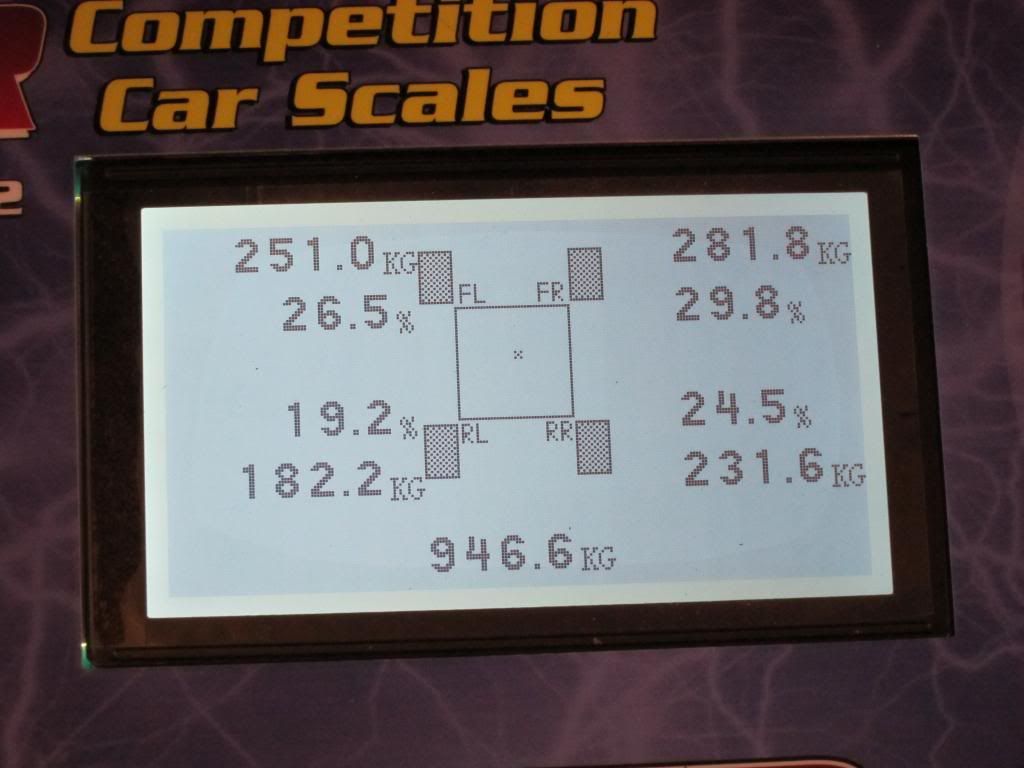

So, after spending getting on for an entire day using the corner weight gauge and seeing different results and the car seemingly getting heavier before my eye, i lost my temper and sold it. This was one of the ADA gauges where the thing looks like a jack and has a hydraulic piston and gauge. I had sent it back as it was not working and they had serviced it for £70!!! And when it came back it was worse. A pile of rubbish i thought...... Having sold the 2nd spare axle i thought i might get my self something to replace the corner weight gauge:     Results:: 849kg total without me but with fuel etc 56.5% / 43.5% Front to rear distribution. Cross weights ended up as 50.5%/49.5% with me sat in the car. Looking at the individual heel percentages there is lots of scope to m ove stuff about in the car to even the weight distribution out but that will be after the first event of the year! These systems are much easier to use although a lot more expensive than using kitchen scales.......... |

| |

|

|

|

|

|

Jul 10, 2015 18:32:37 GMT

|

|

pretty nifty weight balance considering its a tradition FR car

|

| |

|

|

|

|

|

|

|

As i have my first sprint of the year and Saturday i thought i had better have look over the car ready for then. The spark plugs had died over the winter so i have some new NGK NG8EVX now and the engine is sounding much better, these plugs are getting difficult to find so i also bought a load of Champion N64Y which is an equivalent. I had knocked the exhaust going into the garage after its little drive out so i put that all straight and remounted. Whilst underneath i thought i had might as well take off the anti roll bar on the back as i have it disconnected and probably will not put it back on so i took it off and here it is:  IMG_2236 IMG_2236 by Nevtiger, on Flickr This came off my old Lotus PLE and i had tried it but it did not really help and just made the back end even more loose than it is :-) Any way i need more room under there so i can fit these bad boys:  IMG_2237 IMG_2237 by Nevtiger, on Flickr These have dual rate rear springs to allow a form of anti roll with soft springing for traction - thats the theory any way. I can't fit them until i do some work on the front to bring it up to the same rates on springs and also i need to modify the front ARB to allow it to work more effectively. |

| |

|

|

|

|

|

|

|

|

Is it turreted? i hear you mutter

Not turreted, and I shall make new bottom (adjustable) mount on my new axle. The bottom mount of the new damper has to be in the same axis as the original damper but it will be offset slightly.

There is not much room for the coil over but it does fit.......

|

| |

|

|

|

|

|

|

|

|

So an update:

Everything is doom and gloom here at Nev Towers.

The new engine seized at Castle Combe two weekends ago and has just been stripped down to see why.

One thrust washer was found in the sump (again........) and the other - the flywheel side - was found in situ but wafer thin. There is also lots of other damage due to the engine seizing.

This is most interesting as my spare engine that i was going to fit so i can do an event at Goodwood on the 19th has exactly the same problem. I noticed crank movement so took off the sump to find a thrust washer in the bottom and no sign of the other one buts lots of damage to the crank.

These two engines are very different but have two things in common:

1. They have been fitted into my car from new/rebuild (Different engine builders too)

2. They have done very very little work.

Has any one seen thrust washer failures like this before?

Any one got any sensible ideas about why this is happening to me (It could be something i am doing whilst driving?

(With the power of a time machine i do know why this has happened now...........)

|

| |

|

|

|

|

|

|

|

|

t seems that the thrust washer that takes the clutch load can wear away completely and this is what allows the other one to fall out. I am not convinced that it is the clutch only at fault as plenty of other people use heavy duty clutches and have no problem. And in my case its happened to two engines using different gear boxes and clutches........

It also seems to happen really quickly after a rebuild - but i am not sure if that is just co-incidence.

Any way i am still trying to work out what to do to cure it although i have had some good advice over the wekend - cheers Alan.

|

| |

|

|

|

|