|

|

|

Apr 17, 2015 20:39:38 GMT

|

|

And the tune to the Welders Anthem is..?

Looking good on the welding front now. They shouldn't be going anywhere.

Anyway what sort of lousy boss makes you work when you could be painting miles and miles of steel? You need a new one.

|

| |

|

|

|

|

|

|

|

Apr 17, 2015 22:10:16 GMT

|

|

Well, to be honest, there wasn't a discernible tune. Let's call it a sort of free form Jazz kind of thing. Perhaps with a sniff of that wailing sort of singing you hear occasionally.

Anyway, however you might describe it, at least when I come to sing it again nobody will be able to accuse me of getting the tune wrong.

I work shifts. This is my weekend on. Ah well.

Need a new boss? Thats easy. You just wait a while and sooner or later they'll think of a new name for the department and / or have a management reshuffle.

|

| |

|

|

|

|

|

Apr 17, 2015 22:31:36 GMT

|

You just wait a while and sooner or later they'll think of a new name for the department and / or have a management reshuffle. Ah yes, the joys of corporate life. Don't miss a thing about it. I have my board meetings over a beer and new client risk assessments (running to eight pages in my last company) normally consist of "Ah, go on then". Simple life. |

| |

|

|

|

|

|

Apr 19, 2015 21:09:28 GMT

|

|

Eight page risk assessments? Bit short isn't it!?

Actually, being less flippant, I'm not sure how long ours are. I've never bothered to read them...

Hope the boss isn't reading this. I know what I'll be doing on nights if he is.

|

| |

|

|

|

|

|

Apr 20, 2015 10:08:23 GMT

|

Hi, just tell him you do "dynamic risk assessments" it shows you're adaptable and good at problem solving.  Colin |

| |

|

|

|

|

|

Apr 20, 2015 16:52:57 GMT

|

Hi, just tell him you do "dynamic risk assessments" it shows you're adaptable and good at problem solving.  Colin As it 'appens, that's not far from the truth. The 'dynamic risk assessments' bit anyway. Adaptable problem solving might be more debatable. You see God blessed me with a fear of pain - especially when I'm feeling it - which means I tend not to do things that are likely to get me killed or get bits of my person mangled. For this reason I'm still alive and have enough appendages to count to 21. (But only in private.) Back on the job, I painted the steel today.  I considered photoshopping the photo I took last week to make it look like I'd been painting. But then I realised I'm not very good with photoshop and it'd be quicker to actually paint the stuff. I haven't painted the big channel section yet. It needs some more bits welded to it. It'll all become clear next week with a bit of luck. James |

| |

Last Edit: Nov 12, 2018 22:13:03 GMT by Sweetpea

|

|

|

|

|

Apr 27, 2015 22:12:38 GMT

|

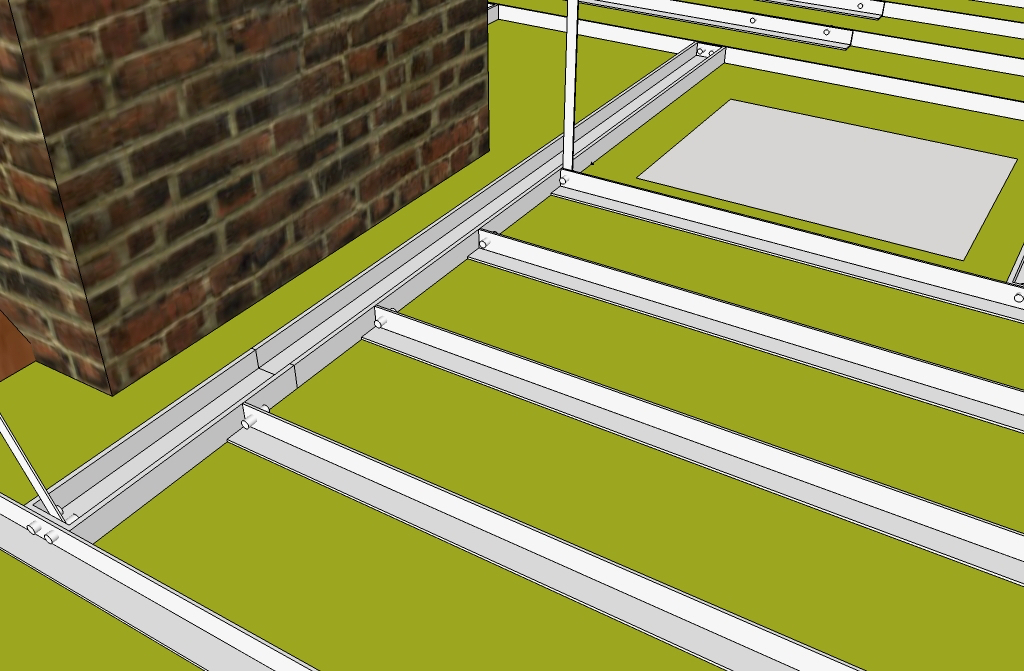

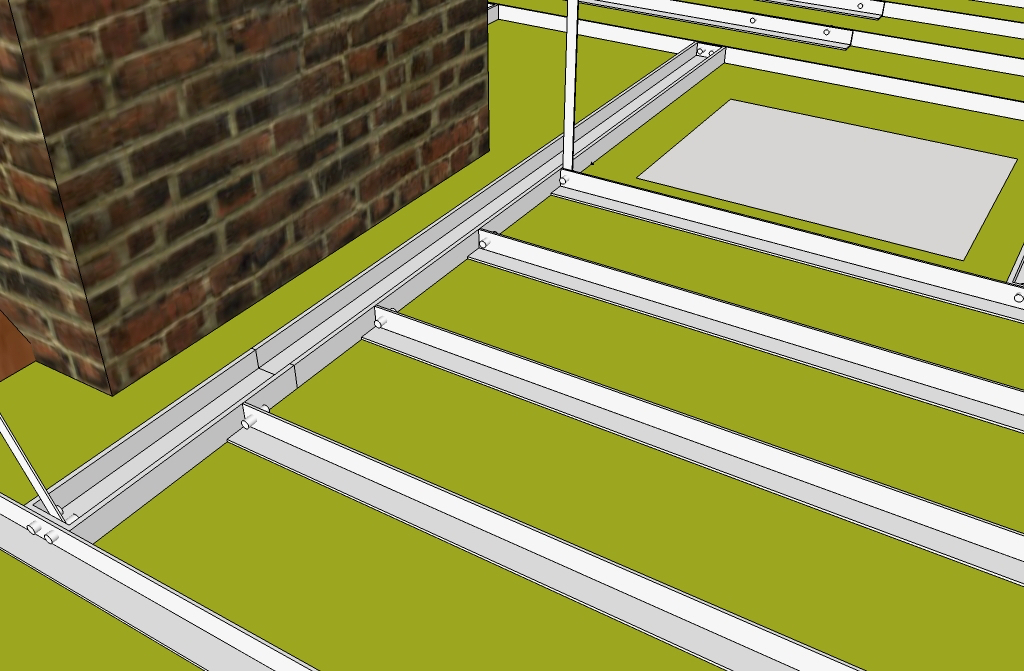

It'll all become clear next week with a bit of luck. James I think this more or less constitutes next week so I'd better have a pop at making things clear…  The angle bits coming from the foot of the rafters bolt onto the channel section where they meet it. They bolt onto a tang welded to the side. There are a couple of ways working out exactly where the tangs should be. 1, Take lots of measurements and transfer them onto the channel. 2, Take all the stuff into the loft and lay it out. Mark where the angle touches the channel. I reckoned that if I measured it I was quite possibly going to muck it up somewhere along the way. Where as if I lay it out in the loft I was onto a dead cert and I'd find out which of the tank bearers were in the way. So that's a plan then.  Didn't take long to find something in the way. It's the end of the original water pipe. Quick bit of grinder action and the short ends are bolted loosely to the foot of each rafter.  The cold water tank was drained and moved again… That turned out to be a challenge because my little pump that I use to clear out the last dregs of water sucked up a bit of crud and jammed. Took ages to get it working again. As I was saying… Tank out and channel in.  Lordy Lordy! I cut it the right length!  Laid out the angle pieces from the rafters and had a couple of issues.  The one on the right just slides along the side of the tank bearer. It needed a bit of relief at the end where the tang will weld to the channel. And a couple of bits over I had to move a bearer over a little. No biggie though. That gives me some accurate marks…  … Where I should weld the tangs on.  That photo still has the slag on and hasn't been cleaned up. One other little problem crops up.  You see the top of the old wooden loft ladder? And you see that piece of white chipboard? Well when it's all shut up the ladder lies flat on the floor about where the white board is. Except in future it won't. I'm about to put a large chunk of steel across right in the way. The whole ladder and loft door it's screwed to needs to go up about 8cm. Like this.  Bit of a gap. I think I have a tube of filler in the garage. I should comment on the decor. The hall and landing is the one part of the house we haven't touched yet. The wall paper is so horrid it's actually trying to take its self off the wall. I've been making excuses for not decorating it for years. The latest being that I wanted to get all the steel for the roof up the stairs first. Guess who is just about to run out of excuses. James |

| |

Last Edit: Nov 12, 2018 22:30:01 GMT by Sweetpea

|

|

|

|

|

Apr 28, 2015 20:57:37 GMT

|

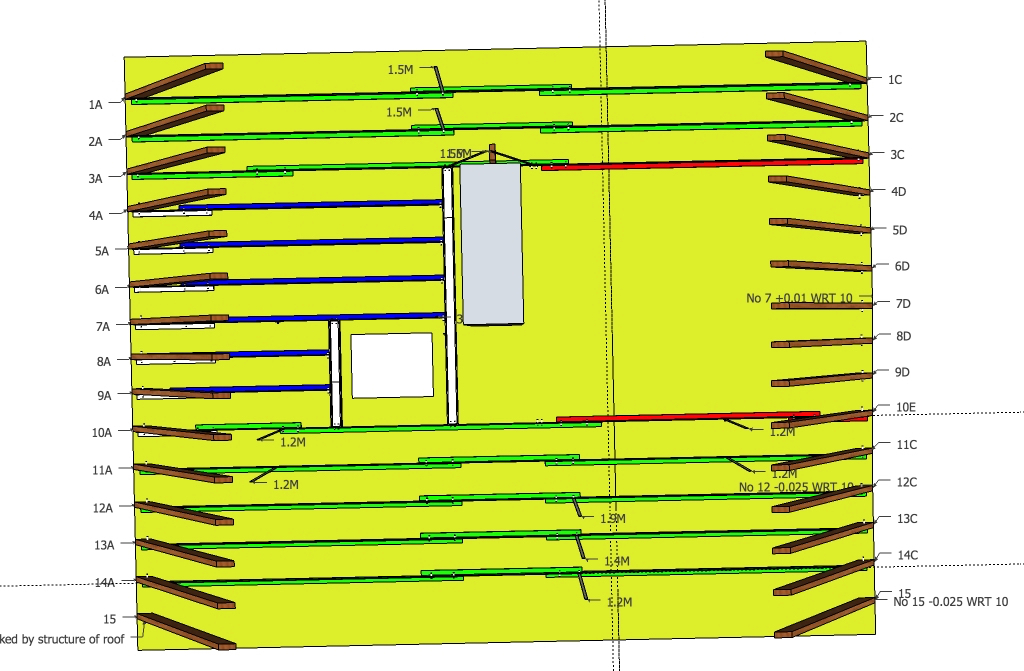

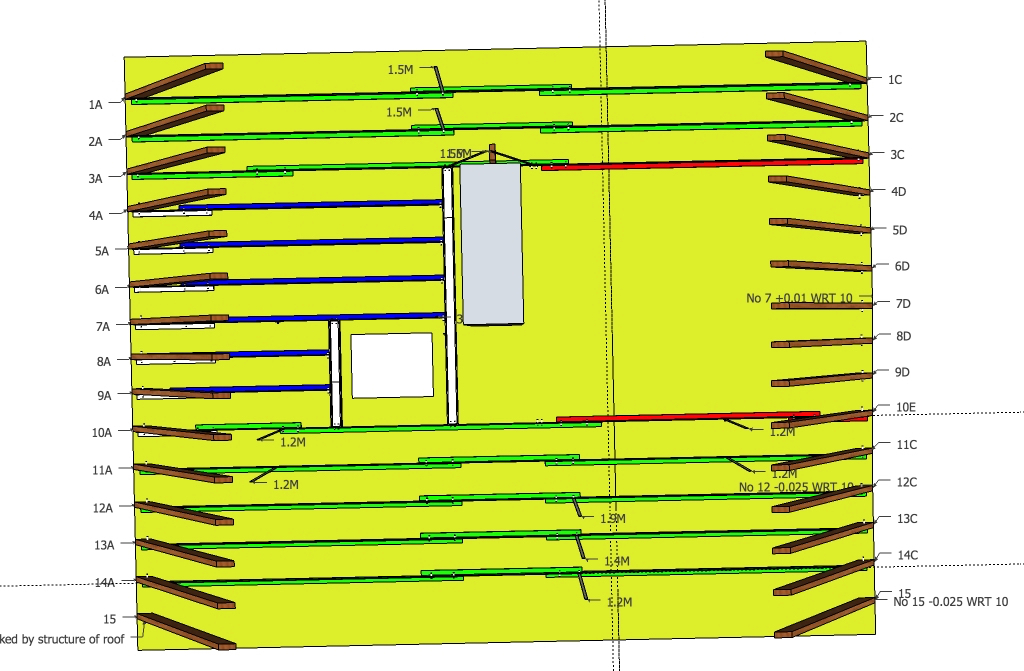

Ok luvvie darling, once more with feeling! Tank out, steel in. Painted and bolted in for ever this time.  There is something nice about this. It's beginning to look like it could actually hold the house up. Proper engineering. Anyway, although it's all sitting there it's not under any tension yet. I need to be a bit careful. This is almost where we are…  The bits at the left of the loft hatch aren't there yet - but they are coming… So, the GREEN bits are fitted and tensioned. The BLUE bits are loosely fitted. The right side of the loft is full of stuff from the left side at the moment. I was going to tension the blue bits, move the all the stuff round, then build and tension the right side. But it strikes me that all the blue bits pulling to the left will massively load the two red bits on the right side. The steel won't care but the foot of the rafters might. So I actually need to build all the right side and tension evenly left and right. In other news the loft ladder has been reinstalled without the loft door. (The ladder was screwed to the back of the door.)  And…  …a new, flush fitting loft door. I'm living in a palace! James |

| |

Last Edit: Nov 12, 2018 22:35:35 GMT by Sweetpea

|

|

|

|

|

|

|

And…  …a new, flush fitting loft door. I'm living in a palace! James I'd be tempted to leave it like this...for that rat look landing. |

| |

|

|

|

|

|

|

|

|

Well it probably is going to get left like this for a while. It matches up with the missing architrave, peeling wall paper and the trashed bit of wall we took down to do the bathroom.

Unfortunately Mrs Sweetpea doesn't really get the 'rat look' so she'd like it decorated. We invited a decorator chappy round to give us a quote. He decided he didn't want to know.

Hmmph. Guess it's my problem then.

|

| |

|

|

|

|

|

|

|

May 14, 2015 21:14:37 GMT

|

It has come to my attention that my thread is a little behind and that I've actually done more than I've admitted to. This is unusual for me as I generally do so little work that I've written the next bit long before I get round to doing it. A couple of posts back I put up a drawing that suggested I'd installed the bits behind the loft door. However, as can be seen below…  …they were still in the garage. Part of the problem was that the big bit crashed into a water pipe that was inconveniently positioned.  So it got moved to a new home. I think that's the third or fourth time that pipe has been replumbed on this job. teaboy will be proud of me.  Once the big bit was finalised and the welding finished it got painted and bolted in. I haven't tensioned it all yet but I did spot a minor problem in that a couple of parts were too long and fouling my tensioning rig.  Nothing that the angle grinder couldn't put right though. So that's the left side of the house all in and ready to be pulled tight.  Just need a load of steel in this side.  And another big channel section to go across the foot of the chimney.  Don't you just love the way the chimney steps off to the left. It looks so, er, well, frankly it looks so wrong. Still, it's not fallen through the hall ceiling yet so it can't be that wrong. James |

| |

Last Edit: Nov 12, 2018 22:47:08 GMT by Sweetpea

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,127

|

|

May 14, 2015 23:14:08 GMT

|

I think that's the third or fourth time that pipe has been replumbed on this job. teaboy will be proud of me.  Well James, you may have to move it another couple of times before you are totally happy with it... |

| |

|

|

|

|

|

May 15, 2015 23:33:08 GMT

|

|

Chimney is usually the strongest part of the house....

|

| |

|

|

|

|

|

|

|

Don't you just love the way the chimney steps off to the left. It looks so, er, well, frankly it looks so wrong. Still, it's not fallen through the hall ceiling yet so it can't be that wrong. James Looks like they made it nearly to the top only to realise they were going to miss t'hole in t' roof! |

| |

|

|

|

|

|

May 17, 2015 18:42:20 GMT

|

|

You've probably explained it and i've forgotten.... but why did you not 'frame' round the chimney with the steel channel so the strength of the chimney would help to anchor the 'framework'?

|

| |

I would be rich if i had not spent so much money on Cars and fast women...oh, i did waste some of it as well!

|

|

|

|

|

May 19, 2015 21:07:15 GMT

|

Sorry chaps, I've had to go to work for a few days. Dashed inconvenient! What! teaboy that pipe is in its final position ever. I'll move the rest of the house round it if I have to but the pipe stays where it is! dodgerover I hope the chimney still is pretty strong. A couple of the other houses like ours have had the stacks taken down 'for structural reasons'. I can't see what the problem would have been though. Mine are showing no signs of any problems. I suspect 'for structural reasons' is a euphemism and what they really mean is 'I can't be bothered to maintain them'. georgeb it does look like they suddenly realised they were going to miss the hole in the roof but the other houses in the street have the same design. At least, the ones I've crawled in the loft of are the same. (We don't have 'loft parties' or anything odd like that so I've only seen a couple of them.) I think they did it deliberately to get the chimney in the centre of the of the rooms below. Nicely done really. maybachman one of my early thoughts was to tie the foot of the rafters to the chimney and use its weight to stop the roof sliding. And undoubtedly it would have worked if I could have got solid enough fixings or tightly framed it as you said. But there was always the nagging doubt that if the roof kept moving it would either rip the chimney apart or pull it over. After that thought I decided that the chimney was quite happy being left to do its own thing and I would build the collar away from it and leave it alone. This way I'm not adding sideways loads that it was never really designed for. James |

| |

|

|

|

|

|

May 20, 2015 11:12:46 GMT

|

|

Hi, a few years ago it was popular to remove the fireplace and chimney breast in the living room. As it supports the rest of the stack it was safer to remove it all the way to the top for 'structural reasons' rather than support it on the joists because it gave more room in the bedroom as well.

Colin

|

| |

|

|

|

|

|

May 21, 2015 19:53:02 GMT

|

Hi, a few years ago it was popular to remove the fireplace and chimney breast in the living room. As it supports the rest of the stack it was safer to remove it all the way to the top for 'structural reasons' rather than support it on the joists because it gave more room in the bedroom as well. Colin I remember dear old dad doing something like that. Anyway that's not what's 'appened in the other houses on this street (apart from one). They have only removed the bit that went through the roof.  |

| |

|

|

|

|

|

May 21, 2015 21:37:47 GMT

|

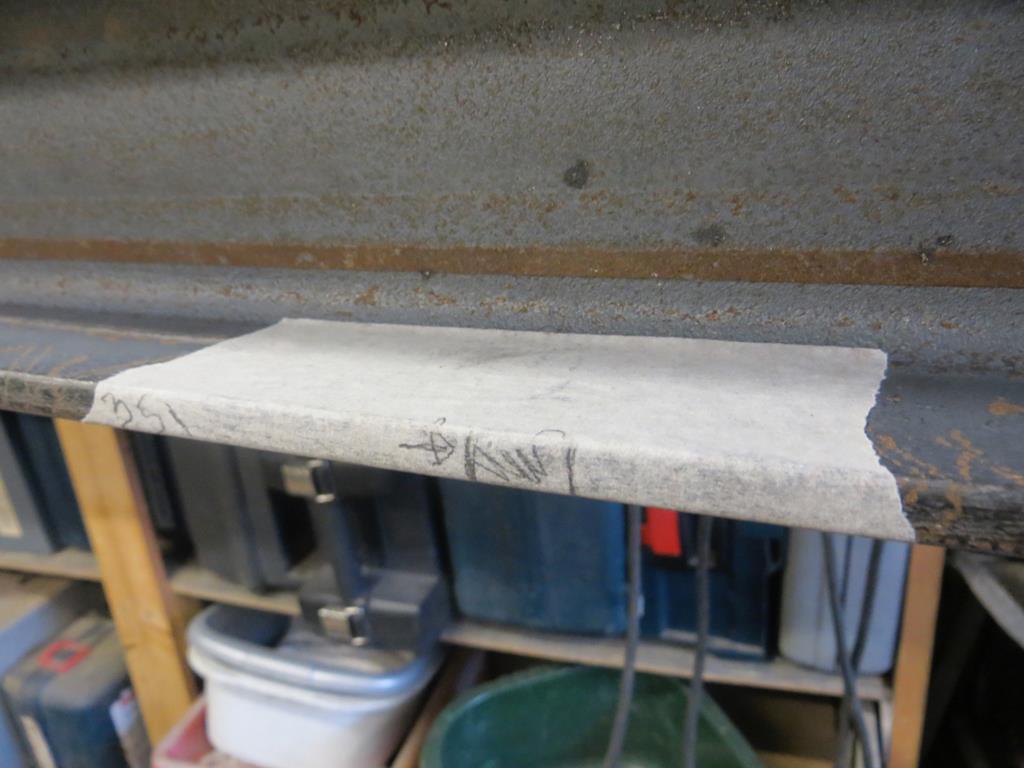

A monumentous occation is almost upon us. Enough of that. Lets start with a digression. Well it's my thread so why not. When it rains in the evening, even lightly, we've heard these occasional SPLAT sounds. It's as if a massive drop of water is landing on the decking but it's irregular, sometimes just one, sometimes several in a row. And there is nowhere for a drop big enough to fall from. It's been a dilemma at our house. The other night we found this chap…  …and two of his friends trying to break into the patio doors. Every time they hop into the glass there is a wet SPLAT noise. Clearly evolution hasn't given frogs an understanding of glass yet. So what now? Ah yes, last week.  It's other bit to go across the other side of the chimney. Measure twice… No. Sod that, I'll put a tape mark on the measure. That way I can't get it wrong.  Weld the tags on the side and there we are, ready for paint.  Now I've been thinking. Always a bad move but stay with me. When I use the battery drill to bash holes through the steal in the loft it takes forever. It's hard work. Yet with the same bit in the pillar drill in the garage it goes through in seconds. Why would this be? Well the pillar drill turns slowly and the pressure on the bit is much greater. That way it cuts but doesn't overheat and go blunt. I can't get the same pressure on the hand drill so I tend to run it faster creating more heat. I had an idea… More complex 3D drawings were made and a great deal of time was spent making and refining the perfect tool for the job.  Nah, I grabbed some bits of stick and threaded rod and knocked it together. You hook the green stick over the rail and push it away...  …increasing the bit pressure. It cuts much better. And faster. I do wish I'd shaped the top of the handle though. And when the bit jammed it nearly had my fingers! It is, obviously, at this point that the battery in the drill went flat so I went to get the spare only to find it was cold in the charger. Odd. The charger usually keeps them warm. And there are no lights on it. Oh my, it's dead! Where am I going to get a replacement Dewalt charger in a hurry? But I fix things for a living… Better take a look inside I suppose. So it turns out that the internal fuse had blown. It was a T2A which I didn't have. A quick measure with a meter suggested that all the rest of it was OK. Input filter looked ok. Diodes - all ok. No massive short across the chopper transistor. Maybe it just blew 'cos it could? So I put a wire across the fuse. If there was a serious problem it'll just blow the 3 amp fuse in the plug top so no big problem. Ta da! It works! I'll get a proper fuse and fit it. But at least I can carry on tomorrow. So sadly I haven't done too much today. I'll just have to leave you with a photo of my nuts.  What did you think I meant??? |

| |

Last Edit: Nov 12, 2018 22:56:44 GMT by Sweetpea

|

|

|

|

|

May 21, 2015 23:06:54 GMT

|

loving your ingenious problem solving and the way you tell the story  but reading it just makes me jealous i don't yet have a house of my own to do big engineering projects but all in due course  |

| |

|

|

|

|