|

|

|

Jan 16, 2014 22:50:26 GMT

|

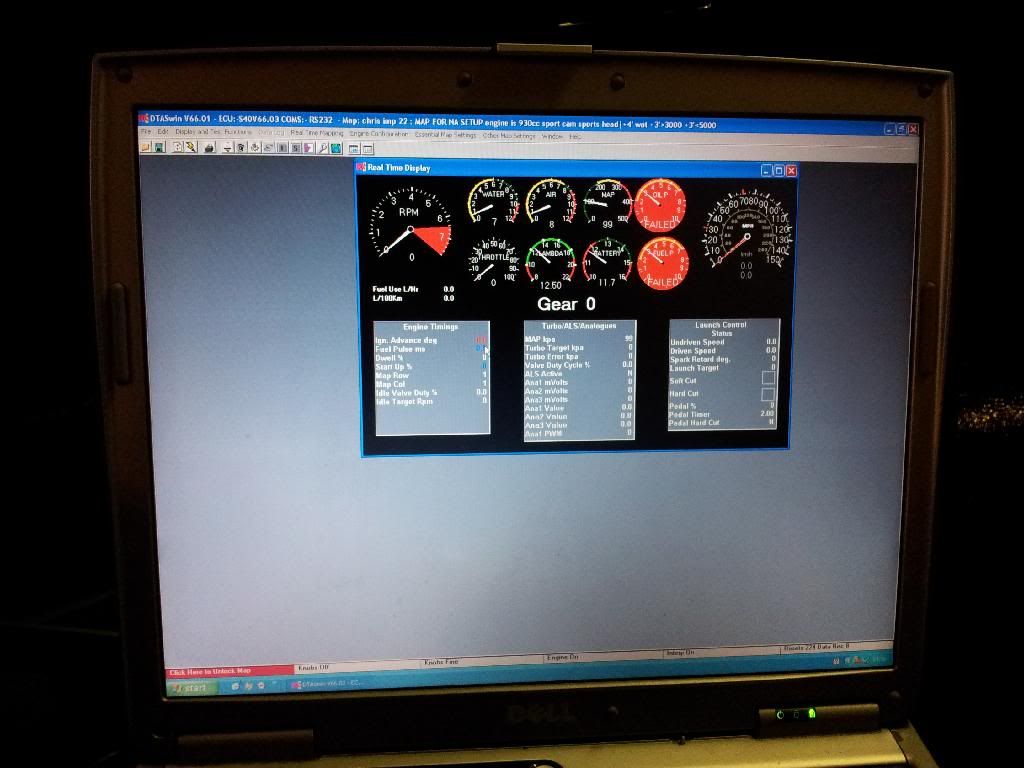

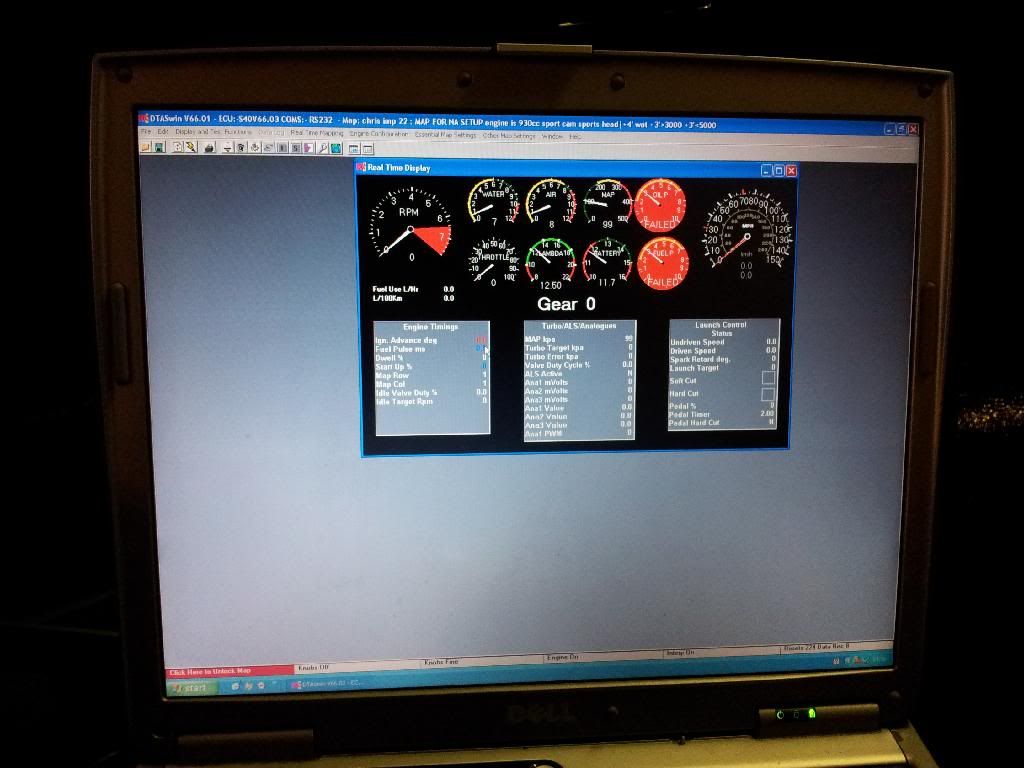

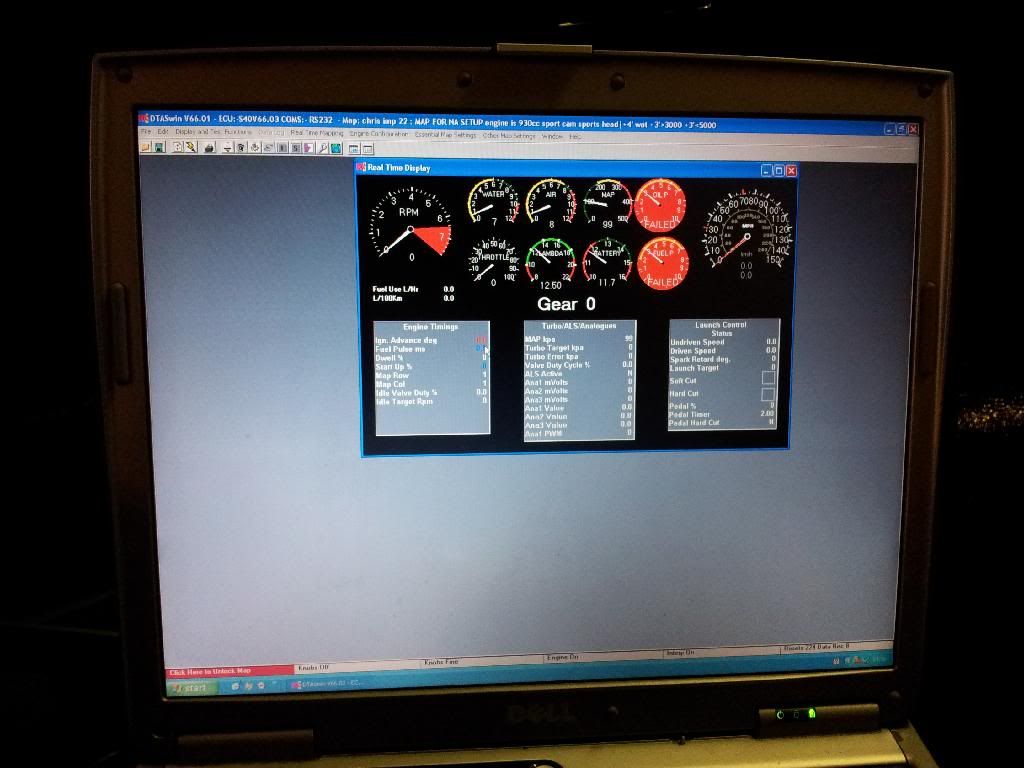

well with not wanting to be slaughtered by the wife if I started it up and woke my son up I decided to tackle a few other bits tonight, connected up all the engine electronics. hooked up the laptop and loaded a turbo map up into the ecu as a starting point. I wont drive it till after the rolling road. nothing quite like the satisfaction of it running up to speed and watching all the components working or failing in front of you, gives you that sense of satisfaction that its safe and usable or zhite and removable lol Pointless screen photo  then I fitted my pedals and connected up the pipes ready to fill and pump as soon as I can drag my dad around and next time its on the drive. Also need to fit 2 longer bolts that go through the chassis but thats easy when I get them. had to cut the carpet end off, but left a little around the pedals edges so it clamps it to the floor.  |

| |

|

|

|

|

|

|

|

Jan 18, 2014 20:01:13 GMT

|

Heres a vid, my dad did the camera work sod knows why he looked at the alternator lol. Its running, as you can see the belt is chucking itself around so will need the tensioner moving to the bottom which was expected You will hear it was high pitched. After that run I stood behind it while dad sat in it, I noticed that the bypass valve will need to be plumbed into the manifold as it didnt open the sound running isnt probably what itll sound like. When I opened it manually the revs picked up like crazy. Oh and initially I started it it ran a second accelerated crazy few fire flys out of the exhaust then cut out couldn't restart then remembered I forgot to add the petrol I had picked up before in a can. Dick. So think ill do a comp test make sure all is ok after that. Fire flys could have been the exhaust mind!  Chris |

| |

|

|

pork

Posted a lot

Posts: 1,666

Member is Online

|

|

Jan 18, 2014 21:13:07 GMT

|

Link don't work for me  |

| |

|

|

|

|

|

Jan 18, 2014 21:38:53 GMT

|

|

Wow... quite a whistle off of it, it doesn't really sound so much like an Imp engine in the video, is in more like how it used to sound in the flesh?

I see what you mean about the whip in the drive belt, it is usually better to put any tensioners in the rear run of a belt or chain which isn't being subjected to the drive load. If the tensioner is a sprung type this will avoid allowing slack in the belt.

I'll bet you are itching to see how it goes now, once fully set up....

|

| |

|

|

|

|

|

Jan 20, 2014 22:45:25 GMT

|

Should make many people happy, as you can see the pulley is now on the correct side. Nice light alloy angle Mount just needs welding up and spacing neatly, shaping, painting in graphite and its done. Again version one, all well Ill make a machined one piece version.  Boot down you can see the pulley unfortunately even if the piece of boot lid was re made that I cut out, You would have to be low down mind or from a distance to see it as the cars that low.  |

| |

Last Edit: Jan 20, 2014 22:46:46 GMT by deadlikeme

|

|

|

|

|

|

|

Well I finally finished off the tensioner last night to the point where I can apply proper pressure to the belt and have noticed that the charger is still able to flex towards the engine in a downwards fashion. Looking at a way forward I think I might be able to add a shallow angle to the rear sump mount under the plate and then need to figure something out at the front as the charger is mounted past the front sump post which I think is allowing it to flex at that corner as the othrt corner is bolted to the engines front face. Also think a angle/side to the mounting plate will stop twist. All this woyld be reduced to nearly nothing if not completely by using a nice thick alloy plate machined I reckon which will be the final plan. First though it looks like more welding after putting it all away and stripping the charger off and doing it all in situ, normal happenings though when doing things from scratch! Still need to finish off the coolant system which now needs the pump to be mounted at the front do rewired too. Lots to do pre rolling road on the 21st. Messing about with wheels too whilst filling the clutch and brake fluids.  |

| |

|

|

|

|

|

Feb 11, 2014 23:56:07 GMT

|

|

Looking forward to the rolling road setup. Should be tasty.

|

| |

|

|

|

|

|

|

|

Looking very good and hoping all goes well for the rolling road setup, then you can unleash the power  . As you said the next thing is to get nice aluminium brackets made, but atleast you now have an idea what they should look like rather than maving them made them having to butcher them or worst getting re-made. |

| |

|

|

|

|

|

Feb 12, 2014 10:03:06 GMT

|

Three header tanks!  Added angle seems to have made a great difference! Not painted yet as itll all be coming off again no doubt lol   |

| |

|

|

|

|

|

Feb 21, 2014 19:25:04 GMT

|

Right quick summary works perfectly fine, no wobble, flex or issues. Outlet flange blew its cork gasket then it blew silicone, I'm going to do what turbeam suggested and add additional fixings into the flange and reseal perfectly. With leaky outlet I have 0.4 bar of boost, 65bhp and many many torques With sealed outlet the ecu recorded 0.8 bar which will equate to around 90bhp and many many many more torques. Had a quick drive and yes the pull is awesome, third more torque than the imp had already!!   |

| |

|

|

|

|

pork

Posted a lot

Posts: 1,666

Member is Online

|

|

Feb 21, 2014 20:08:00 GMT

|

|

I've had exact same problem, blown 2 gaskets allready.

I'm making a thicker metal flange, 5mm thick lol no possibility of it bending now!

If that fails , il do same and bolt down in other places.

Have you sorted your bypass valve? Another member suggested mine was blowing due to pressure surge once throttle was shut

|

| |

|

|

pork

Posted a lot

Posts: 1,666

Member is Online

|

|

Feb 21, 2014 20:09:17 GMT

|

|

Also gunna try some decent gasket material

|

| |

|

|

|

|

|

Feb 21, 2014 20:20:01 GMT

|

|

just use silicon sealant mate not worth messing around I don't think. I would try a thicker flange but cant bring myself to remake it right now lol so extra fixings will do the trick!!

|

| |

|

|

pork

Posted a lot

Posts: 1,666

Member is Online

|

|

Feb 21, 2014 20:32:31 GMT

|

These chargers get really got too! Think the glue in the cork melts a bit with use too and weakens. Good to see yours is getting there now  You were right too, bike carbs and forced induction just never worked right, frustrating ! Converting mine now to efi  |

| |

|

|

|

|

|

Feb 21, 2014 20:40:17 GMT

|

|

did you mean to right really hot? if so mine after hours of use and even straight after boost and turning off was really cold!! Was chuffed how cold it was.

|

| |

|

|

|

|

|

Feb 21, 2014 20:47:50 GMT

|

|

oh and bypass valve was working perfect as far as I could see, opening and closing when expected with no delays

|

| |

|

|

pork

Posted a lot

Posts: 1,666

Member is Online

|

|

Feb 21, 2014 21:02:23 GMT

|

did you mean to right really hot? if so mine after hours of use and even straight after boost and turning off was really cold!! Was chuffed how cold it was. Yeah ?!! Might be due to my turbo too lol Not sure if yours is cold beings it's not compressing fully (just passing air, ie, cooling) with the blown gasket. Compression makes heat I've moved my bypass valve up to my throttle now too, plumbed the piston into the manifold vacuum lines, now it's essentially a BOV  |

| |

|

|

|

|

|

Feb 21, 2014 21:04:41 GMT

|

|

possibly, what pressure has yours made?

|

| |

|

|

pork

Posted a lot

Posts: 1,666

Member is Online

|

|

Feb 21, 2014 21:08:45 GMT

|

|

I was only using the charger to 0.5 bar, then swapping to turbo up to 1.0bar

I had 2psi on idle too, but that was with my homemade valve (which leaked loads! So was recirculating most of the boost it made lol)

Yet to see what it makes with new (air right) changeover valve

On idle it gets quite warm too.

|

| |

|

|

|

|

|

Feb 21, 2014 21:16:23 GMT

|

basically what mine was making all day then so temp wise shouldnt be to different, whilst messing around we put a tacho on the s/c pulley, max allowed is 9k whilst mine was sat at 7.5k when the engine was reving 6.5k so I'm right on the money with pulley size  can you say fluke lol |

| |

|

|

|

|

.

.