johnrh

Part of things

Posts: 958

|

|

May 17, 2014 19:29:45 GMT

|

Really, this an update on my other project, the Volvo 164RS, but I'll copy it here because there are some nice sunny photos including the 245! Getting the 164 out in the sunshine was partly for motivation, but there was also a technical reason. Under fluorescent light in the workshop, I can see some patchiness in the basecoat. I was worried that this might look worse out in daylight, and might necessitate repainting the car again. We had been waiting for a bright sunny day to carefully assess the paint. To my surprise, it's good news! The patchiness is all but invisible in strong natural light. There are a couple of bodywork defects I need to correct (e.g. a crack in the finish, and sinkage on the roof, but it does not need to be painted again. A massive relief! We decided to do a line-up for the photos, with my 245 and Steve's GLT                   I have some tasks in progress on the 245 (air-con, old style dashboard, and ABS brakes) which will take another few months, then later in the summer I will be fully back onto work to progress the 164. John |

| |

|

|

|

|

johnrh

Part of things

Posts: 958

|

|

May 18, 2014 18:34:16 GMT

|

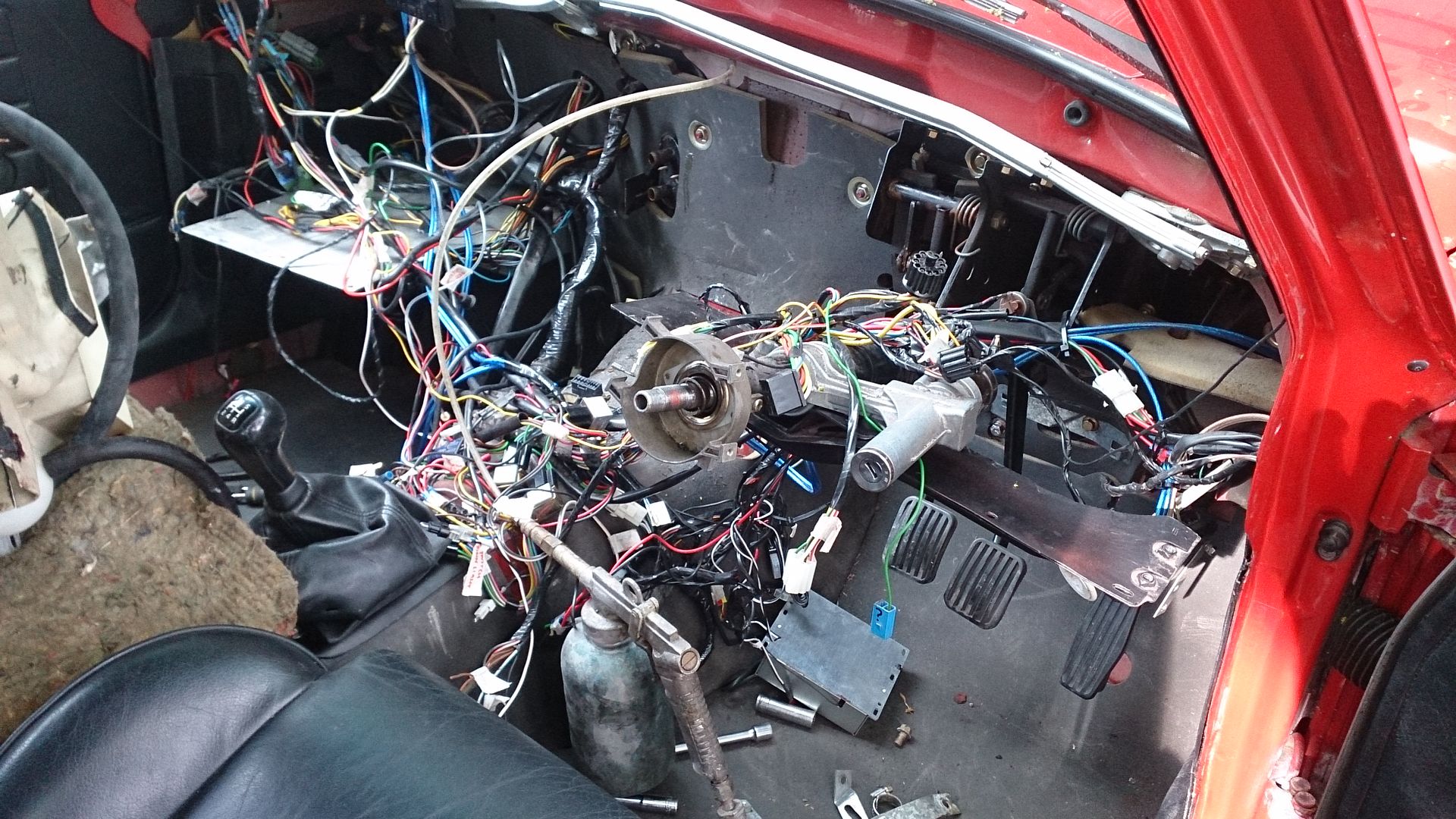

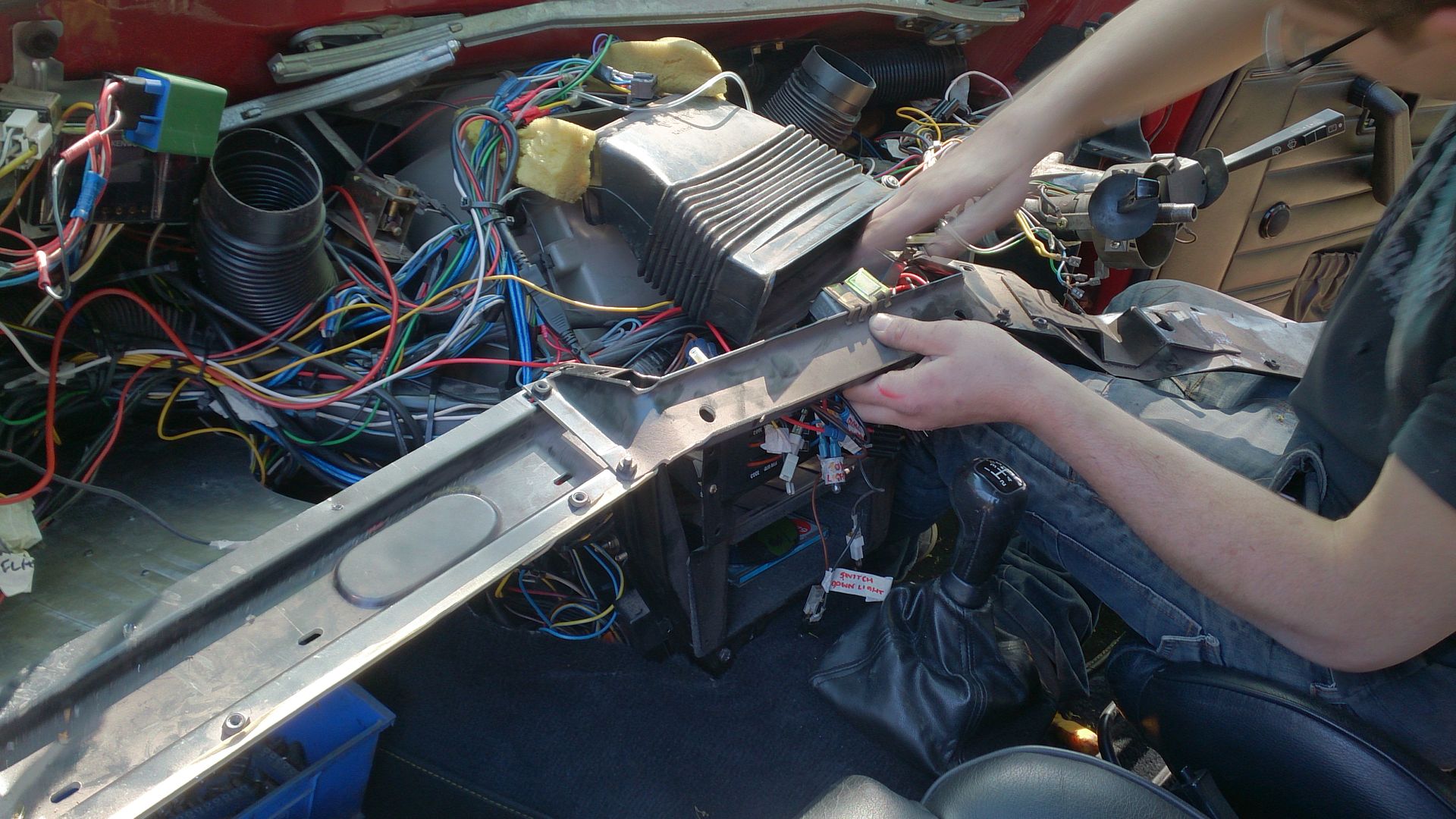

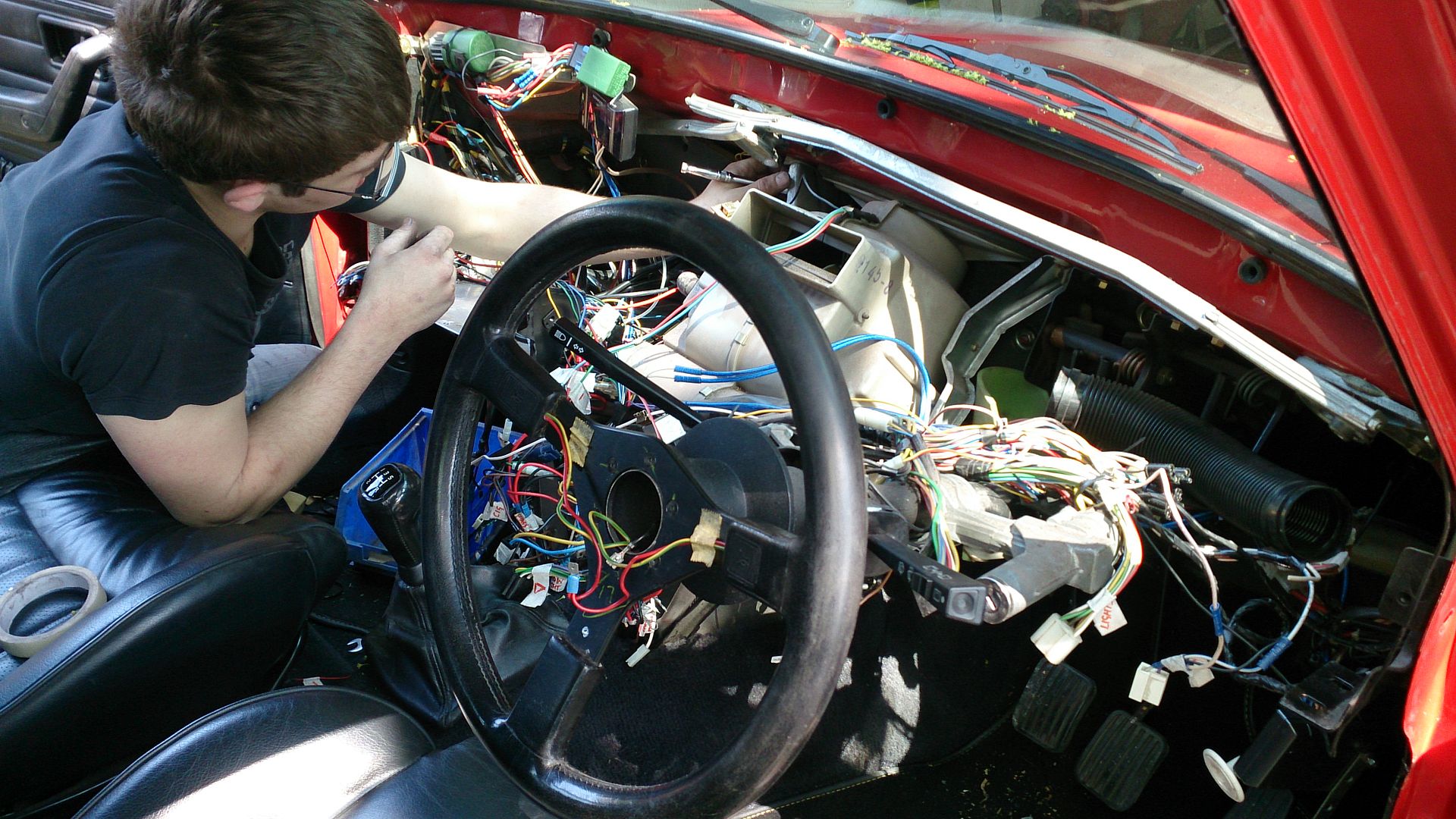

Full update to follow later, but here's our first test fit of the old style dashboard and r-sport cluster   John |

| |

|

|

johnrh

Part of things

Posts: 958

|

|

May 18, 2014 21:28:43 GMT

|

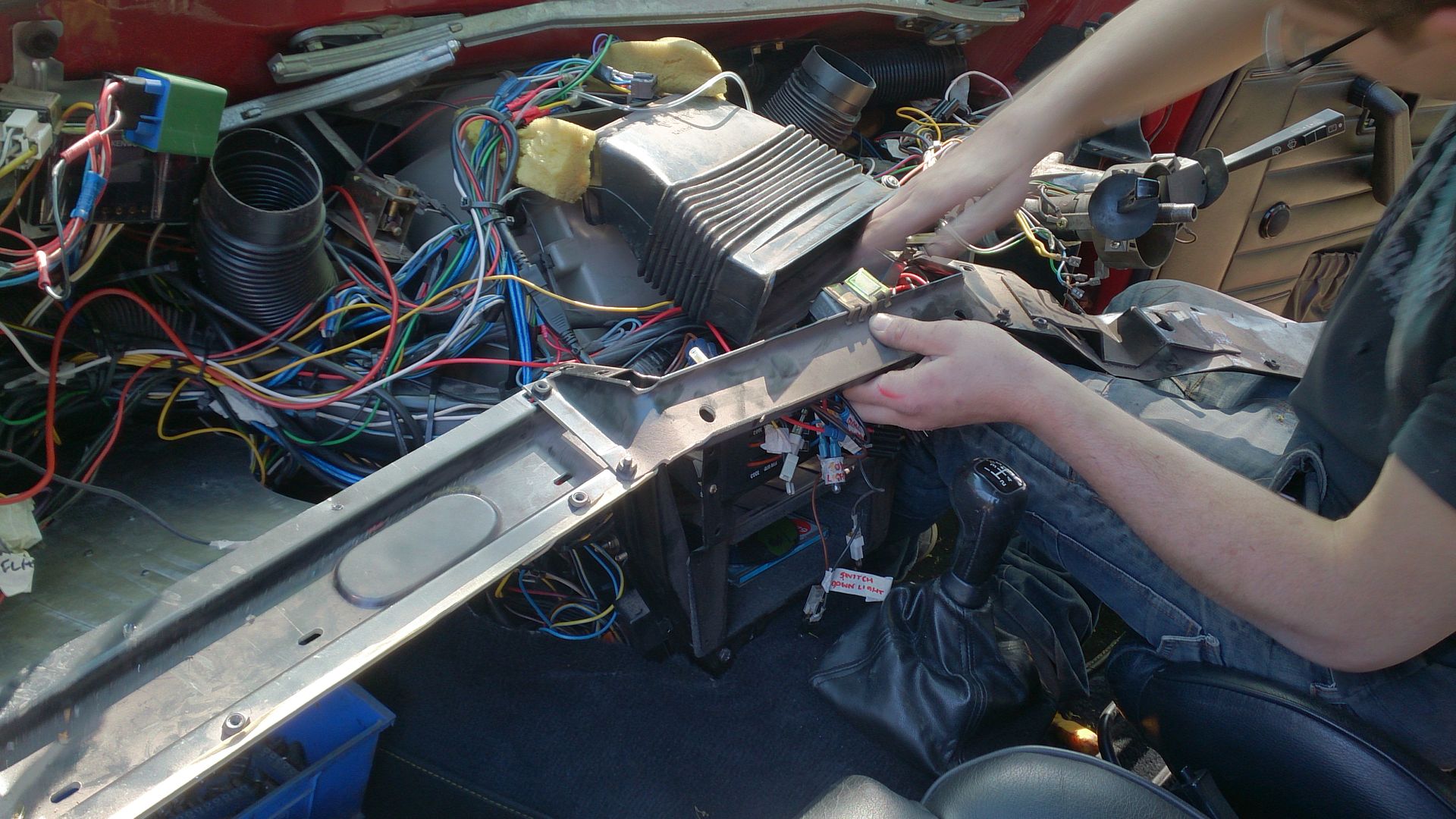

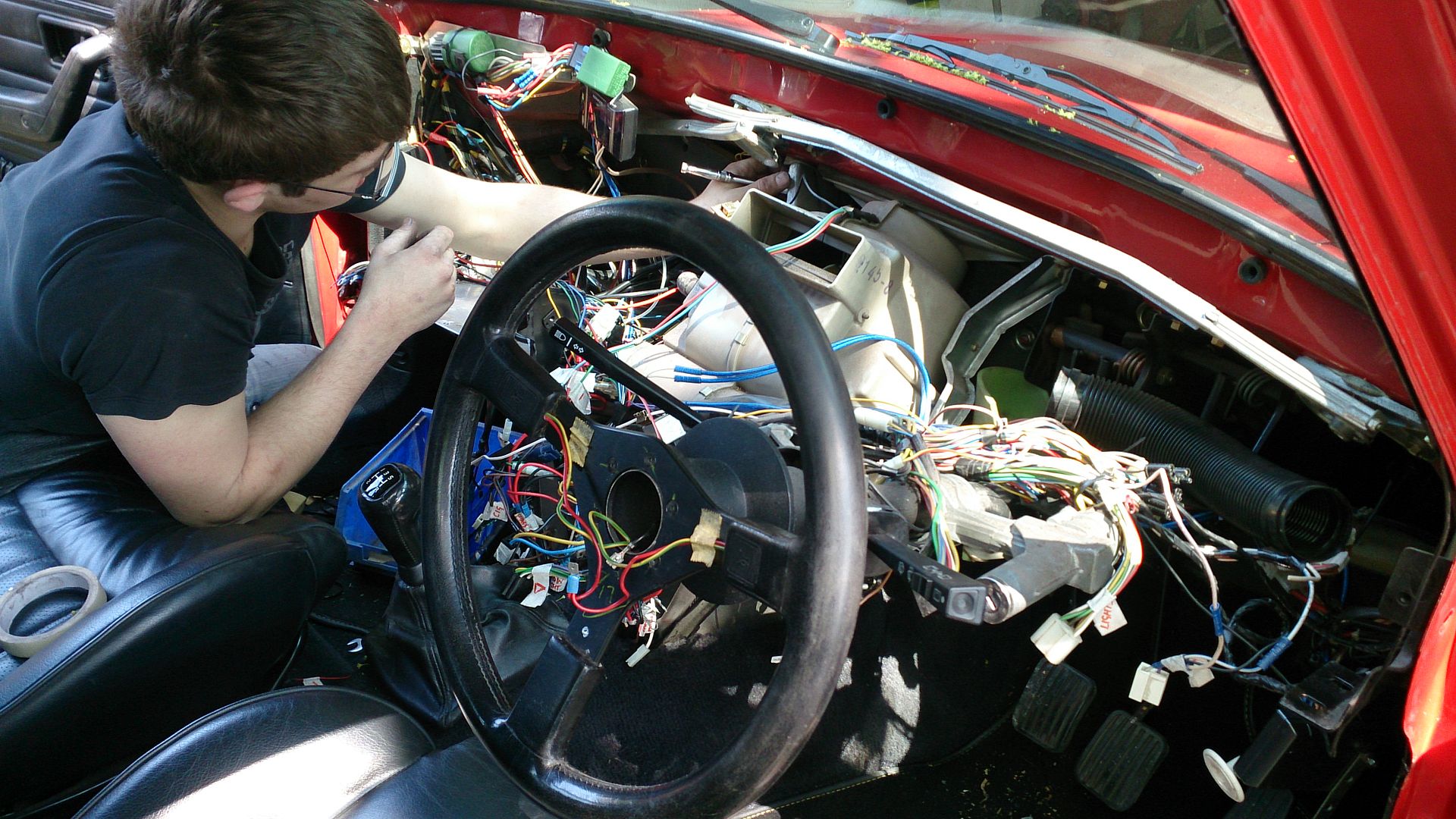

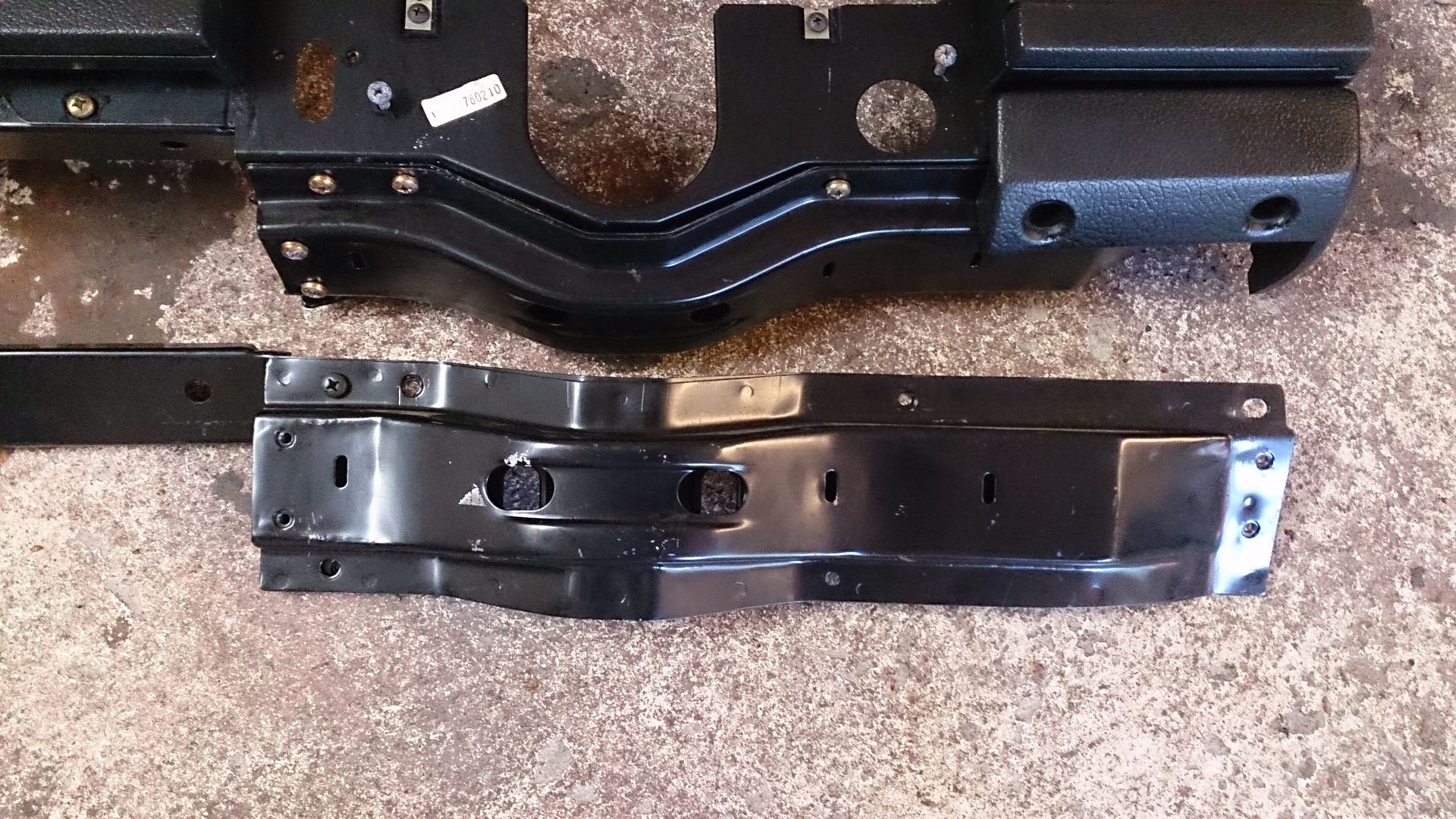

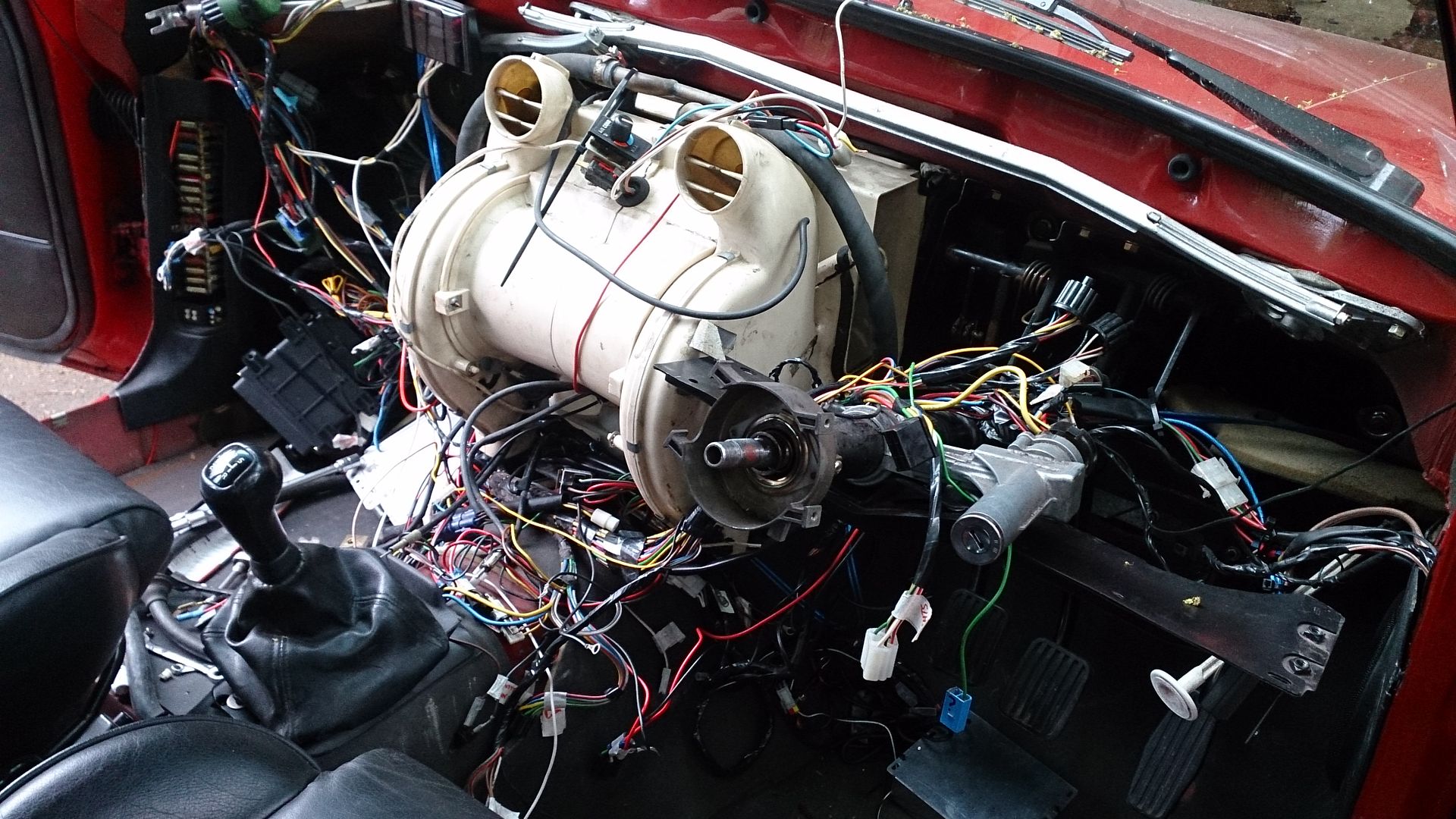

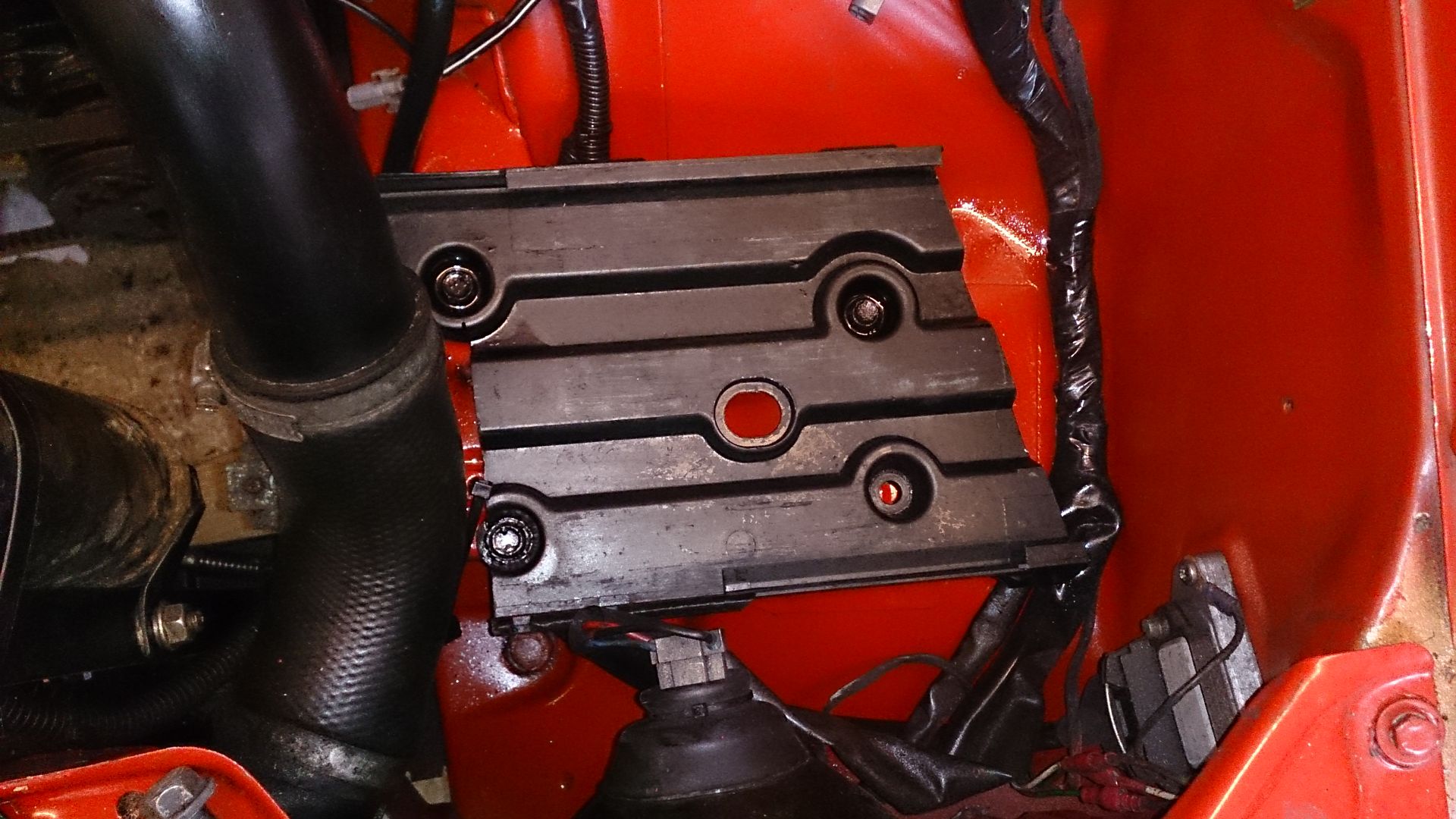

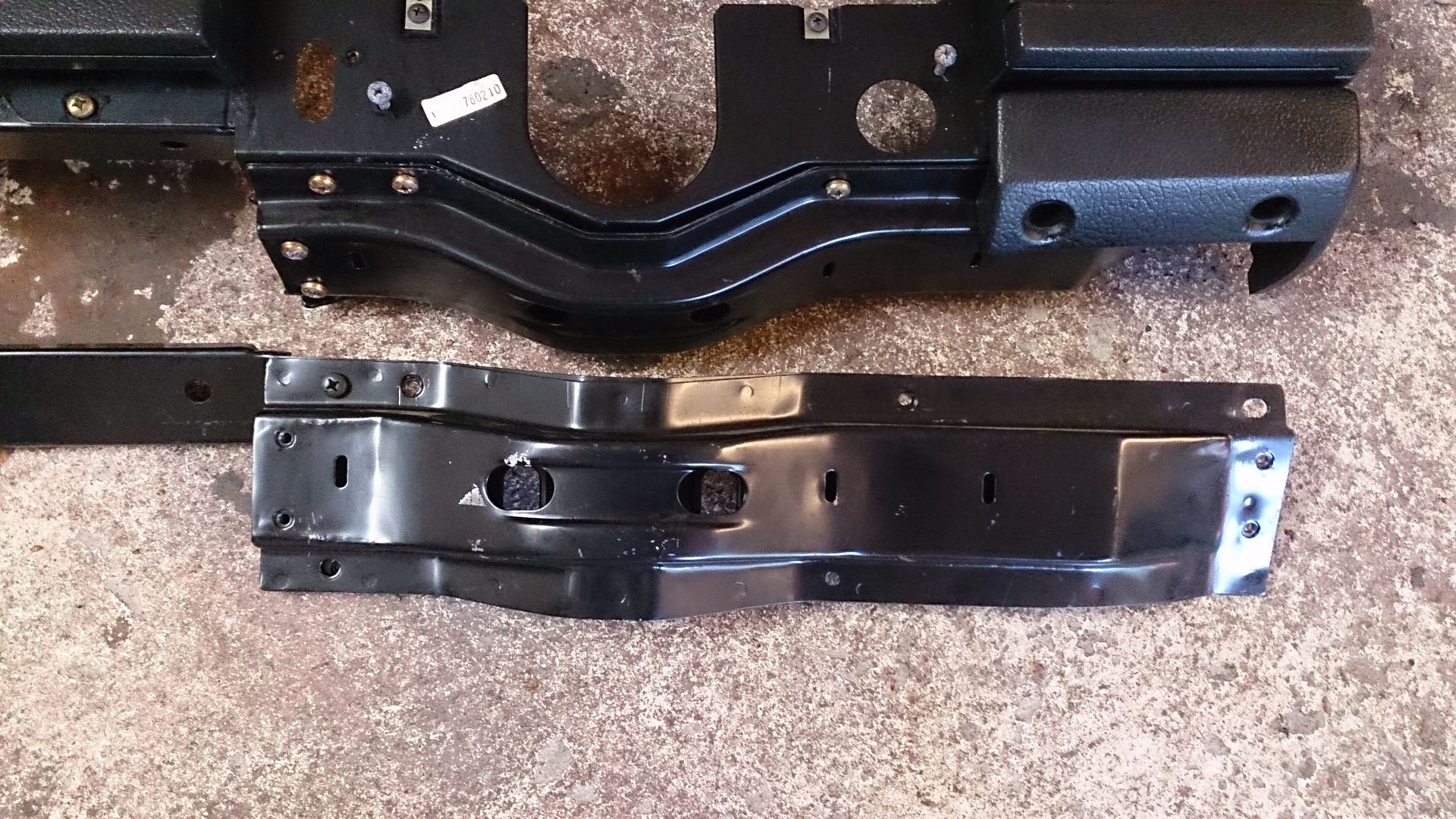

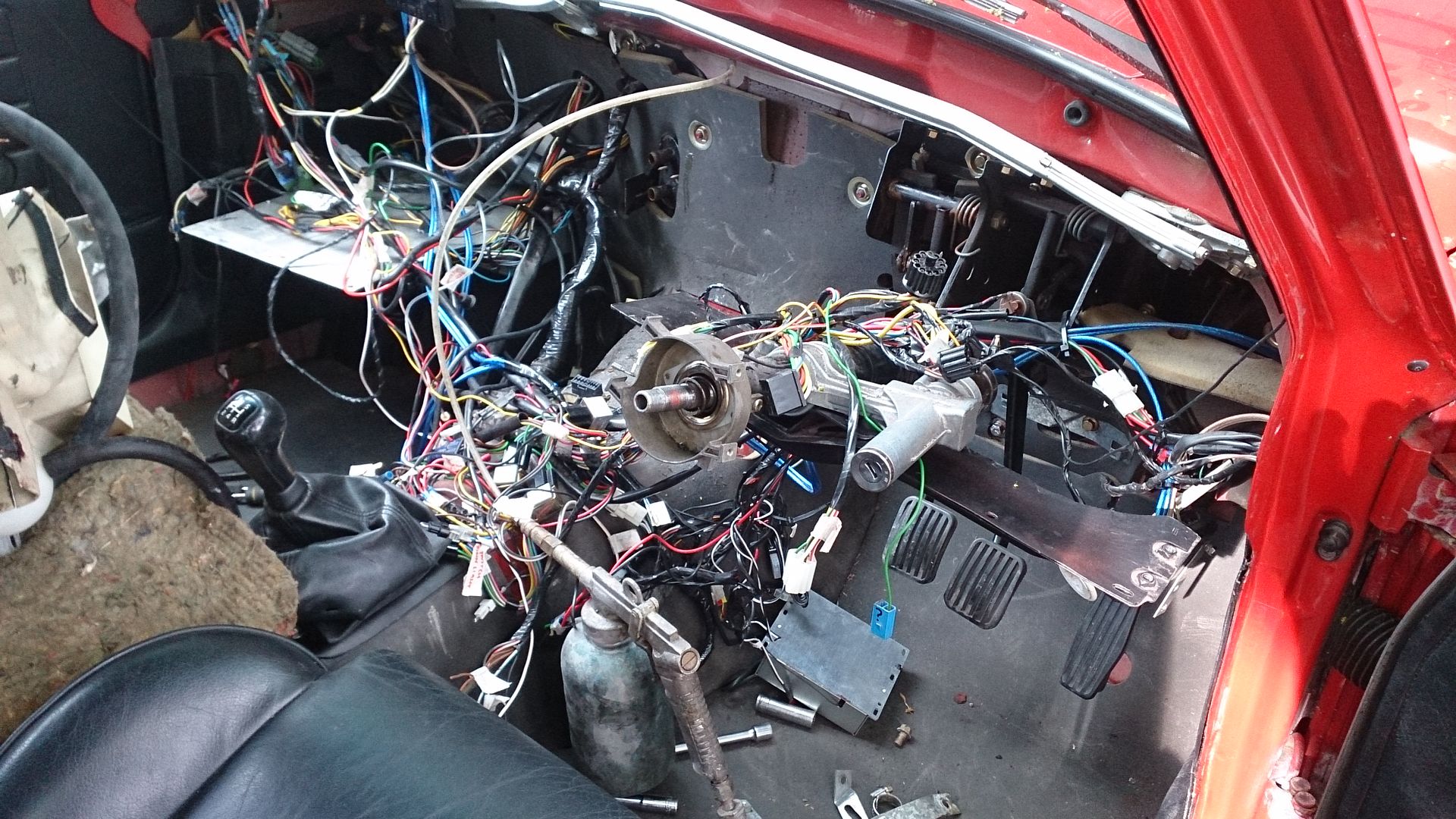

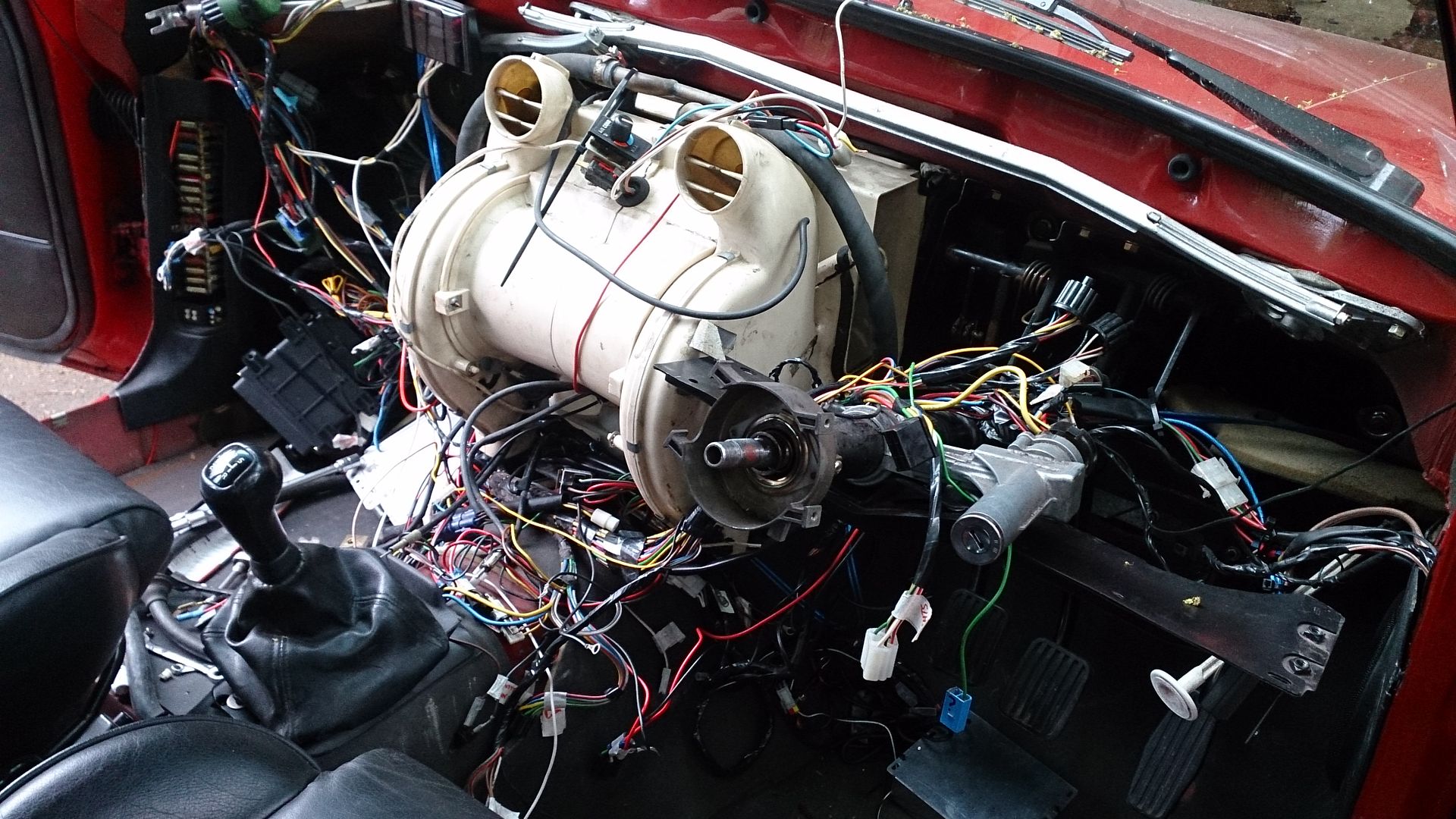

Some more detail as promised... Ste removing the original dashboard and heater     Part of the 'dashboard spares department' brought down from the workshop attic!   I decided the 265 dashboard was the best candidate. The padded section is perfect condition, and it has the advantage of being an OE air-con dash, so it has the right brackets etc. Cleaning it to carefully check condition  The metal section had a few small rust marks, so I removed and restored it    Lots of early vs late dashboard parts are similar but not the same. For example, the steering column-to-dashboard mounting.... the bolt spacing for the steering lock is about 8mm wider on the later 240. I wanted to keep the later ignition lock, to avoid mismatched keys. Luckily, we were able to use the later lower panel with the early dashboard - it just needed some captive nuts ground off and different mounting holes drilled  I am modifying my AC heater box to make the later fan motor fit - I needed to shave down the fan mounting area to give room for the new motor, which unlike the original mounts via a flange sandwiched between the two halves of the heater box.  Our trial fit - to test the swap would work, but mainly for motivation!    I have booked some time off work this week, so more tomorrow! Cheers John |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

May 19, 2014 12:02:16 GMT

|

|

That 164 looks absolutely stunning in that superb colour!

|

| |

|

|

johnrh

Part of things

Posts: 958

|

|

May 19, 2014 20:53:22 GMT

|

That 164 looks absolutely stunning in that superb colour! Thanks! Green-blue is my favourite of the Volvo 100 series colours, by a long way. John |

| |

|

|

johnrh

Part of things

Posts: 958

|

|

May 19, 2014 20:53:43 GMT

|

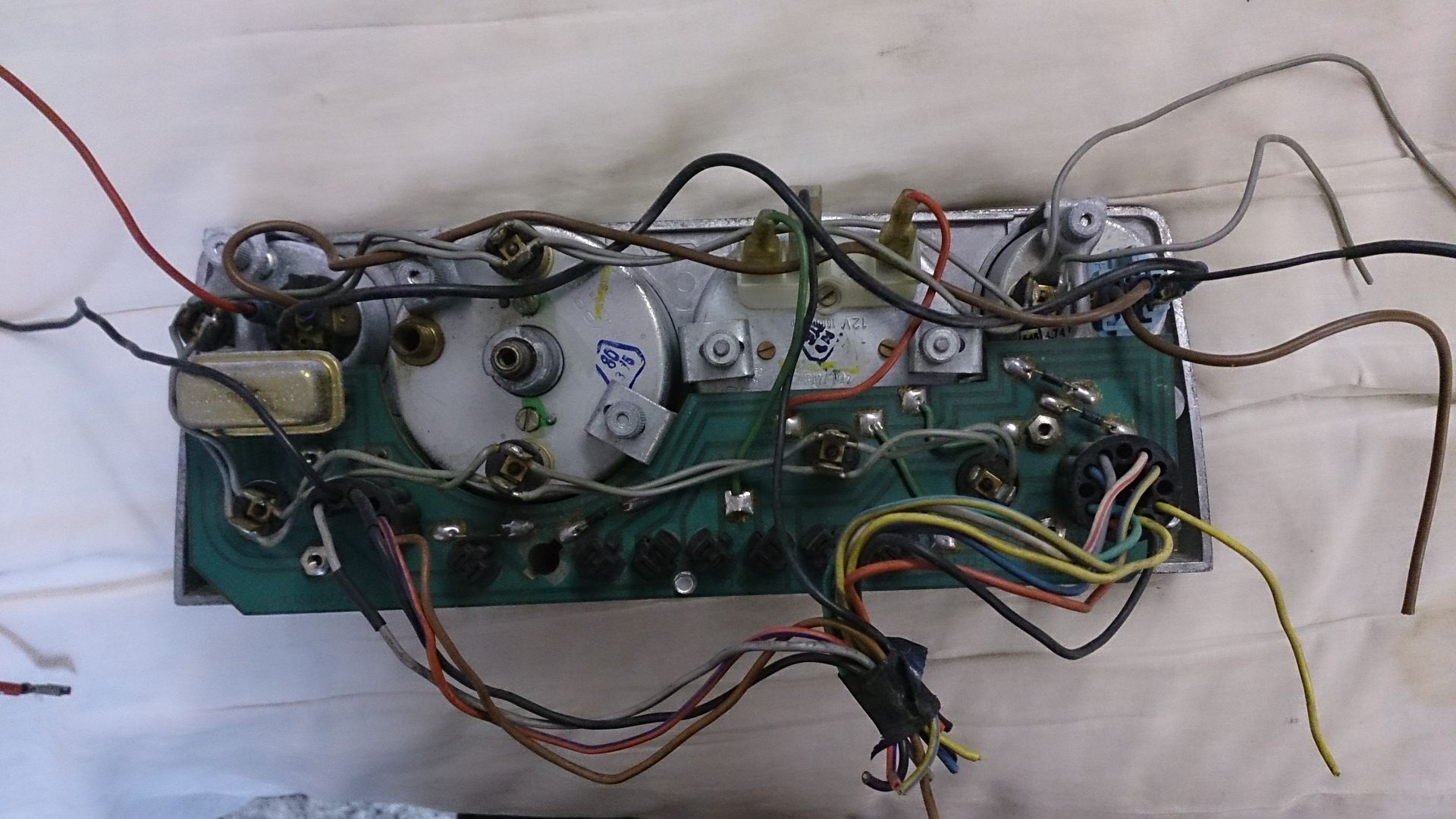

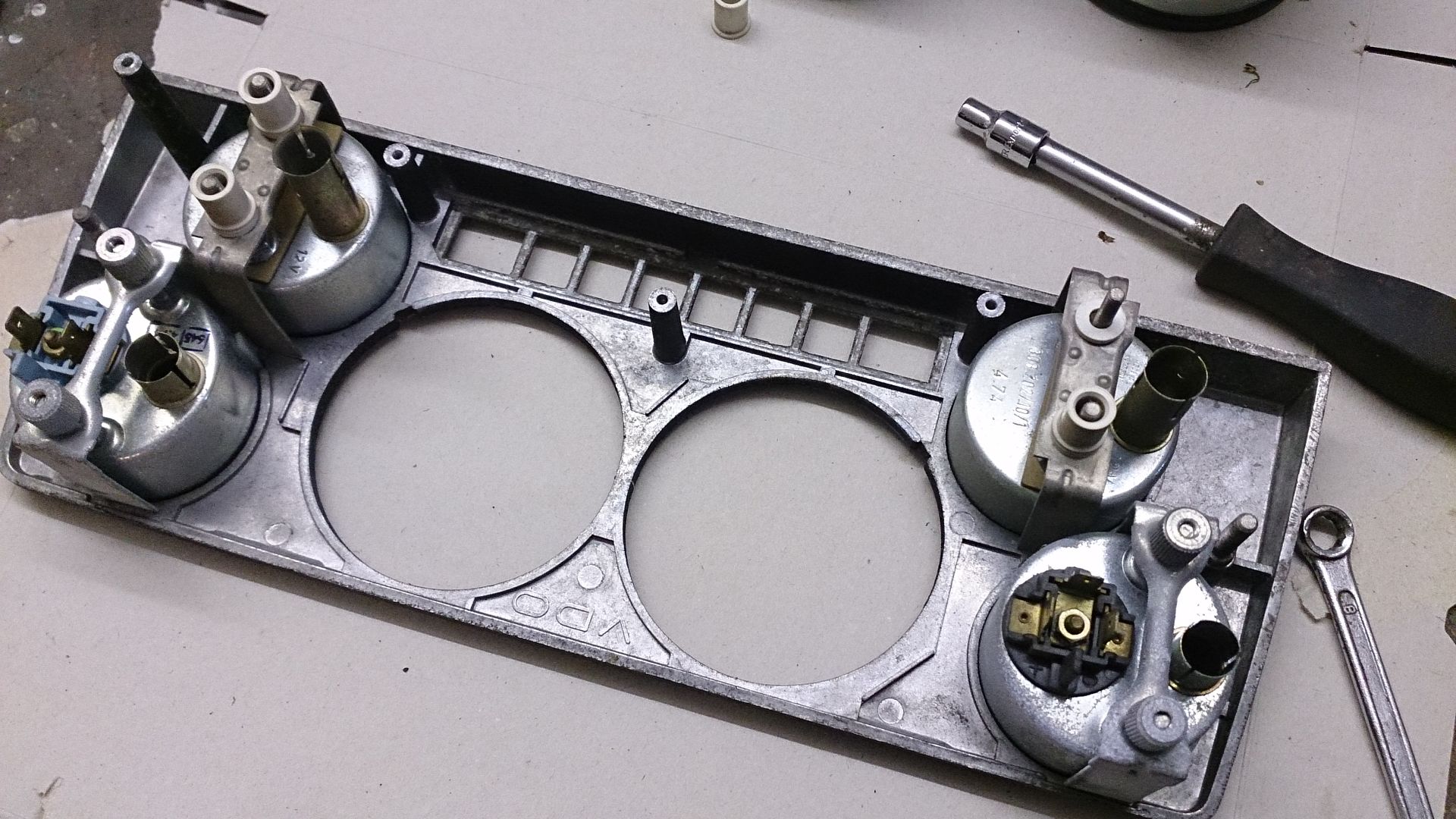

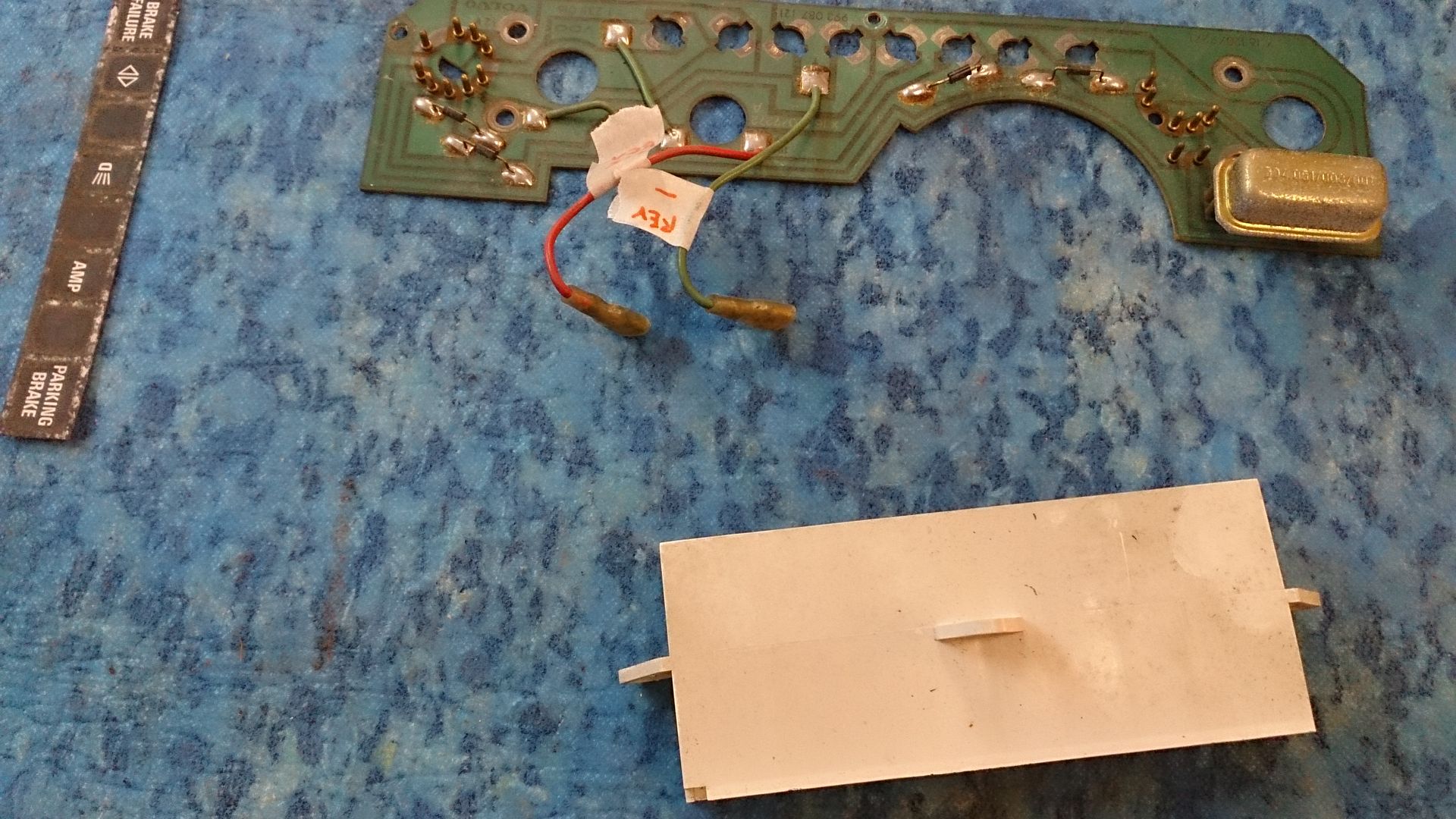

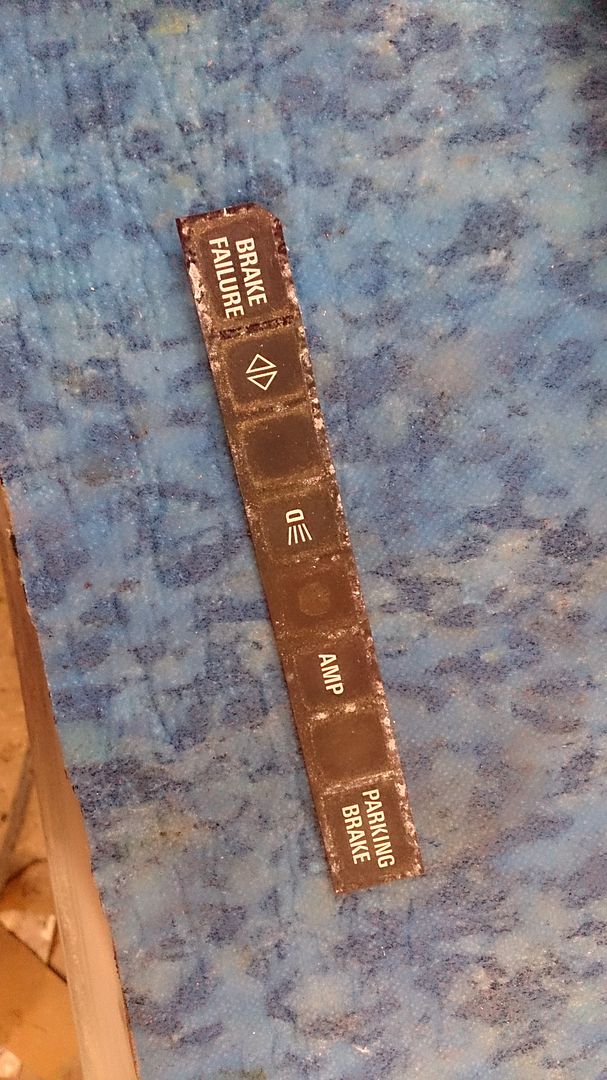

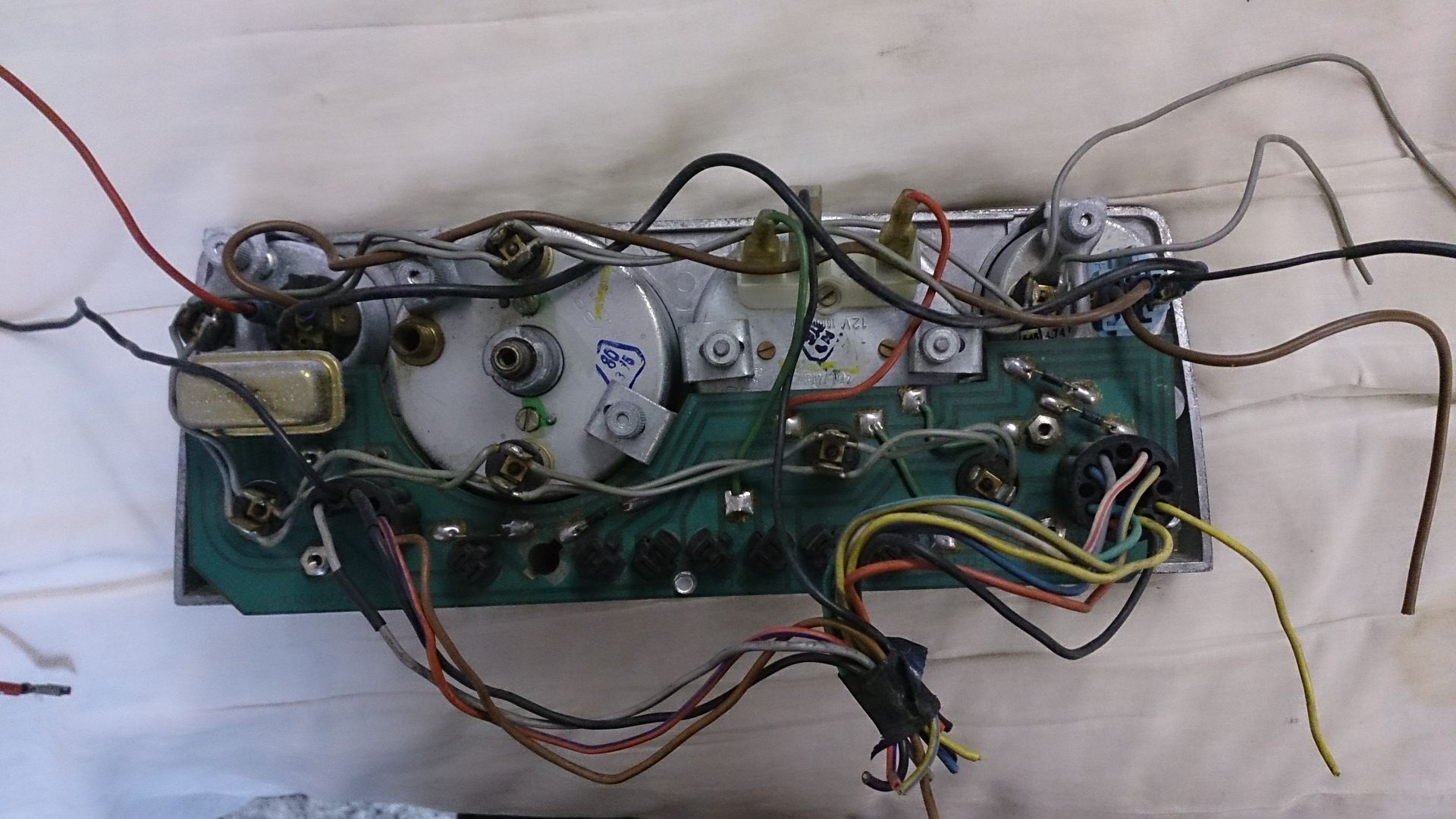

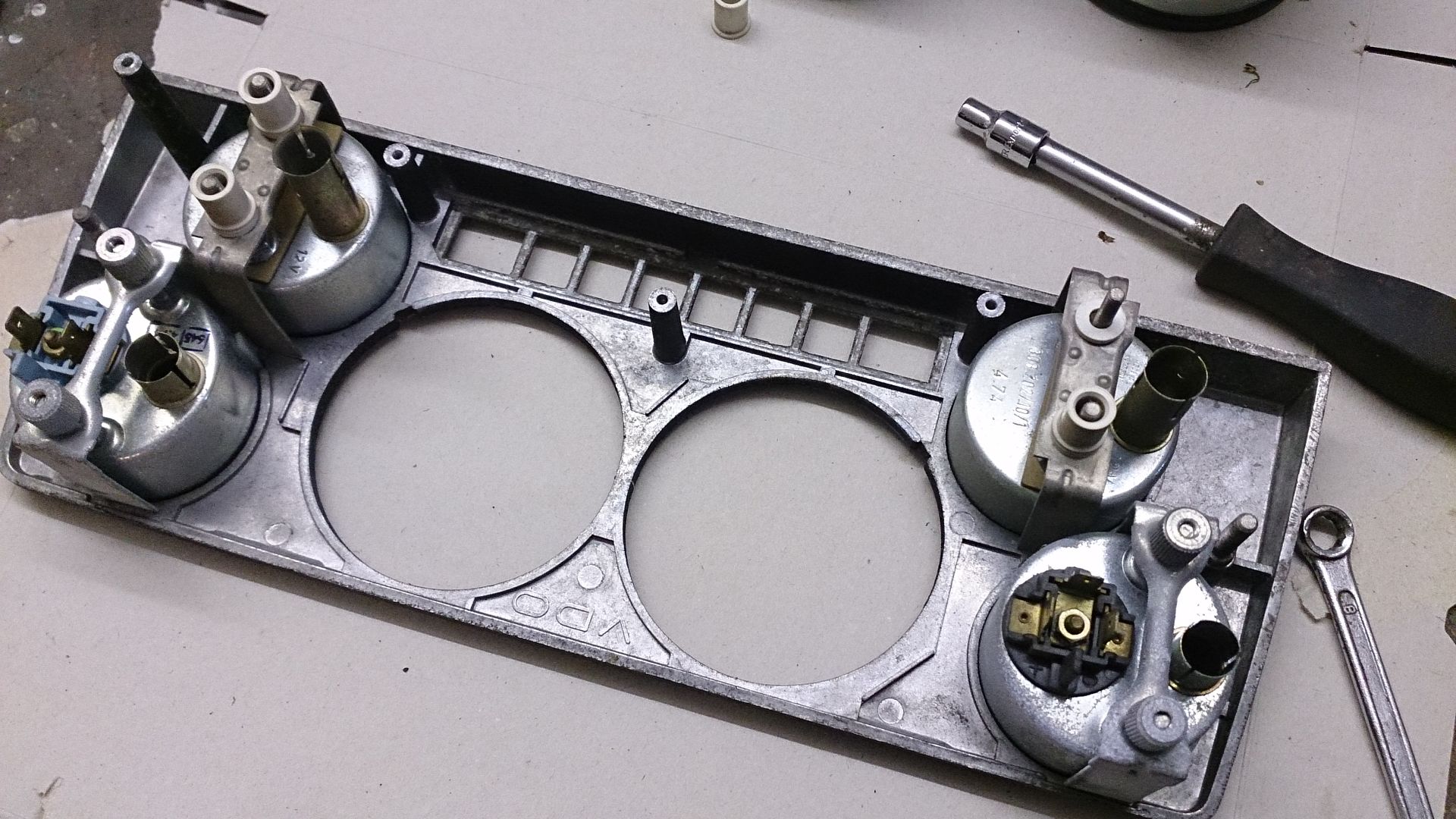

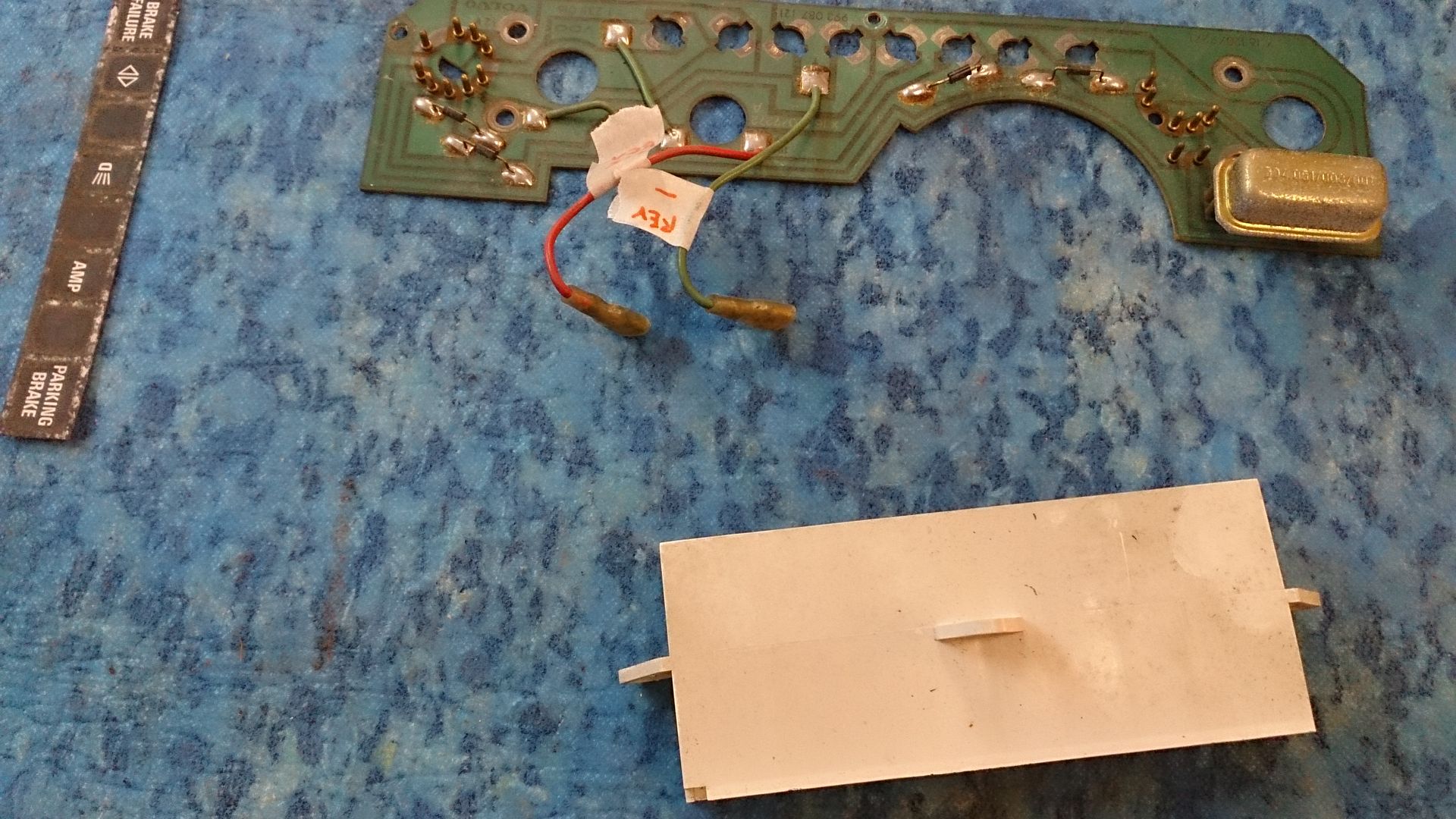

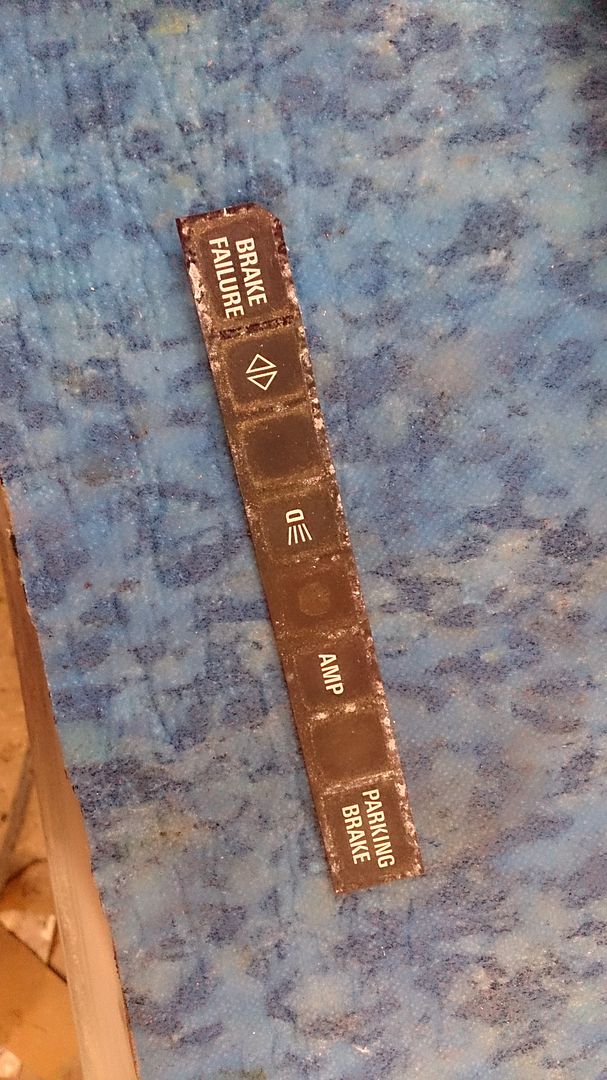

First job today was to refurbish the tired looking R-sport cluster. In the end this took a lot of the day because it's fiddly work. I took reference shots and made notes about the wiring, then removed it. It's simpler than it looks here, but I'll need to consult early and late wiring diagrams and adapt my later car to power this early cluster.  Dismantling the cluster     There is some dust inside the gauges, so my original plan was to dismantles them for cleaning. I did the rev-counter first. It's a difficult job because the glass is held on by the crimped metal surround. This has to be prised out all around the gauge to allow it to come off and release the glass. There might be special tools for this, but I don't have them! I found it nerve-wracking, because there is a high risk of bending the surround (any damage would be visible with the gauges fitted) and/or breaking the glass, which is a special non-reflective type.  For the rest of the gauges, I decided living with some dust inside was better than risking damage, so I carefully dealt with rust on the surrounds with the gauges complete.  Most needed to be stripped to bare metal  I masked the glass then primed with red oxide (no photo) followed by satin black  The warning light strip is plastic which goes very brittle over time. Mine is cracked, but better than some I have seen. A guy on turbobricks, who restores these clusters professionally, makes replacement warning light strips. I will get one from him when I have decided which warning lights I need him to include. For now, I cleaned up and repaired my strip, and taped in an ABS script (donated by the 940 cluster) instead of the EGR warning lamp   The mounting panel was in better condition than the gauge surrounds. As originally made, it has a lumpy crackle finish. Any sanding required would mean losing that finish, but luckily the only corrosion on mine was on a non-visible part. I was able to touch in a few chips, then prime and paint it - keeping the original finish.   99% reassembled (just the black bottom for the trip meter still to refit)    Later, I started to rebuild the AC heater box. Because of the different, later, fan motor I have used, one of the end pieces needed trial and error modification to avoid the fan rubbing (no photos), but the rest is going OK so far.   That's all for now... more tomorrow! John |

| |

Last Edit: May 19, 2014 20:55:28 GMT by johnrh

|

|

johnrh

Part of things

Posts: 958

|

|

May 20, 2014 21:38:26 GMT

|

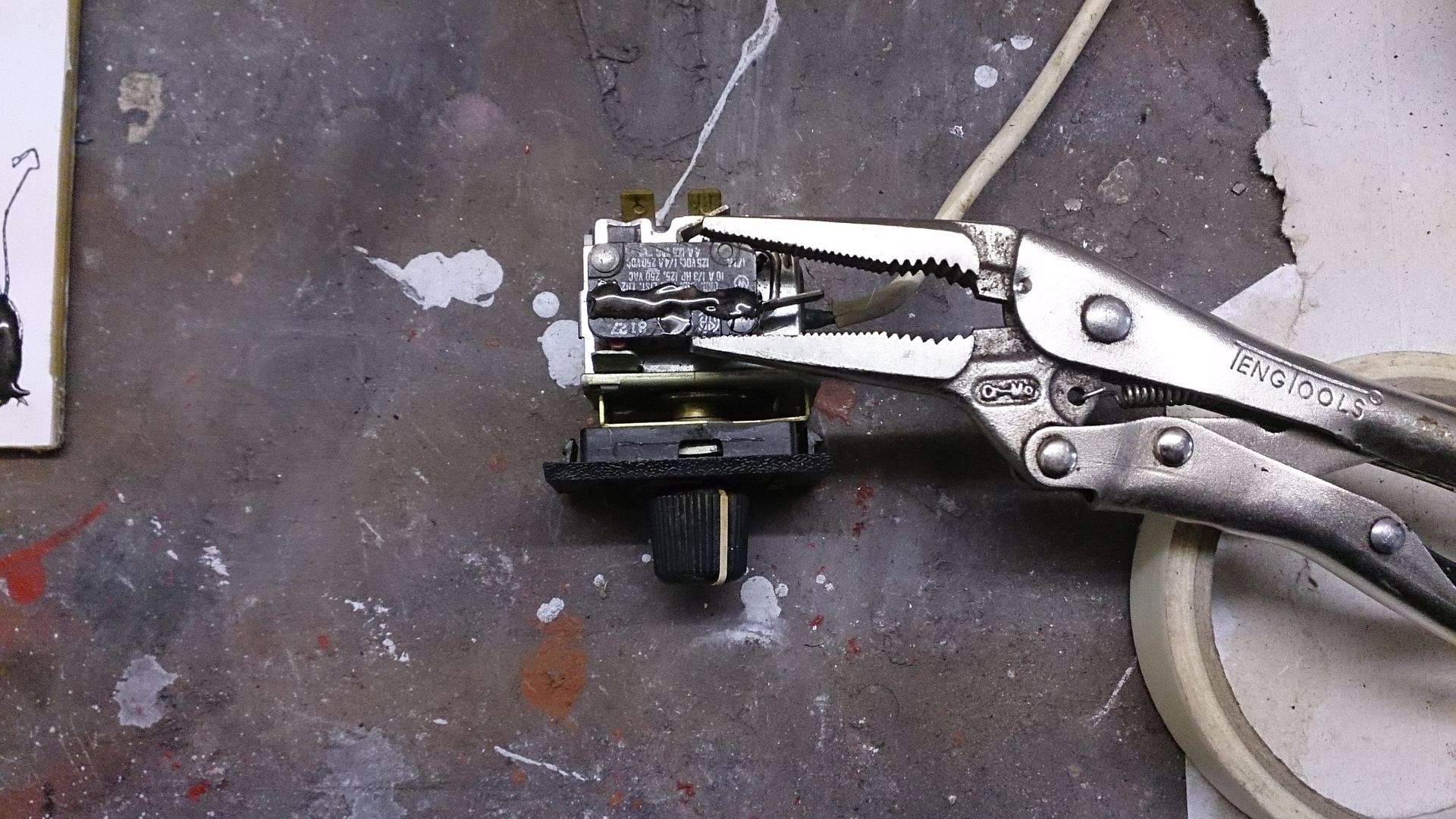

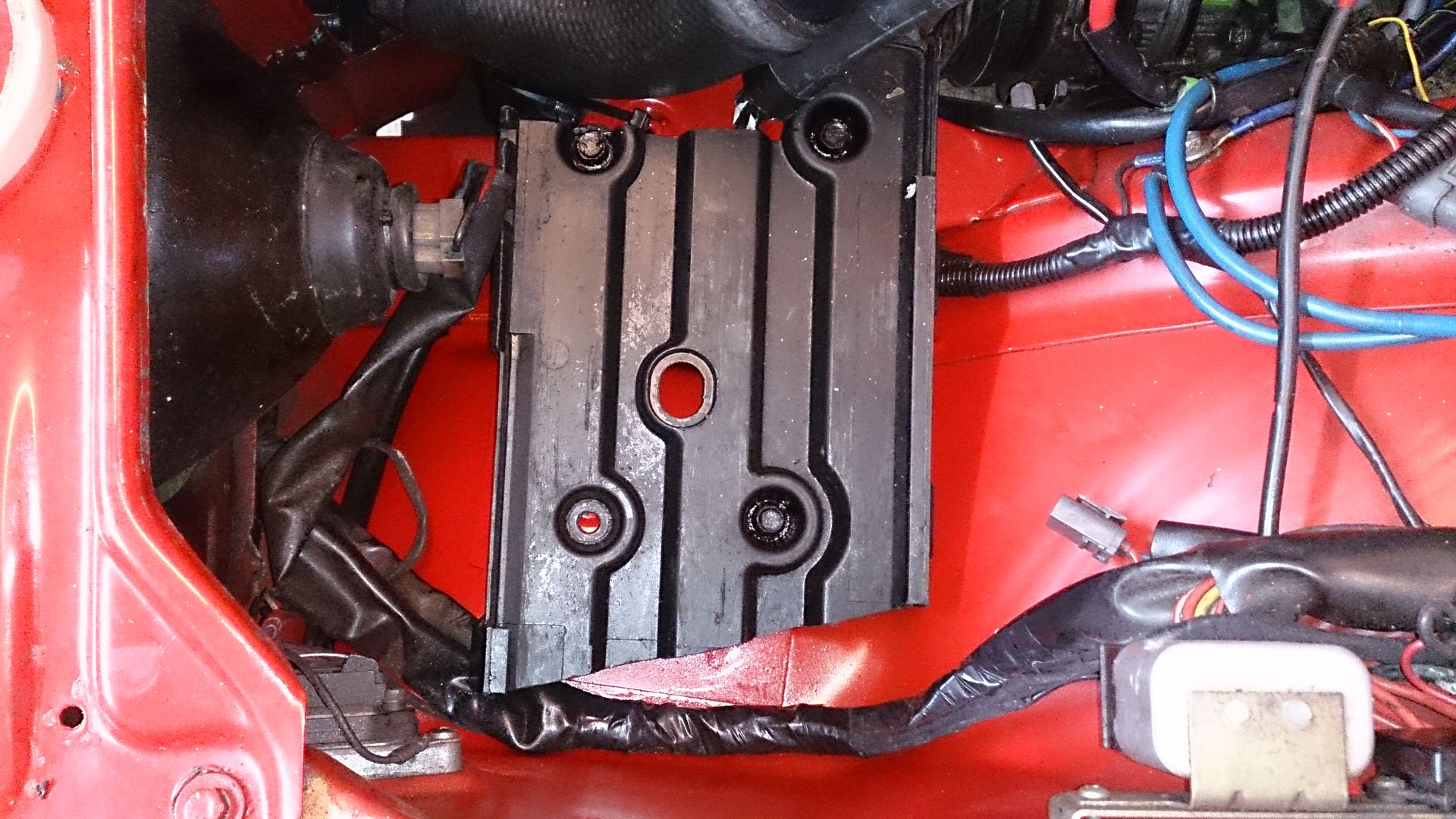

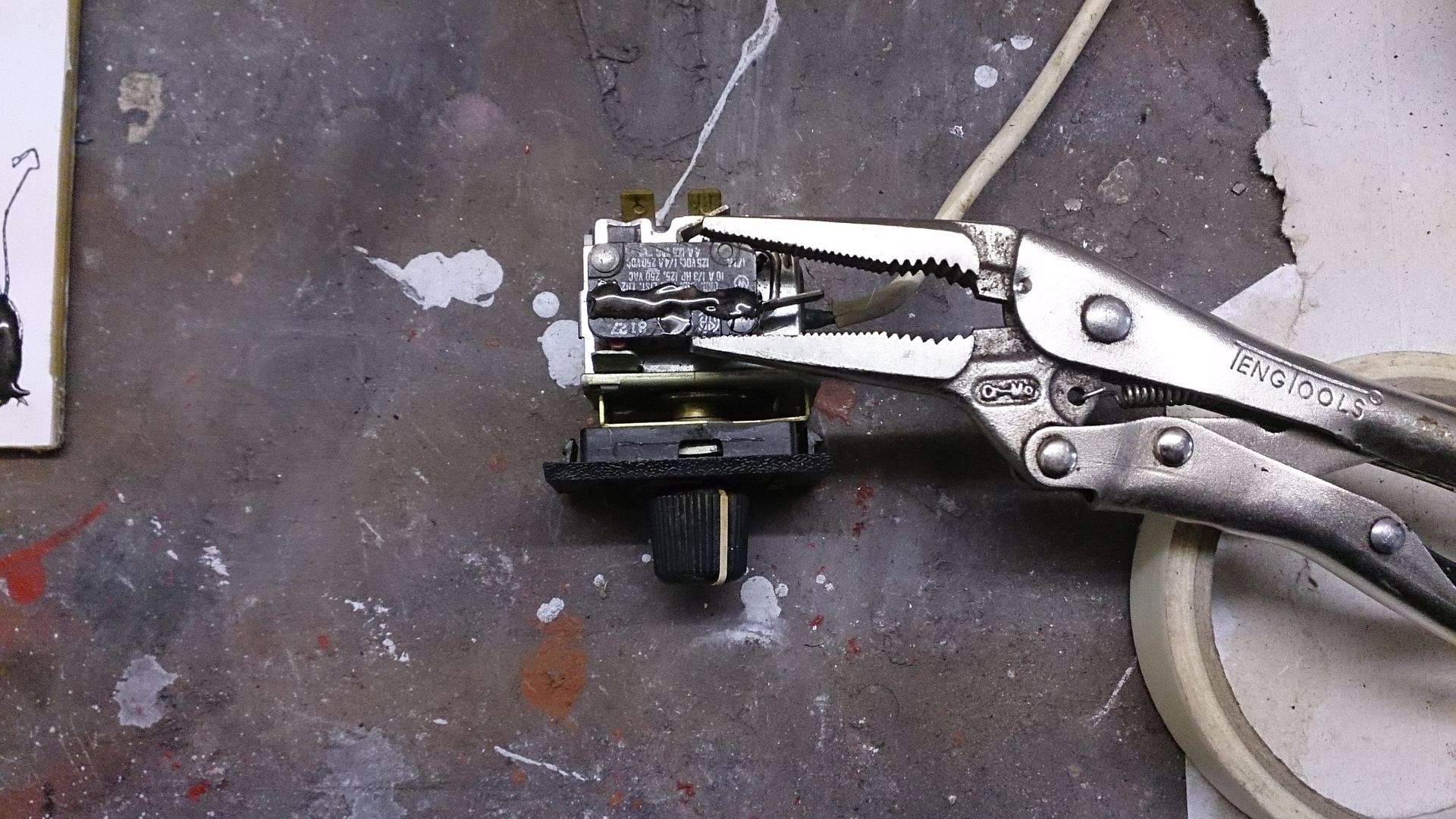

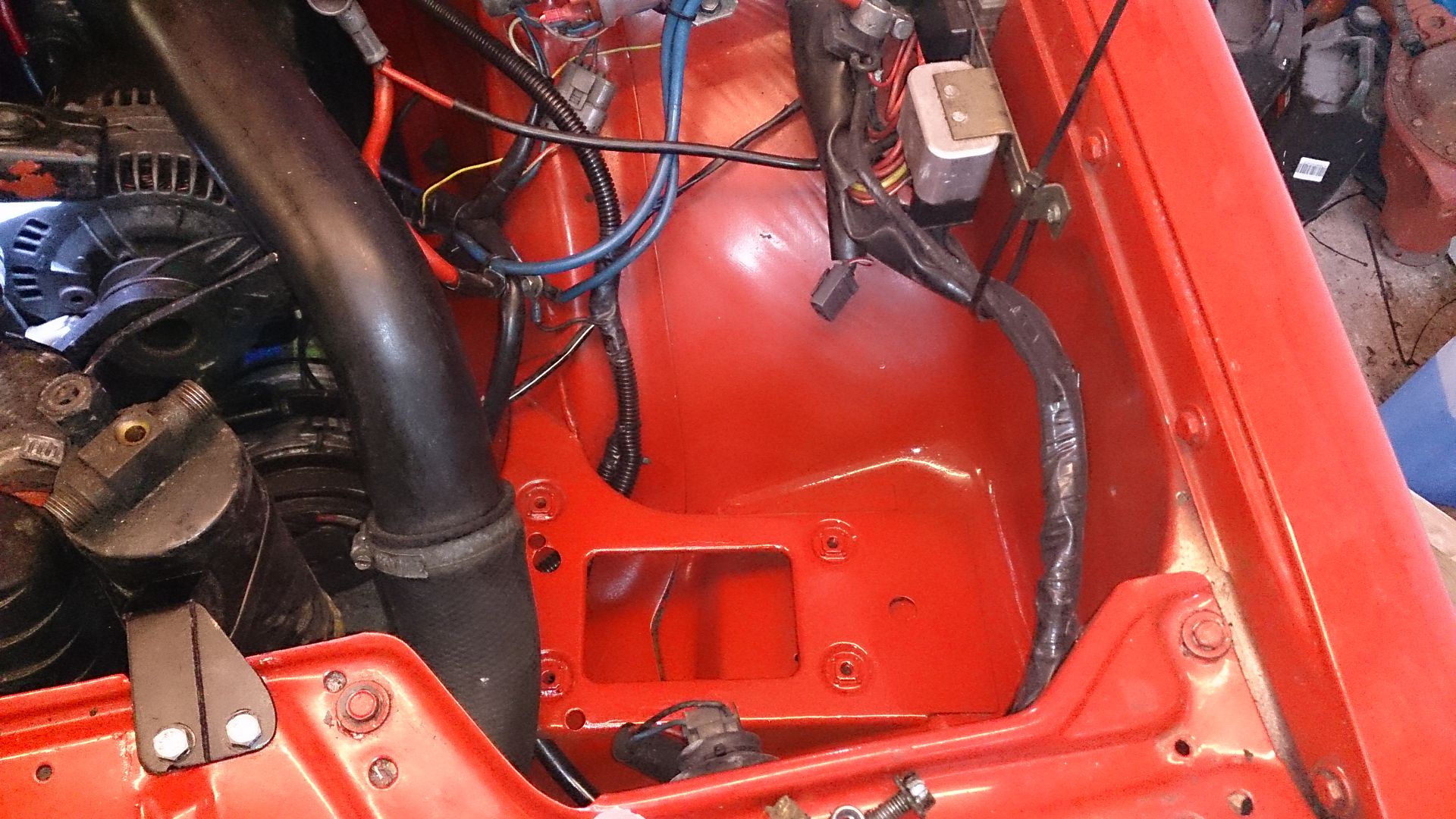

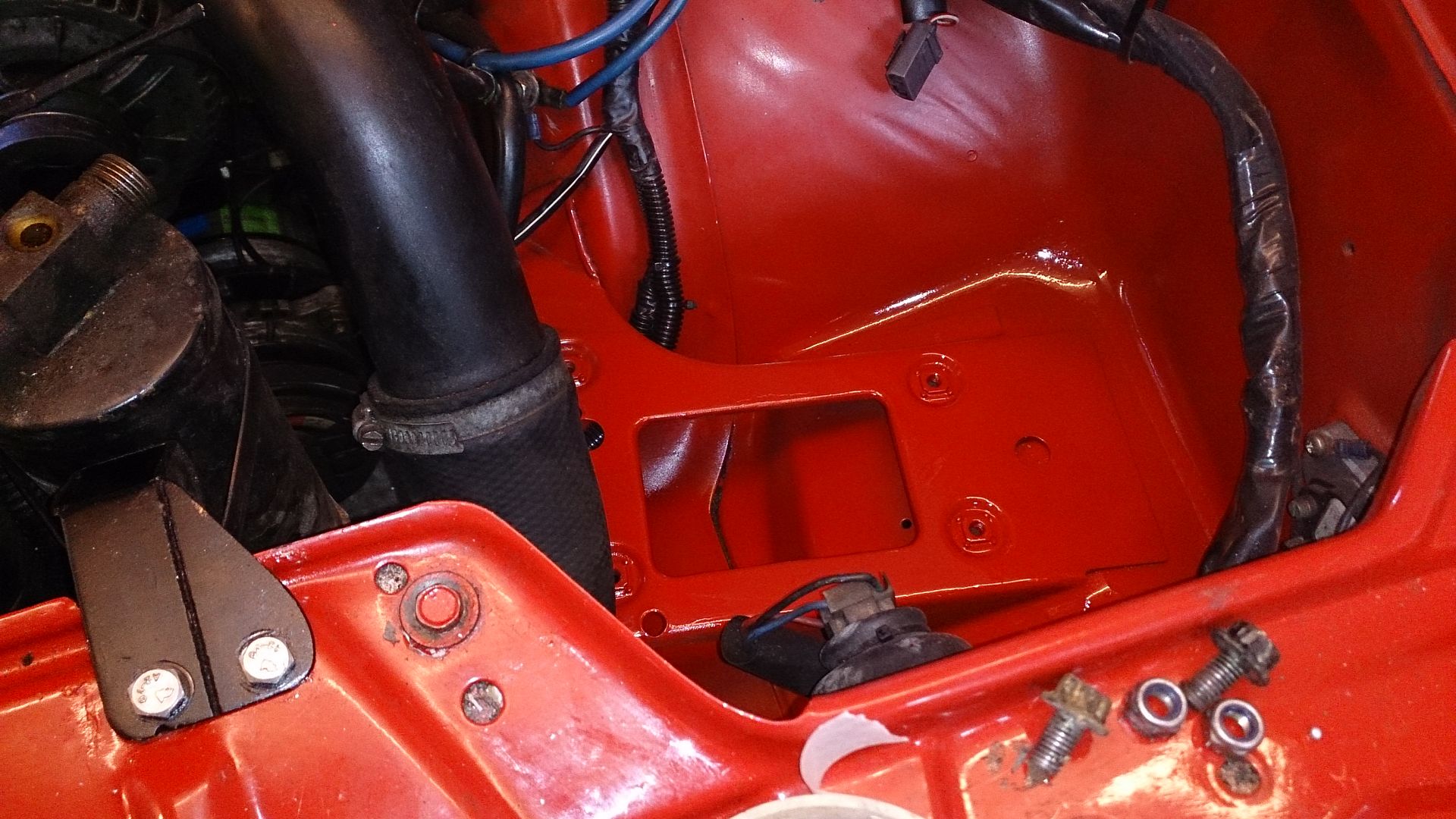

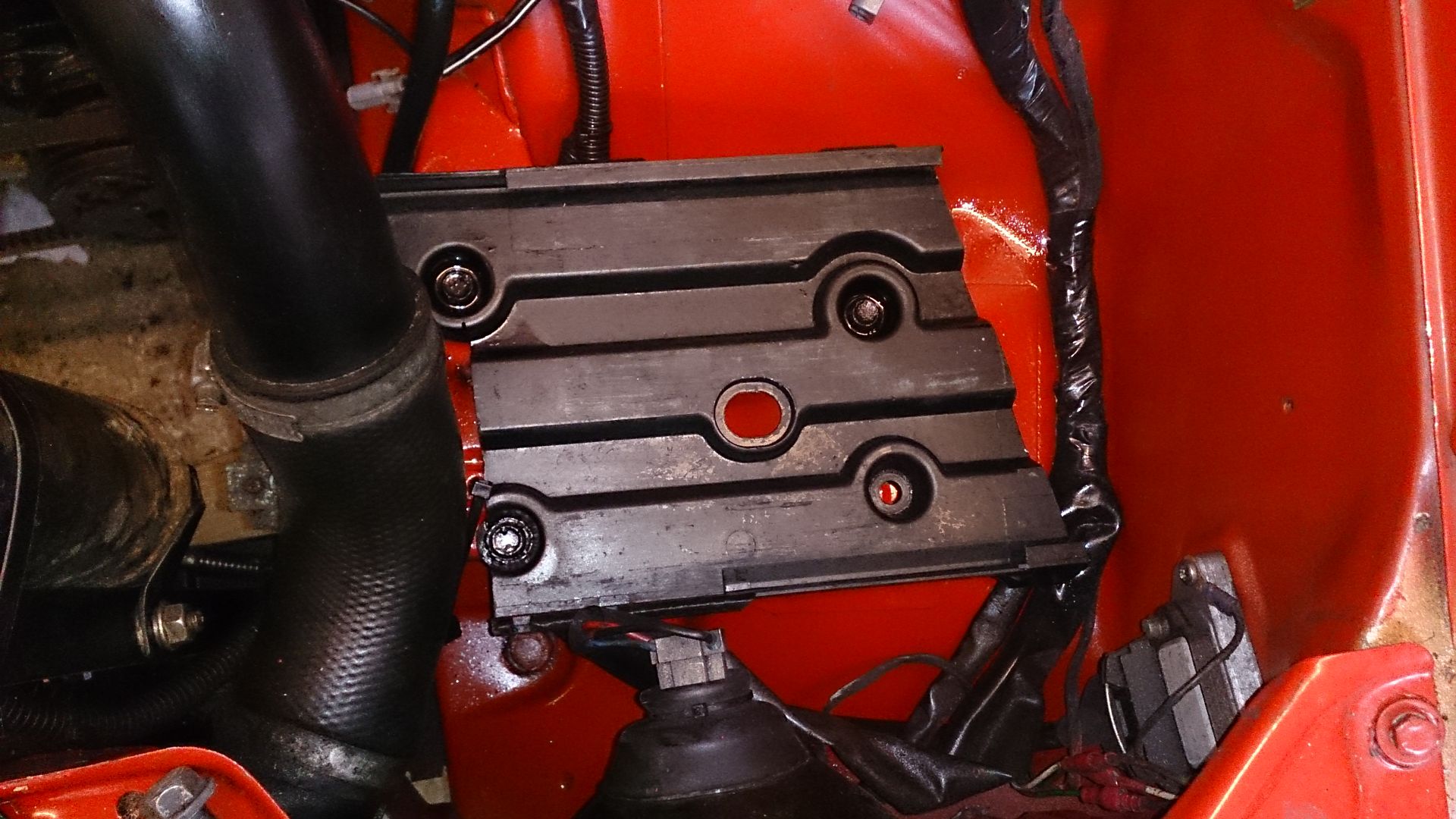

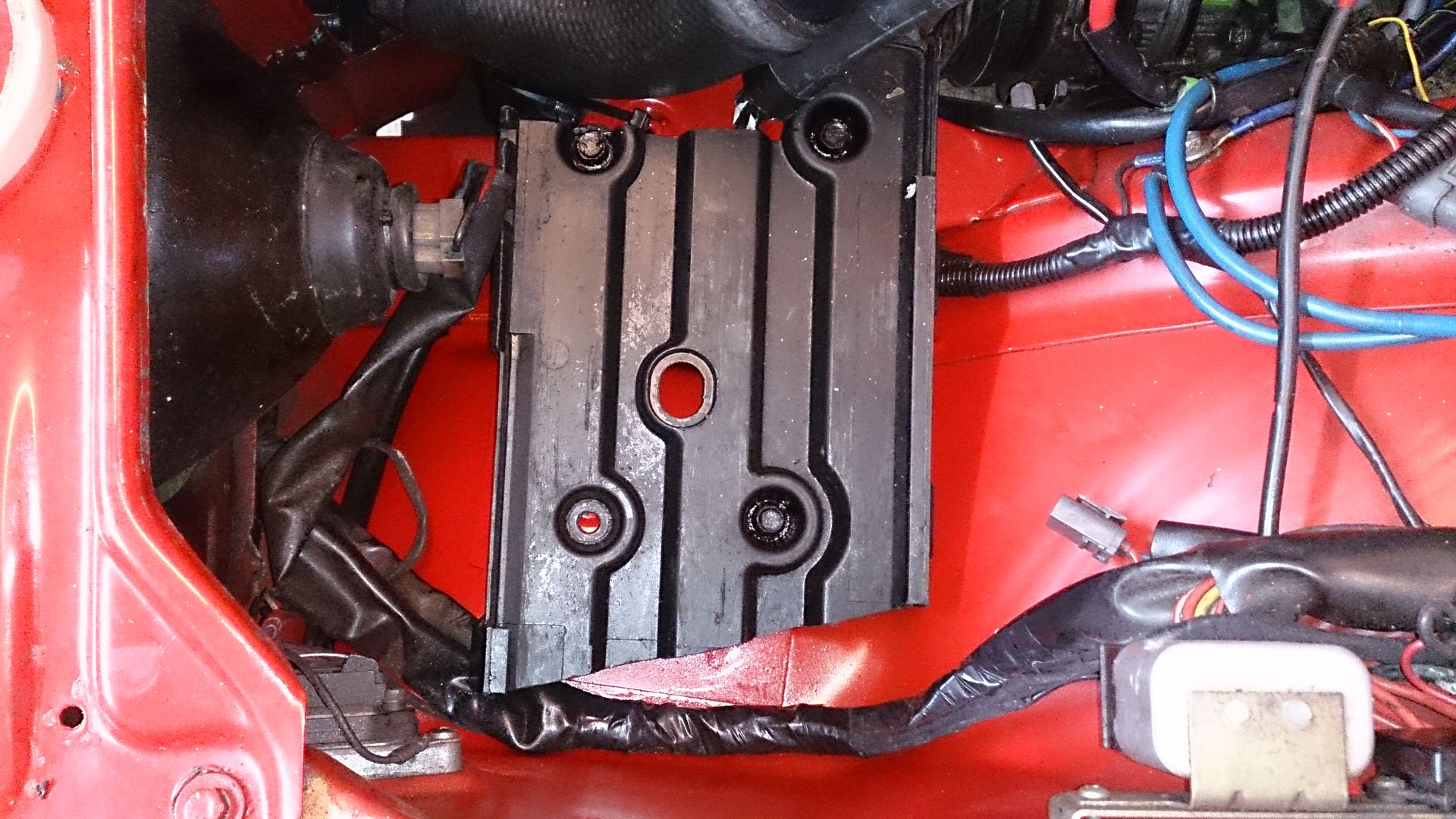

A slightly annoying setback today, which wasted some time, but nothing serious and I'm back on the right track now. I had the choice of two AC heater boxes, a 1982 242 from America, and a UK market 1978 265, which I bought from Max. I was planning to use the 242 box because I had done the work to fit the new motor into it. However, it was mostly reassembled today when I realised LHD and RHD boxes are different. The LHD box has the AC pipe connections on the right. On the RHD version, the AC evaporator fits the other way up, putting the pipes at the left.  It would be fairly simple to adapt the LHD box for RHD, so I'll keep it for future use, but for this installation I decided it would be quicker to install the 265 unit. I pressure tested the 265 matrix - fine - and I decided to take a chance on the evaporator. (I could swap in the 242 one without removing the heater box, if necessary). Another strange difference bewteen the '78 and '82 systems. Look at the fan speeds. The 265 has 0-1-2-3 whereas the 242 has 1-2-3-4, with no 'off' position.  I wired up the 265 fan to test it (thankfully it's quiet and smooth) and both switches do the same thing when connected up, i.e. nothing at the left position, then three increasing speeds of fan operation as the switch is turned clockwise. I modified the 265 box slightly to convert from a simple on/off AC system to the variable control from the '82 system. First I had to repair the variable switch, which was cracked.  Fitting the capilary to the AC pipe. The sealant and dum-dum makes this a messy job! I left the 265's on/off controller in situ on the heater box, so if my variable switch is faulty, I can just swap the wires onto it, with no dismantling needed.  While I had access inside the scuttle panel, I rustproofed it.  Time to fit the new heater box...  Next I need to run various pipes through the bulkhead, connect up the electrical and vacuum circuits, and make ducting that fits using a blend of '79 and '89 parts!  To close on something less ugly than that tangle of wires... I finished off the cluster. Instead of the original (scruffy) felt washer to stop the trip meter shaft rattling on the glass, I used a small spring which looks neater.  More tomorrow! John |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Good going!

|

| |

|

|

aws

Part of things

Just smile and wave boys. Just smile and wave.

Just smile and wave boys. Just smile and wave.

Posts: 389

|

|

|

|

|

Those dials looks realy realy good. Great fidly job there.

|

| |

|

|

eternaloptimist

Posted a lot

Too many projects, not enough time or space...

Too many projects, not enough time or space...

Posts: 2,578

|

|

|

|

|

Brilliant build John.

|

| |

XC70, VW split screen crew cab, Standard Ten

|

|

|

|

|

|

|

May 22, 2014 14:12:00 GMT

|

|

Great work as always! This thread never fails to motivate me.

|

| |

'84 308 GTS /// '88 528e /// '88 M5 /// '89 944 Turbo /// '98 E430

|

|

johnrh

Part of things

Posts: 958

|

|

|

|

|

Thanks for the kind words guys.... update to follow over the weekend.

|

| |

|

|

johnrh

Part of things

Posts: 958

|

|

|

|

Sorry for the delay, it's been a few weeks since I finished the dashboard project but I didn't get round to updating the thread. I am pleased with the result although there is some debugging to do. The speedometer worked fine initially but then a fault inside the instrument led to the needle sticking - I have not looked into that yet. There is an intermittent fault with some of the warning lights and instruments, I suspect that is a poor earth or a fault in the circuit board. The console gauges will look better when I have converted them to match the font and colours of the rally cluster, but that's not high priority and will be done later.      Had a really great time at the BKV (thanks to Mike for this photo). Since then the car has also been to the Thornes Park show in Wakefield, no photos - it was raining!  All for now Cheers John |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Are you using the cable x unit already?

|

| |

|

|

johnrh

Part of things

Posts: 958

|

|

|

|

Are you using the cable x unit already? |

| |

|

|

johnrh

Part of things

Posts: 958

|

|

|

|

Are you using the cable x unit already? Yes, it works, but I have a problem with the speedo head unit, so not tested properly yet John |

| |

|

|

johnrh

Part of things

Posts: 958

|

|

|

|

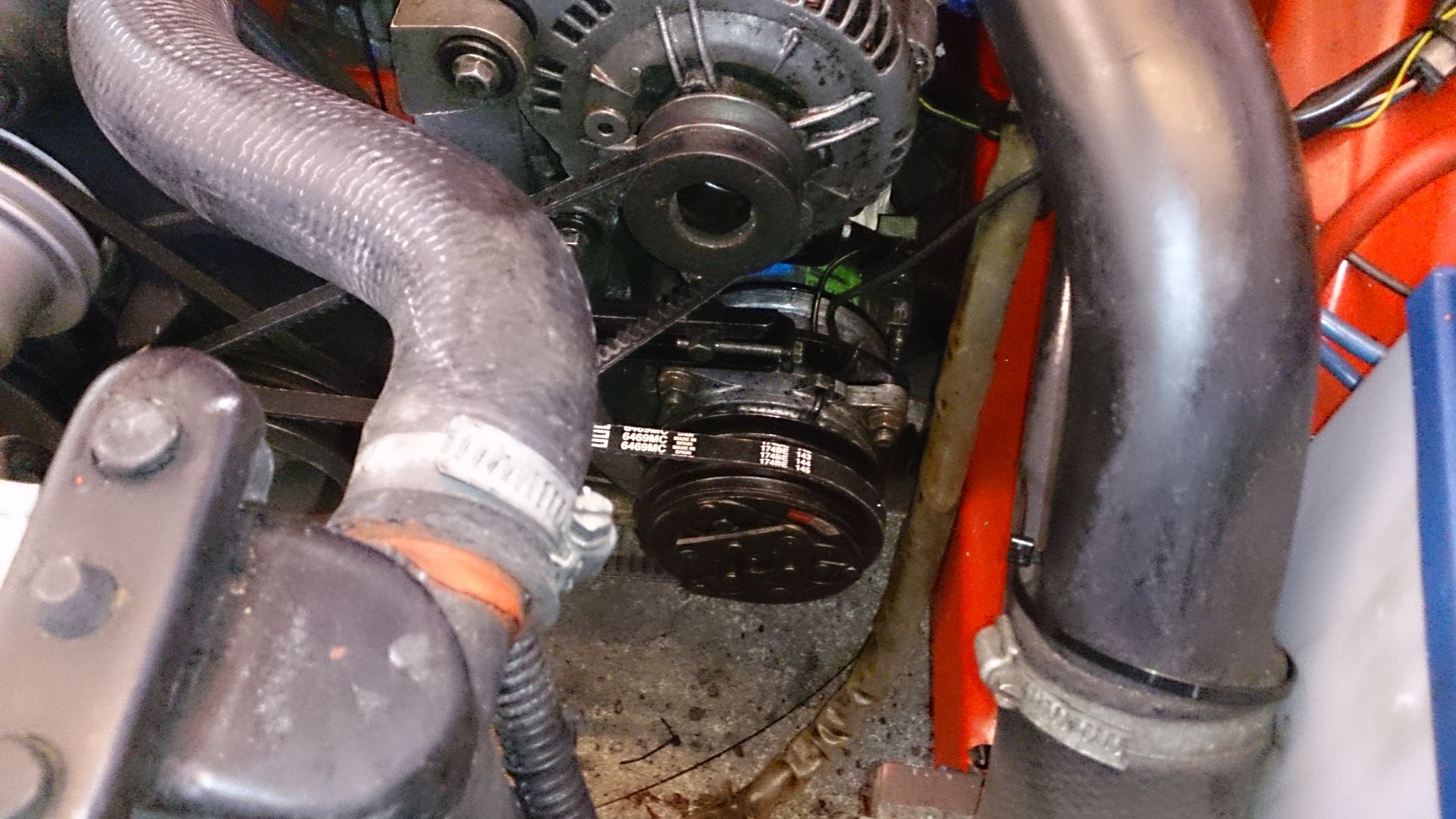

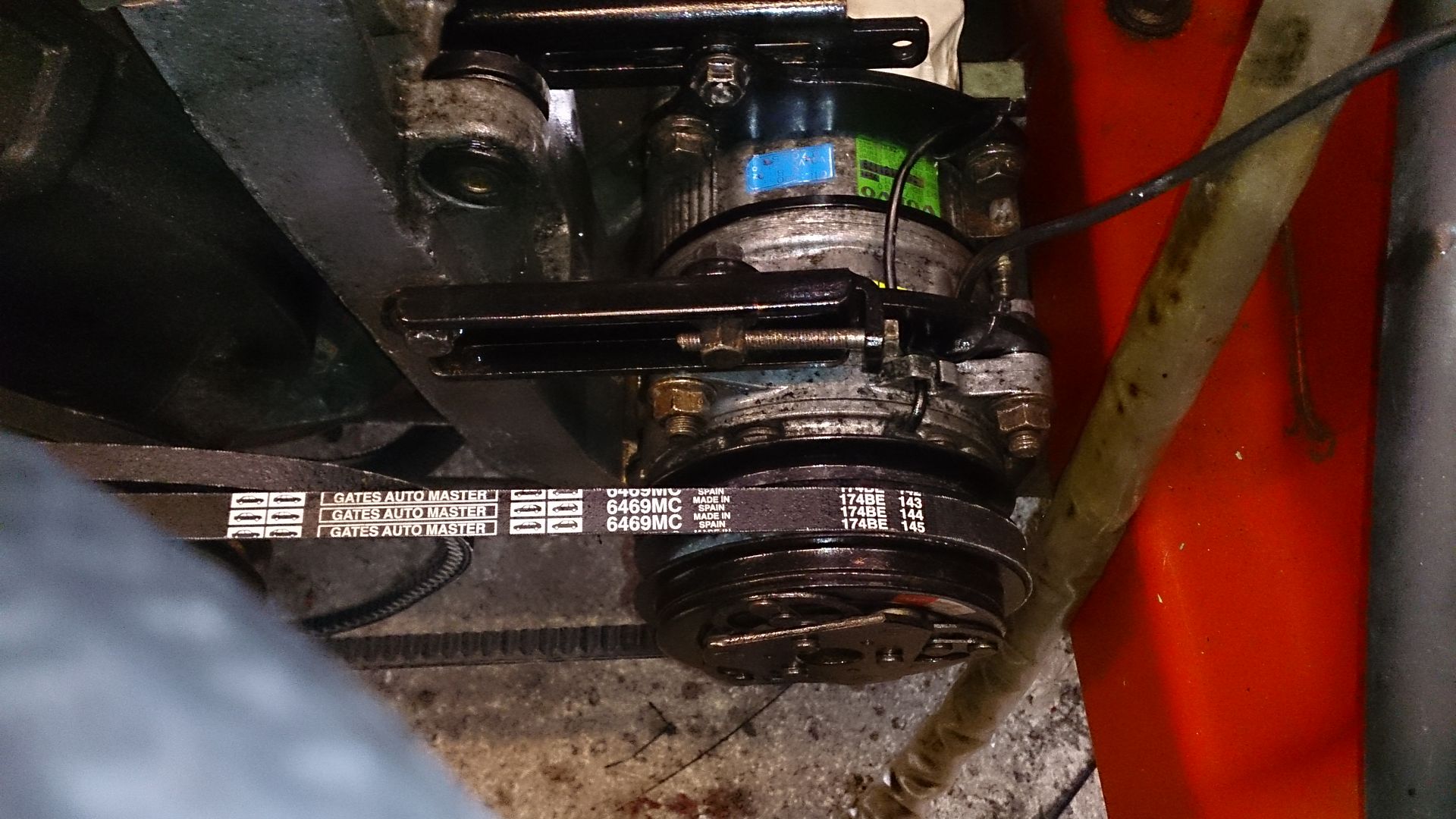

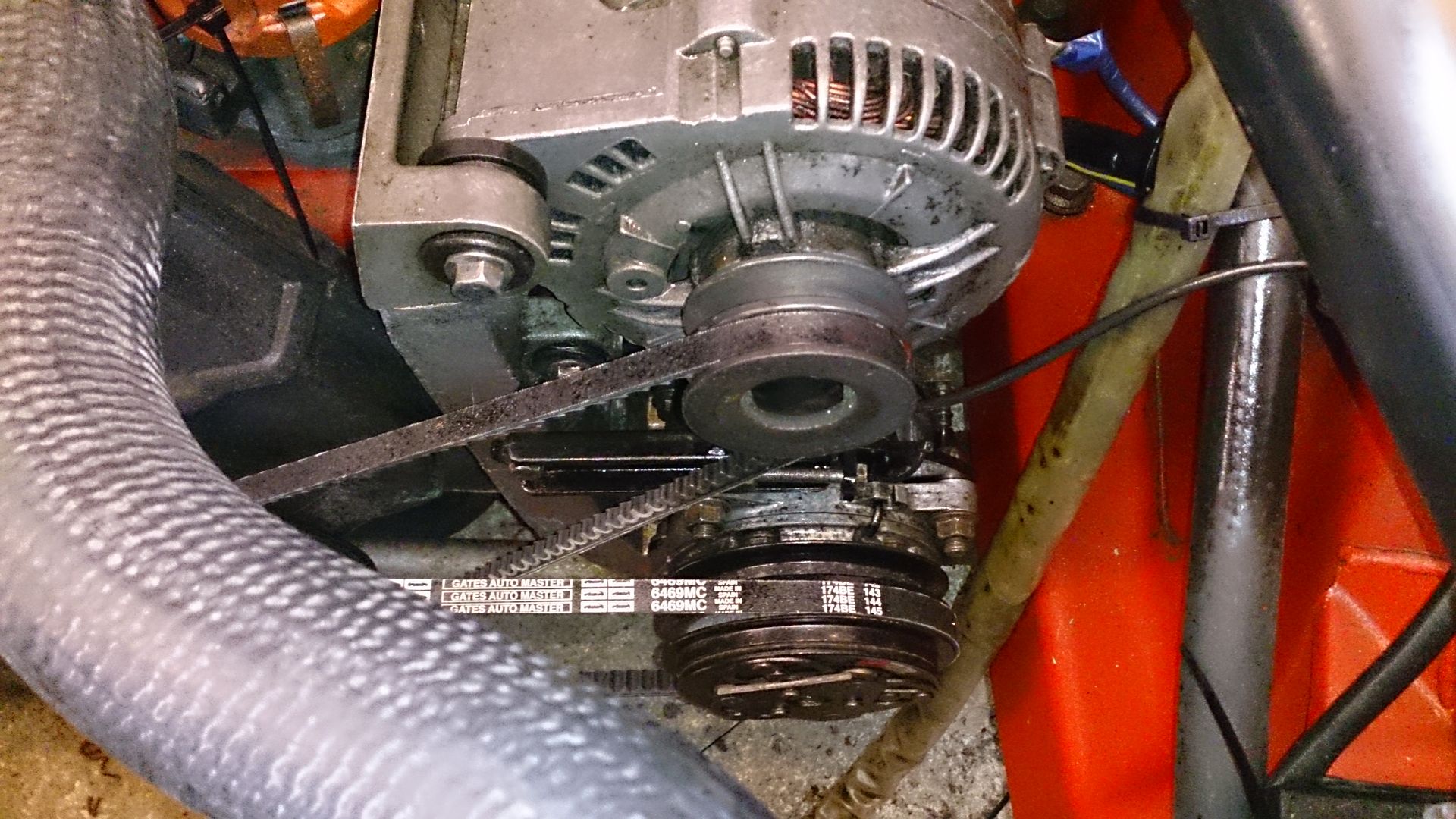

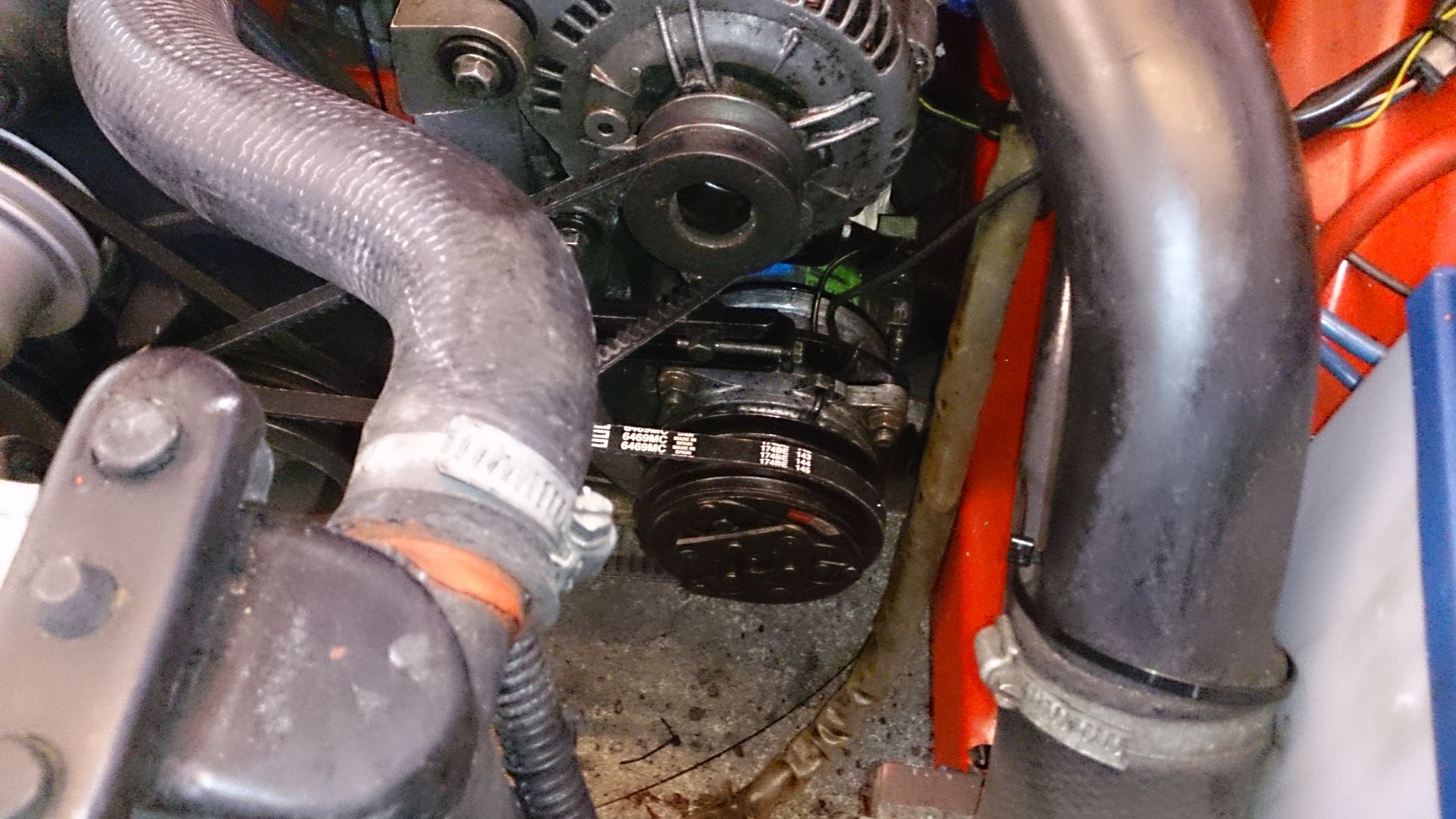

Hi, I am making some progress with the air-con installation CondensorIn the end I am using a 940 condsenor very kindly donated by Chesh. It's a new item with some minor damage - doesn't seem likely that it will leak but I'll get it tested of course. The weight is taken at the bottom on 3 supports, all rubber cushioned. In the centre I fitted a bracket to the bar which links toget the front panels. Either side, a small bracket was welded onto the crossmember to allow the original 940 supports, supplied with the condenser, to be used.  At the top, more rubber support with cable-tie fixings to link it to the intercooler.  Not much to be seen once the slam panel is refitted.

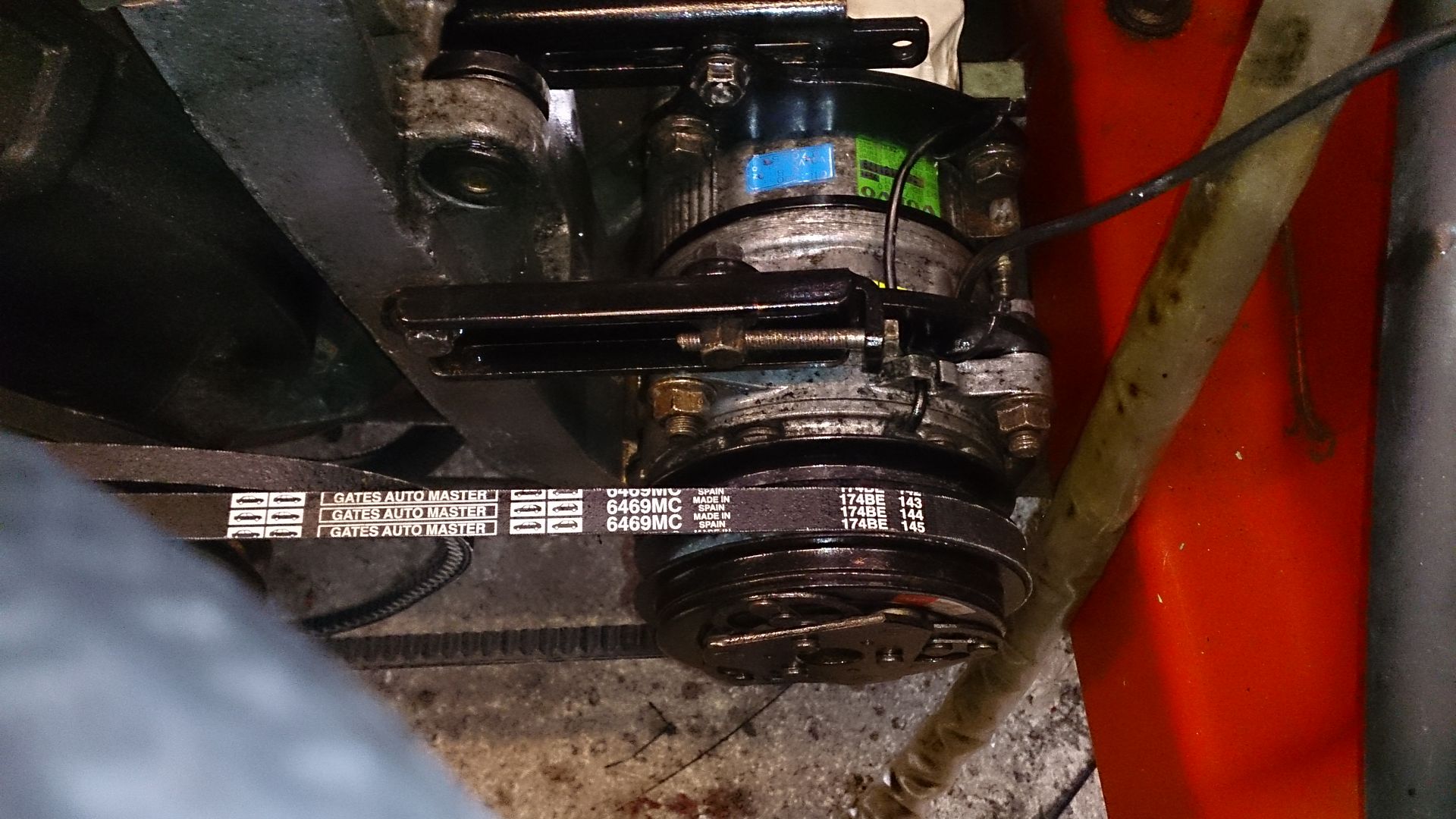

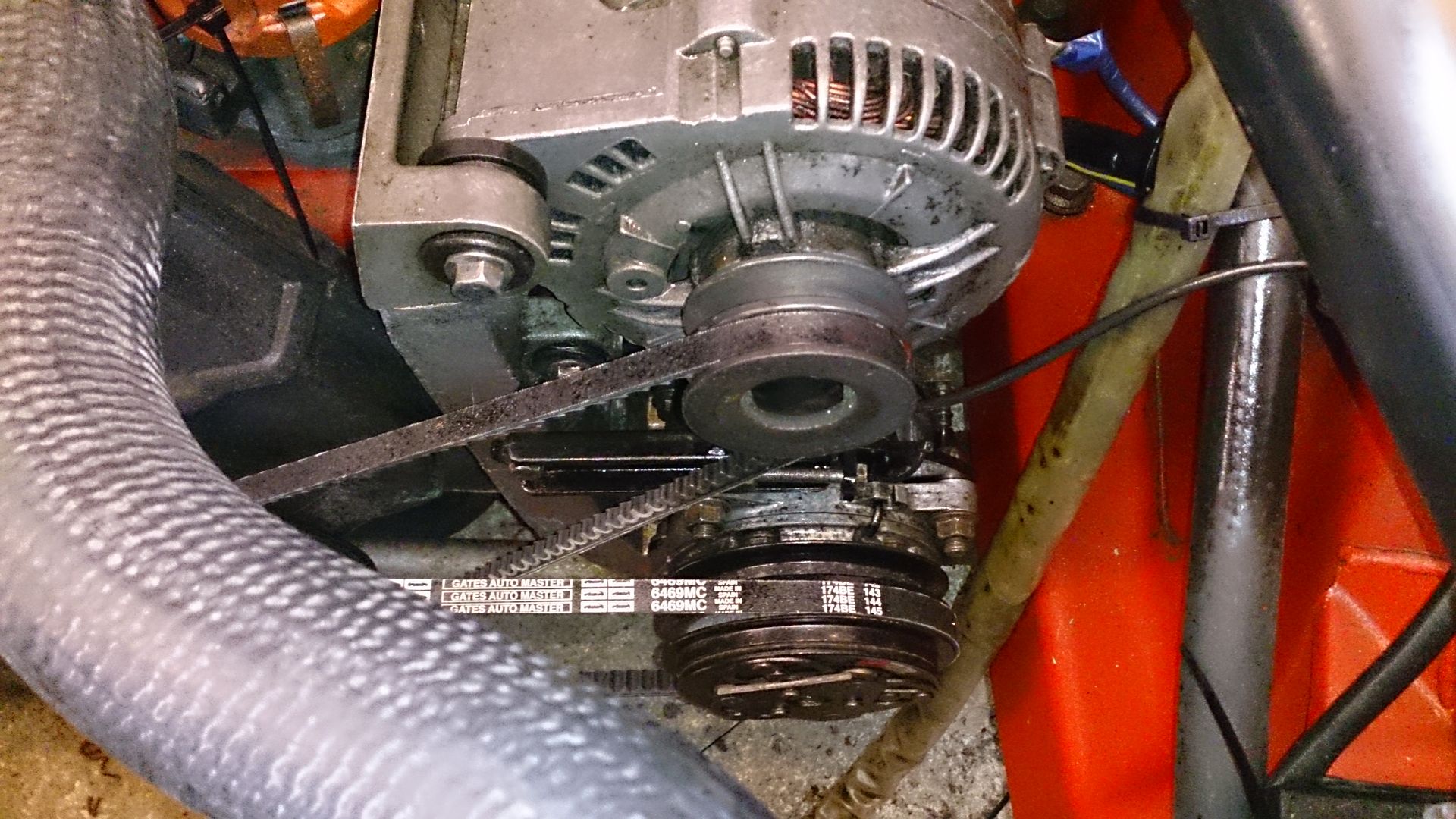

CompressorI cleaned up the compressor from the 940 donor car, here it is being fitted  With the alternator refitted. (The rubber bushes on the alternator mountings are worn. I have ordered new ones, and as temporary measure rotated the old bushes 180 degrees).   More soon! John |

| |

|

|

johnrh

Part of things

Posts: 958

|

|

Jul 13, 2014 20:14:25 GMT

|

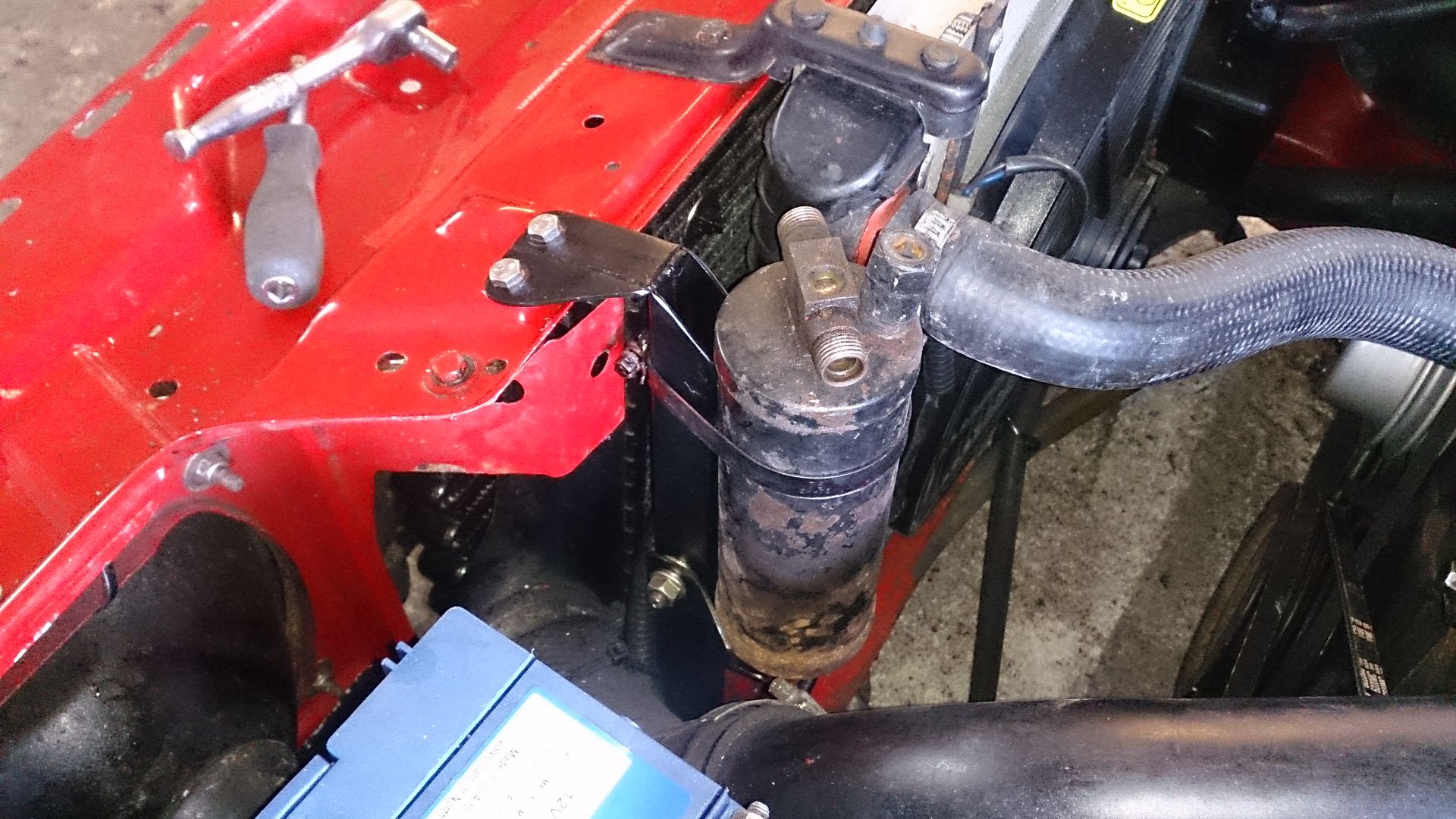

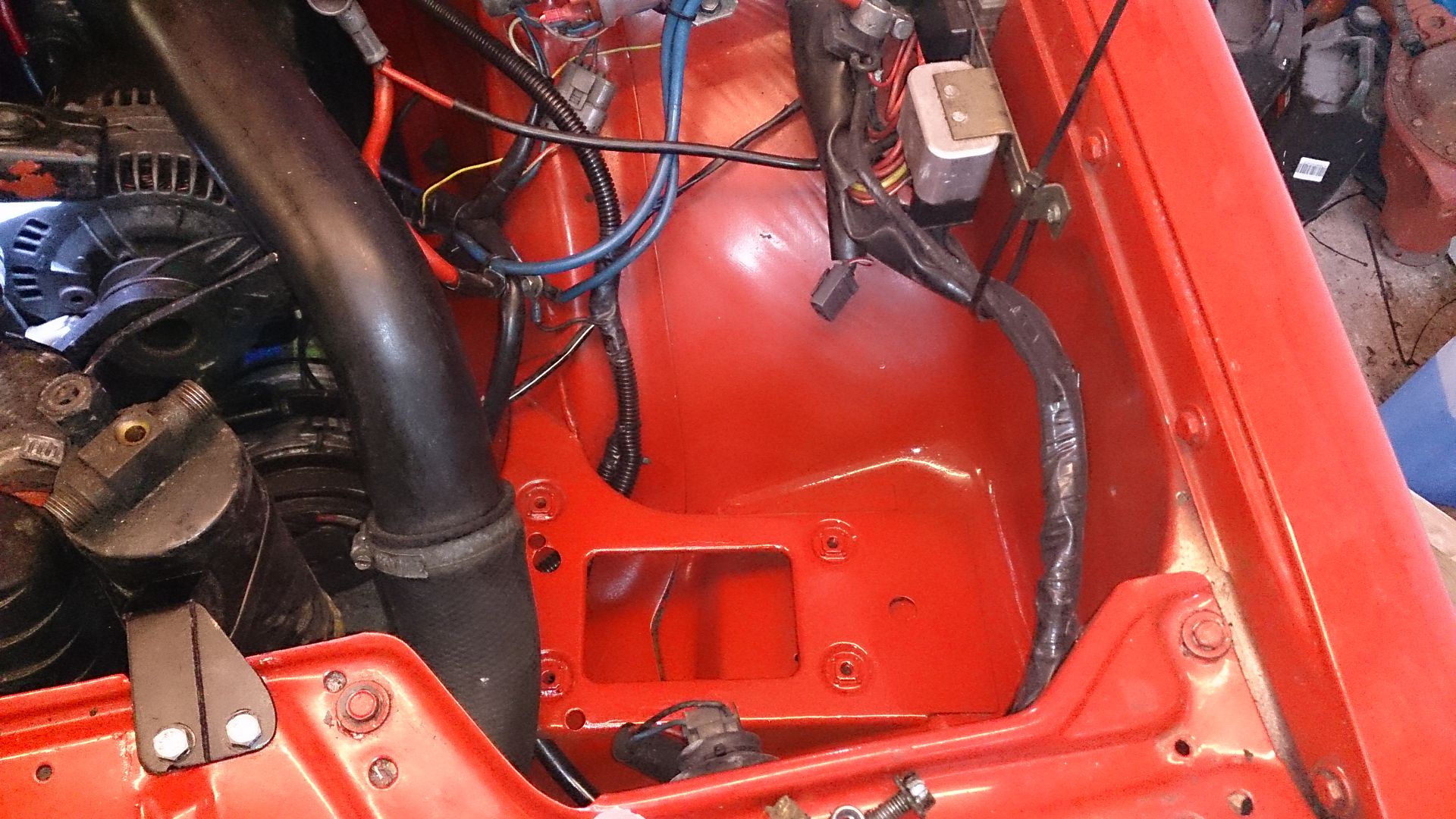

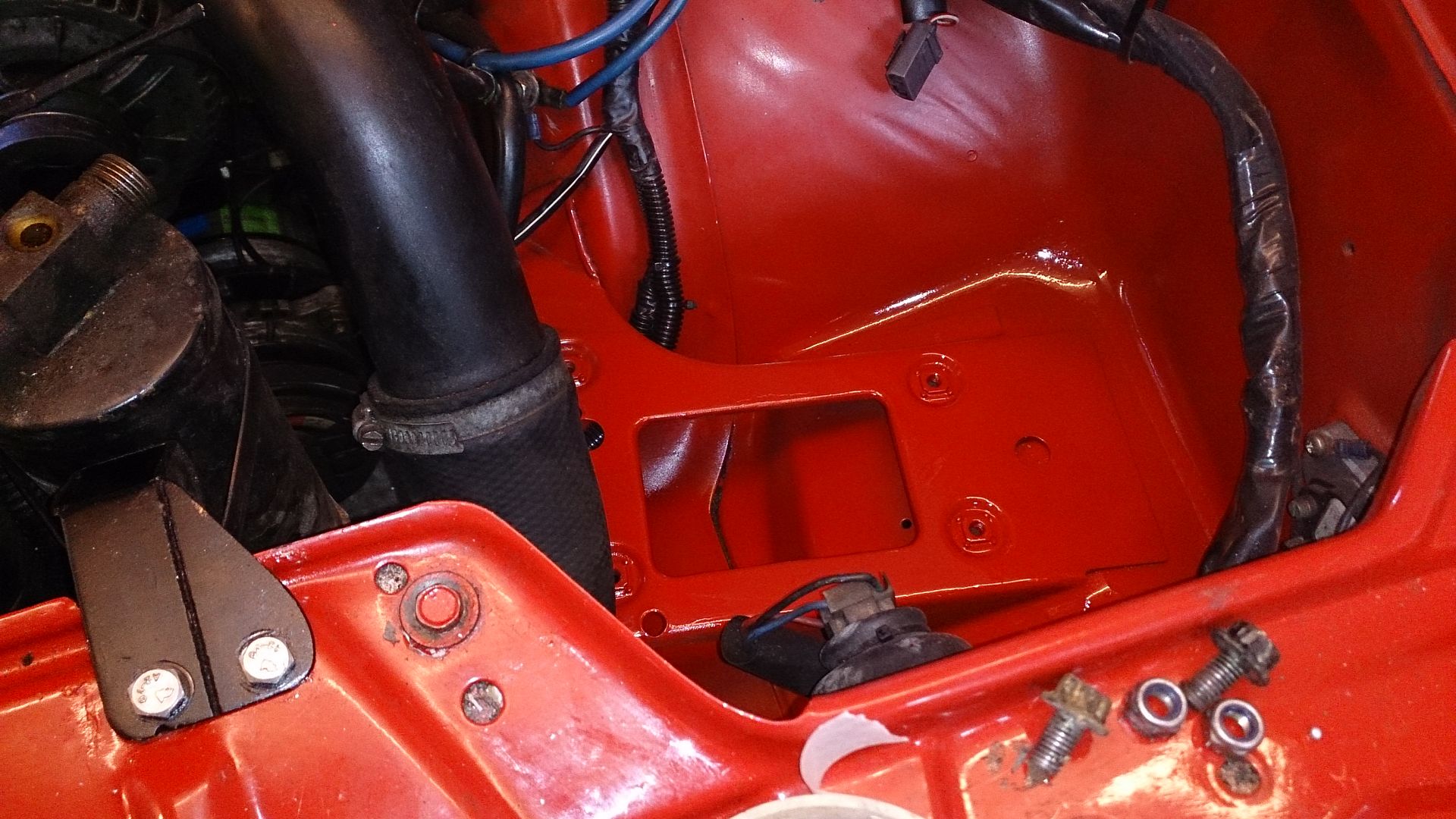

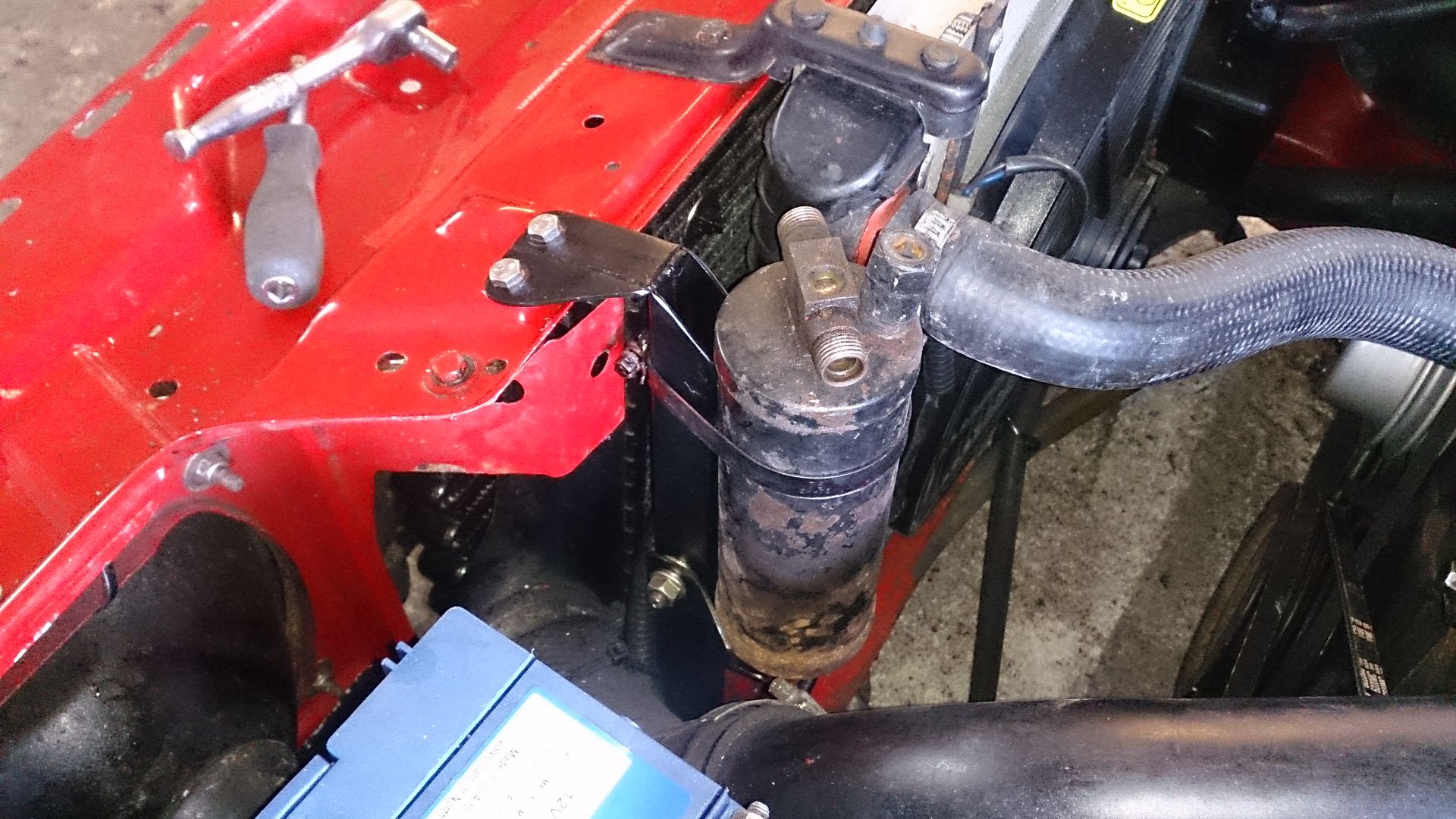

Hi, A/CThe air-con is now at the stage where I need professionals with the right equipment to take over. The final DIY stages: making a mounting bracket for the dryer  Fitted. I have ordered a new dryer, from Volvo classic parts supplier in Germany. Slight language barrier, but I think I 'm getting one the same as this (it's from the 265 donor) but with the addition of an over-pressure cut-out switch.  Refurbished various pipe clips I will be using (I like attention to detail!)  Cleaned up the sections of pipe that will be re-used  I designed and installed the a/c wiring - no photos. I am using a simple circuit, as per the 265 installation but with the addition of the high pressure cut-out and separate control of the radiator fan by an interior switch (to over-ride the coolant thermostat switch already fitted). The compressor has an integral low refrigerant cut-out. The garage Steve works at does air-conditioning, and they have equipment to make any type of pipes needed. It really helps that the owner is a car enthusiast - he has multiple Land Rover and Range Rover projects ongoing. He likes the 245 and as a 'car guy' he understands the project/modifying mindset, whereas I expect many a/c specialists wouldn't want to touch a DIY retro-fitted system on an old car! When the dryer arrives, it now needs 3 pipes to have new ends fitted, and one new pipe made up, then it's ready for leak checking, a vacuum to clean out the internals, and then gassing up. To start with I will try the mainstream r134a gas, to see how it works and test for any leaks. My expansion valve was designed for r12, so I know it won't be optimised for the properties of r134a. If the a/c is ineffective, there are more specialist refrigerants available - legal and compatible with r134a, but with thermal properties more like the old r12. I'll try those if I need to, but I prefer to keep it simple where possible, so I'll try the standard gas first. RustWhile I had some of the front of the car dismantled, I did a holding job with some rust on the battery tray and the edge of the front cross-member.           That's all for today John |

| |

|

|

|

|

|

|

|

|

Very thorough and well thought out, just as we have come to expect from you John

|

| |

|

|

|

|

|

Jul 15, 2014 11:48:56 GMT

|

|

I don't know why but I keep going back to the pics of that r-sport cluster, it just looks so chuffin sweet. I think I'd be happy with that sat on my desk to stare at all day!

The 164 looks amazing, a fantastic colour to go with, and the 245 upgrades are amazing.

So when am I going to be able to see these in the metal then? ;-)

My wife thinks I am mental as I appear to have developed a scary obsession with 740's. Nearly crashed my new lease car while on holiday whilst staring at a mint condition 740GL parked on the side of the road.

These Volvo can get under your skin!

|

| |

The Millenium Volcon"Get yourself a Volvo if that's what you really want, you might be dead next year. In the meantime, you could be going sideways in a gigantic land barge."

|

|

|

|