|

|

|

|

|

I'm attempting to change the cambelt on a PSA 1.9 diesel (XUD9). I've been cranking the engine by hand with a spanner on the camshaft pulley bolt, which WAS working fine, but now when I try the bolt itself turns, rather than the engine. I'm still turning in the same direction (clockwise), nothing else has changed but suddenly it's decided it's loose enough to be tightened  Have I done something wrong/broken something? Logically with enough turns it'll be tight enough to crank the engine again, but I've already tightened it a fair bit and I'm worried about breaking anything (new to this). Any help appreciated! |

| |

|

|

|

|

MrSpeedy

East Midlands

www.vintagediesels.co.uk

Posts: 4,791

|

|

|

|

|

It does sound rather worryingly that you've stripped the thread on the bolt.

Have you undone it at all, or have you just been turning it the same way all the time ?

|

| |

|

|

|

|

|

|

|

|

I did briefly turn it in the opposite direction, but only for a fraction of a turn. It's now done many times that in the original direction so should be tight...

Is there any way I can check if the thread is stripped? And how far up curse word creek am I if it is?

|

| |

Last Edit: Jul 8, 2011 17:20:48 GMT by wichard

|

|

MrSpeedy

East Midlands

www.vintagediesels.co.uk

Posts: 4,791

|

|

|

|

|

Try and unscrew it. If the threads stripped it may be possible to tap it out bigger or helicoil, depending on how hard it is (should be ok in the centre tho) or failing that - replacement

|

| |

|

|

|

|

|

|

|

|

cam or crank?, you should never turn it on the cam.

Try locking the pulley out with a bar through the spokes and retorque the nut with a spot of thread lock. then use the bottom crank pulley to turn it over.

Also don't spin it back you can run the risk of skipping a tooth.

|

| |

|

|

|

|

|

|

|

Yeah, sounds like you broke it. Never ever use a cam pulley bolt to turn the engine over! Try and unscrew the bolt - you may be lucky and find it has turned the bolt threads over without affecting the (much harder) camshaft thread. If so, you just need a new bolt and some threadlock. If the cam thread has come off with the bolt you need a camshaft. Don't even bother trying to helicoil/tap it, just get a cam. XUD9s are common  I wouldn't recommend any sort of bodge to reuse the old bolt either - the cam sprocket is held on by the pressure of the bolt against the taper and it coming slack will be disastrous for the engine. |

| |

To get a standard A40 this low, you'd have to dig a hole to put it in |

|

|

|

|

|

|

|

Bollarks, misread the Haynes manual, been turning it on the cam bolt! Am I likely to have damaged anything (else) by doing that?

I tried to unscrew it and it actually seems tighter that way - then engine, rather than the bolt, was trying to turn. I'll try it tomorrow in gear, wheels on ground, brakes on etc. and see what happens...

I feel like a right dolt now.

Thanks a lot for the help

|

| |

|

|

|

|

|

|

|

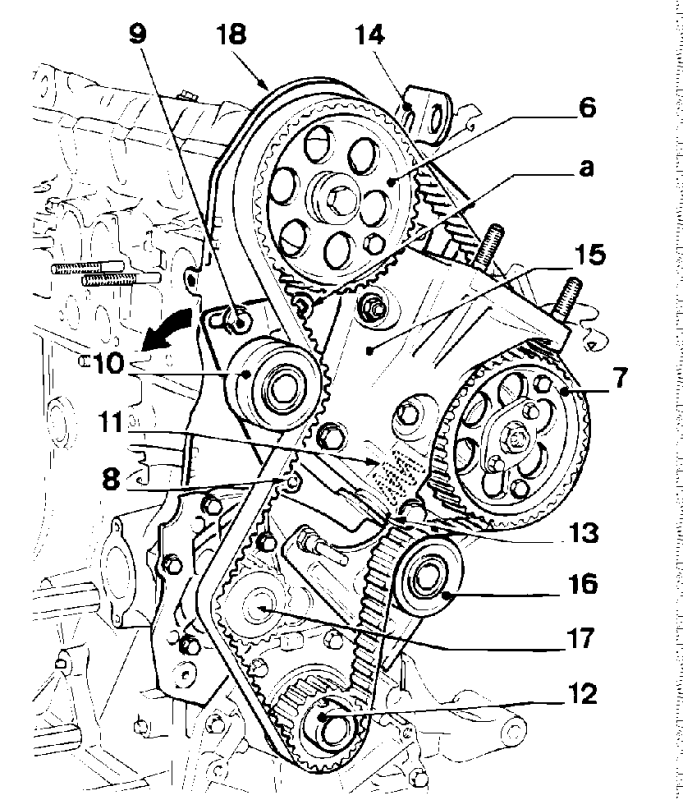

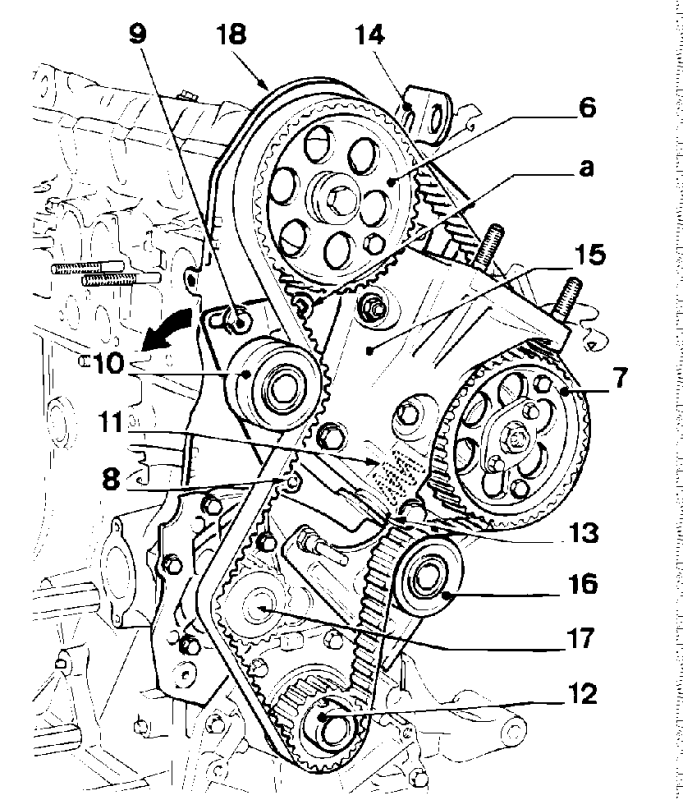

Lock the cam pulley with a M8 bolt through the small hole.  You can see where it goes in this pic... don't try to turn the thing backwards in gear! You could make things far, far worse like that! |

| |

To get a standard A40 this low, you'd have to dig a hole to put it in |

|

|

|

|

|

|

|

Yep, got it at TDC now with cam pulley & fuel pump pulley locked with M8 bolts. Going to try and get it finished tomorrow, got a bit of a problem though as the alternator mount is not the same as pictured in the Haynes - there's no adjuster bolt so I can't work out how to slacken the drive belt and thus remove the crank pulley? (bloody Haynes has been wrong half the time today)

What shall I do about the cam pulley bolt then if I can't get it out?

|

| |

|

|

|

|

|

|

|

There is probably a sprung tensioner on the belt - put a spanner on its central nut and turn anti-clockwise to release it, then pull the belt out from under it with your other hand (there is an art to this!) make a drawing of how the belt goes round all the pulleys first  If you can't get the pulley bolt to come out at all, I'd suggest you need a cam, pulley and bolt at least, and maybe a whole head (iirc cam bearings run plain in the head on these....) |

| |

To get a standard A40 this low, you'd have to dig a hole to put it in |

|

|

|

|

|

|

|

|

|

what vehicle is it in?

do not use the locking pins to unscrew stuff like cam pulley bolts, you'll just bend them/break stuff...

the tensioner is sprung but only when the securing bolts/nuts are loosened.

if you have fudged the cam then just another cam will do, no need to replace the head, though you will need to check and re-shim the clearances.

|

| |

|

|

ChasR

RR Helper

motivation

Posts: 10,307

Club RR Member Number: 170

|

|

|

|

|

|

| |

|

|

bl1300

Posted a lot

Posts: 1,678

|

|

|

|

|

Sounds like youve stripped a thread sorry.

In future if you want to turn the engine over a little bit put the car in 3rd gear and rock it forwards. You wont need to push it far to turn the engine over and are far less likely to damage things.

A trick for locking an engine to remove a pulley bolt is to remove a spark plug and feed a length of paracord through the hole. Then when you try and turn the engine over the piston will lock against it allowing you to undo the bolt.

|

| |

Current fleet.

1967 DAF 44

1974 VW Beetle 1303s

1975 Triumph Spitfire MkIV

1988 VW LT45 Beavertail

1998 Volvo V70 2.5

1959 Fordson Dexta

|

|

|

|

|

|

|

|

It's in a '95 ZX. That tensioner looks a lot like what I've got, thanks.

Is the head the same on all XUD9s or do they differ between n/a (what I've got) and turbo'd units? There's someone on here breaking a 306 Dturbo, would that have the relevant cam? (and if it does, what EXACTLY do I need to do with regards to changing it [should be alright on the rest of the belt change, Haynes permitting]? At this rate I'll be replacing the whole engine...)

|

| |

Last Edit: Jul 8, 2011 21:36:03 GMT by wichard

|

|

ChasR

RR Helper

motivation

Posts: 10,307

Club RR Member Number: 170

|

|

|

|

|

Silly me! I thought you were talking about the aux tensioner! In which case they are spring loaded.

|

| |

|

|

|

|

|

|

|

|

Surprise surprise, I have another problem...

I can't get the intake manifold (air distribution housing, as Haynes call it) off. The bolt on the righthand mounting plate (behind the fuel filter) is impossible to get at with either a socket or spanner -it just fouls on a small coolant pipe below. I've tried to get it off, the jubilee loosens fine but it's on tight. Also looks like the thingybob it connects to would get in the way anyway.

The Haynes shows a socket cap type bolt used, but there's just a normal bolt. It looks like the last twit to take off the manifold lost the socket cap bolts and just put normal ones in instead?

I've got a picture but can't find my ruddy camera lead...

No idea what to do now.

|

| |

Last Edit: Jul 9, 2011 15:14:32 GMT by wichard

|

|

|

|

|

|

|

A trick for locking an engine to remove a pulley bolt is to remove a spark plug and feed a length of paracord through the hole. This tip only works if there is a spark plug hole, which in this case there isnt. |

| |

1974 Lancia Beta Saloon

1975 Mazda 929 Coupé

1986 Mazda 929 Wagon

1979 Mazda 929 Hardtop

1982 Fiat Argenta 2.0 iniezione elettronica

1977 Toyota Carina TA14

1989 Subaru 1800 Wagon

1982 Hyundai Pony 1200TL 2-dr

1985 Hyundai Pony 1200 GL

1986 Maserati 425 Biturbo

1992 Rover 214 SEi 5-dr

2000 Rover 45 V6 Club

1994 Peugeot 205 'Junior' Diesel

1988 Volvo 760 Turbodiesel Saloon

1992 Talbot Express Autosleeper Rambler

2003 Renault Laguna SPEARS OR REAPERS

|

|

|

|

|

|

|

A trick for locking an engine to remove a pulley bolt is to remove a spark plug and feed a length of paracord through the hole. This tip only works if there is a spark plug hole, which in this case there isnt. Is there a good alternative for diesels? |

| |

|

|

|

|

|

|

|

A trick for locking an engine to remove a pulley bolt is to remove a spark plug and feed a length of paracord through the hole. This tip only works if there is a spark plug hole, which in this case there isnt. and it's a cam pulley we are trying to lock! tbh, I would try and lock it with the locking pin - it's not like the bolt is torqued up, it's stripped and won't wind back but if it takes more pressure to turn than you can apply with a small (3/8") ratchet give up and go get a scrapyard cam as advised. |

| |

To get a standard A40 this low, you'd have to dig a hole to put it in |

|

|

|

|

|

|

|

Locking pin as in the M8 bolt I've used? If I can't get it out with a ratchet then won't I have trouble getting a new cam in? Can't even get the chuffing manifold off at the moment!

This is turning into a right ballache

|

| |

|

|

|

|