|

|

|

Apr 29, 2020 22:10:32 GMT

|

Took 5 hours but this video is only the first 2! Don't worry, it is only one minute long :-) Two layers plus additional strip over joints and 6 layers around window openings. Took a lot longer than anticipated so I will bag tomorrow and cook on Firday. Completed.  |

| |

Last Edit: Apr 29, 2020 22:20:10 GMT by nalesutol

|

|

|

|

|

|

|

Apr 29, 2020 12:05:45 GMT

|

Just in case anyone was of the opinion that making stuff out of prepreg carbon was an easy and straighforward task, here are the bits for my car's roof and the vaccuum bag it will all be placed in :-)   |

| |

|

|

|

|

|

Apr 28, 2020 20:14:16 GMT

|

|

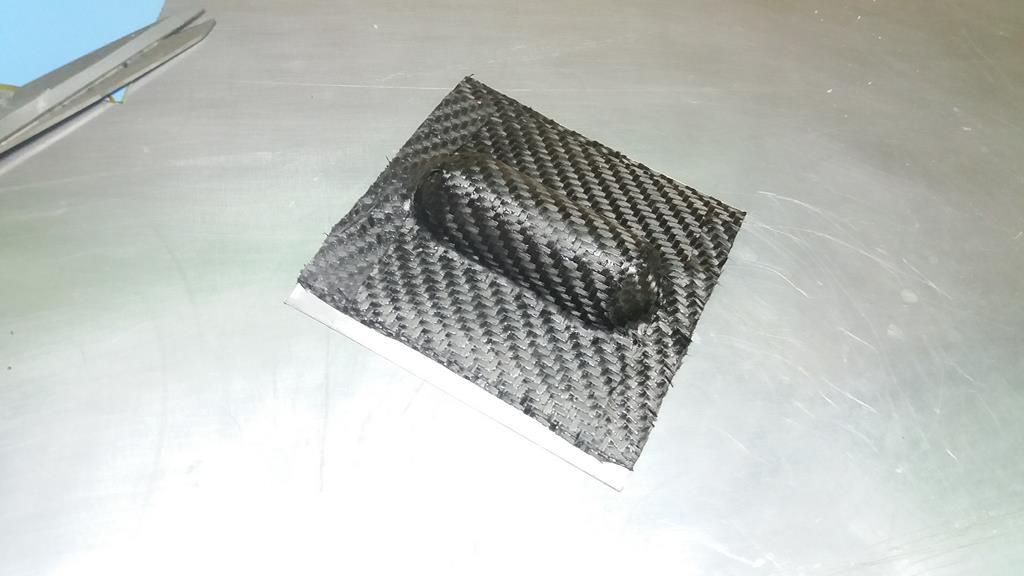

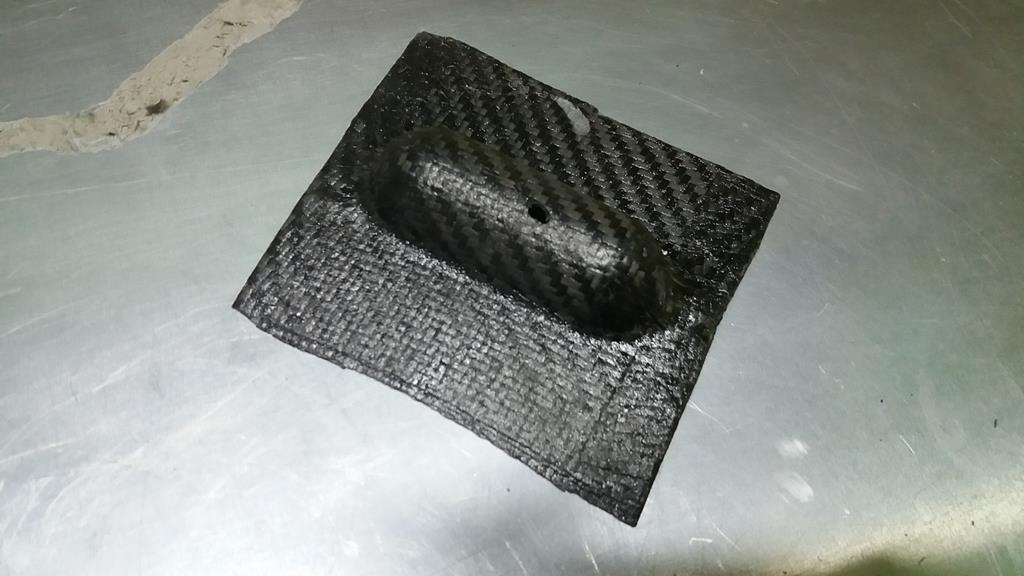

Proof of concept. Once I have taken the slack out of the lock mechanism, it should be good to go. My original push button weighs 42gms, this lever weighs 7gms. Times 2 = 70gms saving :-) All donations gratefully received.

|

| |

Last Edit: Apr 28, 2020 20:33:27 GMT by nalesutol

|

|

|

|

|

Apr 28, 2020 10:10:29 GMT

|

Do you need to pull or push using the internal handle ? iIf pull what about fishing line ? Keeping it plastic fantastic. Nice work as always Janes What weight line? :-) Actually I will be looking at the possibility of doing the same as the outside, if it is possible to reach when sitting in the car. If not then a remote handle with an aluminium welding rod seems the best, reliable, solution. |

| |

|

|

|

|

|

Apr 27, 2020 22:52:13 GMT

|

Just don't fit a black hole - they are really heavy  Ah, but I would use the other end, a white hole :-) |

| |

|

|

|

|

|

Apr 27, 2020 22:49:26 GMT

|

Thick aluminium welding rod would probably be plenty to make a pull for inside. You are on a roll today! :-) I made an aluminium version of the OEM internal door handle a few years ago (top one in photo), which I could adapt to work this latch. And I have aluminium welding rod.  How much would you want as a retained technical adviser? :-) |

| |

Last Edit: Apr 27, 2020 22:50:31 GMT by nalesutol

|

|

|

|

|

Apr 27, 2020 22:27:35 GMT

|

A bit of carbon fibre strand instead of a pull string? Now there is a thought, probably cut my finger off though :-) |

| |

|

|

|

|

|

Apr 27, 2020 22:11:35 GMT

|

This post from stealthstylz nudged me on to a differnt train of thought and made a tricky challenge (the word problem isn't in my lexicon) simple. Shows that not being too proud to ask for help is profitable. Simple solution and less weight, what is there not to like? :-) And works for the MOT for being able to open the door from outside as well  If it didn't it would be tricky to get in :-) Just need to work out how to open from inside. |

| |

|

|

|

|

|

Apr 27, 2020 21:47:20 GMT

|

How much travel is needed on the lever to release the catch? Could you just have a hole in the door so you can poke the end of your finger through and pop it? Would be the lightest solution. This post from stealthstylz nudged me on to a differnt train of thought and made a tricky challenge (the word problem isn't in my lexicon) simple. Shows that not being too proud to ask for help is profitable. Simple solution and less weight, what is there not to like? :-) |

| |

|

|

|

|

|

Apr 27, 2020 21:41:22 GMT

|

Door carcus fits, fortunately :-)  |

| |

|

|

|

|

|

Apr 27, 2020 21:22:13 GMT

|

Roof mould ready for carbon, just awaiting the arrival of peel ply as I have run out. However, curing is going to be a long, drawn out process. I didn't realise that the mould paste that I used to form the window recesses is only designed for low temperatures, lower than the minimum temp that the carbon will cure at. However, speaking to EasyComposites they reckon that it can be pushed to an absolute maximum of 80 deg C. The carbon's minimum cure temp happens to be 80 so I think that I may get away with it. However the cure time is 16 hours! This means an early start time as I don't want to leave the oven running unattended over night.  |

| |

Last Edit: Apr 27, 2020 21:30:46 GMT by nalesutol

|

|

|

|

|

Apr 27, 2020 21:02:18 GMT

|

|

|

| |

Last Edit: Apr 27, 2020 21:25:48 GMT by nalesutol

|

|

|

|

|

Apr 27, 2020 19:07:36 GMT

|

Only if you extract all of the air :-) Surely it depends how the hole is kept in place and what fixtures it needs to stay there  Well, of course, that is obvious to anyone with an ounce of common sense. They are in short supply but I managed to get a packet of, and I have to confess that they are Catholic, 'on a wing and a prayer' fixings. |

| |

|

|

|

|

|

Apr 27, 2020 14:14:27 GMT

|

|

Proof of concept. Initially it was hard to actuate the latch. However, the fulcrum joint was very sloppy, tightening this up made a hell of a difference and it now works pretty well. Probably remove the fulfrum pin and replace with a nut and bolt.

|

| |

Last Edit: Apr 27, 2020 17:13:00 GMT by nalesutol

|

|

|

|

|

Apr 27, 2020 10:14:10 GMT

|

Isn't a hole the lightest material known to man? Only if you extract all of the air :-) |

| |

|

|

|

|

|

|

|

How much travel is needed on the lever to release the catch? Could you just have a hole in the door so you can poke the end of your finger through and pop it? Would be the lightest solution. That is not the daftest idea :-) Another idea I have thought about is a rod welded to the lever that just pokes through the door . It has to move less than 10mm so would only need a short slot. I could even make a neat little recessed slot so the lever doesn't protrude. And, as you say, lighter :-) Hmmmmm, got me thinking :-) |

| |

|

|

|

|

|

Apr 26, 2020 20:26:13 GMT

|

|

Just had a thought, how about using a bowden cable? I will look into this, could make the job easy.

|

| |

|

|

|

|

|

Apr 26, 2020 19:55:11 GMT

|

Have a look on my website www.hotrodphotos.co.uk for a write up for fitting those bear claws, might be of help. Thanks for that. I will plough through the photos later. You didn't have a lot of car to start with :-) Unfortunately, you are using a turning handle and I will be using a push button. |

| |

|

|

|

|

|

Apr 26, 2020 19:44:41 GMT

|

Had a look at your youtube channel, what are the chances of an indepth step by step of making the mould for a larger part - door, wing, roof etc with all the prep stages up to the final production? Now that I would be really interested in to learn from your experiences, and I'm sure many others would be too! I have thought about that, but that takes a lot more preparation and time. What I could do is a thread on here using the photos I have taken. Also, there are a lot of YouTube videos detailing exactly that, and their work is a much better than mine. |

| |

Last Edit: Apr 26, 2020 19:45:33 GMT by nalesutol

|

|

|

|

|

Apr 25, 2020 21:36:55 GMT

|

Right, looking for some help. Plan to use CarBuilderSolutions' Mini Bear 75mm Claw Door Latches. Before I reinvent the wheel, I want to pick your brains or check that someone hasn't already sorted a solution. I need to activate the latch from the outside but the lever works at 90 degrees to the door button movement. I have worked out how to do it using a lever and fulcrum, but this problem must have surfaced before. Is there an off the shelf adaptor or, failing that, plans for an adapter out there?   |

| |

Last Edit: Apr 25, 2020 21:38:49 GMT by nalesutol

|

|