|

|

|

|

|

Day 17 - Picked Elan up from GPE.  First task is to sort out the isolator so we can start on the button. Then fill with clutch and brake fluid and check for and fix leaks. Finish Pneumatic lines to compressor and set up gear change system, fingers crossed that I fitted a big enough actuator. Fill with coolant. I had planned to use Evans waterless coolant but decided against for a couple of reasons. Santa Pod hate the stuff so will ban you if they find out. But more importantly I have just discovered that, due to its viscosity, it robs engine power! So boring old water and antifreeze it is. Now I need to sell the stuff. |

| |

Last Edit: Nov 6, 2023 22:35:46 GMT by nalesutol

|

|

|

|

|

|

|

|

|

|

Paint ordered. Only a litre, enough to do the clam, just in case the result is a disaster :-)

|

| |

|

|

|

|

|

|

|

Front clam ready as it will ever be for paint.  |

| |

|

|

|

|

|

|

|

|

|

|

Hopefully, we will know for sure once the new ECU arrives, which should be on Monday. We can then sort out the DBW and a few other issues. For example, the isolator isn't working so we have to bypass it at the moment. Also, we have yet to test the DASH 2 screen or steering wheel buttons. But we are getting there.

|

| |

Last Edit: Nov 2, 2023 23:10:18 GMT by nalesutol

|

|

|

|

|

|

|

|

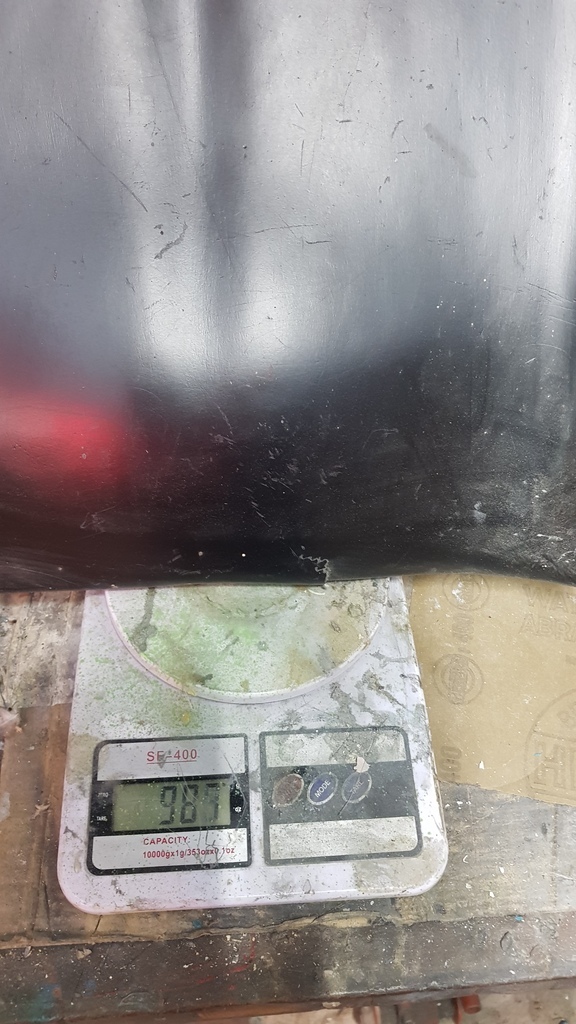

With PDM working the starter button works! I am still amazed that the tiny lithium battery (weighing just under 1Kg ) works :-)

|

| |

Last Edit: Nov 1, 2023 21:58:25 GMT by nalesutol

|

|

|

|

|

|

|

|

Day 14 - Alex had a chat with the PDM manufacturer in Denmark via Teamviewer. Guy sorted out installation issues caused by the unit being so old :-) They will update the firmware for free if I send them the unit, or upgrade to the latest spec (which comes out next week) for 500 Euros.

Only job left for Alex to do is connect the starter motor and then I will bring the car home. As soon as I get the PDM undated/upgraded I will get the ECU guru back to complete the setting up of the ECU and PDM.

Things are moving along, with the plan to get the car on to the hub dyno before Xmas on track.

|

| |

|

|

|

|

|

Oct 29, 2023 18:12:02 GMT

|

Great to hear the engine running! Well Done. Built around 15 years ago and never fired up until this point :-) |

| |

|

|

|

|

|

Oct 29, 2023 10:10:21 GMT

|

|

Yes, it is an HP8441. The main issue is when trying to load the installation software we get a fail message. My son, Alex, is planning to talk to PH Electronik tomorrow via Teamviewer, where they can, hopefully, sort out the issues remotely. Fingers and toes crossed. I may also find out the cost of the replacement ECU.

This is all part of the build so I prefer to keep it here.

|

| |

|

|

|

|

|

Oct 27, 2023 18:15:57 GMT

|

|

Unfortunately, as the photo shows, it is a Delta PDM, supplied by SCS Ltd but made by HP Electronik in Denmark.

|

| |

|

|

|

|

|

Oct 27, 2023 17:06:46 GMT

|

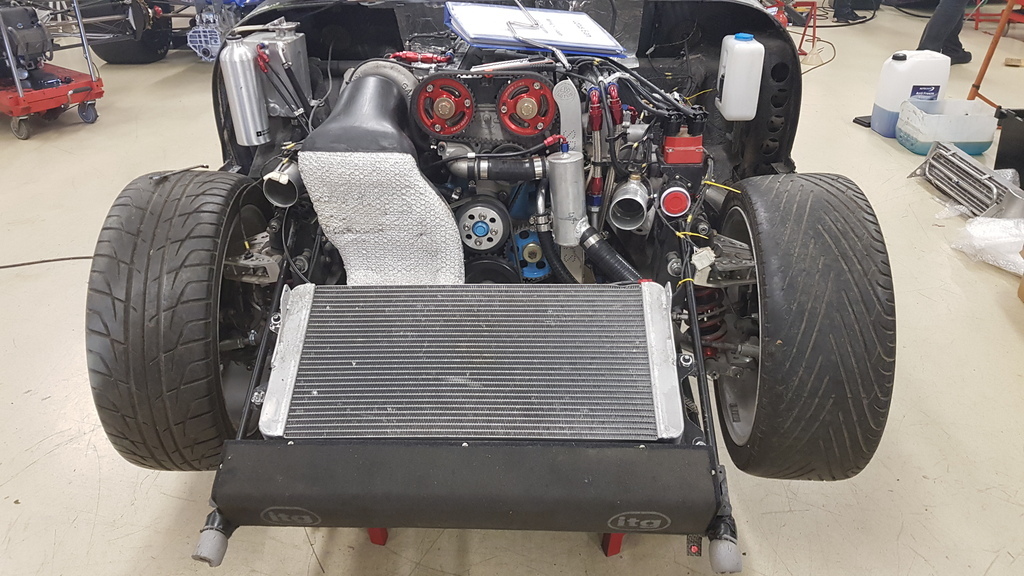

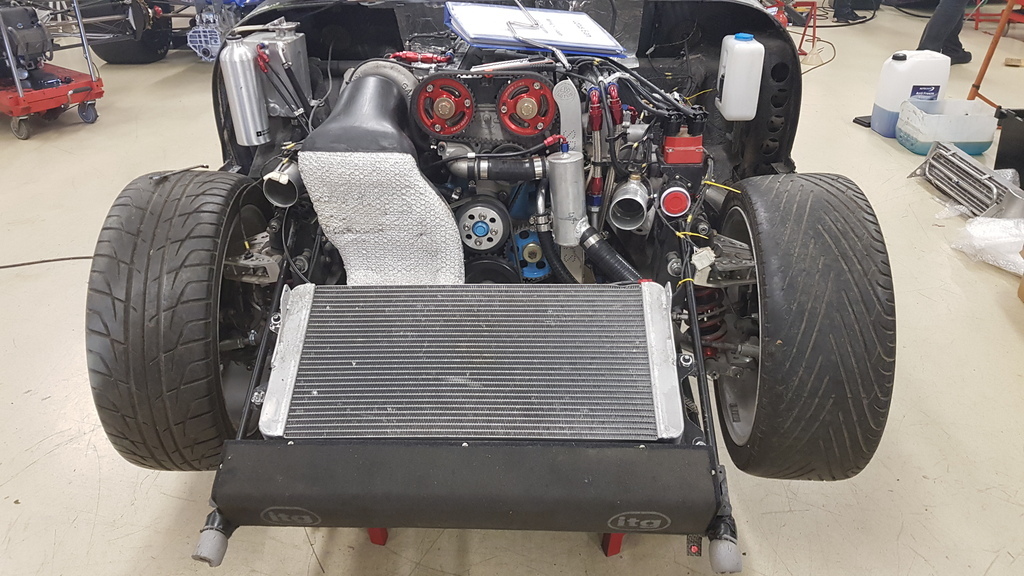

Day 11. New ECU ordered but no idea of cost :-( Anybody interested in a Life F88 ECU? Recent software update but no DBW facility. Basically used for around 2 minutes.  Still no further along with sorting the PDM. Anyone know about these things or know someone who does that is not too far from Chelmsford?  Bolted up radiator and hoses so we can fill with coolant on Monday. Fitted air filter and ducting to turbo.  The plan is to have the car ready for the hub dyno before Christmas. No pressure, then :-) |

| |

Last Edit: Oct 27, 2023 17:22:49 GMT by nalesutol

|

|

|

|

|

Oct 26, 2023 15:27:16 GMT

|

|

Day 9. Visiting father and friends in Essex so no visit to car.

Day 10 Picked up Sam, the Life F88 guru. He discovered that although my ECU was top of the range 6-8 years ago when I purchased it there was no facility for drive by wire. At the time of purchase we were using cables as FBW wasn't that reliable for racing purposes so this wasn't thought of. Unfortunately the ECU isn't capable of an upgrade to do this so a new one is required. That puts me back walking the streets for the funds :-) I should be able to sell my one for a reasonable amount to offset the cost of the replacement as it is basically unused and still very good. My son would love it but he has also gone DBW.

We are also having problem programming the PDM as the only person we know who can do it is in the Far East for the next 6 weeks :-( However, Alex will contact the Danish manufacturers tomorrow as they offer a Facetime type service to help in setting up. Fingers crossed.

Anyway we were still able to start the engine without a throttle so we could check the oil pressure (which sorted itself out) and the hydraulic lifters (which filled with oil after a quit blip of the throttle by hand). Phew!

First fire up!

No turbo, no water and no throttle control.

|

| |

Last Edit: Oct 26, 2023 22:16:48 GMT by nalesutol

|

|

|

|

|

Oct 25, 2023 20:57:16 GMT

|

Does the level shoot a laser out the front of it? If so then yeah you should be able to use it to transcribe a curve on something. If you measure the distance to the thing you're pointing at you can calculate the degrees as well. The main issue as I can see is that you'll get a bit of drift from the arc of your suspension, but I'm sure you can account for that enough to give you a decent reading. Yes, if you look behind the left hand clamp you can just see the laser switch and the laser is below this but recessed. Good point. However, as there will only be around 50-60mm movement in the suspension there isn't going to be much bump steer and probably even less drift so I reckon placing the graph paper around 2m from the laser should give me a decent amount of measurable movement. It will be fun finding out. |

| |

|

|

|

|

|

Oct 24, 2023 21:36:00 GMT

|

Thoughts and info please. The on going issues with the 2L petrol Beetle are leading me to believe the cat may have collapsed. I'm still to do the coil pack which I've purchased, just prepairing for that to not sort the issue. I'm no way in the market for paying £500 for a re-map on a car that cost £650. Re-mqps are around half that. |

| |

|

|

|

|

|

Oct 24, 2023 21:31:42 GMT

|

|

What overall diameter tyre are you thinking of? A 10" tyre on a 17" wheel isn't going to have a very tall side wall. 285s are around the right size for 10" rims, unless you are one of those idiots who stretches their tyres way outside manufacturers recommendations. Pirelli do the P7 Corsa Classis in a 17/285/40 size which is 602mm diameter. They also do it in 305/35 but this is only 592mm tall.

|

| |

Last Edit: Oct 24, 2023 21:33:21 GMT by nalesutol

|

|

|

|

|

Oct 24, 2023 17:48:48 GMT

|

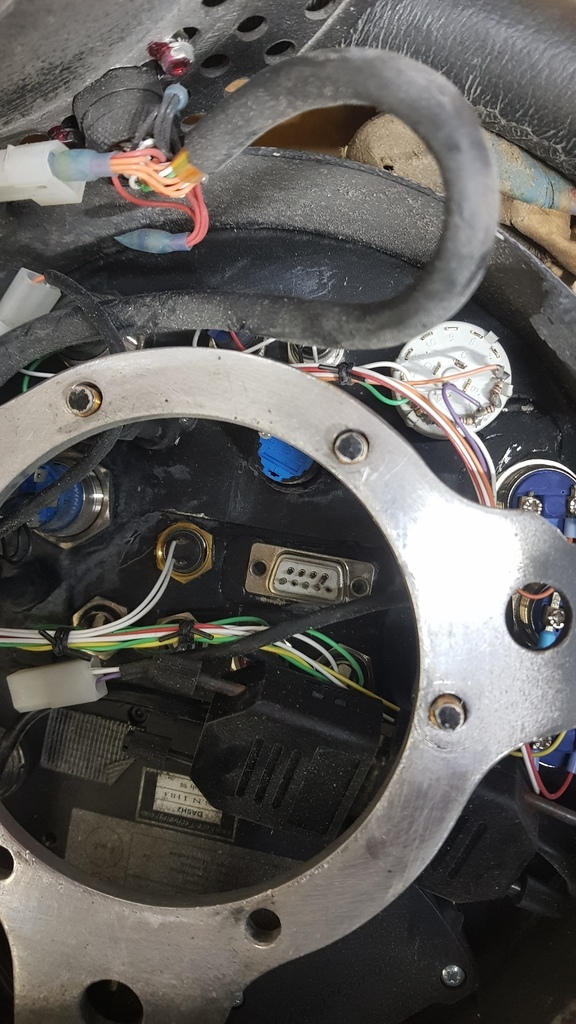

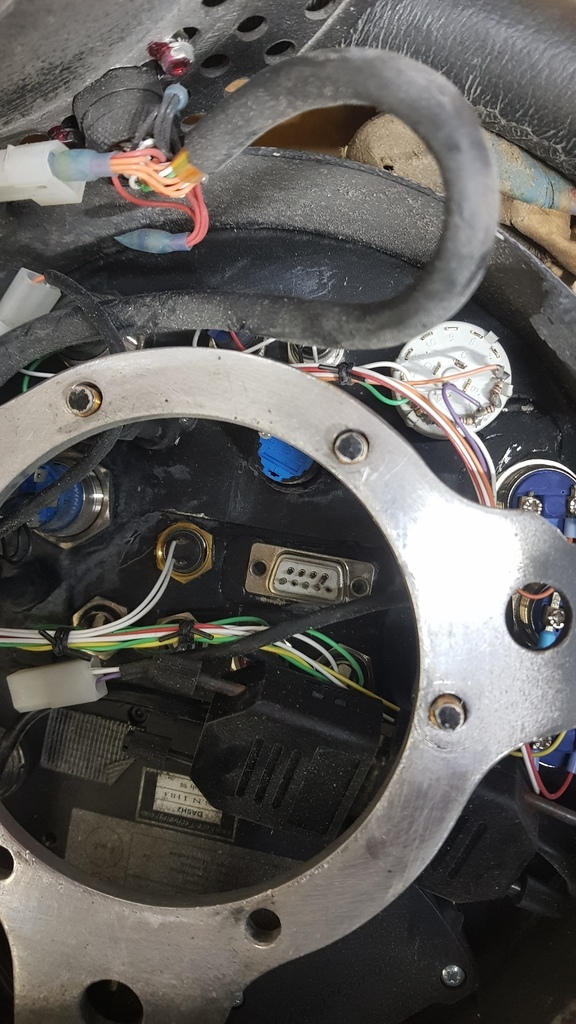

Day 8. Nothing much happed today. Managed to find someone who can sort out the ECU set up so we can start the engine. However, the guy who knows about the PDM is in the far East for 6 weeks so that will have to wait, but at least we should be able to get the engine started which will be a big step. One problem I discovered when I took the steering wheel apart was that the company that wired up the car failed to connect the D connector to the Dash 2 screen so it cant be set up! Hopefully that is something that I can do but but it won't delay start up.  As there was nothing to do at the workshop I went home and continued on the front clam, tidying up the underside of the splitter.  In between layers of filler I thought about how to build a bump steer gauge. MANY years ago (40+) I built one using two pieces of ply hinged together with 2 pins that contacted the wheel. By moving the car up and down (dampers removed) I managed to virtually eliminate bump steer. Didn't fancy making another one so wondered if there was an easier way. Then had a brainstorm. I have a laser level. Could I use that bolted to the wheel? Tested it on a spare wheel and it fits fine. See any reason why this won't work?  |

| |

Last Edit: Oct 24, 2023 17:51:15 GMT by nalesutol

|

|

|

|

|

Oct 24, 2023 13:24:07 GMT

|

Can you use an accusump or similar on a temp basis to get the oil pressure up? Almost want an F1 style oil warmer and pressure system to plug in for first starts like this don't you. Sure all will be well. James Low oil pressure isn't the problem, it's too much as the release valve is probably stuck due to lack of use. Hopefully it will pop open when engine starts and revs pick up. If not then it is a sump off job. Start up is planned for Thursday. |

| |

|

|

|

|

|

|

|

Tease ! Waiting with bated breath here. Fingers crossed for you. James Cheers. There are a couple of critical issues that could be a pain. Oil pressure is around 4 bar on turnover so the release valve is stuck. Hopefully when started it will shake loose. If not that will be a pain as the pump is in the sump. The other potential problem are the hydraulic lifters. Having sat for around 15 years we hope that they refill with oil before doing any damage. |

| |

|

|

|

|

|

Oct 23, 2023 20:09:00 GMT

|

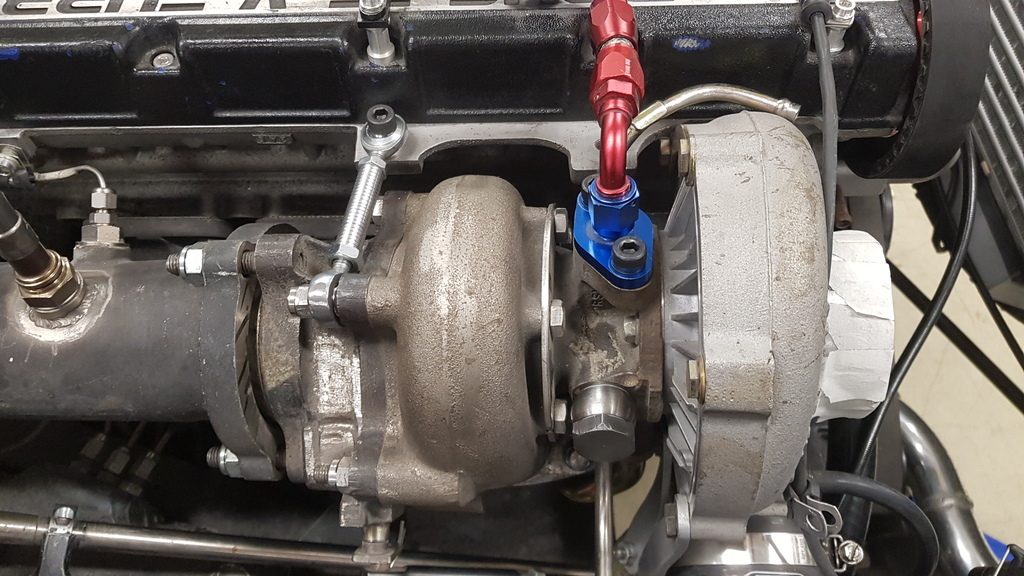

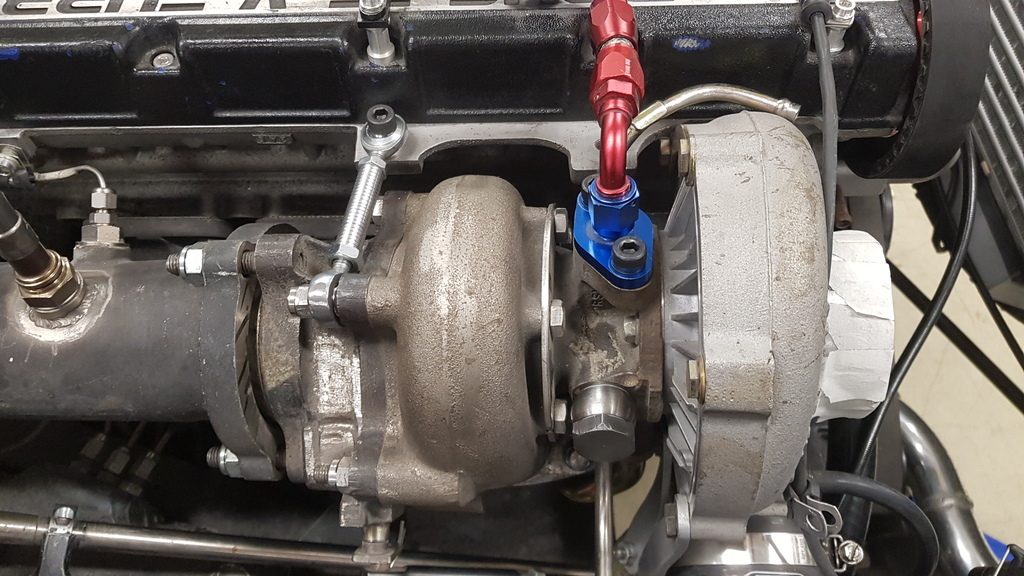

Day 7 Fitted modified fuel hoses and we have no leaks! Fitted new turbo support.  However, it was deemed that this was too rigid so could cause problems. Due to the car's intended use it has been decreed that one isn't actually needed! Oh, well, another 80gms saved :-) Turbo water supply pipes connected. Oil added to engine. Plugs removed for first turn over. This was to check that we have oil pressure, which we do. Getting there, although we still need a PDM specialist to set the PDM up. |

| |

|

|

|

|

|

Oct 23, 2023 16:10:56 GMT

|

Agreed, but Vizard was/is an engine genius, not a suspension expert. Cutting springs is dangerous, alters the spring rate in strange ways and is an MOT failure if spotted (usually when the car is jacked up to check bearings etc as the spring drops out of the cup :-) ) Back in the day they didn't have the options available that we do today. Anyone chopping springs now is a cheapskate idiot who shouldn't be allowed to play with cars (IMO). When they cut them do they flatten and grind the the end flat so it sits in the cup properly? No, they don't. If they cut springs to save money what else have they skimped on? Cut springs aren't an MOT fail. Nothing in the manual for it, but pig tailed springs with no locating device is a fail  Agreed, as long as the modification has been done safely. Just found this: A Lesjofors spokesperson said: “Despite some improvements, the regulations are still too vague and should be updated with specific examples of reasons for rejecting a coil spring.” Currently, a coil spring should only be rejected if the spring is insecurely attached to the chassis or axle, or has loose fixings to the extent that relative movement is visible Other reasons for rejection include a spring fracture, missing spring and unsafe spring modification. The spokesperson added: “These guidelines give MOT testers a lot of leeway to pass a spring which may in fact be dangerous, as words like ‘insecurely’ and ‘seriously’ are not defined and thus must be interpreted by the tester. “The new guidelines finally include ‘unsafe modification’ of a coil spring as a potential reason for rejection/failure, but still allow welded repairs in certain circumstances, despite the fact that introducing heat to a coil spring can pose a significant safety risk. “Every automotive coil spring requires heat-treatment during the production process. “This involves hardening, tempering and stress-relieving, followed by pre-setting to further improve fatigue performance and reduce the risk of breakage. “Once the heat-treatment process is complete, introducing extreme temperatures via welding will alter the internal structure of the spring, while the electrode rod used to complete the weld will not be of spring-steel quality, significantly increasing the risk of breakage. “Even errant weld spatter from neighbouring repairs can create stress risers in the spring, leading to premature failure.” Lesjofors claims that the document also states that “welded repairs to highly-stressed components aren’t normally acceptable, other than where the component is made up of sections that are welded together. To pass, the repair should appear to be as strong as the original design.” The Lesjofors spokesperson added: “This ambiguous guideline appears to allow welded springs to be passed without testing the actual strength of the spring, as long as it looks as strong as the original. “As the ‘appearance’ of strength does not necessarily indicate a strong spring, this is potentially dangerous.” This indicates that it is down to the interpretation of the regs by the tester. The ones I have spoken to err on the safety side. |

| |

|

|