|

|

|

|

|

Not all was plain sailing doing the rear sub frame. The above toe arms which are adjustable, had seized bolts. I reckon the toe was never adjusted. I broke out the blow torch, the torch won. Below more seized bolts, these were for the handbrake retaining bracket and the a/r/b retaining bolts were the same. I had problem fitting the larger rear mounting bushes, no way could I get them out. The local garage came to the rescue with a their hydraulic press. And I haven't mentioned cleaning & painting the underfloor etc...Anyway, it's done now but I don't want to see a rear sub frame again for a long time!  The diff breather cap was semi seized and slightly bent. It should freely rotate 360 degrees but barely managed 90. One screwdriver, a vice grips and some WD40 sorted it.  The original rear a/r/b links are plastic. They were in good condition but since I was upping the roll bar stiffness by 60% I decided to fit metal links from an E-Class estate (W124). They're the same length, same bolt diameter but the lower bushes are longer. I fitted the original bushes to the metal links, job done.  |

| |

Last Edit: Apr 8, 2020 23:17:06 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

|

Nice merc fella how you finding the new anti roll bars 😊 Thanks, but nice? How about rough around the edges  And it's silver...it's sure not a nice navy like yours. As for the bars the jury is still out. I only fitted them four weeks ago and managed 150 miles in total, Covid 19 and all that. I'm messing about with ride heights and rebound on the shocks at the moment so I can't definitively say how good the bars are and it doesn't help that I'm unsure what I'm doing! But, they've made a difference especially on corners. |

| |

Last Edit: Apr 8, 2020 23:49:31 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

Cheers bbb. If the current battery starts to fail that is what I'll buy.

Yeah, seats. A good call btw. Well, it's an issue because the current seats are heavy, really heavy. I recon I can save 25kg + by fitting buckets, it's just the cost holding me back as the only suitable sliding seat bases come from Recaro. Those alone on their own are not cheap. But as I said in a previous post I'm considering replacement seats.

Removing the rear reg motors is sadly not worth it. I need operating rear windows and the manual regulators are not that much lighter. So, cost wise it's not practical against the minor weight loss.

Thanks for the suggestions.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

Lovely colour combination.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

Nice car the C240. Looking forward to updates and photos.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

I mentioned previously I had two issues with the suspension. A slight knocking/creaking coming from the n/s/r lower control arm and the car wandered on decelerating from high speed. In a nutshell these issues were due to worn rear suspension bushes. Time to pull the rear sub frame out.   Stripped and cleaned the s/frame.  Rebuilt and painted. The lower control arm bushes and front mount bushes were shot. The diff bushes didn't look great either. Everything was replaced except the small control arms, bushes were surprisingly in good condition.  S/frame back in.  I broke out and fitted a set of thicker roll bars.  |

| |

Last Edit: Apr 8, 2020 1:01:17 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

Another issue worth taking note of, is fuel hose quality. Tthis time it's nothing to do with Mercedes themselves, the hose quality they use is excellent no matter if it's coolant, air or fuel. I replaced the rubber fuel hoses at the pump & filter sometime back. About two years later this was the condition of the hose.  fuel hose fuel hose by Johnny Slow, on Flickr Just caught in time. I can't recall where I bought that hose, maybe eBay or a motor factors. I ordered some Cohline hose and it still looks perfect to this day. |

| |

Last Edit: Apr 7, 2020 23:52:19 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

An issue with C, CLK & E- Class's of the late 90's and early 2000's is the front spring perch rotting. It can rot on the top or rot where it joints the inner wing allowing the suspension to collapse. It's not a big deal (provided it doesn't fail while driving) ,new perches are cheap and there's only few welds holding them to the inner wing but it's always best to check their condition. In my case they started to rot at the top, a few holes were present but otherwise they were good. I guess I was lucky, it could have been much worse. I decided an easy way to sort the problem was to have some 3mm cresent shaped plates welded to the top and to the inner wing for good measure. All in between the machine shop supplying the plates and the local garage welding them in, total cost €50. Bargain. Perch (with spring removed)  IMG_20200405_111023357 IMG_20200405_111023357 by Johnny Slow, on Flickr Perch, looking up.  W202 SPRING PERCH W202 SPRING PERCH by Johnny Slow, on Flickr Plates welded in prior to painting. (sorry about another rubbish photo)  spring plates spring plates by Johnny Slow, on Flickr Plates.  front spring pearch plates front spring pearch plates by Johnny Slow, on Flickr |

| |

Last Edit: Apr 7, 2020 22:42:14 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

What this man said. Petrol all the way. I'd prefer to pay seven grand for a petrol than five grand for a similar diesel. |

| |

Last Edit: Apr 7, 2020 15:37:42 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

|

Weight reduction. Ideally I want more power or a quicker car. But, I've no plans on porting or running a smaller pulley on the S/C etc So, my only option is to lighten the car, the problem there is I don't want to strip it either. I set a modest target of 50kg/110lb. Items gone: Rear split folding seats, head rests, belt receivers, rear shelf speakers and first aid kit. 28.5kg/62.7lb Exhaust resonator 2.5kg/5.5lb - mistake, doesn't sound too good. A/C system 17kg/37.5lb - wasn't working, so into the bin. Original spare wheel, replaced with a space saver from a later C-Class 6kg/13lb Lighter battery 6kg/13lb Total: 60kg/132lb The car weighs 1420kg including driver@ 68kg, luggage @ 7kg and 90% fuel @ 42kg (all according to Mercedes). Subtracting those items leaves a dry weight of 1303kg/2866lb, 1303kg - 60kg + myself 95kg + 50% fuel @ 22.6kg, wet weight 1360kg/2992lb, So, overall not a bad reduction giving 165 bhp/ton (225/1360). Ideally, I'd really like 180 bhp/ton but I'll dream on. Power @ the wheels is 185-190 bhp. The only way I can see on reducing the weight further is to fit light weight seats, lighter wheels and custom exhaust system. All pricey things to fit and they become very expensive when the actual value of the car is about zero. But if I found good used parts I'd be tempted. There's an easy 40kg/88lb weight reduction with that lot. Rear seat delete, a bit of painted thin ply and rubber trim for the bulkhead.  Rear seat delete Rear seat delete by Johnny Slow, on Flickr Looking from the boot, bolted in two hollow cross braces and added insulation to the ply.  Rear bulkhead from boot Rear bulkhead from boot by Johnny Slow, on Flickr  Space saver Space saver by Johnny Slow, on Flickr The standard battery was massive, this smaller one still does the job.  Small battery Small battery by Johnny Slow, on Flickr |

| |

Last Edit: Apr 8, 2020 19:41:12 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

I could have all the boost pressure in the world but it's worth sod all if it leaks. I did have a couple and they're not easy to find, actually impossible really without pressurising the system. Any boost pressure loss would be upsetting.  I used two silicone hoses, both blanked off with one fitted with tyre valve. Then it's only a matter of using low air pressure from a mini compressor and listen for leaks around the boost hoses, bypass valve and throttle body.  IMG_20200405_142505212 IMG_20200405_142505212 by Johnny Slow, on Flickr |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

On the topic of induction and boost, one critical item that I overlooked is the S/C belt. I initially did change it when doing the other belt while replacing the tensioners and idlers.. Having just checked the S/C belt tensioner, it was at 90%+ (yellow mark) within the min-max cast rectangle (outlined in blue) , there's a good chance the belt was slipping at higher boost levels. A new belt got it back to 33% (cast line) and then after 100 miles it settled at 50%. But this time I fitted a Conti Elite belt (which is similar to popular Goodyear gator back belt) rather than using a standard six rib belt. So far, so good and the chirping noise on start up from the S/C has gone.  I haven't got a photo of the belt but here's a generic photo. You see the hatching on the belt rather that ribs. It will be interesting to see how this belt fairs out, the previous Conti 6 rib lasted less than 25,000 miles.  96c947123bab4dd4d3fb1ac6080b8636 96c947123bab4dd4d3fb1ac6080b8636 by Johnny Slow, on Flickr |

| |

Last Edit: Apr 6, 2020 21:49:31 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

Yeah, you're all correct guys. Silicone is a no,no. Too use to using silicone hoses for air, but forgot it has it's limitations. Just ignore me infuture!😀

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

|

Bookmarked.

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

One of most noticeable things about these S/C engines is heat build up generally. Heat is just not good for performance. Sticking with modifications, I was keen to remove the air filter housing completely and make up a home brew cold air inlet system, not handy to do due to limited space and the S/C blow off valve mounts to the filter housing.  Here's a popular CAI setup, there's a couple of ways of doing but it needs to be boxed in as the S/C and exhaust manifold are on that side.  I may get around to doing a proper CAI someday, in the meantime I gutted the air box of it's baffle system, fitted a larger inlet hose with a bell mouth.  IMG_20200405_225754556 IMG_20200405_225754556 by Johnny Slow, on Flickr Then added a second inlet which gets it's air feed on the front bumper. I fitted a cover plate as it can only be used in dry weather. It's crude but hell if it helps I can live with the looks.  CAI sealed CAI sealed by Johnny Slow, on Flickr  CAI summer CAI summer by Johnny Slow, on Flickr And talking about crude, I chopped up the bonnet! Nothing to lose I reckoned as it was in poor condition so I 'added' a few vents!   W202 C230K I.C. & Vents W202 C230K I.C. & Vents by Johnny Slow, on Flickr  Bonnet vents Bonnet vents by Johnny Slow, on Flickr |

| |

Last Edit: Apr 6, 2020 22:40:39 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

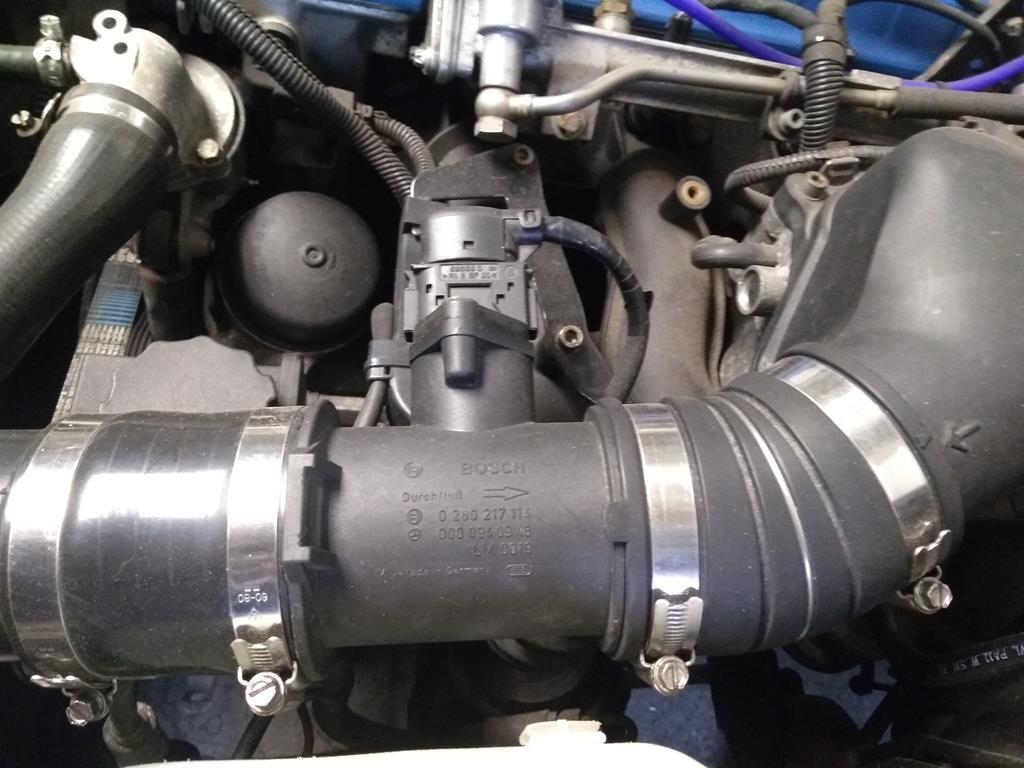

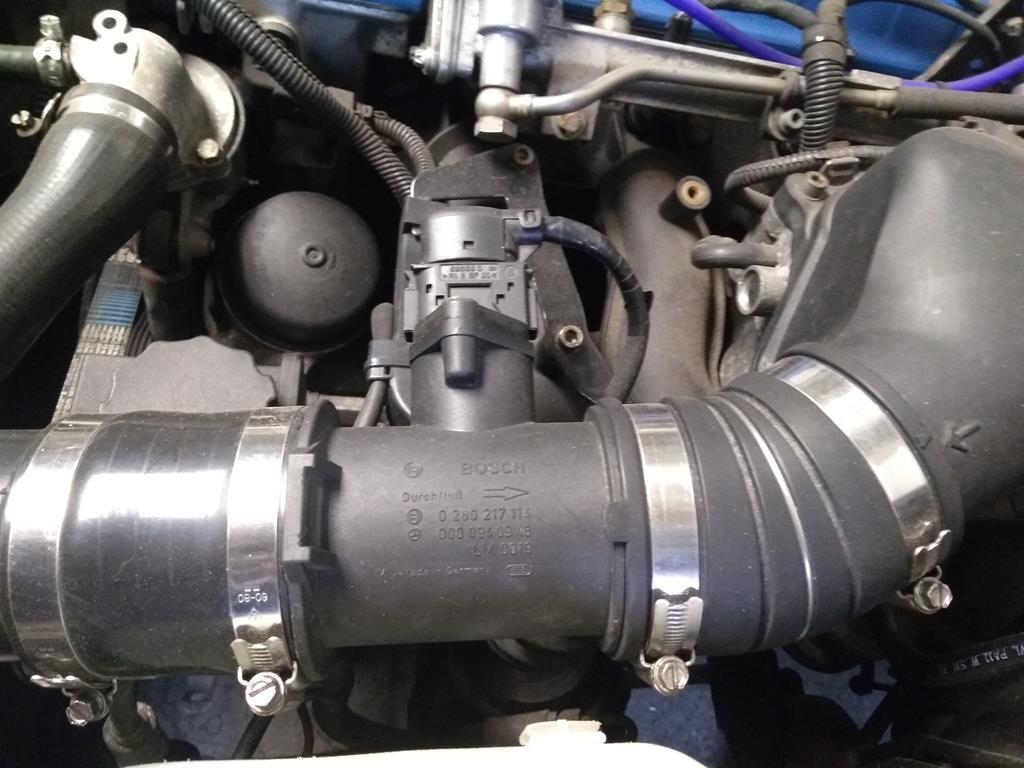

I also fitted the later ( plastic) T/B inlet rather than the original metal one. It's fitted to the later S/C engines which use the small Eaton M45 charger. The plastic has a much nicer radius (not as sharp), plus it's got a divider inside, the metal one didn't . I presume that aids/smooths air flow at boost pressure. Has it made any difference? I don't know being candid but since it was free I reckoned there was no harm fitting it. I did have an issue with the boost hose coming adrift, so I fitted good new wide band hose clips and changed the pipe setup slightly.   One thing I have been meaning to experiment with is different Maf's. I've tried a standard Pierberg (Merc use Bosch) didn't notice ant difference but didn't do any logging on the OBD scanner. I also have two other Bosch Maf's, both for BMW's E46/E39's & E60's. So between two possible Maf locations and four different Maf's I've a fair bit of experimenting to do but I;m not expecting massive results possibly just problems. What I can say is, I did run the car a few years back with the BMW M5 E60 Maf and the increase in torque was really impressive but I ran into a problem after 250 miles of driving, the S/C clutch would disengage and would only engage after switching off and starting again. The only way to overcome the cutting out was disconnect the battery for 30 mins, and then it was good for another 250 miles. What I presume was happening, during the 250 miles the ECU is going thru it's learning phase and then decides it doesn't like the MAF signal output @ wide open throttle . It's real pity as it drives great with the E60 Maf. |

| |

Last Edit: Apr 6, 2020 20:24:00 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

As well fitting the new all alloy I.C. I made a few other minor modifications to the induction system. A popular mod is to relocate the MAF from directly at the I.C. outlet closer to the throttle body. This eliminates an engine hesitation/flat spot between 2500-3000 RPM, it's all got to do with boost pressure air resonances (don't fully understand it myself) created by the increase in boost pressure over stock. It's a simple mod and works a treat.   |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

. not happy with the epoxy putty I've used to blank the regulator off with. Could you not simply fit a silicone blanking cap and a hose clip? Keep up the good work.  s-l400 s-l400 by Johnny Slow, on Flickr |

| |

Last Edit: Apr 5, 2020 21:08:39 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

Here's a photo of the all alloy stock I.C. (no plastic end tanks). These are fitted to C250 diesels.  All alloy I.C. All alloy I.C. by Johnny Slow, on Flickr The idea behind getting one of these is that it will be easy to get a larger core fitted, thicker in my case ( giving a 50% increase in core size, matching the SLK overall core size plus 20%) and then it will still mount without any issues and it's far cheaper than a complete custom I.C.. I bought a used one for 30 quid which is currently fitted to the car. I also bought a new one for £90 which I'm going to fit soon and then have the old one ready for re-coring at some stage. The other advantage being all alloy is that it should act a better heat sink, assisting cooling where the plastic can't.  New I.C. New I.C. by Johnny Slow, on Flickr |

| |

Last Edit: Apr 5, 2020 17:02:47 GMT by Woofwoof

Still learning...still spending...still breaking things!

|

|

|

|

And it's silver...it's sure not a nice navy like yours.

And it's silver...it's sure not a nice navy like yours.