hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

insomnia and guilt made me drive over to the unit in the early hours of the morning. first off was a cup of coffee. i noticed the abseiling mice have been at the emergency confectionery store on top of my pillar drill. i relocated the remaining comestibles in one of the file cabinet drawers. i hope that it will be a while before the ninja rodents work out how to fire up the plasma  i started to weld the joins in the sill closing piece. this didn't go too well as the weld was very inconsistent. steve's (asoc forum) comments on penetration made me think about something i had read about shroud length. the last lot of shrouds i bought were for a mb14 torch(they were 1/5th of the price of sip items) i had measured them and they were the same size as my old shroud. i filed one down by 3mm to get the tip nearer to the torch end, this seemed to make a positive difference to the penetration. when i had a rummage in my mig spares drawer i found the shroud that came with the welder. it was 2+ mm shorter than the last sip replacement i had used   from left to right- last sip shroud, one that came with the welder,mb14 -3mm and mb14 stock fundamentally all this means is i need another excuse for my poor welding   this time it was due to the almost impossible task of getting myself and the car in a position where i could see what i was doing  probably ;D it felt a bit late to be grinding and cutting so i decided to leave it at that for now. i am hopeful it will look a bit better when its finished  also it was getting even colder- the coffee was freezing in the cup after 30 minutes  total time spent (trying not to wake the neighbors) 198.8 hours total spend £1495ish (i am having ridiculous thoughts about getting some epoxy primer. the wildly optimistic voice in my head is telling me i could strip+paint most of the underside over christmas. the bad voice is telling me not to be so stupid  ) |

| |

whats that burning smell?

oh curse word :-(

|

|

|

|

luckygti

Posted a lot

I need to try harder!

I need to try harder!

Posts: 4,912

|

|

|

|

Go with the bad voice mate!!! You know it makes sense, and there would be nothing worse than all the hard work going to waste in this shitey weather! Looks good though  |

| |

|

|

m0rris

Part of things

Posts: 195

|

|

|

|

|

Keep up the good work, you're an inspiration to us all!

m0rris

|

| |

|

|

hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

taking my lead from the controversy caused by angyl in the bonnet mascot thread  @ @bstardchild - thanks for reading my updates  @ @neil - as ever thanks for the pic  . that car (avon no. 23 of 50 afaik) has been half heartedly up for sale for ages @Anglia68 - thanks, but my work is not a patch on the superb work you have done to your anglia  . liking your location too  @ @gernster - cheers for you diagnosis of my mental condition  @ @luckygti - you may be right, see the weather update below!. ps i enjoyed following your garage thread  @ @m0rris - thanks  @ @anyone interested indoor micro-climates (or ninja rodents) semi irrelevant unit update:- due to the (at best) -5c temps at my workplace i popped into the unit to pick up some extreme weather PPE (some nice 3m gloves i had ruined earlier  ). it appears the mice were abseiling through holes they had cut in the roof. the melting snow is causing comedy (but extensive) rainfall inside my unit. as the roof is a mix of corrugated tin and asbestos, 8m in the air, i guess i may be moving stuff out of the deluge and marking the danger spots on the floor   |

| |

whats that burning smell?

oh curse word :-(

|

|

|

|

|

|

|

|

Mel

It could be your welder that is playing up, I have heard a few bad story's about SIP welders, not being able to hold a continuous weld.

|

| |

|

|

mirafioriman

Posted a lot

My next project.......

My next project.......

Posts: 1,361

|

|

|

|

|

Funny you should mention that Tony. I have a SIP welder and have always had problems with inconsistent wire feed. Tried new liners, tips, shrouds etc but the problem always seems to persist. I'm not in the financial position to do it now but if I was buying a new MIG I don't think I would buy another SIP one.

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

|

|

|

|

Funny you should mention that Tony. I have a SIP welder and have always had problems with inconsistent wire feed. Tried new liners, tips, shrouds etc but the problem always seems to persist. I'm not in the financial position to do it now but if I was buying a new MIG I don't think I would buy another SIP one. Mel - Mines been pretty modified now - I think you saw the thread on Mig Welding - if you want I'll loan it to you - I've kept it as a back up if I didn't like my Portamig but it's really doing nothing right now |

| |

|

|

|

|

|

|

|

|

I've suffered the SIP welder blues and have found that the most common problem with them is that the plastic mounting for the wire feed rollers gradually flexes which leaves the rollers at angles to each other to the point that the lower edges of the rollers touch before the wire is clamped, this results in poor and interupted wire feed. I cured this on mine by using the roller retainer screws to hold two right angled plates with a bolt between them to pull the top of the rollers together. To see if this is the problem on yours, pinch the top of the rollers together and pull the trigger, if you let go the wire feed will stop or become erratic. Hope this helps, it saved me throwing away an otherwise good welder. Good luck with the car, as a welder by trade the work you have done so far deserves the utmost respect, most of us despite being competent welders would have resigned this motor to the scrap heap. I look forward to seeing it finished, time to get back to my Mini now, you've fired me up to get it done.

|

| |

|

|

hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

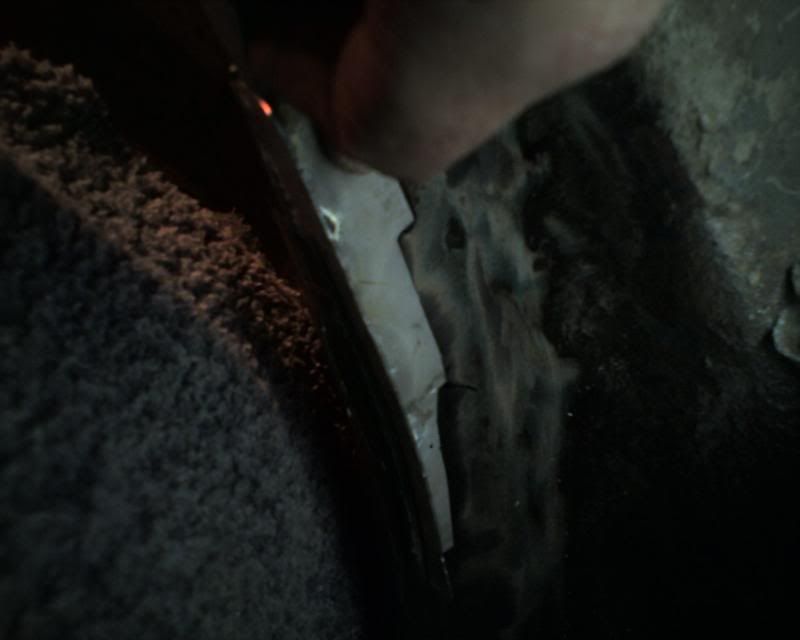

this afternoon every one else at work buggered off early, leaving me 2 1/2 hours of outdoor forklifting before i could knock off  by 5.30 i was fairly chilly  so i thought a bit of welding would warm me up  i had to do a bit of maintenance to the powerfile first. my hands were so cold i was using mole grips to pick things up, because i literally couldn't grip with my fingertips  latex gloves with cotton workgloves on top and a fondle of the kettle restored enough circulation to make a start  sill end slitted, hammered over, overlaps trimmed and tacked, holes drilled for spotwelds, spotwelded, slits welded, arch profile trimmed to size, welds ground back, previous welds flatted off a bit, zinc primer squirted and breathe....  no work in progress pics due to extreme cold      nearby there was a bit of seam bulging.  a bit of a poke reveals a bit of a hole  chop chop  floorpan flange is too far gone to save  only real bonus of the cold - underseal chips off in big chunks   chop chop and wire brush clean  flange replaced   and face ground back  coffee cup sacrificed to make a (bendy) template  why is it, as soon as i label a drawer for scissors, they all dissapear?  shape transferred to metal  trimmed to fit and tacked in  spot wed holes drilled, fully welded, ground back and flange trimmed to size  I drank coffee until i was sure the seam sealer inside the car wasn't going to burst into flames again, then called it a night  total time spent (trying not to freeze to the spot  ) 202.8 hours total spend £1495ish (still waiting for delivery of my previous 'bargains'. snow has melted what is the excuse now?  . new ebay sourced consumables are trickling in  |

| |

whats that burning smell?

oh curse word :-(

|

|

hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

wow what a flurry of sip related comments  @ @tony - i think we have discussed this before, or not  welding in subzero temps rots my brain  @ @mirafioriman - sip hobby migs may be rubbish but how come your welding is light years ahead of mine? ;D @bstardchild - thanks very much for your kind offer  . i may try a wire feed power mod on mine (if i get annoyed enough) but will soldier on for a bit yet. i also refer you to my previous answer, in that my ego needs an excuse for my shoddy welding ;D @zoompod - i have modded the feed rollers already, infact the awesome projects i came across when researching the dodgy wire feed probably started this whole bout of madness  glad to have given you a bit of mojo  . put up a build thread and pass it on  |

| |

whats that burning smell?

oh curse word :-(

|

|

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

|

|

|

|

wow what a flurry of sip related comments  It's cos they are Sh*te @bstardchild - thanks very much for your kind offer  . I may try a wire feed power mod on mine (if I get annoyed enough) but will soldier on for a bit yet. I also refer you to my previous answer, in that my ego needs an excuse for my shoddy welding ;D I remember your previous answer...... I'm driving past Stanstead tonight too but it's not far even if I had to make a special trip - even if you borrowed it to try it and see if it was an "improvement" v your own before carrying out similar modifications The really killer for SIP's is that on low settings and CO2 rather than an argoshield light mix the arc is not at all stable |

| |

|

|

|

|

|

|

|

|

Me, courting controversy? Yeah, that sounds about right.

You're brave to be working in this cold. Do you think if you put a lollipop stick in your warm coffee that when it freezes it can be an iced coffee lolly?

These latest updates make me feel bad about not going up to the garage last weekend for fear of getting stranded in the snow. Should've just braved it with a thermos flask and a shovel!

|

| |

|

|

Brigsy

Part of things

Posts: 617

|

|

|

|

|

Epic weldathon keep up the good work!

|

| |

|

|

hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

mondays update was delayed by a nice bottle of wine and dinner  tuesdays belated update was put off as I had misplaced my phone again  so todays update is a 2 for 1  monday: monday:cold temps, low life mojo and an almost empty coffee jar made everything a bit difficult  . powering on through I made a start  ignoring the crusty bits of wheelarch I gave the bottom of the rear quarter a prod  a bit too crumbly for my taste. snip snip  inner panel isn't very solid either  started to bash out a repair piece for the drain channel    I think if I had started with the coachbolt rather than the ballpien(sp?) it would be less like the schoolboy toilet graffiti I started with  I couldn't face going again so just carried on regardless  hole for ugly repair to fit into  repair hacked into roughly the right shape   blobbed into place and next bit removed   a suitable profile is found in my rapidly growing supply of discarded(and then retrieved  ) body panels (transit?)  snip snip  blob blob  by now I had completely lost the will to live and called it a day, hoping it would all be better in the morning  wednesday: wednesday:happily today the great gods of consumerism brought me a little mojo boost  factory workshop manual 99p  pair of box fans from the same seller £1.98, shame about the £13 postage.  set of nibbler dies/punches bought as a bit of a flier for my chinese no name nibbler (they fit yay  ) plus free gift 6" mini steel rule ;D  even more powerfile belts, piranha brand seem mostly useless, silverline 50% don't snap straight away   last lot were (supposedly) european and not a huge amount better. are b+d belts really worth paying 10x the price?  anyway back to the unit and a bit of belt testing later  return scribed with a grinder to the correct-ish profile  last bit replaced (top right) all ground back, pinholes filled, trimmed to size and zinc primer liberally applied   not my best effort by any stretch of the imagination  a lot more to do in this area, hopefully it will turn out better (at least the bits you can see ;D) total time spent (trying not to drop dead on the spot with depression  ) 208 hours total spend £1505ish (whirr grind flap-flap-flap ping there goes another 20p ;D also £10 on handbrake and throttle cables  ) \edit for words missing from sentences\ |

| |

Last Edit: Dec 16, 2010 11:46:40 GMT by hairymel

whats that burning smell?

oh curse word :-(

|

|

hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

bstardchild- if your ever in the area and fancy a black coffee, tesco's diet coke or a rodent nibbled mars bar, you are more than welcome  angyl- don't feel bad, i often can't even be bothered to walk the 100yards from work to my unit  Epic whinathon please learn to weld/fabricate! efa ;D |

| |

whats that burning smell?

oh curse word :-(

|

|

|

|

|

|

|

|

When I'm struggling with a project that I want to be getting on with but aren't feeling up to it, I put it away for a few days and then, to get myself all excited, absorb myself in as much of the plans and fun stuff I'm going to do as possible.

You might be ready for a break from the welding and the grinding and the cold, could well be time to play with the shiny stuff you've been getting off eBay and just have some fun imagining the end result.

Besides, this is the time of year when copious amounts of Port and Mince Pies must be consumed, ideally in front of an open fire and/or at a cosy pub.

|

| |

|

|

|

|

hairymel

Club Retro Rides Member

avatar by volksangyl

Posts: 1,081

Club RR Member Number: 207

|

|

|

|

had to pop out to get some electric and gas- they joys of card meters  i used the poor road conditions as an excuse for taking 3 hours  first job of the day was to dust off the kettle/kitchen as the mouse hole lets in snow as well!   pauls cars at the back of the unit had a fine dusting of snow as well   i then spent a while repairing my crappy 12v tyre pump. the conrod in the pump had snapped  i cut a small bit of 6mm plate, drilled holes for the big/little ends and ground it to shape. no pics as it looked scary but was better than the oem one ;D back to the car- brass wire wheeled the inner and outer arch     rest looks ok    bit of crust here and there between the seams but i think i am going to soak it in rust converter and hope for the best  cardboard template of inner arch  transferred to metal  cut out with a nibbler (only shook itself to bits once  ) bent to shape and a strip welded on at right angles. strange burning smell   will need a lot of cosmetic seam sealer on the other side   trimmed to size and marked out on inner arch  excess lip will be trimmed off after fitting  got a call ordering poppadoms and naan breads so had to go back to the shops and then home for dinner, so stopped there   i narrowed the burning smell down to my favourite cold weather working fleece   i was also a bit dirty when i went to the shops  my little girl said to me 'why do you always look scary in photos'  ;D total time spent (trying not to get angry with the ebayer who is refusing to sell me the 'project' +parts i won  ) 210 hours total spend £1505ish (not including the few braking parts just paid for and the 'next project'+bits for this) |

| |

whats that burning smell?

oh curse word :-(

|

|

|

|

|

|

|

Top work Mel,hope you enjoyed yer ruby.... ;D Have another pic.  love the Exacton alloys...i'll get my anorak........ ;D |

| |

|

|

|

|

|

Dec 19, 2010 10:23:07 GMT

|

Mel, I've read through this thread a couple of times now. If I wore a hat I'd tip it to ya.  Your efforts and will to carry on with this project are nothing short of unbelievable. Who would take on such a poor base car that is not only badly rusted but bashed, abused and welded/plated up for motorsport? TBH, the base car was utter wibblepoo, the vast majority of us wouldn't have given it a second look and sidestepped it as a possible project. You however have taken it by the scruff of the neck and despite working in far from ideal freezing conditions have continued to produce some fantastic repair work and are well on the way to turning this car round. Absolutely amazing work mate. Keep us updated Mel, this is a fantastic build thread. Good luck with it mate. Cheers, Richard. |

| |

|

|

|

|

)

)

)

)

. new ebay sourced consumables are trickling in

. new ebay sourced consumables are trickling in

.

.