remmoc

Part of things

Posts: 931

|

|

Dec 19, 2016 18:48:11 GMT

|

Long time no update . Still a few bits have been done - well one actually . With the intergalactic mileage this has done stuff that should last a cars lifetime are gradually wearing out . One such thing is the throttle pedal which had 5mm of play in it and clunked about all over the shop. The idea i has was to fit oilite bushes and eventally i found some suitable from a Briggs and Stratton lawnmower The original pedal pivot idea is totally pants if I'm honest , just a 2mm thick hole in the mounting plates  Bush fit was perfect - you can see the wear groove in this shot  so i made up and welded up some bush holders - holes are for oiling the erm oilite bushes  Then hack the pedal in half - make a threaded joiner - thread the two halves of the pedal - thread lock - locking washers and double locknuts mean its not coming undone without a fight - i could alter the pedal position using this but decided against the idea - I could of welded it together but its threaded so the bushes can be replaced if needed  it fits like so - zero clunking or play and very smooth - well happy with it now   |

| |

Last Edit: Dec 19, 2016 18:51:06 GMT by remmoc

|

|

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 28, 2017 20:48:13 GMT

|

Not done masses as usual but this now has a full stainless exhaust system . Manifold made in Australia and the box and tailpipe from a well known auction site .  |

| |

Last Edit: Apr 22, 2017 17:07:14 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Mar 19, 2017 15:22:02 GMT

|

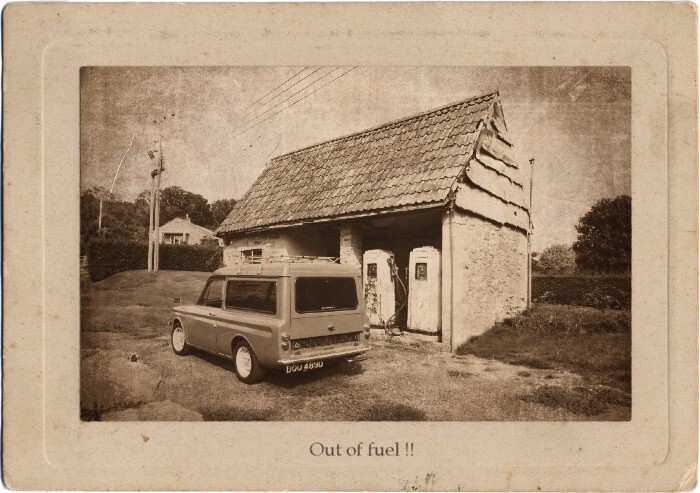

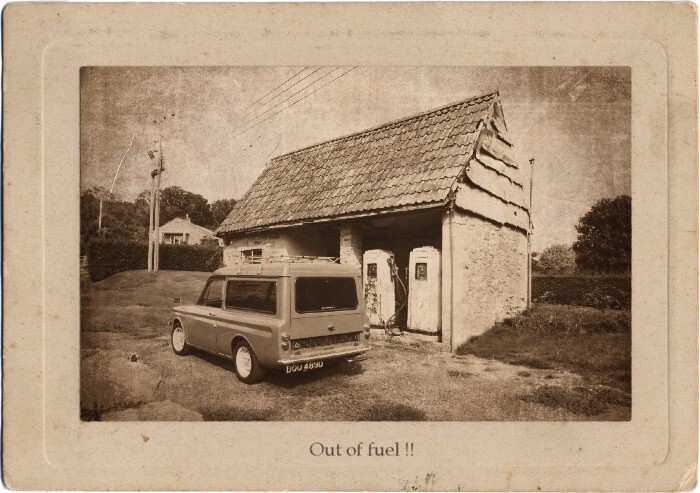

Not done much to this of late except use it - get it covered in mud and generally abuse the poor thing . Apart from some alterations to the throttle linkage due to the new zorst manifold getting in the way its been utterly reliable.A pic i found which dates back to 92 or 93 when it was that hideous Caribbean blue colour someone had troweled on .  |

| |

Last Edit: Apr 15, 2017 18:11:06 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Apr 22, 2017 17:19:18 GMT

|

Well another month has gone by . It passed its MOT last month with only the customary oil leak advisory - the only way this wouldnt leak oil is if i drained it all out so i consider it normal .  Again ive not done much although the passenger door started to sound like a 16th century barn door when opened so a squirt of oil and grease eventually shut that up . In fact i got carried away and squirted oil in every lock and hinge on it - much of which ran out down the doors and onto the garage floor . Need to sort the steering rack out Pronto as its stopped leaking and started haemorrhaging so thats the next plan of attack i guess. Some pics from a trip to Lulworth cove last month . My beloved getting ready to face the cold outside  Ringstead bay overlooking Weymouth and Portland - Portland is the grey lump of land behind    |

| |

Last Edit: Apr 22, 2017 17:23:57 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Aug 24, 2017 21:13:52 GMT

|

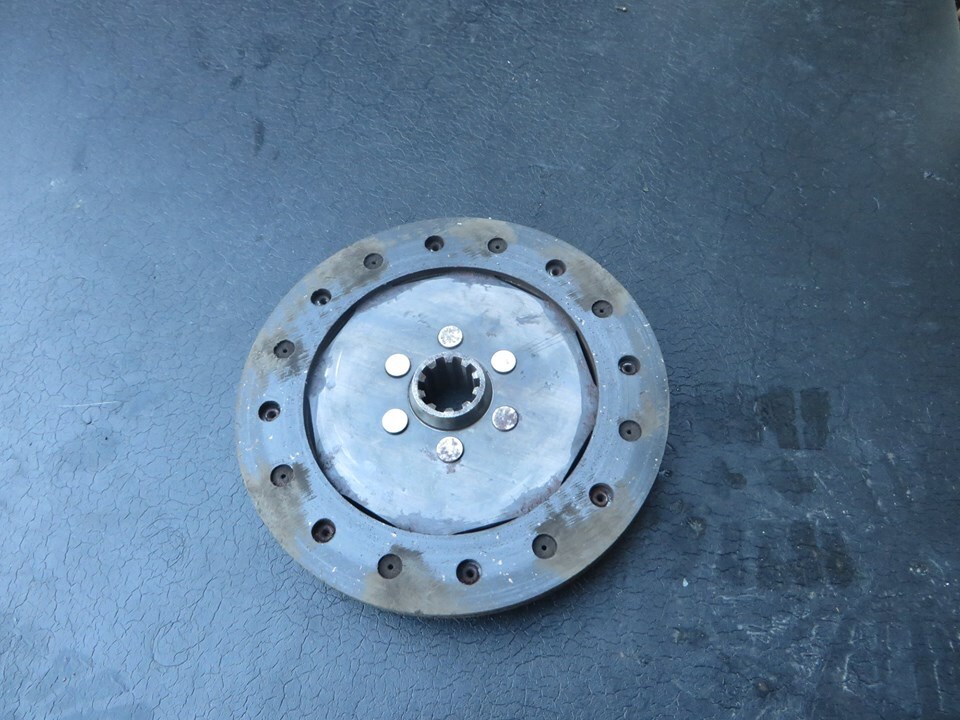

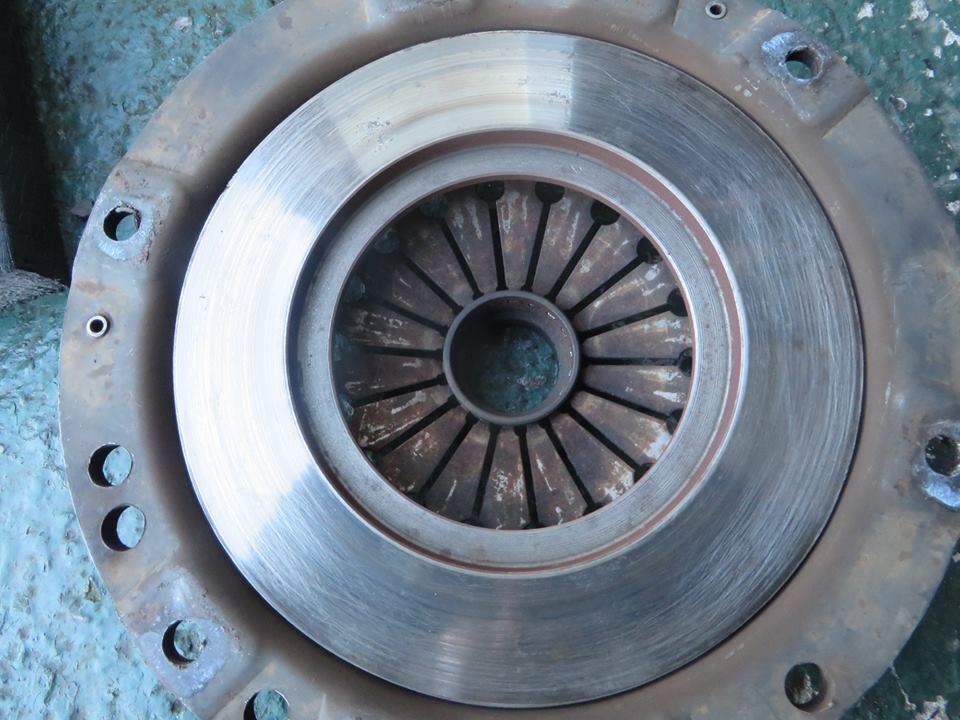

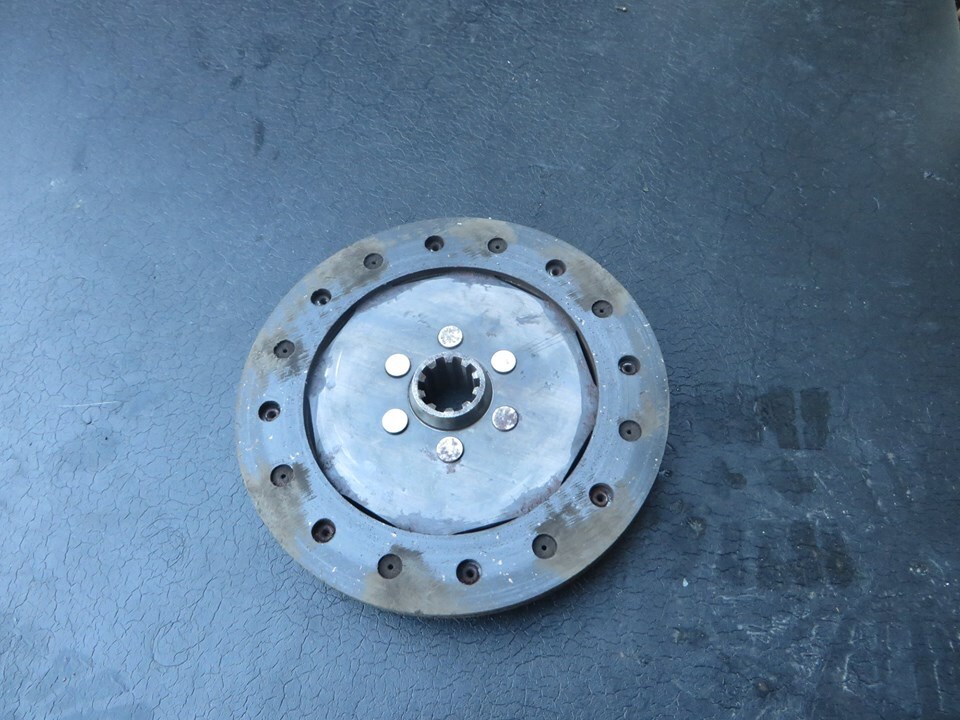

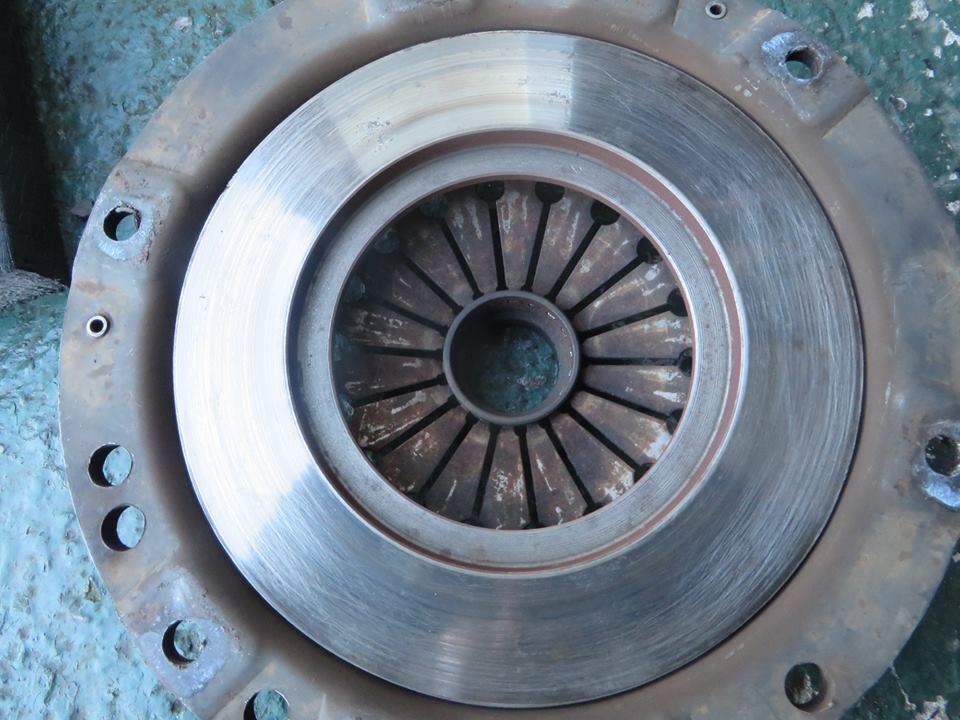

Well it ate its clutch although to be fair it did keep moving and only three weeks ago went to Kent and back on a 400 mile drive fully loaded. So out with the engine and box   Thrust carbon bearing was royally worn - i last had the engine out 12 years ag so cant complain  Should look like this  Pressure plate is also knackered  So more expense and more work to do .  |

| |

Last Edit: Aug 24, 2017 21:16:10 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Aug 26, 2017 18:16:22 GMT

|

New clutch in and working along with a fully rebuilt transaxle i had - done just over 100 miles so far and its all good . As you all like pics heres a few from todays trip out    And finally an arty farty one at a local very disused petrol station  |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Nov 18, 2017 18:35:13 GMT

|

|

Well the new transaxle turned out to be not so good , 1st was real hard to find as was reverse , added to which the clutch judder was horrible especially changing down and quite frankly terrible going from 4th to 3rd .

So it all got hoofed out yet again , i refitted the old box , a new flywheel , another new driven plate , another cover and guess what --- it still judders but only when pulling away this time and not changing down so slightly better

the rebuilt transaxles gone back for a sort out and since then apart from a few runs out its more or less been abandoned and dumped in the garage in disgrace

|

| |

Last Edit: Nov 18, 2017 18:38:15 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Nov 18, 2017 18:37:56 GMT

|

A pic of it in happier times covered in mud  |

| |

Last Edit: Nov 18, 2017 18:38:46 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

|

|

Still not fixed - still waiting for the transaxle to come back. It still drives though as the old ones back in - we think the input shaft is worn , both the new one and the old one fitted both have loads of spline wear . Engines running rather well though and if you give it some spirited revs pulling away it doesnt judder . Anyway its still alive if rather unused I have at least washed the mud off it  |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

|

|

Well even though the cluch isnt working right ive splashed out on two new front tyres The old ones whilst still having a fair bit of usable tread left had reached ten years old . I never run tyres past this regardless of condition or tread left . These were cracking anyway so had to go . I ve fitted Yokohama A539s to match the rears already on it although the rears are 185/60/13s and the fronts 175/60/13 . Its run this odd size combo for decades and its suits the cars handling and suspension set up plus theres zero scrub on the inner arch on lock you can sometimes get with 185s on the front .     |

| |

|

|

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 10, 2018 19:55:26 GMT

|

|

In an effort to sort the clutch out theres now the thought that excessive play in the input shaft splines might be the cause - driven plate is very slack on the shaft with about 10mm movement rocking it back and forth - well ive tried everything else ,

So a known working transaxle will soon be on its way from Scotland .

If this doesnt work i can see me torching the thing

Wish it and me some luck - i need it

|

| |

Last Edit: Jan 10, 2018 19:56:44 GMT by remmoc

|

|

düdo

Part of things

wide as house

wide as house

Posts: 770

|

|

Jan 10, 2018 20:14:19 GMT

|

|

If you torch it - as threatened - it will be like torching yourself after twenty five years of marriage to the thing! I think it's great and well done for keeping at it

A bloke on the street where I grew up had a blue one like this but it was called a Hillman Husky. Car is long gone but bloke is still there as spotted on a recent visit to my parents and I don't think I'd seen him since the 70s and he looked a bit different. I still had that kid's image of him in his Husky.

|

| |

|

|

vader

Part of things

Posts: 425  Club RR Member Number: 93

Club RR Member Number: 93

|

|

Jan 10, 2018 20:33:20 GMT

|

|

Hi, re your clutch judder. We Stag owners can suffer the same problem if the gearbox isn’t aligned properly, I know it’s sounds easy with an alignment tool but there aren’t any dowels on a stag box/engine. Just wondered if this may be your Imps problem too?

|

| |

Triumph Stag

Ducati Supersport

Shanks’s Pony

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 10, 2018 21:13:23 GMT

|

Hi, re your clutch judder. We Stag owners can suffer the same problem if the gearbox isn’t aligned properly, I know it’s sounds easy with an alignment tool but there aren’t any dowels on a stag box/engine. Just wondered if this may be your Imps problem too? thanks for the suggestion  Flywheels have two dowels so they are OK in that respect as do the engine / bellhousing - never had this seemingly unsolvable judder before and ive done a fair few Imp clutches in my time |

| |

Last Edit: Jan 10, 2018 21:15:16 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 20, 2018 17:48:34 GMT

|

In a frantic " lets just rip the feckin thing to bits " kind of way and dosed up to the armpits in pain killers Ive ripped the engine and box out in 1 hour 40 minutes . There isnt ---- Any contamination , driven plate is dry . Spigot bush is fine , flywheel centre is dry so nothing getting through the flywheel bolts or leaking out the spigot bush . Pressure plate surface looks fine - centre has no play or rattly fingers fitted or not fitted . There is ---- A distinct mark where it looks like the driven plate is grabbing the flywheel . The clips that hold the thrust bearing in were no longer on the arm= and although there was a slight rattle the slave does hold it in place - il reserve judgement as to wether this is the cause or not - after all the springs don't exactly hold it tight . I found one behind the flywheel Logic says if the pressure plate contact surface looks fine and the flywheel one does not then A -- The driven plate must be ok on one side at least and B --- the flywheel might be at fault or the driven plate is wonky on the flywheel side - I'm clutching at straws now ( get it ) Not even bedded in  tother side  Pressure plate surface looks perfect  Flywheel side looks weird , strange marks between 11 oclock and 3 oclock  Thrust bearing spring shouldnt be here  |

| |

Last Edit: Jan 20, 2018 17:49:16 GMT by remmoc

|

|

|

|

|

Jan 20, 2018 18:18:46 GMT

|

|

Never been a fan of Imps but that's a good looking ride, the marks on the flywheel look like burn marks almost as if your not getting even pressure from the cover?

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 20, 2018 18:20:48 GMT

|

Never been a fan of Imps but that's a good looking ride, the marks on the flywheel look like burn marks almost as if your not getting even pressure from the cover? Thanks for your liking it , something is definitely not right - not sure what though |

| |

|

|

|

|

|

Jan 20, 2018 18:25:13 GMT

|

|

Infact the clutch cover fixing hole at the 2 oclock position does not look right at all or is it just the picture?

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 20, 2018 18:34:02 GMT

|

Infact the clutch cover fixing hole at the 2 oclock position does not look right at all or is it just the picture? Its threadloc i think ( just semi permanent stuff ) , thread was fine and the bolt tight |

| |

|

|

raumer

Part of things

Posts: 138

|

|

Jan 20, 2018 19:19:07 GMT

|

|

How well does the plate slide on the input shaft splines? I've put a small amount of grease between the two before to make sure it operated smoothly. The thrust bearing spring being off I've found causes an annoying rattle but doesn't change how the clutch operates. Probably worth putting the pressure plate on a sheet of glass to check if it is 100% flat. Could always try a flat edge on the flywheel as well. Only other thought is how old is the clutch plate? It looks good but wonder if it has had a storage issue of some form. Apologies if I've missed you doing any of those already or teaching grandmother to suck eggs!

Another slightly odd thought - are the gearbox mounts good? Wonder if them going could cause a similar effect?

Ed

|

| |

Mine: 1938 Scammell Pioneer R100, 1944 Scammell Pioneer SV2/S, 1959 Kraz 255b tractor unit, 1960 Unipower Industrial ballast tractor, 1960 88 Landrover Series 2 SWB, 1983 110 Landrover CSW

Look after:

1935 Scammell Rigid 6, 1951 Scammell Scarab, 1961 Landrover Prototype, 1985 Landrover 110

|

|

|

|