|

|

|

Aug 31, 2018 13:13:16 GMT

|

|

really top work on the minutia!

I have roughly a 50/50 success rate with worn out motors and things of that nature. rewinding was never a thought!

well done

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

Aug 31, 2018 16:10:40 GMT

|

|

Nice work, Its great to know there are still firms in the UK doing the rewind stuff!

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Aug 31, 2018 16:19:08 GMT

|

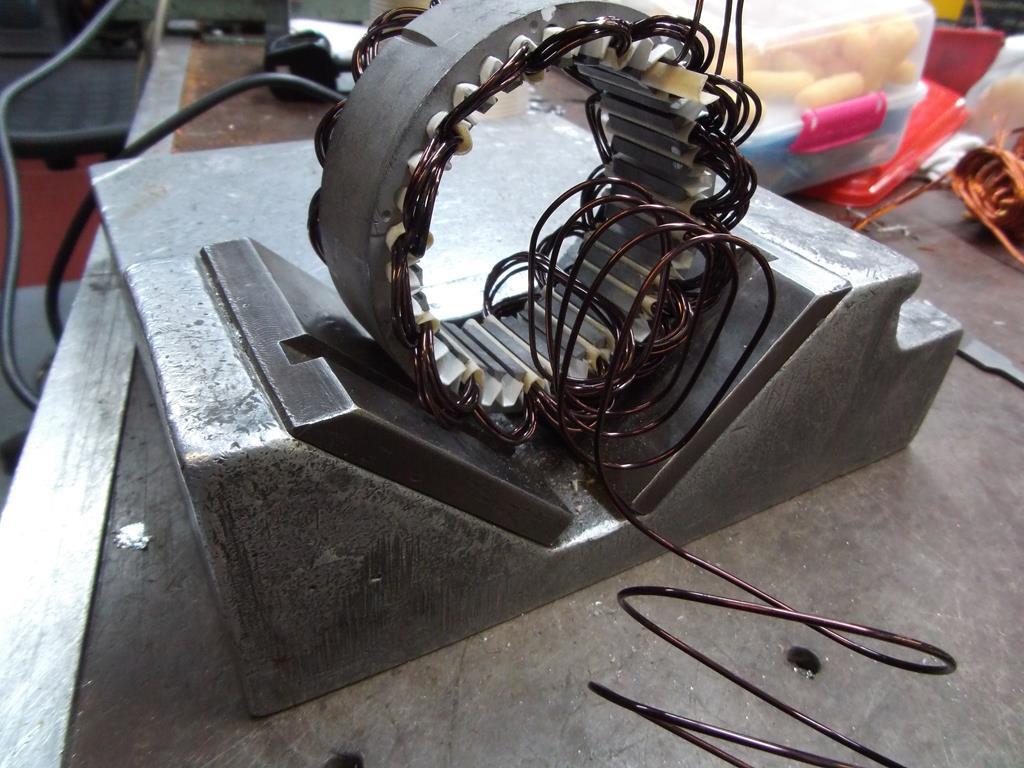

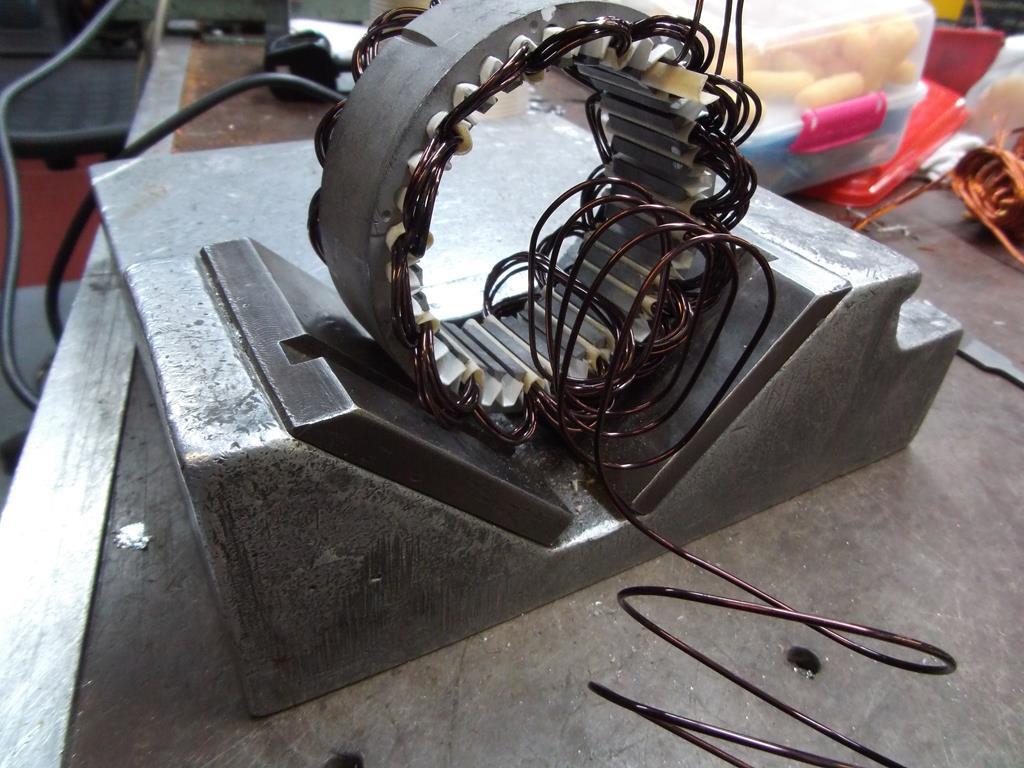

really top work on the minutia! I have roughly a 50/50 success rate with worn out motors and things of that nature. rewinding was never a thought! well done JP Its handy having this as a job , ive also altered the output of the Denso alternator by rewinding it , this only gives 5A more ( 45A instead of the usual 40A ) but the output curve is very steep so it produces 16A at 1000RPM ( alternator revs not engine ) - and the maximum output at just 3,200RPM - handy when stuck in traffic with the lights / heater fan / indicators on etc  , also fitted flexi leads out for anti vibration Heres the process in case your interested Old stator ready for stripping  Done by torching it to death after cutting one end off   You end up with this mess   Sandblasted and stripped out ready for rewind  Coils made on here  Insulations fitted and coils made  Coils going in - all fitted by hand   After winding and fitting the leads its then tied , varnished and cooked for 10 hours at 160˚C , finally sprayed up just for looks  Fits in here , case is cleaned up first though  |

| |

Last Edit: Aug 31, 2018 16:35:36 GMT by remmoc

|

|

|

|

|

|

|

|

Good work, its nice to know there are still some jobs that take care and skill, you wont get a Robot to do that job!

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Sept 1, 2018 17:53:34 GMT

|

New rad seems to be coping rather well Steady 70 ish (  ) for 7 miles without backing off got the temp gauge as far as the middle so thats 83˚C according to previous tests ive done - heater was OFF . Ambient temperature 23˚C . I recon thats OK Checked the plug colours after that blast - ( turned off when moving and rolling to a stop ) checked number 2 and 4 Number 2  Number 4 - given that these carbs were set up by me I'm quite chuffed   |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Sept 9, 2018 16:43:24 GMT

|

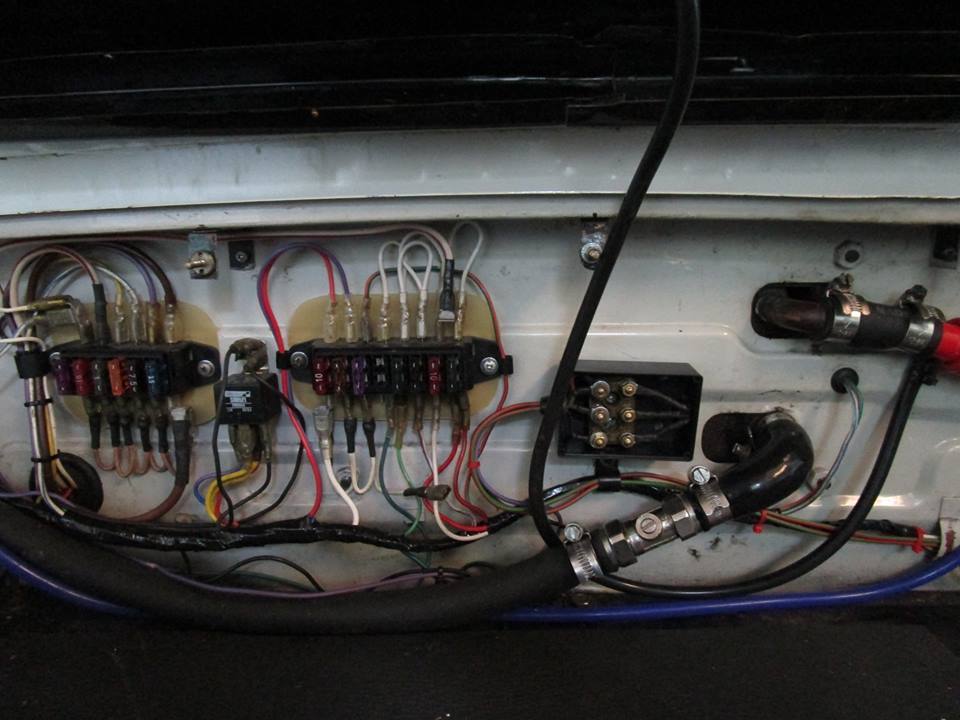

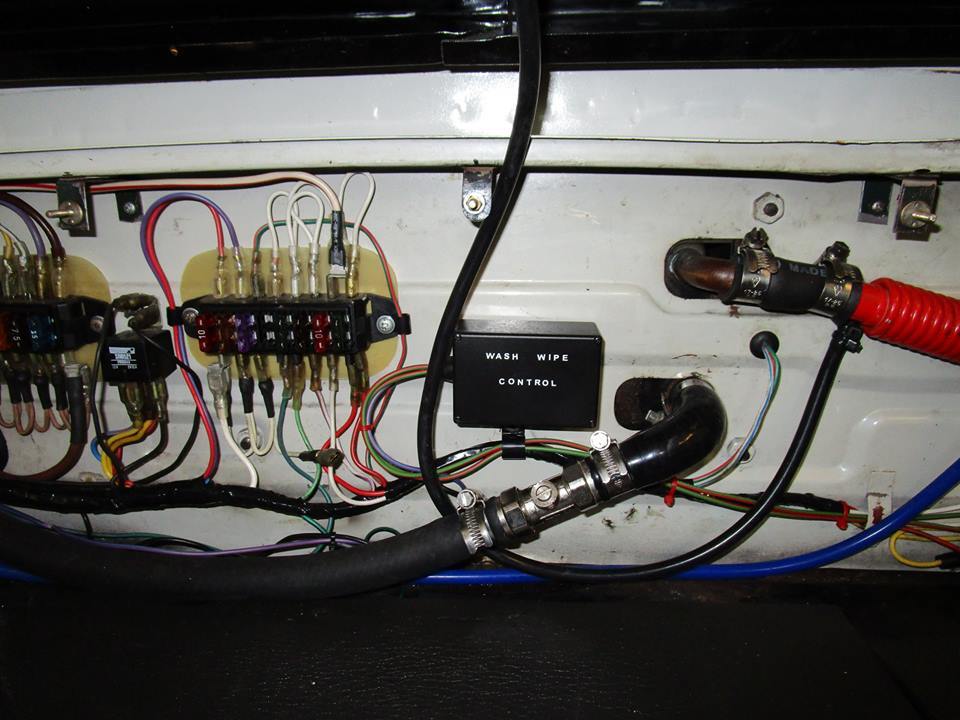

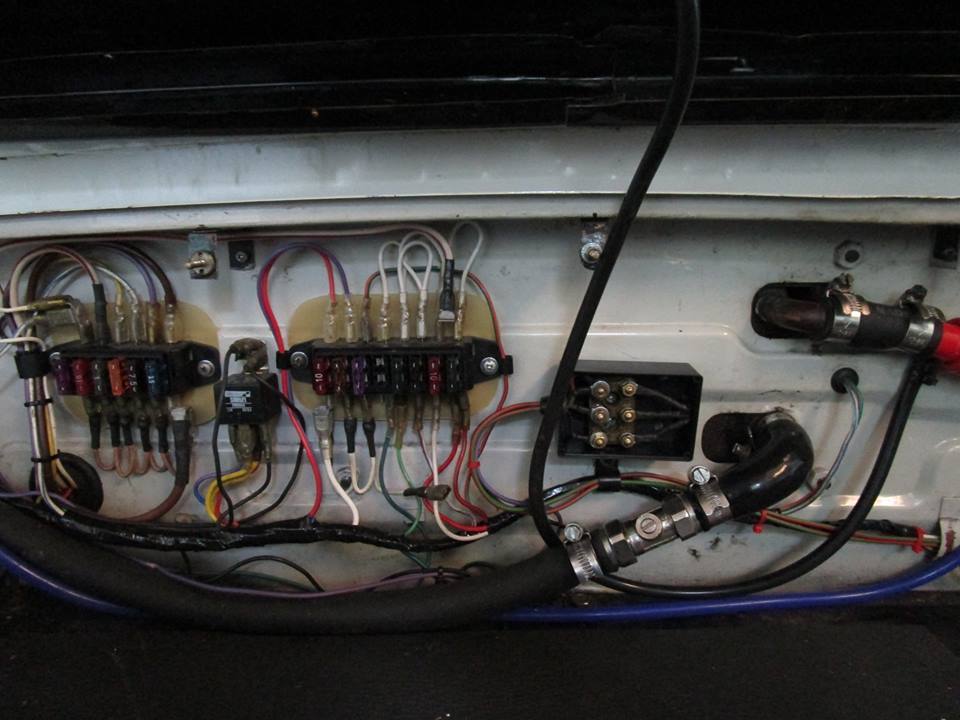

A quick last minute change of plan re. the gauge wiring has meant instead of using two fuses the Volt , Temperature and Fuel gauges now all run from one fuse meaning the spare is still spare . Fuse box cover now labelled with the new set up.  |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Sept 17, 2018 16:11:00 GMT

|

Did 177 miles in this over the weekend . Ran perfectly , no oil used , no water used , temp sat at 82˚C even after 19 miles at a steady 70MPH on the A303 . It was on a small but important mission taking a groom and best man to my stepdaughters wedding . Some pics for you all.     |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Sept 22, 2018 13:13:12 GMT

|

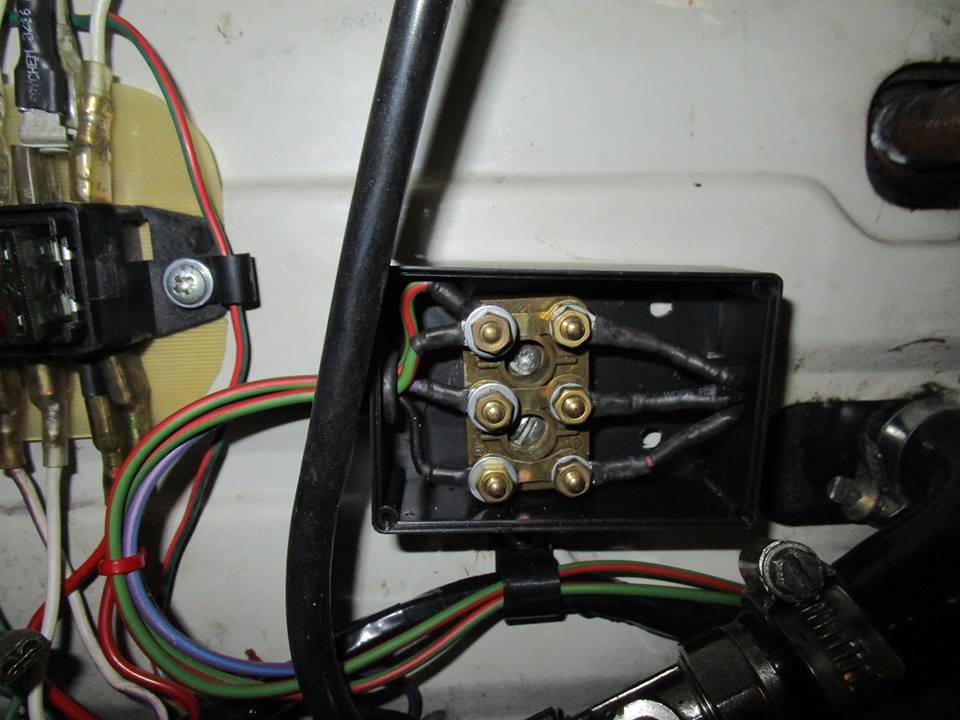

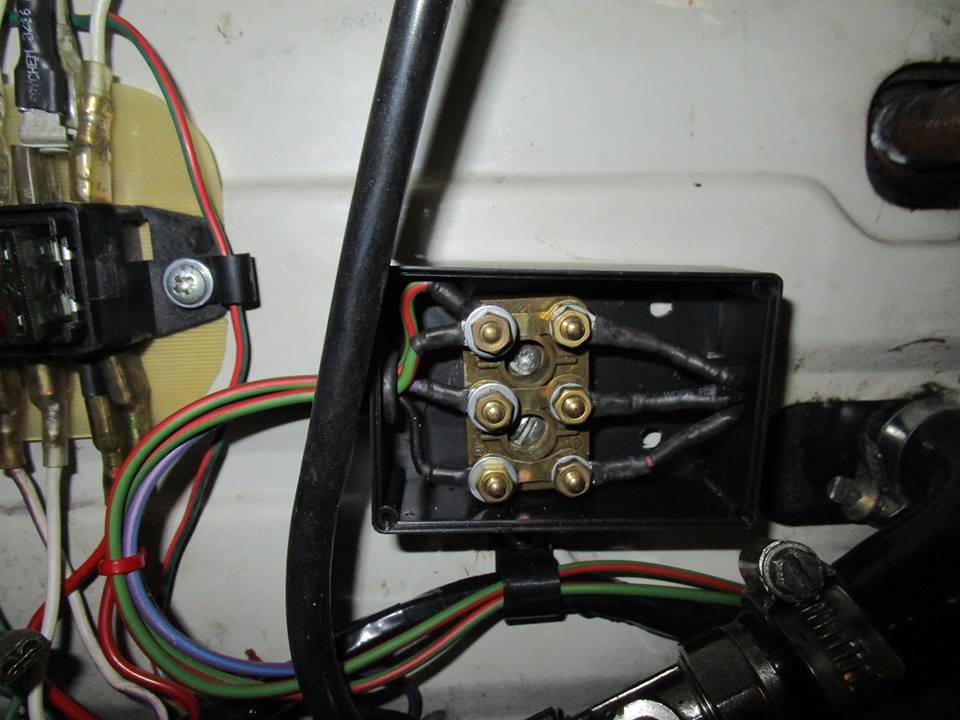

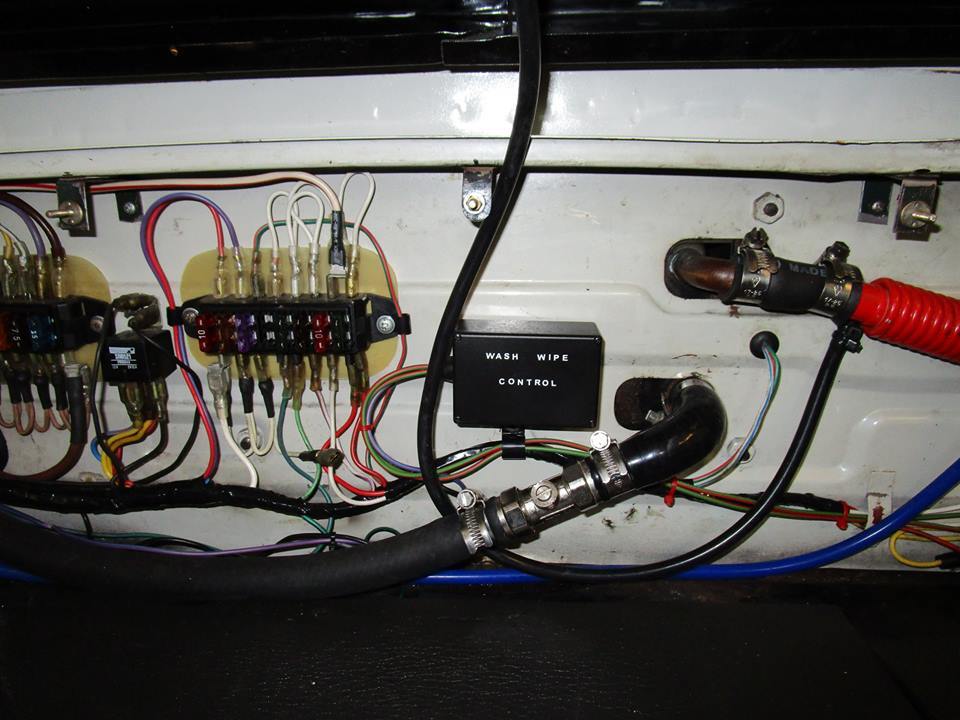

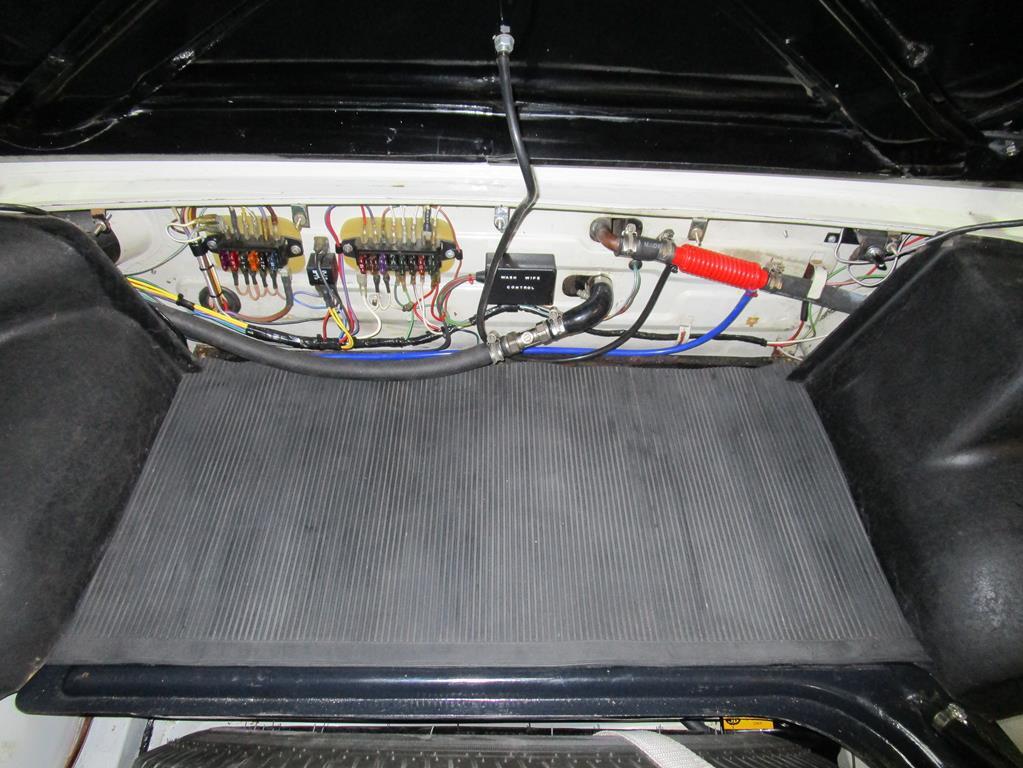

So more wiring alterations , , ive done both Imps the same . Basically ive altered the electric washers so every time these are operated the wipers wipe one full cycle even if the washer switch is released . wipers operate as normal without the washers . As the washers are instant and the wipers have a 1/2 second delay by default ( something to do with the field coil ) theres no chance of the wipers going up the screen dry . Best part is the part required only cost £2     |

| |

Last Edit: Sept 22, 2018 13:28:37 GMT by remmoc

|

|

|

|

|

Sept 22, 2018 18:23:03 GMT

|

|

Very neat indeed!

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Nov 14, 2018 19:41:19 GMT

|

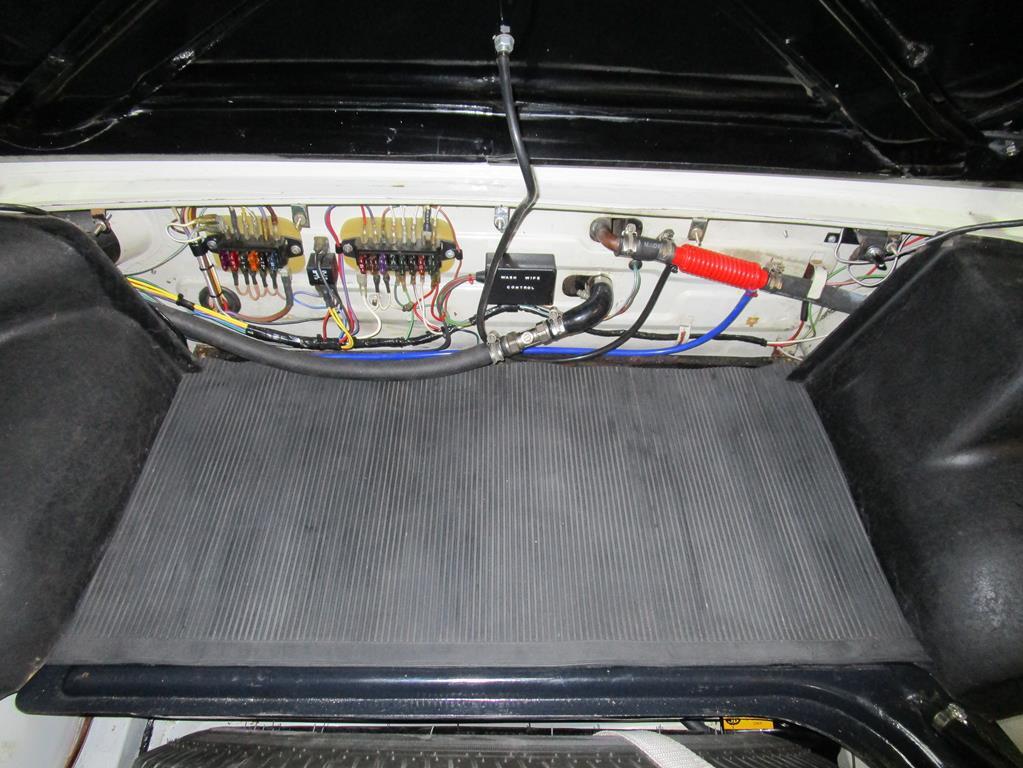

Ages ago i replaced the card boot centre on this with new however with the continued cycle of damp , then heat / cold etc it kept warping . I tried various ideas to stop it but i guess being a natural product it was bound to distort just like the factory millboard did . A rethink was needed and I decided early on not to do the centre part as one piece as the factory did but in two bits , a back and a base . I replaced the back with some highly flexible fibreglass sprayed black which wont distort no matter what the weather or temperature does to it . For the base i used some factory rubber mat thats usually used behind the rear seat on the shelf. Pictures say 1000 words so here they are As it was , this was just after it was fitted , sadly it didnt stay flat for long  Mill board removed , i filled the tank grooves with thick closed cell foam to get a level base for the rubber mat  Base in , rubber mat now extended almost to the bulkhead , the idea being the back board when fitted would pin it in place  1.6MM thick flexi fibreglass back all cut out ready for fitting  Board now fitted , rubber mat is covered by a Mopar fender protector cut down for shows etc but normally theres just the rubber mat in there   |

| |

Last Edit: Nov 14, 2018 19:46:27 GMT by remmoc

|

|

|

|

remmoc

Part of things

Posts: 931

|

|

Dec 21, 2018 18:39:24 GMT

|

This has reached 19,721 days old , in other words it came off the line 54 years ago . Well the shell and some of the paint did . Just about everything else has been changed , altered or just isnt there anymore   |

| |

Last Edit: Dec 21, 2018 18:40:02 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Jan 30, 2019 20:26:53 GMT

|

Apart from total lack of use and time resulting in a now very flat battery which ive got to replace ive done a few small things to this First off ive referbed my home made " well it kind of fits in " high level brake light     I also cracked my export all amber front indicator lenses , these are for a late car anyway and much shallower with a domed indicator part ( L792 ) Unfortunately theres no such thing as the early deep lenses in all Amber ( L717 ) . However by cutting up two pairs of amber indicator lenses i managed to make my own , bonding the two together using all weather translucent silicon Chop this bit out of each lens  Trim true and bond together  Gives you this . Sidelights are now in the headlights so the factory sidelight position is redundant . Figured id turn them into small amber running lights  L792 ive replaced  What an L717 should look like  |

| |

Last Edit: Jan 30, 2019 20:41:29 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

Feb 16, 2019 19:30:42 GMT

|

In an effort to get the heater more efficient years ago i fitted a 3 inch bilge blower meant for boats which replaced the wheezy factory effort . One thing that does restrict air flow is the front air intake grill , slots are narrow however they can be twisted to make the gaps wider. Time will tell it it helps , ive twisted them so air gaps are double in size but doesnt overly show looking at it New grill with twisted slats painted ready for fitting  The original  And again , not much gap for air  New twisted one  And a close up  No real difference looks wise  |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

|

|

Not much has happened lately as ive been too busy sorting out the Commer . However a trip out tother week proved its all running perfectly. Heater is slightly better with the new twisted grill however it is running too cool so i need an 82˚ or 88˚ stat as the summer one fitted ( 72˚ ) is way too cold .  |

| |

|

|

|

|

|

|

|

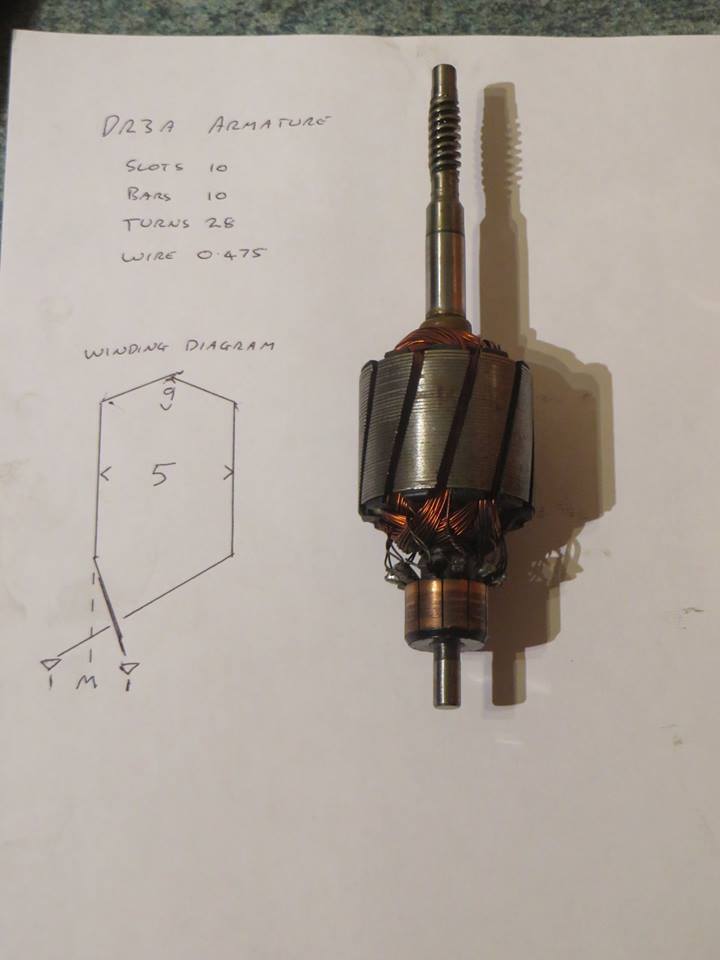

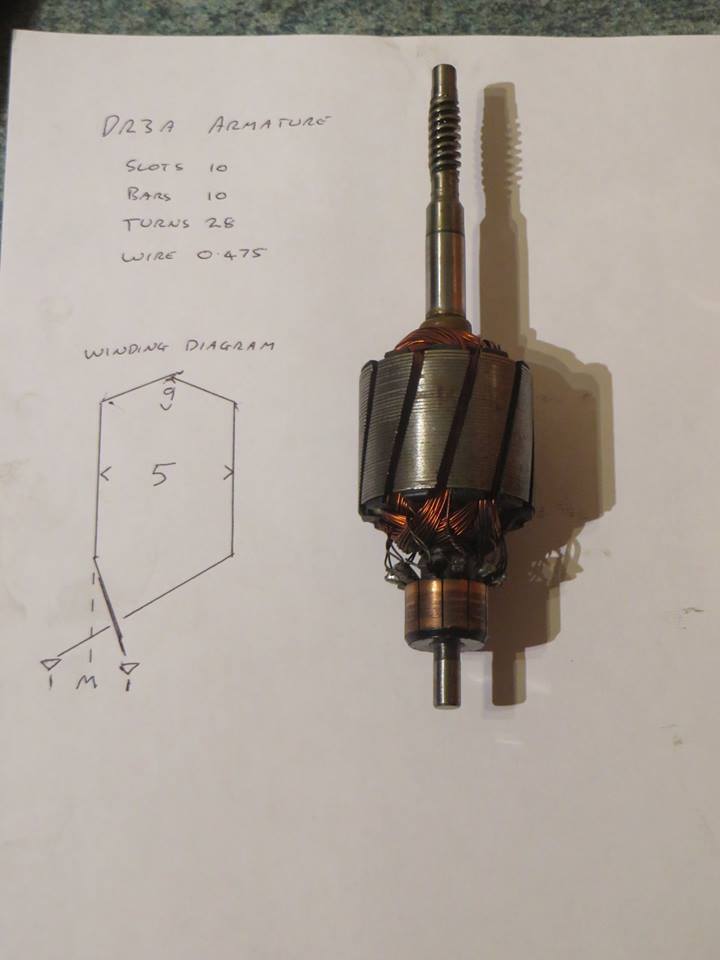

This is remarkable 👍🏻 I’d been wondering if this was possible for my Lucas CW2 wipers, which are both slow and lack torque. Fixing those two things would go a very long way to making it a more useable car. Are there companies, yours?, that would do this as a service? Stephen Well the wipers on this has always been a bit slow , with the new speed blades fitted they do actually wipe the screen well but its all a bit slow . I could fit 2 speed from a Maxi but that involves finding a motor , altering the internal gears and fining the right switch . Seeing as i work for a rewind company a plan was hatched to rewind the armature for more torque and maybe a bit more speed , the problem has been they wipe fine in really heavy rain but the drag on the blades during a drizzle is such that they are quite slow . Anyway a spec was eventually drawn up after getting the original Lucas one , armature rewound and fitted in . Its slightly quicker but more importantly they don't slow down much even if the screen is dry . Armature before rewind with Lucas spec  Now rewound  |

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Mar 10, 2019 10:54:36 GMT

|

This is remarkable 👍🏻 I’d been wondering if this was possible for my Lucas CW2 wipers, which are both slow and lack torque. Fixing those two things would go a very long way to making it a more useable car. Are there companies, yours?, that would do this as a service? Thanks  I tried a few different specs before getting anywhere because although they all worked there was no improvement or it made it worst . each trial wind takes 1 1/2 to 2 hours plus refitting and testing . Its all a massive black art and over the years weve discovered that theory of what should work better isnt always the case . So yes i guess anything is possible and yes I / we could strip your motor out , take the spec , try a few different windings but sadly that costs money and with no absolute guarantee of a big improvement its not something we normally do . I'm lucky as i don't charge myself labour and the company don't mind me doing my own during lunch . A good full service of your CW2 might well improve things without the need for rewinding , grease gets sticky and solid over the years , brushes wear , comm gets dirty etc etc so as a first port of call id try this and see what state yours is in . |

| |

|

|

|

|

|

Mar 10, 2019 20:58:46 GMT

|

|

Thank you ! I’ve just rebuilt the mechanicals with fresh grease. I’ll see how I can live with them - but now I know this is possible I might PM you at some point 😊

Thanks for sharing !

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

|

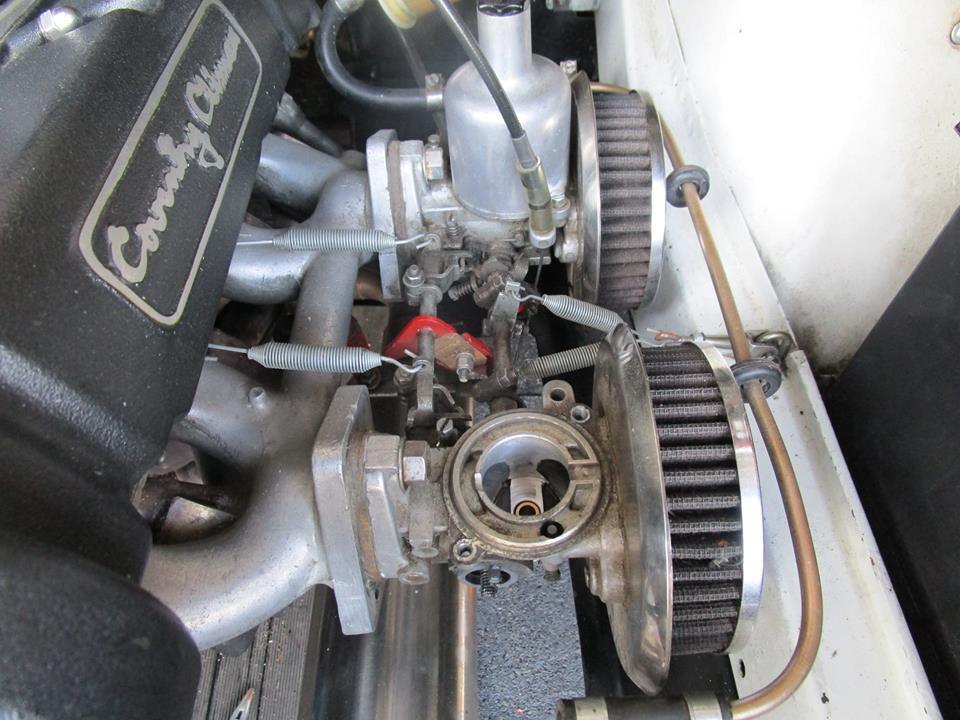

|

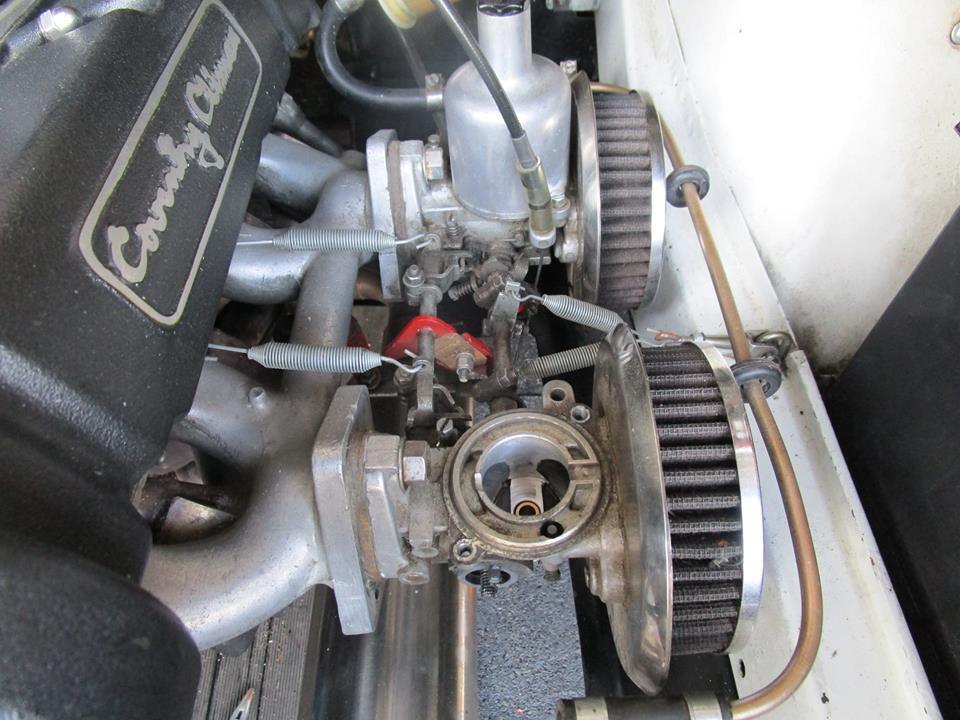

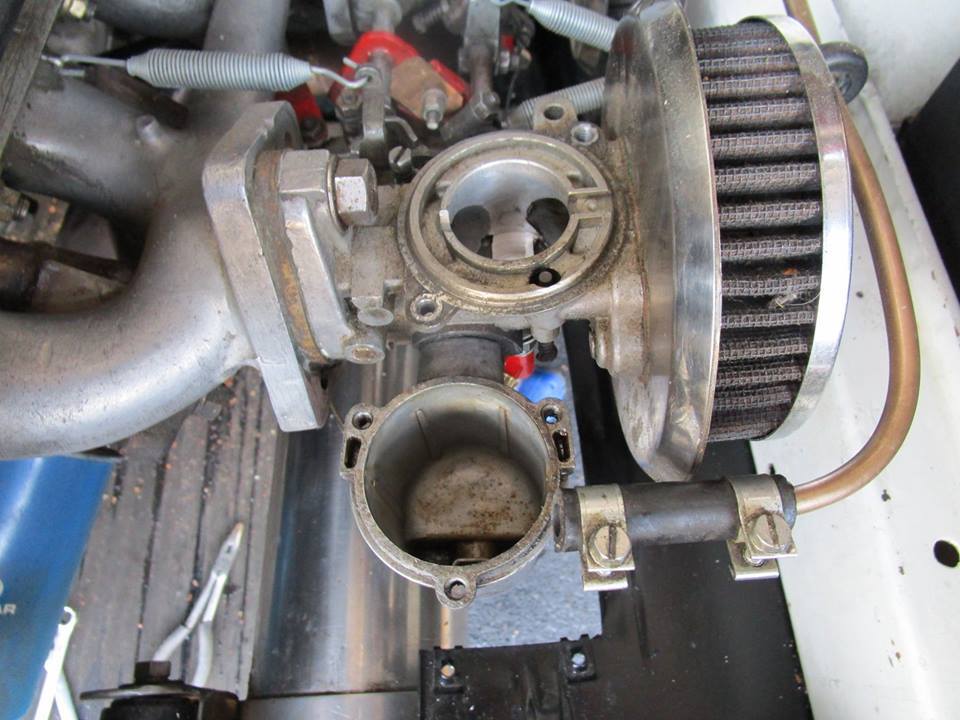

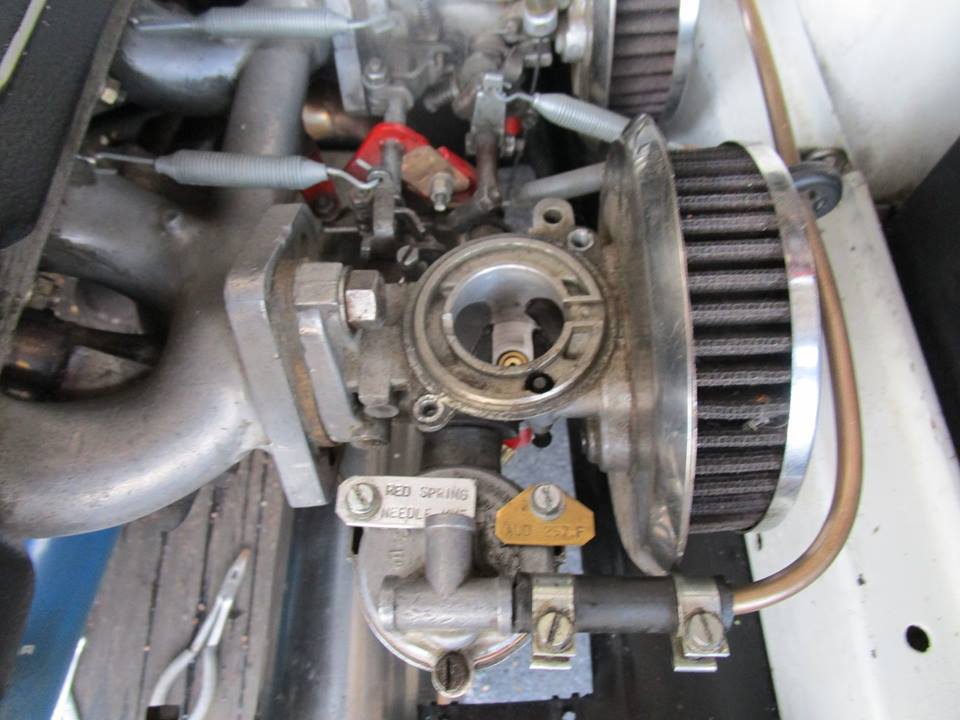

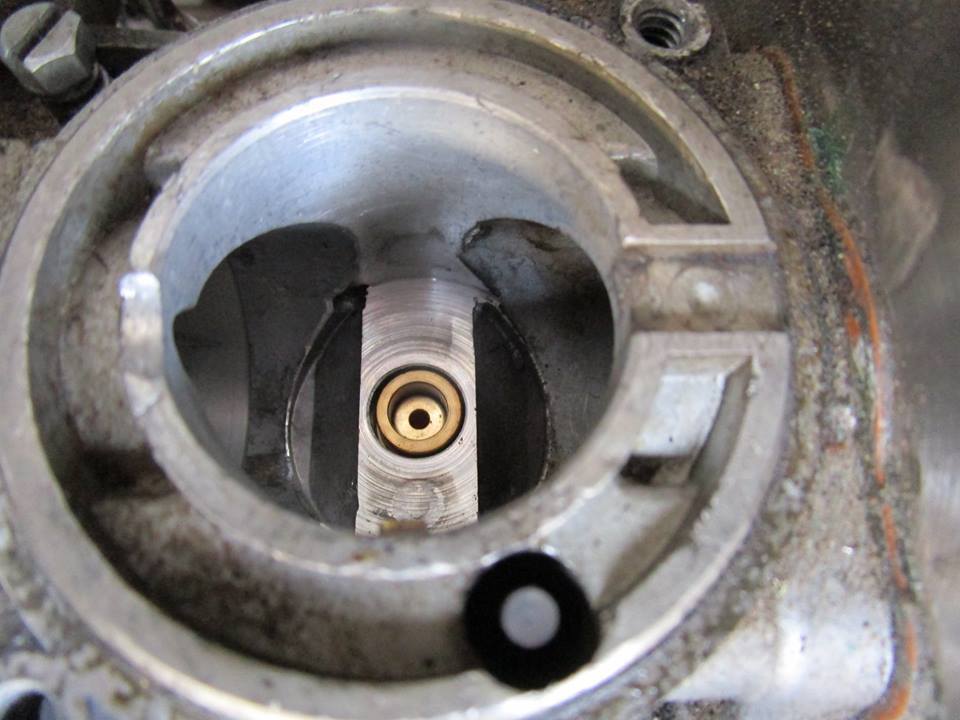

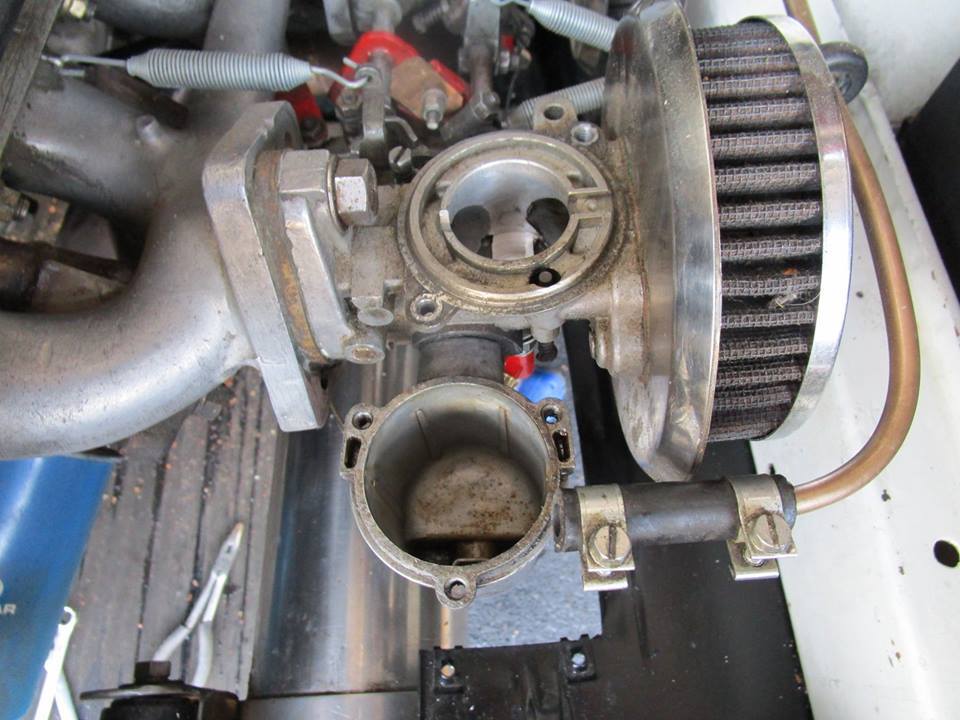

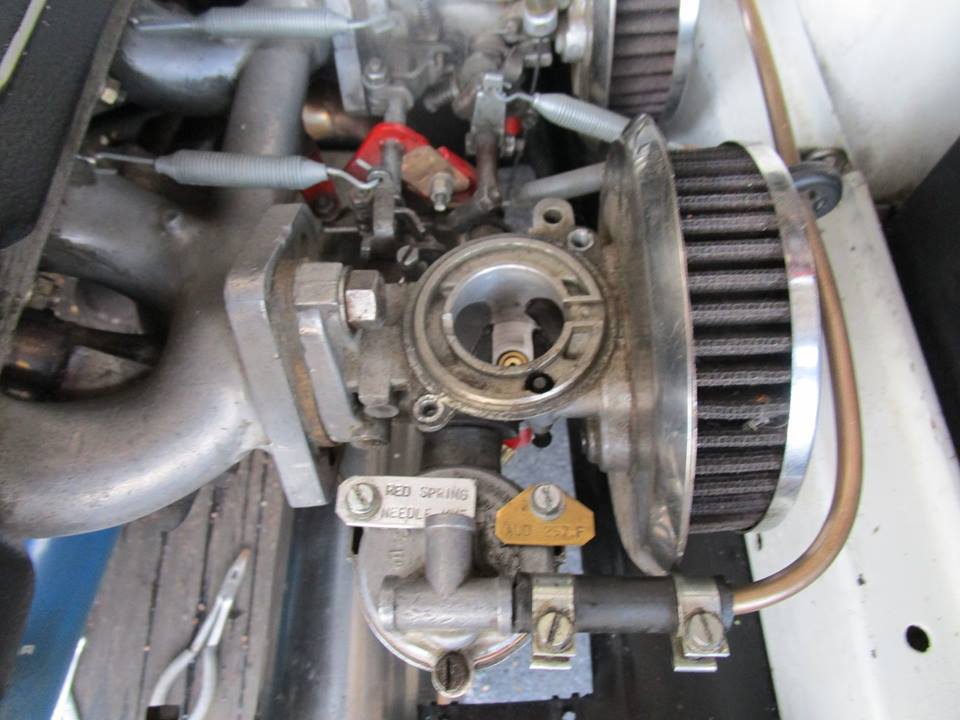

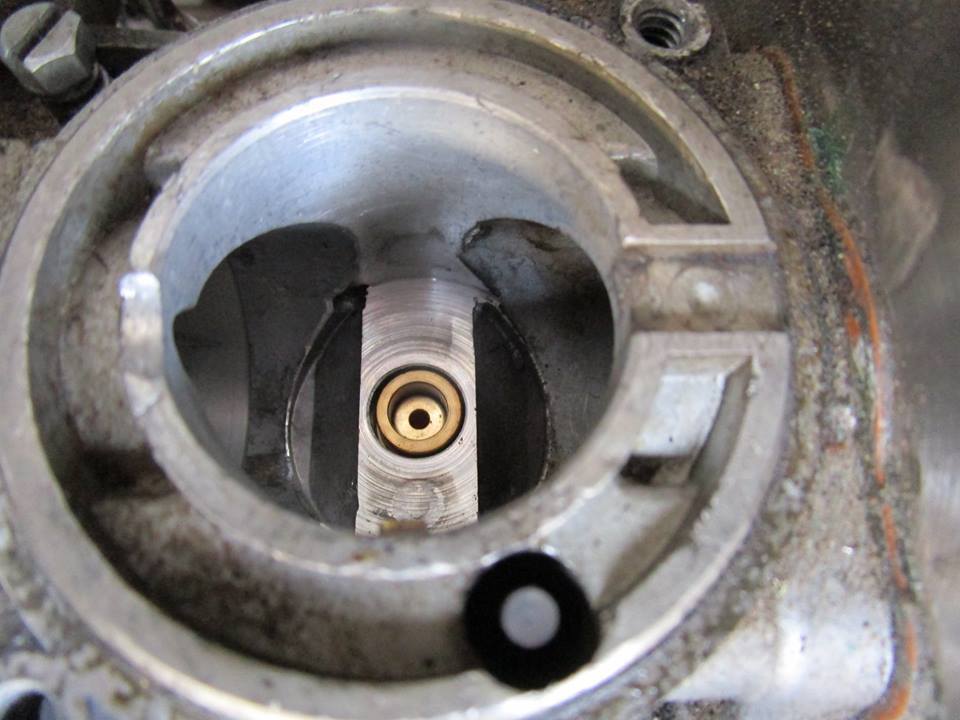

I swear my two Imps talk to each other . Tother week the SUs on the Commer went a bit tits up. Guess whats happened to the Singer .    OK so its only a leaky jet where it screws into the float bowl and for some totally unknown reason a piston is a bit sticky on the front carb but still ---- I wish the sodding things spoke a different language to each other . Feckin things do my bonce in sometimes  Still its time to sort the Singers carbs out , twas the one nearest the rear causing all the issues . Piston was slightly sticky in one spot just above tickover , i changed the pot which solved that instantly although i cant see whats wrong with said pot .  Fuel leak turned out not to be the jet or its seal but the float chamber which has a damaged thread , luckily its easy to change that in situ so i fitted a spare i had plus a new jet and seal at the same time.  Easy fix come the end , just a few hours faffing about . I guess seeing as the carbs have been on over ten years and are basically made of spare bits i cant complain , a new set is £400 which i just don't have at present , however seeing as it seems OK again il live with it .  All in bits , float chamber off  Replacement fitted  Top back on  Choke operation checking , choke pulled on and jet dropped as it should  |

| |

Last Edit: Apr 6, 2019 16:27:01 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

|

|

Choke off , jet came back up , if these stick all hell breaks loose  Plug colours after the Singers carb fiasco and a 10 mile non stop blast at 70MPH . Engine temp 80˚C - Oil pressure 47 PSI , Plug colours as in pics , might richen the rear carb up a tad , tricky to tell when its this close . All in all I'm a happy bunny again Damage to float chamber thread that caused the leak  Number 1  Number 2  Number 3  Number 4  |

| |

Last Edit: Apr 6, 2019 16:14:42 GMT by remmoc

|

|

remmoc

Part of things

Posts: 931

|

|

|

|

Coolant level at 80˚C is spot on  |

| |

|

|

|

|

, also fitted flexi leads out for anti vibration

, also fitted flexi leads out for anti vibration

) for 7 miles without backing off got the temp gauge as far as the middle so thats 83˚C according to previous tests ive done - heater was OFF .

) for 7 miles without backing off got the temp gauge as far as the middle so thats 83˚C according to previous tests ive done - heater was OFF .