|

|

|

|

|

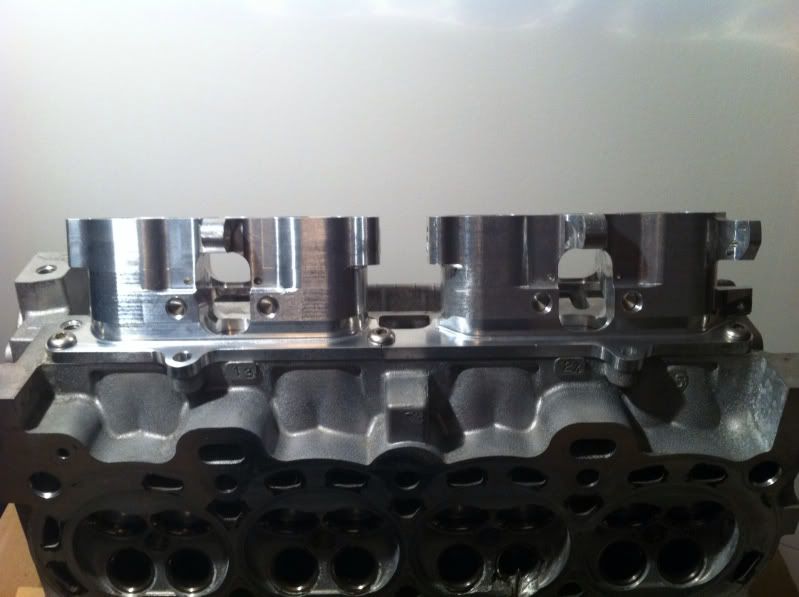

Carbs:  Spare head:  Head & carbs  Hopefully soon to be joined together Although I did also get the offer of another DTA ecu this weekend too  |

| |

|

|

|

|

|

|

|

|

|

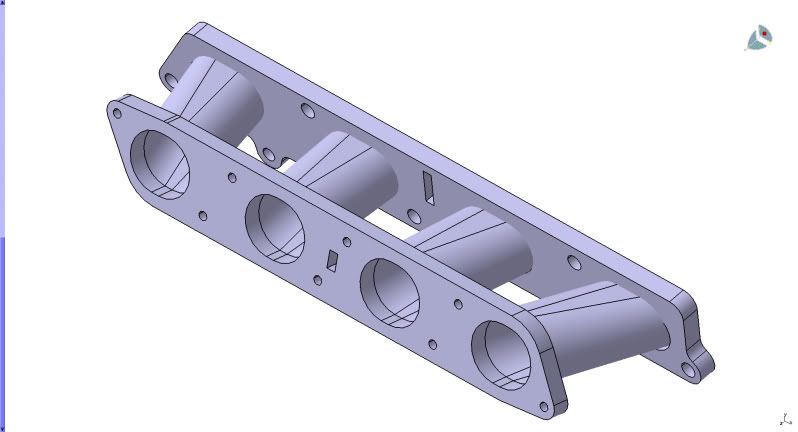

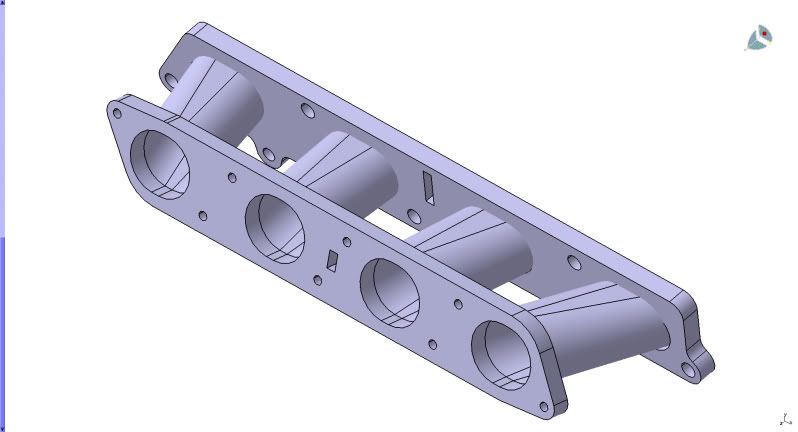

So, a quick recap I had these in stock  Complete with air box etc And I need to mate up with this head  So some measuring and a bit of time on Catia gives me this assembly  And 2 DXF files for the 2 flanges to laser cut from. Which then gives me these test pieces to prove the concept before cutting metal  Carb flange needs a tiny tweak but there on 3 out of 4 ports  Intake flange was bang on   And stripped of backing   On their own  So it's just a minor tweak to the carb flange now, another test piece to check I've got it right and then I can finalise the position and jig pieces and get the flanges laser cut from aluminium, ready for welding |

| |

|

|

|

|

|

|

|

|

Good work dude I like your style! I'm guessing you have good access to the cutting equipment etc? the test bits look great so the real thing will do too. How thick are you going with the flanges?

|

| |

|

|

|

|

|

|

|

Cheers fella, It's just using a different set of tools, I haven't got the luxury of time in the shed sadly, so I have to work with the tools I can use at home. Tweaking it on a CAD tube I can do at home and then my better half can laser cut it from Perspex at work.... The same files can then be used once I've checked and tweaked them, to cut the Aluminium pieces on a much bigger laser, but I have to get that done outside. The finished flanges will be 8-10mm thick, so I can still face them flat after welding  |

| |

|

|

|

|

|

|

|

|

|

| |

Last Edit: Mar 9, 2012 21:22:33 GMT by CR500Dom

|

|

|

|

|

|

|

|

Great to see this coming together.

|

| |

|

|

|

|

|

Mar 10, 2012 19:58:56 GMT

|

Before and after    And the stainless components cleaned up before fitting too   Also got the test pieces back and assembled for the carb manifold, so lots of options coming together now.  Hoping to get some time down at the barn tomorrow and get the spare block assembled in the car with the dry sump so I can get the pump mounting schemed up. |

| |

|

|

|

|

|

Mar 11, 2012 23:46:35 GMT

|

Got a couple of hours on it today and there is an engine back in the bay !! Good fun on my own with no lifting kit    Trying to find a home for a dry sump pump  Plenty of room for a proper intake tract while running N/A  Dry sump pan   Front end  Intake side minus supercharger  Quite pleased, will hopefully get some more time on it this week and try and get a location sorted for the scavenge pump |

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,975

Club RR Member Number: 71

|

|

|

|

|

Love those throttle bodies - sexy as F*ck

|

| |

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

|

|

|

Please, please, please get some clear perspex tubes cnc'd to make a complete plastic manifold. Even if it served no purpose other than to look pretty on a shelf ;D

|

| |

Follow your dreams or you might as well be a vegetable. |

|

|

|

|

|

|

Mar 12, 2012 10:49:07 GMT

|

|

Good work chap and fair play for getting the engine in there with out a lift. Are you going to have the front end blasted of try and sand it up as best you can? I'm contemplating having mine soda blasted.

|

| |

|

|

|

|

|

Mar 12, 2012 19:21:41 GMT

|

Love those throttle bodies - sexy as F*ck They are available in dcoe fitment  |

| |

|

|

|

|

|

Mar 12, 2012 19:23:57 GMT

|

Please, please, please get some clear perspex tubes cnc'd to make a complete plastic manifold. Even if it served no purpose other than to look pretty on a shelf ;D Contemplating doing the tubes as a 2D flat development and heating / rolling them up to form them....... Bit of chloroform to glue it all together and job done  |

| |

|

|

|

|

|

Mar 12, 2012 19:27:18 GMT

|

Good work chap and fair play for getting the engine in there with out a lift. Are you going to have the front end blasted of try and sand it up as best you can? I'm contemplating having mine soda blasted. Soda blasting is the plan once the metalwork is finished and then straight into prep and paint, it's still very much "dry build" stage now, it's really tempting to clean and paint it but all the holes need to be put in now, everything fitted and mounted etc As I don't want to be drilling a freshly painted shell  This way, once it's in colour it is just a case of carefully bolting bits back on |

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,975

Club RR Member Number: 71

|

|

Mar 12, 2012 21:11:52 GMT

|

Love those throttle bodies - sexy as F*ck They are available in dcoe fitment  Pointless doing that - direct to head is far better as the DCOE/DHLA manifold I have is a compromise Besides they aren't cheap when you factor in the EMS required |

| |

|

|

|

|

|

Mar 12, 2012 21:38:32 GMT

|

They are available in dcoe fitment  Pointless doing that - direct to head is far better as the DCOE/DHLA manifold I have is a compromise Besides they aren't cheap when you factor in the EMS required Could do it with a direct to head flange and singles instead then  Yeah a decent EMS is a big cost, but you could run it on all the vehicles, just swap the maps to suit  Works quite well then |

| |

|

|

rysz

Club Retro Rides Member

Posts: 2,558

|

|

Mar 13, 2012 13:31:12 GMT

|

Please, please, please get some clear perspex tubes cnc'd to make a complete plastic manifold. Even if it served no purpose other than to look pretty on a shelf ;D Contemplating doing the tubes as a 2D flat development and heating / rolling them up to form them....... Bit of chloroform to glue it all together and job done  Have you thought about some rapid prototyping / 3D printing? Possibly not as attractive on the shelf, but certainly a good way of getting complex 3D shapes... Loving the progress on this! Always a delight to see what a professional engineer produces! Rysz. |

| |

|

|

|

|

|

Mar 13, 2012 19:52:11 GMT

|

Cheers fella  It's only a proof of concept, so it doesn't warrant any spend ! And the cad software will flatten to a flat pattern in the sheet metal modelling program, then I really can just laser cut the bits from aluminium and form the runners to suit the flanges  Been down there tonight to have a measure up as I need to get my order in for some additional roll cage tubing and brackets  I'm going to pick up the front damper turrets and tie them into the cage in preparation for the phase 2 front end I now have an Elise front calliper. So hopefully I can have lighter front brakes and no loss of steering lock either, it shocked me that the Astra caliper was the same weight as the volvo 4 pot, so I went searching for a lighter alternative  |

| |

|

|

|

|

|

Mar 13, 2012 20:25:13 GMT

|

|

Good job Dom I will be interested to see how the latest caliper option turns out and what a phase two front end consists of?

|

| |

|

|

|

|

|

Mar 13, 2012 21:31:19 GMT

|

Good job Dom I will be interested to see how the latest caliper option turns out and what a phase two front end consists of? I'll keep you posted re calipers  I was looking at the front end while I was down there tonight and it's all a bit tight on space. I have the piazza rear axle which is quite a lot wider than the standard kadett, and then there is the caliper / lower wishbone clash, and a crossmember that only really now holds the rack in place as the engine is chassis mounted. So, if I now tie the front turret loads into the cage, and brace between them, that opens up some real possibilities. I can go coil over and tubular wishbones at the front, with a nice long damper from the lwr wishbone. This removes The need for a huge crossmember as it now doesn't have any spring load through it, so the crossmember only needs to brace the front wishbone pickups together, and hold the steering rack in the right place  I can run 2.5" springs at a sensible length and be able to set the corner weights properly, the smaller diameter springs also solve the small wheels, lots of lock, caliper to wishbone clearance too Tubular wishbones give me adjustable geometry and an easy route to wider front track to match the rear axle...... It's more work, but will solve a lot of headache in that area, as well as saving a shed load of weight too |

| |

|

|

|

|