craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

another month, another update  Well, some progress has been made over the past few weeks The seats are now with rusty at Retro Retrims and the spec's are all finalised (should be ready soon along with the new headling and other goodies ), there has been some progress on the engine (and then I dropped a nut down into the head which we can't find even after taking the head off ) and Gaz (pickmeup) has wet sanded and mopped the paintwork for me (and it is looking mighty fine )  Plan is to start bolting Pootle back together as far as I can at the mo and see where we get to L2B next year has been mentioned  |

| |

|

|

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

well, a couple more productive hours at the lockup tonight. 1st job was to push pootle outside and get some better pic's     Not too bad considering, but there will be more work needed on it next spring. But the paint is now sealed with polish to keep the world at bay till then  As the wind was getting up (and the doors starting to bash about), I pushed him back inside to continue. next up was building the doors back up and the door seals back in. 1st door handle, dropped one of the screws down inside the door  1/2 hr wasted fishing it back out with a magnetic screwdriver  but after that the locks went back easily and with the door seals back in, the doors shut nicely and fit pretty good. Next up, fit up the bootlid. It will need to come off for more paint (its only had 1 coat on the outside) but it will be safer bolted up. Only problem was initially fitting the hinges to the wrong sides (after carefully thinking about which side was which  final job for the day, get the bonnet onto the riser brackets in on to the hinges. Forgotten what a pain they were to fit on your own, but got there in the end. Then realised it was time I should have been on the road so packed up (and forgot to take any more pic's  ) Back up on Sat, so should make some more good progress and have Pootle looking more like a mini again  Plus rusty @ retro retrims is cracking on with the seats, will have them back in a couple of weeks  |

| |

|

|

|

|

|

|

|

|

Hi Craig, just been having a read through this buld post and realised who you are! I bought Gaz's White Clubman a couple of years ago now!

Keep up the good work.

|

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

|

Ah, the spam trooper, he still misses that little beasty. I see you sold it a while back (he was gutted that he couldn't get the funds together to buy it back again). What toys have you got at the mo?

|

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Oct 21, 2011 17:20:20 GMT

|

Well, a bit more progress today  1st off though was to push Pootle outside and take a couple of pic's of the last times progress   Doors fully built, bonnet on (on riser brackets) And the boots on as well  Next off was fitting the 'new' carpet I was given during the week, black MPI one it good condition   Then I decided it was Time Pootle had some eyes again  and trail fitted the mk2 rears (need to find the seals for them  )  I them tried out the opening rear 1/4's, sadly the seals have shrunk so they don't fit very well  Hopefully get a bit more done tomorrow, next Sunday see the interior going in so I want him water tight  |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Oct 31, 2011 18:00:23 GMT

|

Not the normal point in a build, but the interior was ready and I need a boost of mojo so on Sat I received these sneaky pic's from retro retims   Sunday lunch and rusty appears with a caddy full of goodies  Thankfully he is fitting the new headlining, me and Gaz did 1 many years back, 4 evening it took us. Thankfully Chris knows what he is doing and within 3 hours the inside was looking like this (plus there is a thick layer of sound deadening under the headlining now, the roof doesn't ring now when you tap it  )  He still has to come back to trim the A, B and C pillars plus the dash top rail (and to deliver the head rests, custom sun visors and the gaiters  ), but I am well chuffed Even more so when we dropped in the seats    No all I have to do is keep them clean whilst I finish off the build  |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Nov 11, 2011 17:33:59 GMT

|

|

|

| |

|

|

|

|

|

Nov 11, 2011 21:24:44 GMT

|

|

Looking good!

Nice interior, curious to see the trimmed A.B and C-pillars.

Are you changing the doorcards as well?

|

| |

Click picture for more |

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Nov 13, 2011 16:07:07 GMT

|

Cheers, it will be nice to get the pillars and the dash top trimmed so that 's all finished. Should hopefully look quite classy inside  Nope, the door cards are staying (had them custom made a couple of years back and love'm  ) |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

Shhhh, don't tell anyone, but there has been some progress on pootle  With the lockup now equipped with an engine hoist it seemed rude not to use it. A bit of a sort out in the lockup was needed 1st, and then removal of the bonnet and the brake master/servo and we were ready to go  Got the rope around the engine and it lifted nice and square, so far so good. Then the 1st problem, the hoists legs were fouling on the bottom arms. No probs, lift the front up and stick some axle stands under and jobs a good'n the hoist goes under  and shortly afterwards the engine was sitting in the subframe. Then the fun began, fitted mini engines with 2 new engine mounts is always a pain, but today it was really being  after a bit of juggling, we got the flywheel end mounts bolts in and done up a little (left lose enough to allow the engine to be rocked), but the rad end wasn't having any of it. We tried levering, using ratchet straps to pull the engine down, but it wouldn't get close. in the end we gave in and fitted a used (but good) engine mount, and after much hammering we had it bolted it  So with that completed, I started to bolt a few of the engine bits on. Some (like the oil cooler) will have to come back off in the near future, but mean that I can work out where to mount stuff. So a frustraiting day, but thanks to Gaz, a productive one      |

| |

|

|

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

May 20, 2012 16:40:47 GMT

|

decided to spend a little bit of time on some work for Pootle this afternoon and started to plan out the dash. Because I kept the webber box in, this makes running the centre clocks a bit more tricky, so for Christmas Rosie brought me a works dash set from minisport and I've been working out how to do it since. So today i broke out the CAD (morris had convieniantly finished a box of whiskers last night :lol: ) So out with the pens and the scissors and this is what I have come up with before  template  unbolt the top to check the dials actually fit  and it should look something like this  Not sure of the best way to cut the holes out, I have a hole saw that will do the temp and oil pressure, and the bezzel on the rev counter sits on top so the edge doesn't need to be perfect, but the speedo will be a bit more 'fun'  I suspect it will be a case of drill a chain of holes and then get busy with the dremmel |

| |

|

|

|

|

|

May 20, 2012 19:00:02 GMT

|

i think rob has a decent selection of hole tools mate, i used your hole saw to attack the mx5 last week  |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Jul 17, 2012 19:21:17 GMT

|

Hmm, been a while since I've updated/ done much  Well, Pootle is coming home now I've sold my Cooper as my garage is free, so no 60 mile round trip to the lockup to wok on him  Last week I spent a bit of time working through what bits I have and haven't got, found some I had forgotten about too  So the main task I wanted to get done was to get the engine all back together, so that needs the head actually bolting on  So 1st task was to lift the head back off (sat on the block to stop cack getting into the bores) and clean up the block face (after pulling the studs out). Also whilst the head was off it was easier to fit the fuel pump blanking plate and the water pump    Then found out I couldn't find the bypass hose :x Luckily there is an old rover dealer near by, and they had one on the shelf (they had to try about 6 different part numbers first  ), was surprised how much stiffer it was compared to the hoses from Moss ect (and not the flexi type ones either) So with that fitted and the studs back in the block we were looking like this  So then it was the turn of the head for a quick clean up  And on it went. Nearly made a clanger, was just about to start bolting it down when I realised that the pushrods were still in the card sheet I used to keep them in order :oops: Also realised that I had left my torque wrench at home so its all just nipped up at the min and will be torqued down tomorrow. So then went through and started to dummy build up the engine, more than anything to confirm whats missing and that everything fits. So that left the engine looking like  Last night I made a bit more progress, got the head torqued down, so 1 more job completed  Also bolted up the heater tap (with a new gasket of course  ) and then tried to get the clutch arm out of the spare wok cover. Wasn't playing ball so had to leave that with some pen oil over it, hopefully be able to get it swapped over tomorrow. So I fitted the clutch master and pipe work and refitted the brake master. Still got to work out how to bolt on the pressure valve and make the final pipe. So will be back up for a few hours tomorrow evening, hopefully make a bit more progress   |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Jul 18, 2012 19:35:57 GMT

|

wow, 2 updates of progress in a week, I think i need to sit down  So a couple of productive hours this evening, not quite the jobs I intended doing, but happy that they are done  1st job was to fit the arches, and then the new bonnet strap (as it was there and I had the drill out  ) which also meant bolting the bonnet back on (useful for trailering on Saturday anyway)    With that done I then fitted the washer jets (I found them in a box whilst looking for something else  ) and the it seemed logical to fit the wiper motor  Final job of the day was to fit the starter solinoid and then reconnect the battery wire  Then on went the door outer weather strips (help keep the inside dry  ) Not a bad evenings work |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

Jul 21, 2012 18:33:35 GMT

|

Well, update 3 in a week  Yesterday was the final day of working on Pootle, progress made, gear linkage fitted (but only due to Gaz, I got it a bit wrong  ) but for some reason it only selects 1st and 3rd (more investigation needed I think. The exhaust manifold is fitted (cooper freeflow  and the carb is bolted up. also fitted the front brake hoses and tightened up the tie rod bolts (must go round and bolt check the entire front subframe). So today was the day that Pootle was coming home. So 1st job was to get him outside    he was very grubby (the joys of parking in a barn) so a quick wash was in order    much better Then an afternoon spent wiring the towbar in on Pickmeups (Gary's) new sprinter so we could tow him home (Cheers Gary  which, apart from me wiring the indicators the wrong way round  ) went pretty smoothly So it was time to get him loaded up and head home  And now he is back, resting in my garage, waiting for me to get om and finish him   |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

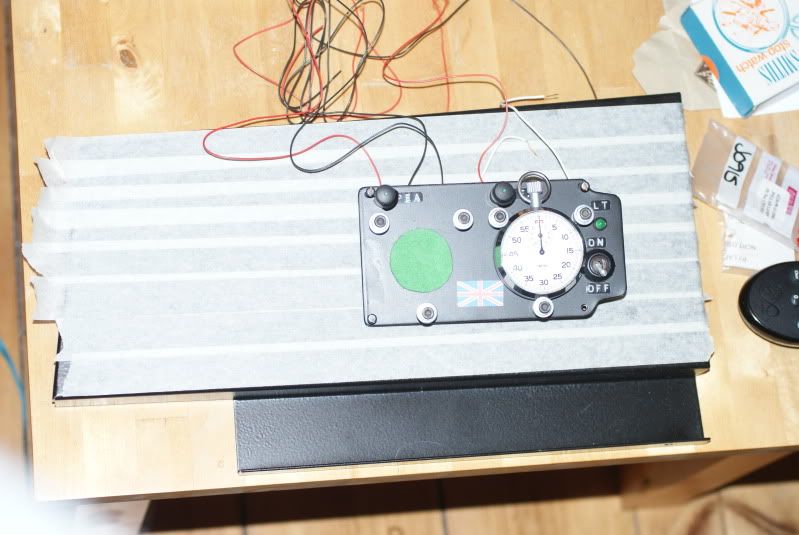

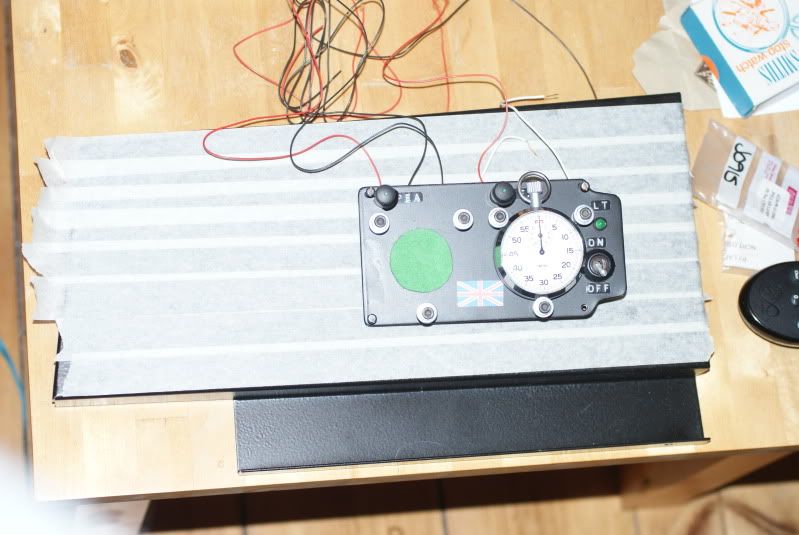

Oh, not updated this for a while, and there has been a small amount of progress Part of the interior that has been giving me the most trouble finalising the design has been the dash. I knew I wanted a retro look, and I loved the works dash pod's, but getting it laid out right has been a struggle. But I have finally got there (I think :lol: ) I've also been collecting more bits too. I wanted to have a set of stop watches on the passenger pod, and mini sport have recently started to make replica mounts. They offered them with or without the 'pea' lights (to iluminate them), but the ones they use are nasty chromed ones, not in keeping with the works look at all. So some time was spent researching what was originally used and it turned out that they are aircraft instrument lights and I managed to find a pair of MoD surplus ones for less than the price of 1 minisport one  So today I've been assembling the panel, fitting up the lights and trying the stopwatch (need to find another or possibly a watch so I have the time  ) and working out were to cut the pod I've come to the conclusion that the easiest and neatest solution is to strip it right down and then to drill through and bolt everything through the pod and the mount Anyway, we all like pic's Pea lights installed   Stop watch in (need to adjust the position of the posts as its set of a 55mm watch and I've got a 50mm one)  and it roughly in position on the pod (taped up to stop scratches)  took it all to bits to start drilling quite a few holes, and filing out a few of them to suit the watch. But its all together and and I'm pretty chuffed (Although i did manage to break the leg off the LED  and I need to do the wiring)  Its far to cold to venture out to the garage, so I thought it was time that I man up and cut the holes in the drivers pod for the dials. I've been putting it off for a while, but finally plucked up the courage to start drilling. 1st issue was the 52mm hole cutter I've got was blunt, so had to resort to chain drilling and filing out the holes with the dremmel (great fun). But I think it came out ok  Still need to find/re-make the retaining straps for the dials, but I'm happy with how they look  So I got the passenger pod out of storage to get an idea of how they will look  Pretty chuffed with that  I've also brought another set of 10's with good Yoko A008's on them (should be arriving this week, but not sure if I'll just be using the tyres or the rims too), and will be putting in an order with minispares after payday to get the next batch of parts to start getting closer to the road soon  |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

Must be a bank holiday, some progress  Well, stuck an order in to minispares the other week for the next stage of bits, so thought I should get on and do something with them  1st off was the new steering column, the splines had gone on the original and I replaced the rack as a precaution, but had been using one of Gaz's spares. So a new one was delivered and (after a trip out to buy the right sized socket to get the steering wheel off) it was stripped and rebuilt with ought any great drama  Fitting was another matter. 1st off had to clear the space infront so I could get him outside, but trying to get the new column onto the splines was a real struggle. Seems that they are closed up new and need spreading to go over but stay a snug fit. Its still not on 100% (need to dig out a suitable bit of wood and the lump hammer to help drive it home) but its fine for pushing in and out of the garage  Also had a play with the gears. Before we brought him home I could only get 1st and 3rd which I thought was down to the engine and subframes only being losely in at the mo, but some working through of the gear linkage has got all the gears  1 less thing to worry about  So feeling on a good streak, decided to mock out the dash pods. 1st thing was to fit in place the padded lower dash rail, which looks like it'll need some of Rusty's magic to get it sitting right. Then out with the masking tape to hold the pods in place. Pretty happy with them, the drovers pod is sitting high and the passenger side is sitting low, but once the lower dash rail is sitting right then I think a lot of that will sort its self out. But the dials are sitting perfect in the line of sight from drivers seat  and the watch I've sourced works really well with the stopwatch  So, pics's now I guess       |

| |

|

|

toreno

Part of things

Posts: 385

|

|

|

|

|

looking good mate

|

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

Time to raise this from the depths. Been mulling things over with whats needed to get Pootle back on the road, and the best way to tackle it as very little has happened in the last 18 months. I have slowly been building up the parts, but the list of jobs needed is a long one. So 2 weeks ago, after work and armed with a big list of jobs (and an empty bladder ) I headed over to Maks at Minitec to chat through him over a few brews what could be done. And we have a plan I've got a list of jobs to do, and a week off work next week, and on the 22nd on June, Pootle is going to Maks to be finished to an MOT'd/running state by the end of the 1st week in July so over the next few days, I'll be putting the list up here and then starting to work my way through it / working out what remaining parts are missing (or I've lost) To say I'm slightly excited is a bit of an under statement here we go then, the list of jobs front subframe - Fit rear mounts (1 side Done) - retorque top mounts - buy/shim/fit front mount bolts - Tighten/check lower arms and tiebars - Tighten/check/grease upper arms - Cut down bump stops - fit front shocks Steering - fit new column/ fit bolt - adjust tracking/ fit lock nuts - strip/clean/replace grease nipples/ regrease ball joints - build/fit drive shafts Engine - find/buy/fit pot joint (Mak supplying)/ FOUND - tap top steady bolt holes/ fit top steady (done, but bottoms out to early still) - fit proper engine mount bolts - fit lower gearbox steady - Buy/fit eleccy dizzy (On order) - buy/fit oil pressure sender (done) - set tappets/fit missing lock nuts - service - Fit exhaust - Check gear linkage mount is correct way round - Bolt up fan - install rad - Buy/fit alternator / bracket (Orignal alternator fitted) - Change oil cooler for pipe (Done) - Fit speedo drive - Fit speedo cable - Fit throttle cable Brakes - Fit pedal box (Done) - Buy/Fit brake MC (Done) - Fit pressure dist valve (Done) - Connect MC to Valve (need new pipe) - Connect Valve to front subframe - Check front flexi hoses correct sides - Bleed system Clutch - Fit clutch arm - (Done) - Buy/Fit MC (Done) - Fit hard/flexi pipe (Done) - fit Slave/connect (Done) - Bleed/adjust system Interior/wiring - Finish /fit wiring main loom (90% done now and installed  - Fit headlight looms/ connect to main (3/4 done) - Fit lower dash rail (DONE ) - fit switch panel - Cut hole for speedo in bulkhead box - Fit speedo - Cover Upper dash rail - Fit dash pods - Build looms for dials - Drill out holes for choke/heater - fit heater/choke cables - fit heater Bodyork - Replace drivers sill - sort hole under rear light - sort hole Drivers rear shock mount - Tidy/stone chip/paint sills - touch up paint on A panel - tweak/fit front seams - paint front seams - prep/paint rear valance - paint bootlid - repaint roof - change back window seal - change rear 1/4 window seals - Trim front wings to suit tyres Wheels - strip tyres off rims - blast /powder coat wheels - tyres refitted |

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

|

|

So, progress over the last 10 days. I dug out the wiring loom, spent a few hours looking at it trying to remember all I had done last year and I think its not far off ready to go in. 1 of the jobs stopping that was that the lower dash rail needed fitting, so I dragged Pootle outside so I could do that and also have a bit of a sort through in my garage Got the loom 1/2 installed now, headlight looms are in and connected (although I need to change the side lights to suit the H4 headlights I've got) and my new elecy dizzy and coil turned up today as well I spent this evening fighting with installing the pedal box (it took 4 attempts to get it in and with teh pedals in teh right place  ). Seems its a pre 76 one and therefore doesn't have a brake light switch mount on it So i'm either going to have to make some sort of bracket or revert to the earlier type pressure switch setup. some more progress (although most jobs seem to be a battle at the mo). Got the passenger side front subby rear mount fitted (was a bit of a pain and took longer than it should), but when I went to do the drovers side I couldn't get the subframe to tilt back far enough. After struggling with it for a while, I moved on to sort the clutch hydraulics out. Got the clutch arm greased and the new clevis pin fitted, bolted up the salve and master and the pipe work still got to fit the pedal clevis mind, that'll be fun Was during this I noticed that the drivers inner wing was overhanging the front subframe, so that was stopping the subframe tilting and stopping the rear mount going in . So at least I know what went wrong there. Also cracked on with the alternator. Had to re-tap the holes for the bracket (as well as tap the hole in the bracket as it was slightly too small for the bolt), but I got the original alternator fitted up. Whilst I had the tap and die set out, I thought I'd sort the threads out in the block for the engine steady. The new bolt I bought a few years back only ever went in about 1/2 way, so I dug out the tap and ran it in and out a few times and its still bottoming out the bolt about 10mm to early. I know it'll have a washer and the earth strap on it which will take out some of the gap, but it still seems to short Final jobs this weekend was to remove the oil cooler (not really needed for a stg1 1098  ) and replace it with the braided pipe instead. I also got the oil pressure gauge pipe and T peice fitted up and in the right place |

| |

|

|

|

|

1/2 hr wasted fishing it back out with a magnetic screwdriver

1/2 hr wasted fishing it back out with a magnetic screwdriver  but after that the locks went back easily and with the door seals back in, the doors shut nicely and fit pretty good.

but after that the locks went back easily and with the door seals back in, the doors shut nicely and fit pretty good.

1st off though was to push Pootle outside and take a couple of pic's of the last times progress

1st off though was to push Pootle outside and take a couple of pic's of the last times progress

and the carb is bolted up. also fitted the front brake hoses and tightened up the tie rod bolts (must go round and bolt check the entire front subframe).

and the carb is bolted up. also fitted the front brake hoses and tightened up the tie rod bolts (must go round and bolt check the entire front subframe).