Ah, well it's been far too long since these blue pages have frequented this browser. About time for an update...

You all know Roger, our beloved '83 Dodge B250 Camper. In fact, I think most of you have been drunk and talked nonsense in him at some RR event or other over the years.

Anyway, all quiet here in recent years. We moved to Switzerland in 2018, and that was that. Roger was originally left with the ever talented Gobin at Custom Restore. The initial estimate of welding required quickly escalated, then escalated more. Oh good lord he was rusty! I should post some photos of his incredible work at some point. Before the Swiss opportunity arose, the intent was to do all the welding myself. So pleased I left it to the professional!

Anyway, some two years later after a bout of Covid lockdowns etc, we finally collected him, and placed him into further storage in the UK. It was then in April this year that I finally secured insanely expensive storage for him here in Zürich. The great thing about this storage is that it is under cover and the landlord, far as we can tell, doesn't really seem to give a stuff what we are up to so long as he gets the rent. It's 5 miles from home, and basically the perfect facility for allowing us to completely strip the interior and start again.

What?! you may well ask. He looks fantastic inside.

Cool retro looking motorhome. Well yes.. but after 39 years of abuse, the last 17 from us, he's looking tired inside at best, and completely falling apart in reality. It's not the sort of broken you can just fix either. Originally made from chipboard with a paper (yes, paper!) walnut veneer, he's done basically done bloody well to get this far. Dry rot is the key term here. The chipboard was literally breaking up into its composite parts - every time we went in there, we swept up more and more cupboard dust.

You can see in the photos below by the state of the floor what we were up against here. Every wooden surface was in this condition.

All waste is weighed in here, not just metal when you go to the tip. We were shocked to find his interior weighed in at over 300kg. And I reckon we've still got another 100kg or so kept back here to be used as templates in the new build. Chipboard is heavy!

OK, so blank canvas, what the plan? Well, pleased you asked...

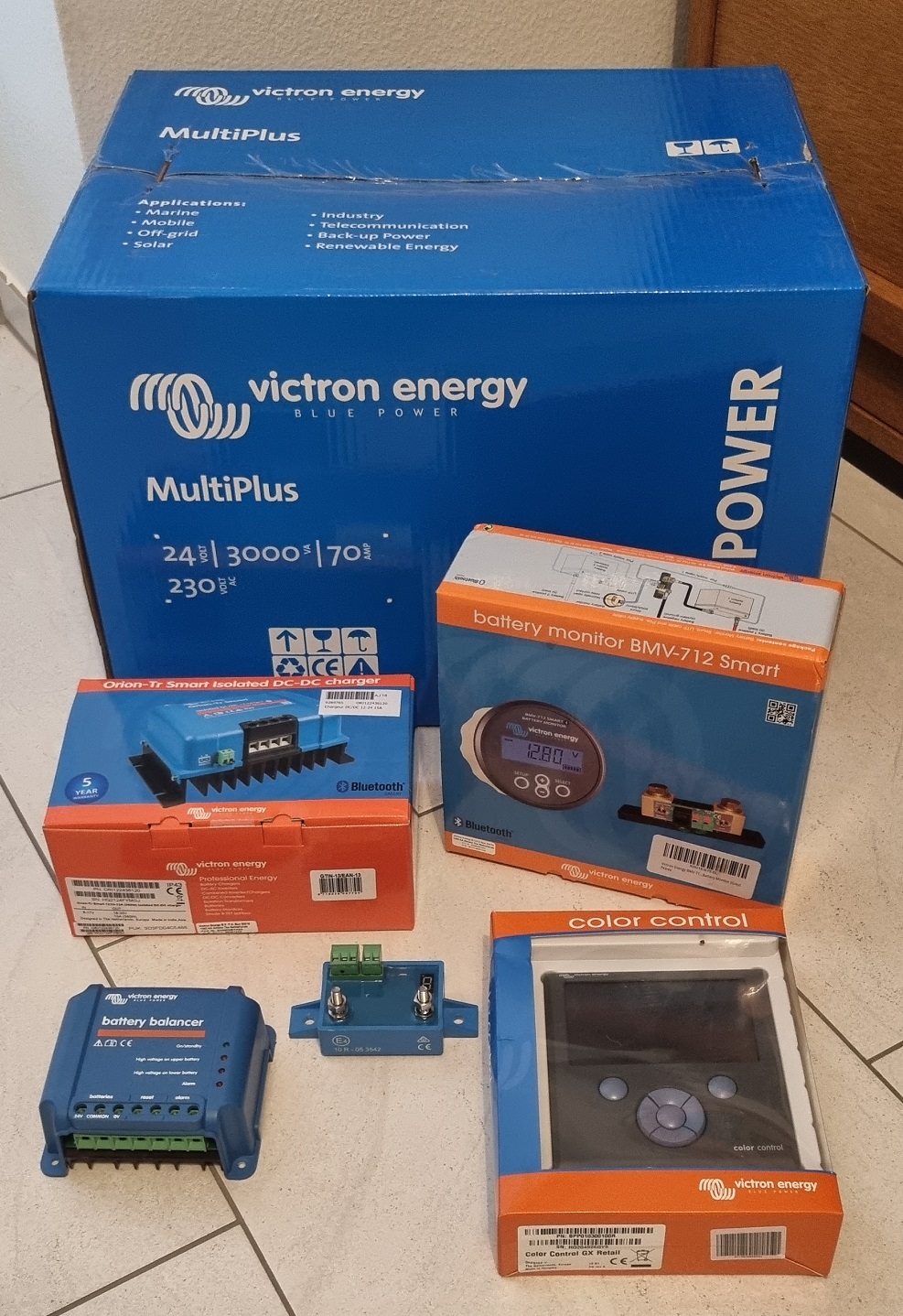

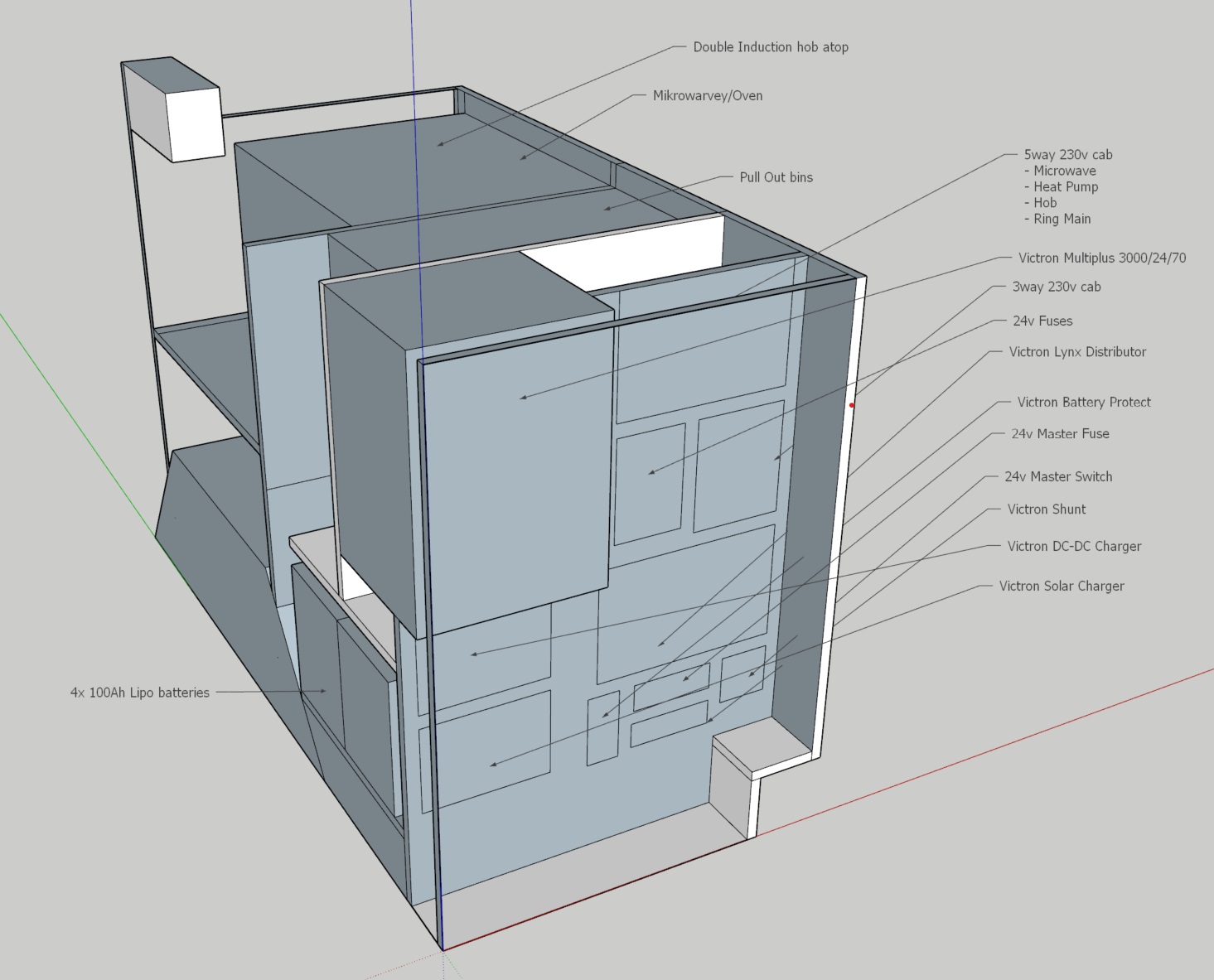

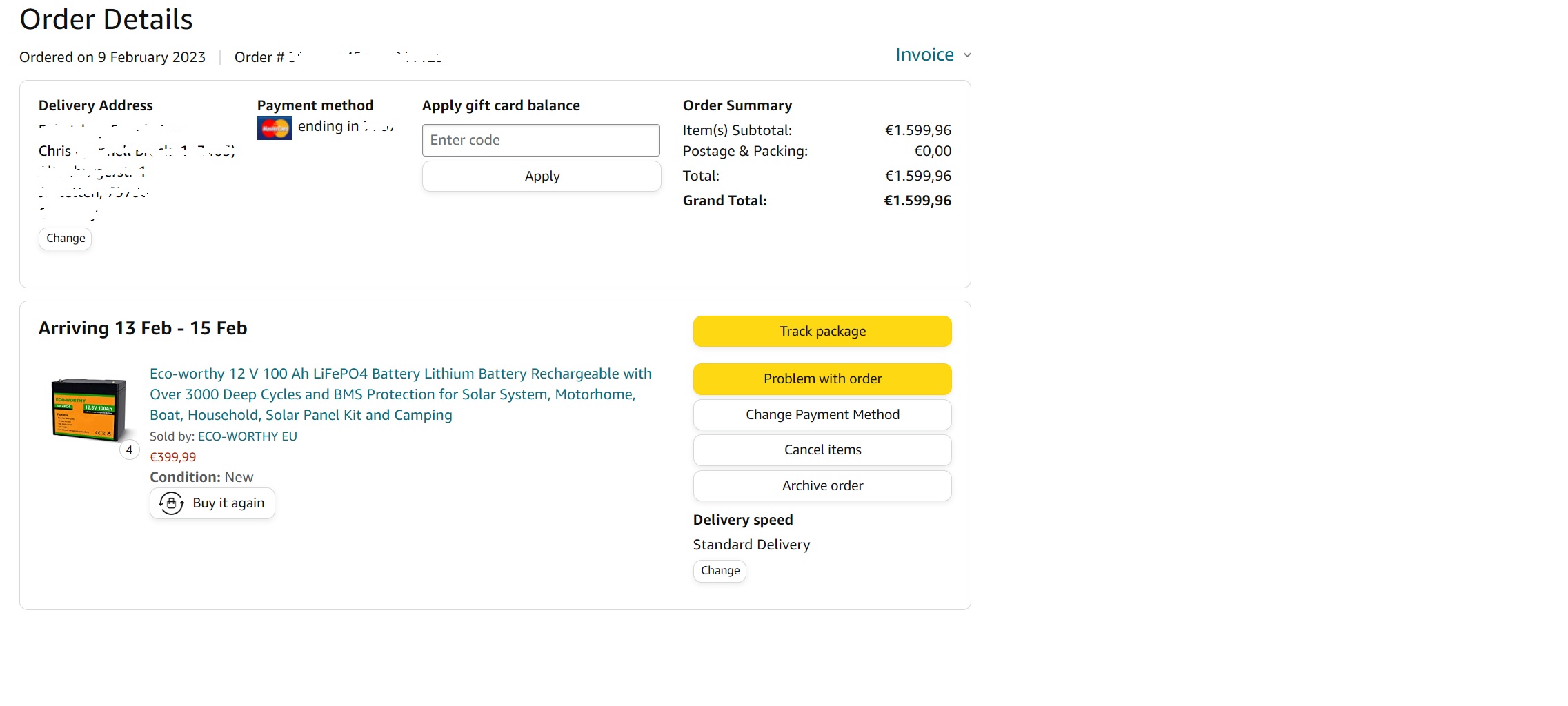

We want a similar retro vibe ideally, we'd like it to look like an 80s interior still, but just in good condition. We need to bring him up to date inside though, and I have plans for some interesting technology that will be mostly tucked away. More on that later. Interior wise, we'd still like to go for the dark wood look - although I'm currently struggling to find a source of laminate backed ply boards here in Switzerland. Most people seem to just paint the wood interior, but I somehow want it to still have that factory look about it. Not sure if possible, but we'll stick with that idea for now. Layout will be similar, but with a couple of tweaks here and there to make better use of the space.

Right, lets strip!

I was absolutely blown away with how good the metal floor is under all that dry-rot. I was expecting to have to get the hot stick out, but we literally just wire brushed and touched up where necessary.

It was around this time that I got the opportuntiy to buy a bunch of rather exclusive leather/alcantara Mercedes Vanio/Vito/v-class? captains chairs for a really good price. Only thing is they are in the UK. We'll work on the logistics of that later!

The roof panel looked awful. It was dirty, a previous owner had coloured in some of the squares, and worst was the sag. It had dropped 6 inches or more in places.

Lilla spent a couple hours scrubbing it back to beige, we strapped some metal to the edges to stop it sagging again, then swore and cursed for an hour or so trying to put the bloody thing back up. Forgot to get a photo of it back up there, but it looks a thousand times better now!

On to the floor. Floor base was a simple 12mm ply, with a couple ducting things added for later use.

Sealing them here on the back balcony - not a bad view!

And installed

Using what we had (left over insulation and laminate boards from the house) this is basically the current state of play

Not managed to get up there for a couple weeks now as we've had a house full, but work will start in ernest in the new year. Hope to keep a regular update here Happy New Year good people, cheers!

Happy New Year good people, cheers!

You all know Roger, our beloved '83 Dodge B250 Camper. In fact, I think most of you have been drunk and talked nonsense in him at some RR event or other over the years.

Anyway, all quiet here in recent years. We moved to Switzerland in 2018, and that was that. Roger was originally left with the ever talented Gobin at Custom Restore. The initial estimate of welding required quickly escalated, then escalated more. Oh good lord he was rusty! I should post some photos of his incredible work at some point. Before the Swiss opportunity arose, the intent was to do all the welding myself. So pleased I left it to the professional!

Anyway, some two years later after a bout of Covid lockdowns etc, we finally collected him, and placed him into further storage in the UK. It was then in April this year that I finally secured insanely expensive storage for him here in Zürich. The great thing about this storage is that it is under cover and the landlord, far as we can tell, doesn't really seem to give a stuff what we are up to so long as he gets the rent. It's 5 miles from home, and basically the perfect facility for allowing us to completely strip the interior and start again.

What?! you may well ask. He looks fantastic inside.

Cool retro looking motorhome. Well yes.. but after 39 years of abuse, the last 17 from us, he's looking tired inside at best, and completely falling apart in reality. It's not the sort of broken you can just fix either. Originally made from chipboard with a paper (yes, paper!) walnut veneer, he's done basically done bloody well to get this far. Dry rot is the key term here. The chipboard was literally breaking up into its composite parts - every time we went in there, we swept up more and more cupboard dust.

You can see in the photos below by the state of the floor what we were up against here. Every wooden surface was in this condition.

All waste is weighed in here, not just metal when you go to the tip. We were shocked to find his interior weighed in at over 300kg. And I reckon we've still got another 100kg or so kept back here to be used as templates in the new build. Chipboard is heavy!

OK, so blank canvas, what the plan? Well, pleased you asked...

We want a similar retro vibe ideally, we'd like it to look like an 80s interior still, but just in good condition. We need to bring him up to date inside though, and I have plans for some interesting technology that will be mostly tucked away. More on that later. Interior wise, we'd still like to go for the dark wood look - although I'm currently struggling to find a source of laminate backed ply boards here in Switzerland. Most people seem to just paint the wood interior, but I somehow want it to still have that factory look about it. Not sure if possible, but we'll stick with that idea for now. Layout will be similar, but with a couple of tweaks here and there to make better use of the space.

Right, lets strip!

I was absolutely blown away with how good the metal floor is under all that dry-rot. I was expecting to have to get the hot stick out, but we literally just wire brushed and touched up where necessary.

It was around this time that I got the opportuntiy to buy a bunch of rather exclusive leather/alcantara Mercedes Vanio/Vito/v-class? captains chairs for a really good price. Only thing is they are in the UK. We'll work on the logistics of that later!

The roof panel looked awful. It was dirty, a previous owner had coloured in some of the squares, and worst was the sag. It had dropped 6 inches or more in places.

Lilla spent a couple hours scrubbing it back to beige, we strapped some metal to the edges to stop it sagging again, then swore and cursed for an hour or so trying to put the bloody thing back up. Forgot to get a photo of it back up there, but it looks a thousand times better now!

On to the floor. Floor base was a simple 12mm ply, with a couple ducting things added for later use.

Sealing them here on the back balcony - not a bad view!

And installed

Using what we had (left over insulation and laminate boards from the house) this is basically the current state of play

Not managed to get up there for a couple weeks now as we've had a house full, but work will start in ernest in the new year. Hope to keep a regular update here

Happy New Year good people, cheers!

Happy New Year good people, cheers!