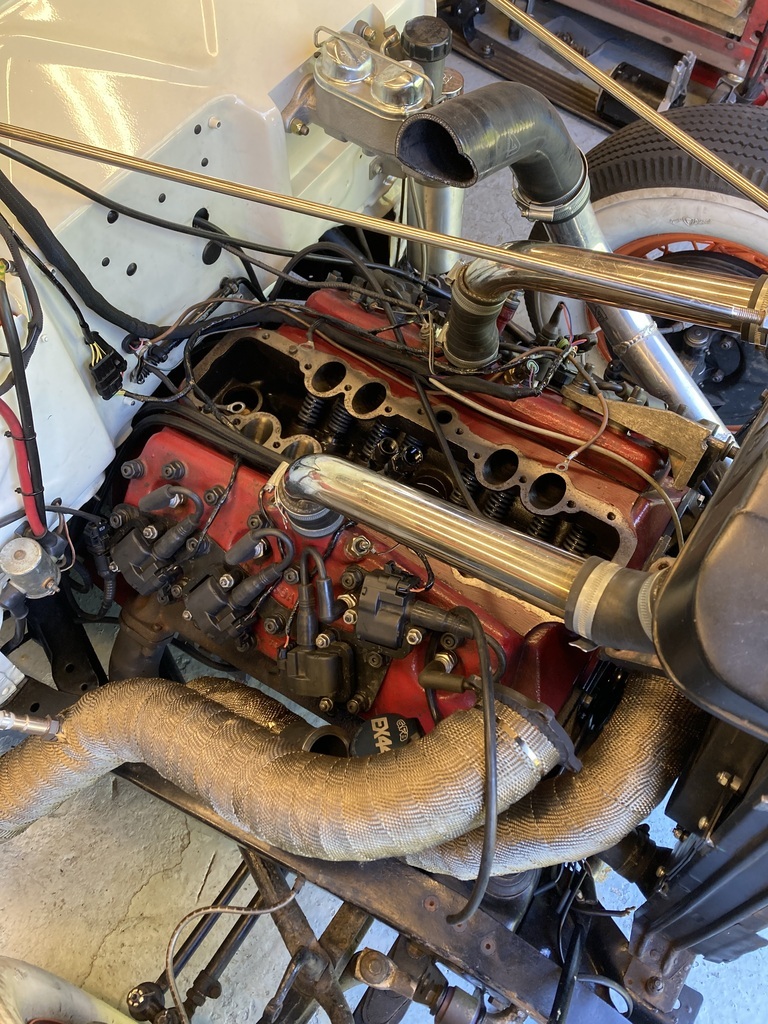

With it running somewhat ok it was time to hit the road for a test drive.

Before heading out I added another gauge in the form of the big Vacuum/pressure tester gauge as it’s easier to read than peering across to the laptop on the passenger seat.

Out on the road things felt better, much tamer and torquier as you’d expect from the smaller cam but still not amazing.

I think I saw over 5psi for the first time… Maybe…

A quick run out turned into a massive detour because a truck had broken down on the flyover at that exact moment instantly turning the whole area into a gridlocked mess. #londonlife

What this did provide was more run in time and a test of the cooling system.

It still overheats.

Returning home the toothed wheel had come loose already 🤦♂️ but the cooling issues I was prepared for. That’s why I left the front panels off. 😁

I’d already dug out the 14” fan, the one I originally wanted to fit but couldn’t squeeze it in.

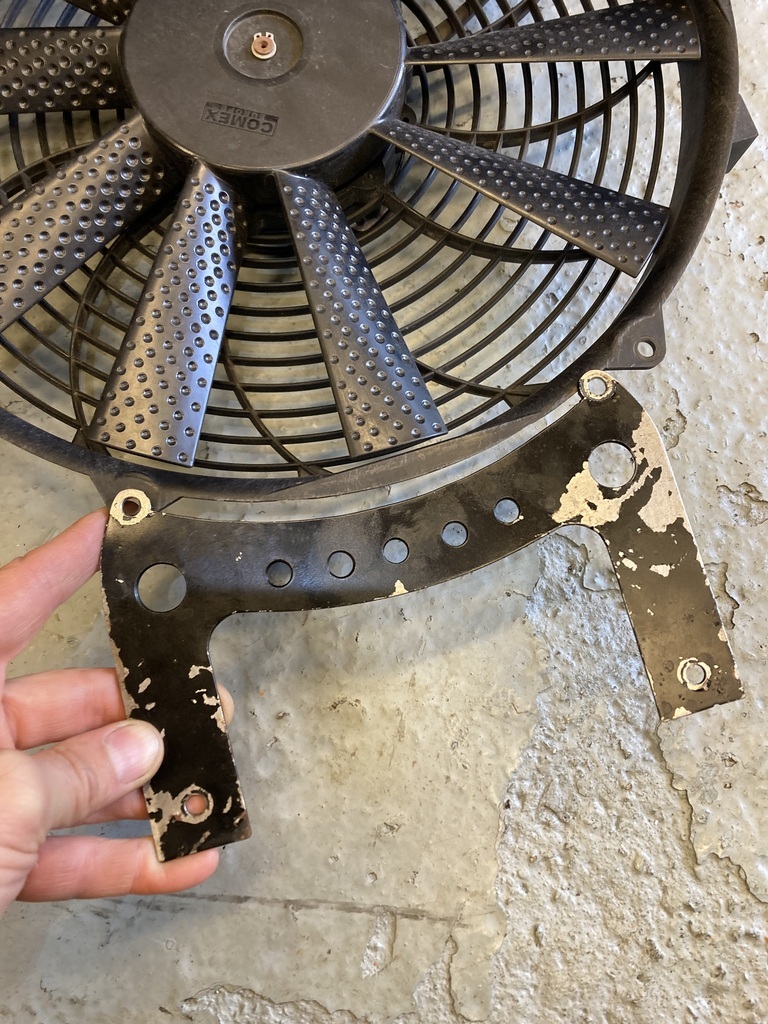

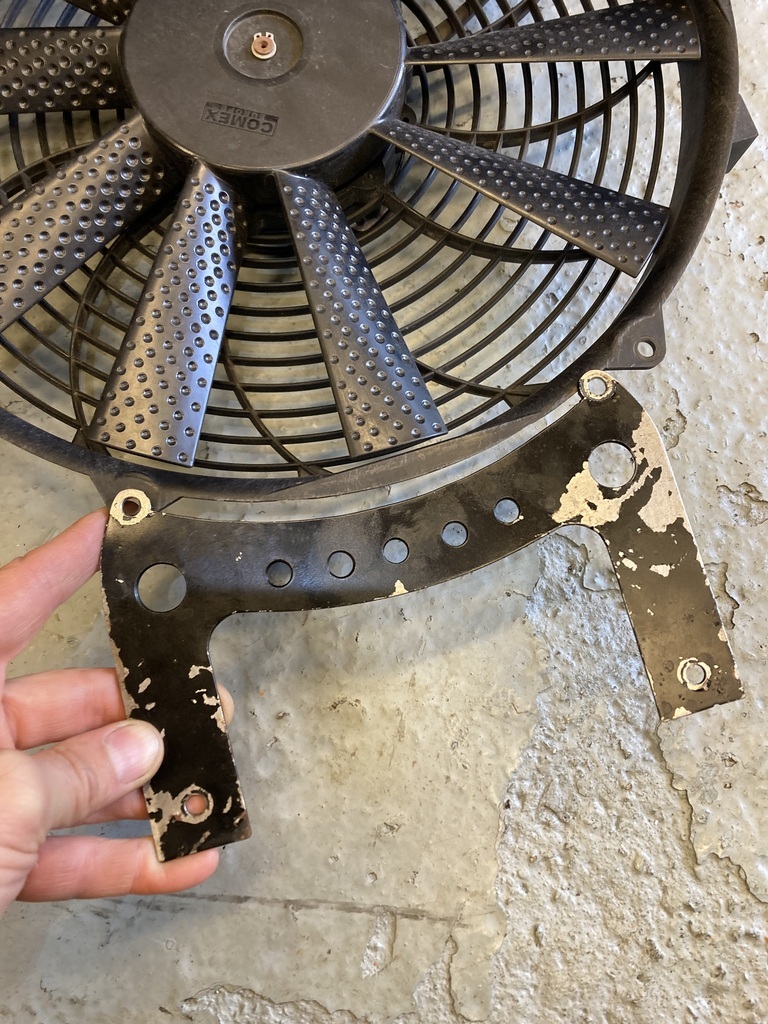

Here it is compared to the 12” that was on it. I think the 12” may also have been a slimline version all adding up to even less cfm capacity.

I wanted to mount the new, bigger fan the same as I’d mounted the previous one which consisted of two brackets with captive nuts welded to the radiator frame and another two brackets bolted to the fan itself so the whole fan assembly can be dropped and removed from the engine bay.

The fans were both Revotec so used the same mountings but annoyingly each fan diameter has a bigger spread on the mounting holes.

I was feeling particularly lazy this day and cut the original one I made in half and added this jigsaw piece to give me the extra spacing.

The original 12” fan was mounted over to one side because of the clearance issues at the time which meant I ended up with a long legged bracket and a really short one.

The short side I had no choice but to remake it.

I remade two new end pieces with captives for welding to the rad frame.

And realised the mounting holes would clash with the previously drilled holes in the repurposed bracket.

Still determined to not make a new one I filled all the holes!

At this point I should have just made a new one.. 🙄

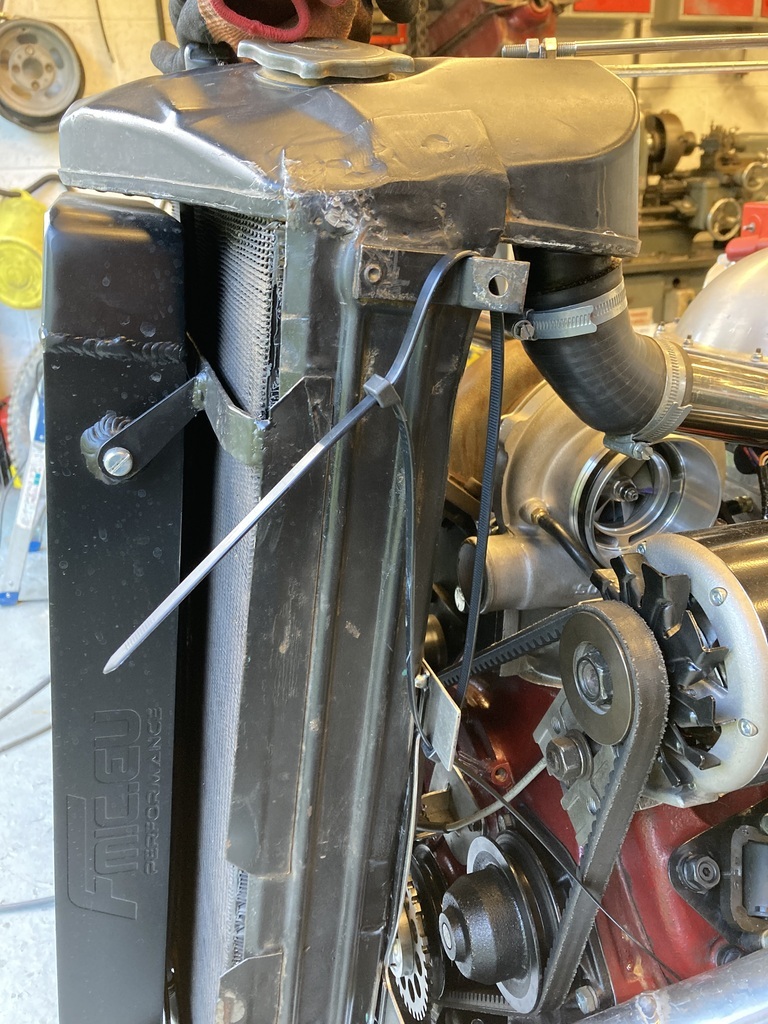

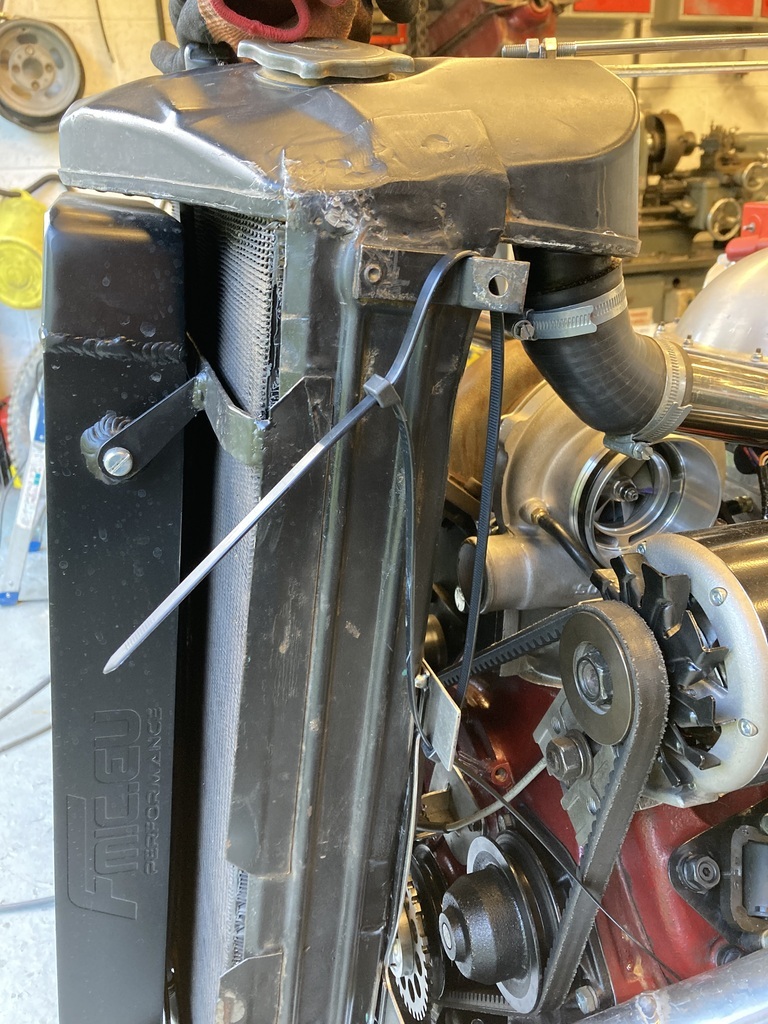

Trying to balance it in position for welding was a challenge on my own but hanging it from cable-ties worked great and I could click them up one notch at a time to get it dead level.

The new fan position made for much stiffer mounts which meant the fan wasn’t flopping into the rad core now and sat proud by 1/4”/6mm.

I quickly turned up some spacers to push the fan forward.

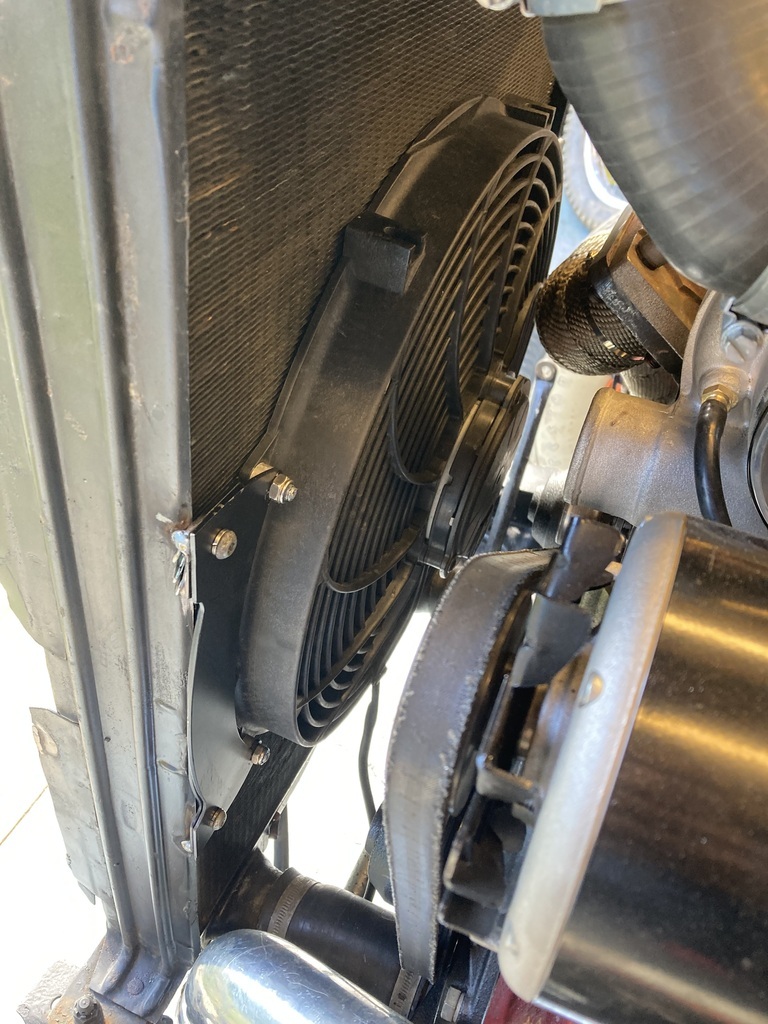

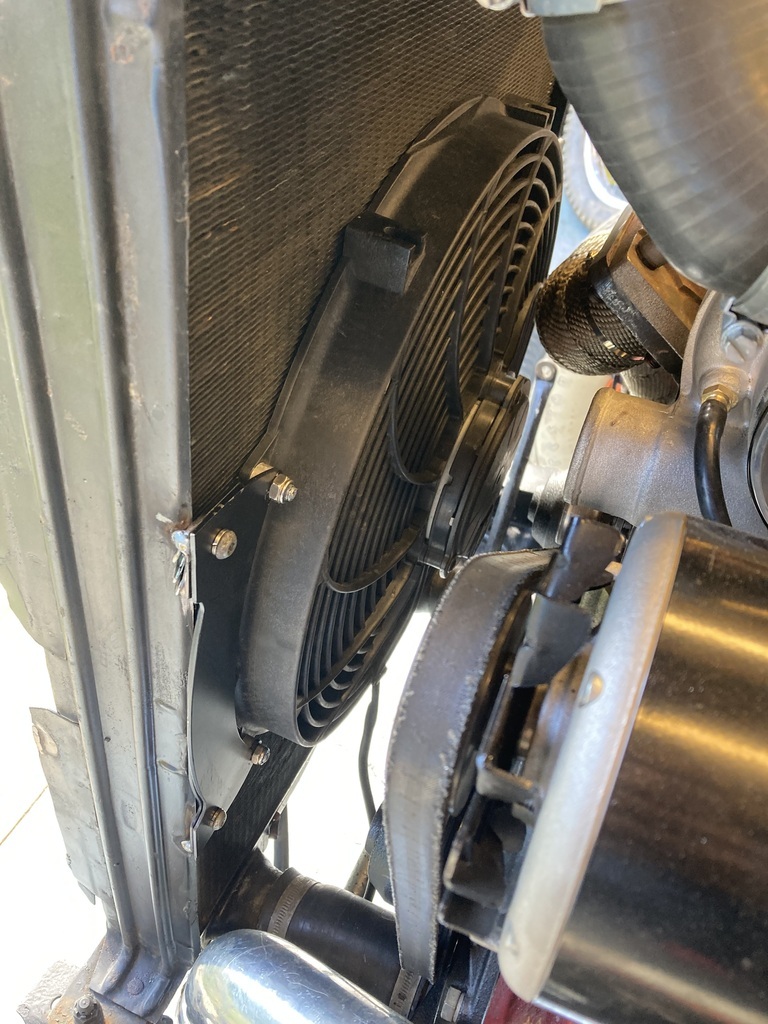

All fitted up and as most everything on this car it’s bloody tight but fits!

Before heading out I added another gauge in the form of the big Vacuum/pressure tester gauge as it’s easier to read than peering across to the laptop on the passenger seat.

Out on the road things felt better, much tamer and torquier as you’d expect from the smaller cam but still not amazing.

I think I saw over 5psi for the first time… Maybe…

A quick run out turned into a massive detour because a truck had broken down on the flyover at that exact moment instantly turning the whole area into a gridlocked mess. #londonlife

What this did provide was more run in time and a test of the cooling system.

It still overheats.

Returning home the toothed wheel had come loose already 🤦♂️ but the cooling issues I was prepared for. That’s why I left the front panels off. 😁

I’d already dug out the 14” fan, the one I originally wanted to fit but couldn’t squeeze it in.

Here it is compared to the 12” that was on it. I think the 12” may also have been a slimline version all adding up to even less cfm capacity.

I wanted to mount the new, bigger fan the same as I’d mounted the previous one which consisted of two brackets with captive nuts welded to the radiator frame and another two brackets bolted to the fan itself so the whole fan assembly can be dropped and removed from the engine bay.

The fans were both Revotec so used the same mountings but annoyingly each fan diameter has a bigger spread on the mounting holes.

I was feeling particularly lazy this day and cut the original one I made in half and added this jigsaw piece to give me the extra spacing.

The original 12” fan was mounted over to one side because of the clearance issues at the time which meant I ended up with a long legged bracket and a really short one.

The short side I had no choice but to remake it.

I remade two new end pieces with captives for welding to the rad frame.

And realised the mounting holes would clash with the previously drilled holes in the repurposed bracket.

Still determined to not make a new one I filled all the holes!

At this point I should have just made a new one.. 🙄

Trying to balance it in position for welding was a challenge on my own but hanging it from cable-ties worked great and I could click them up one notch at a time to get it dead level.

The new fan position made for much stiffer mounts which meant the fan wasn’t flopping into the rad core now and sat proud by 1/4”/6mm.

I quickly turned up some spacers to push the fan forward.

All fitted up and as most everything on this car it’s bloody tight but fits!