Enbloc

Part of things

Posts: 399

|

|

|

|

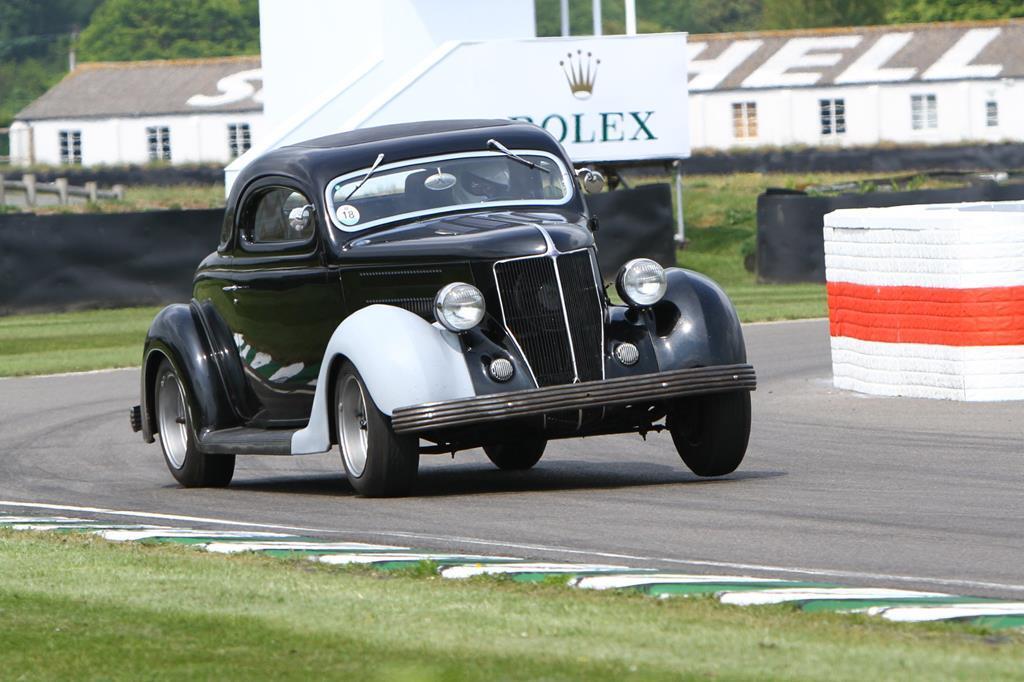

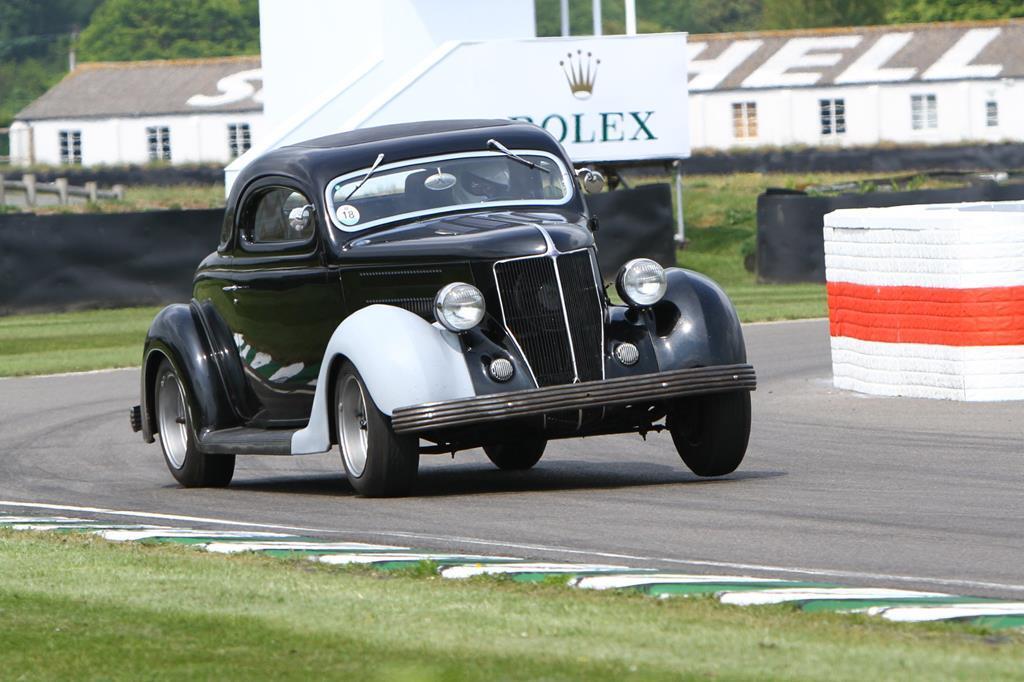

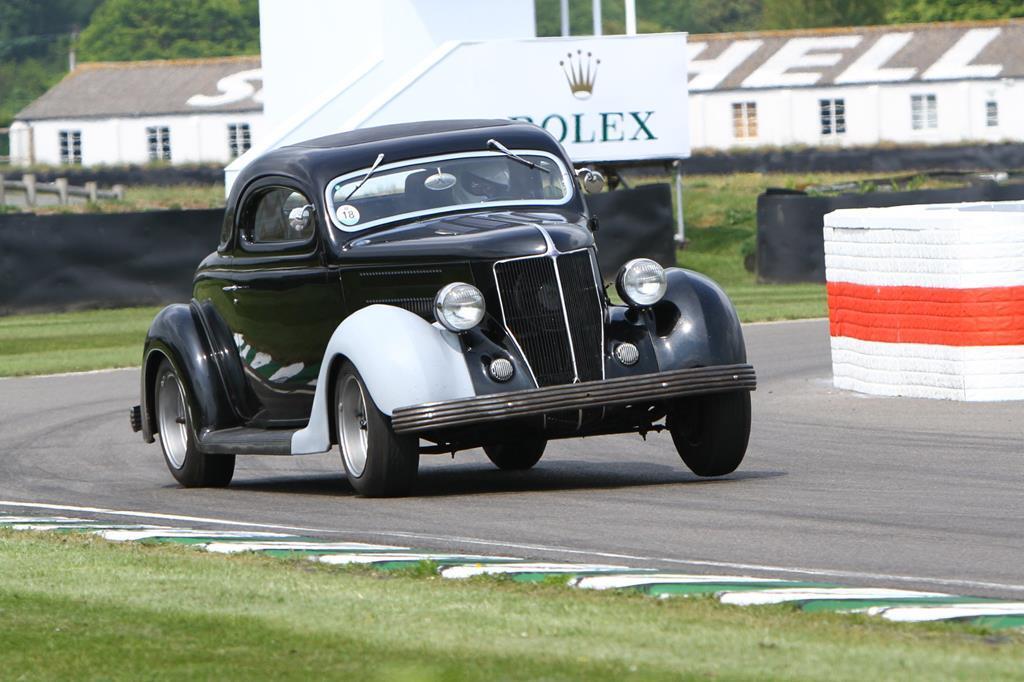

Let's start off on a high! I'm a part time lurker that after some time on the dark side that is social media I've found myself gravitating back to forums because let's be honest there are only so many glamour shots that can hold your interest. I thought my current distraction, what you see above, would be a good as thing as any to start a build thread and hopefully give something back. Lets wind the clock back to 2009. After a couple of Ford Model A's, (I was dailying my first Model A at 19!) I got burnt out with them, sold it all and tried to buy a Porsche 356, as you do. Couldn't find the right 356, got impatient and bought this 1936 Ford 3W coupe instead. This was a full project it had no engine, gearbox, interior, floors etc. It needed everything.  I covered the full build of the car and what's left of the thread can be viewed here. www.jalopyjournal.com/forum/threads/ooh-the-horror-my-36-coupe.378308/I did EVERYTHING in this car from shows, drag racing, dirt tracks, sprinting and hillclimbing. I've driven it through most of European. As far south as the Mediterranean Sea, over the Swiss Alps in East and as far north as Sweden. It's even lapped the Nurburgring! It became and still is quite the all rounder I always wanted it to be.  What's all this rambling got to do with a turbo'd Flathead? Alot of this action? abuse? happened with the power of a little small bore Flathead engine. Remember me starting with an engineless project? At the time I was looking for an Flatty and one came up on EBay for a few hundred ££. Take out, runner (Aren't they all!?). Flatheads aren't particularly rare here but they don't grow on trees either. The days of a couple of hundread ££ are llooonggg gone now. The story from the seller was that he had removed it from his '42 war time CMP (Canadian Military Pattern) truck because he'd fitted a big capacity French Flatty so he could run it on LPG! The story checked out because he took me out in the CMP truck with French motor and LPG. He also showed me his Flatty powered tracked Bren Gun Carrier and '41 Ford Woody staff car! This is a CMP truck.  This is a Flatty powered Bren. Interesting fact about the Bren's is that they are steered with a steering wheel not levers or pedals and initial steering input tweaks the tracks so you can steer a sweeping curve. As more steering lock is applied it locks a track to be able to rotate on itself like a conventional track vehicle.  To be continued… |

| |

Last Edit: Oct 13, 2022 18:43:35 GMT by Enbloc

|

|

|

|

|

|

|

|

|

Well this looks like it could be interesting. Have you bought the Bren?  |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Feb 25, 2022 11:27:08 GMT

|

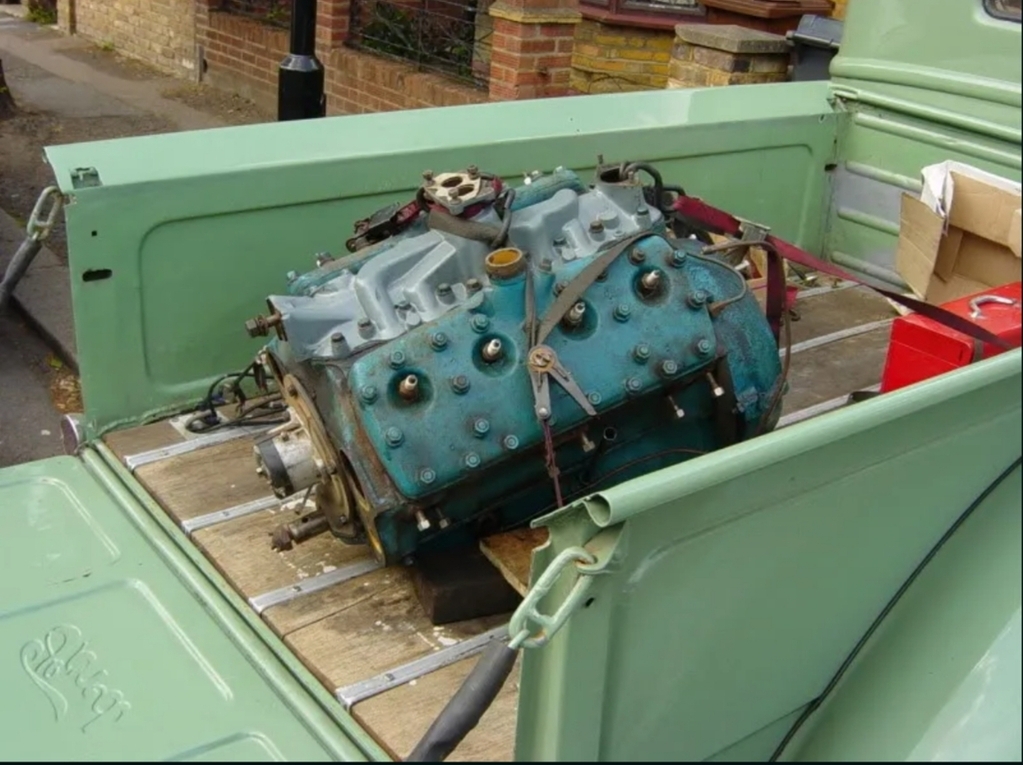

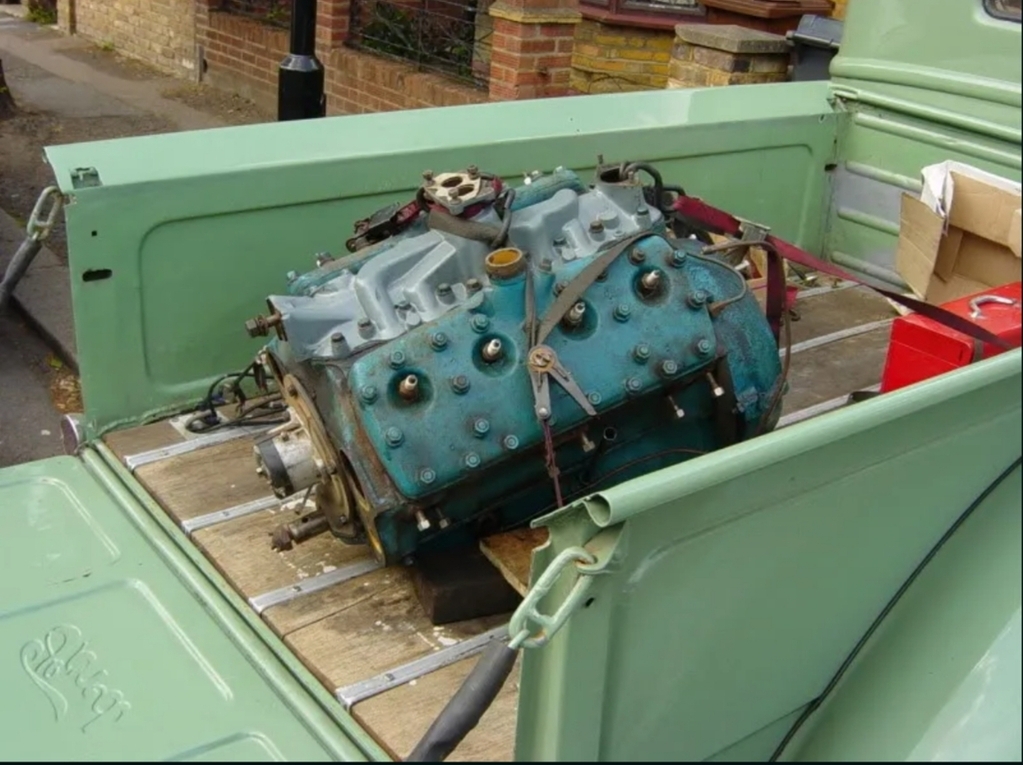

Here is the day in '09 when I came back with the engine in a friends '41 Ford pickup. Flathead powered of course. It had the ancillaries robbed but most of that I wouldn't be using anyway.  Now the question of how much do you prod the bear? Very little it turns out. I did pull the sump to make sure there was something actually inside the block and then hit it with the paint gun.   The project moved on and eventually it was time for the first start. This old video shows me as a very gawky 26 y/o, somethings never change! In the video you can hear the starter solenoid jam and hear me give it a wack to unstick it. The same solenoid is still fitted today and still randomly jams on 12 years later! The car got finished and put on the road and the engine did sterling service for years apart from a brief hiccup early on with a faulty thermostat that cooked a head gasket on one bank. I started to notice that it was getting a little rattly and smokey so knew it time was limited. I remember the exact time its fate was sealed. I gave it a boot full on the local bypass, looked in the rear view mirror and saw nothing but a cloud of blue smoke. Opps. Shorty after that it was pulled and replaced with a built French Flathead waiting in the wings. I certainly got my money's worth. This was the condition of the big ends when I pulled it apart. The bearing surface had long since left the building and was running on the copper backing which itself was breaking up! They all looked like this.  |

| |

Last Edit: Feb 25, 2022 11:28:39 GMT by Enbloc

|

|

Enbloc

Part of things

Posts: 399

|

|

Feb 26, 2022 20:24:15 GMT

|

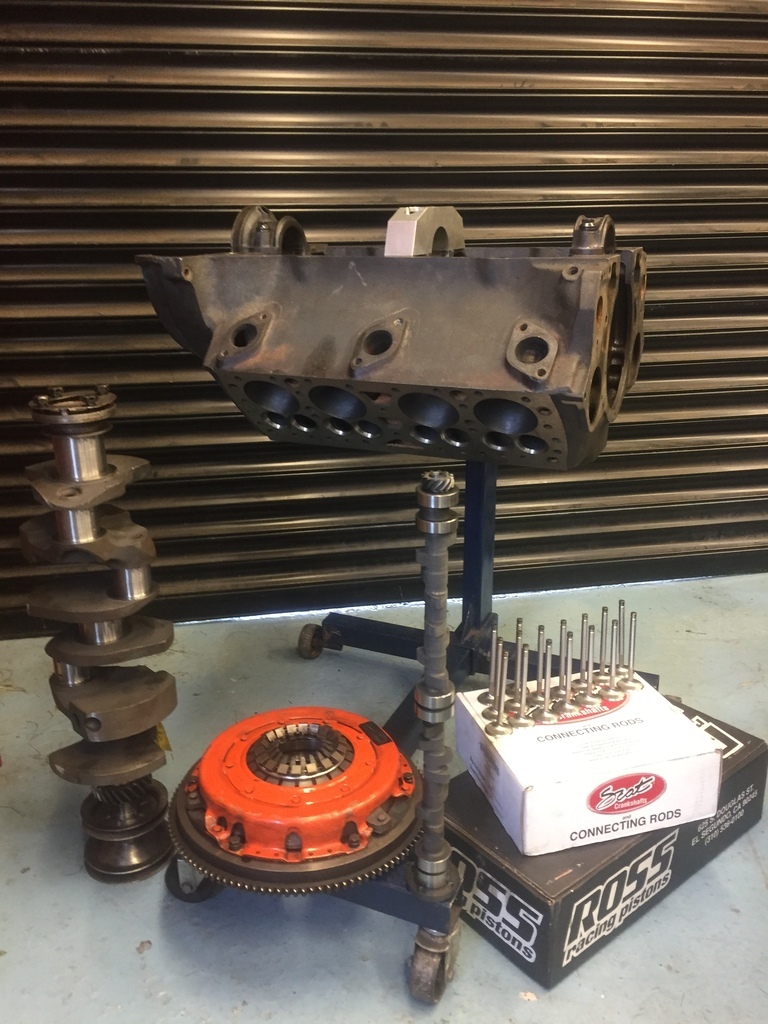

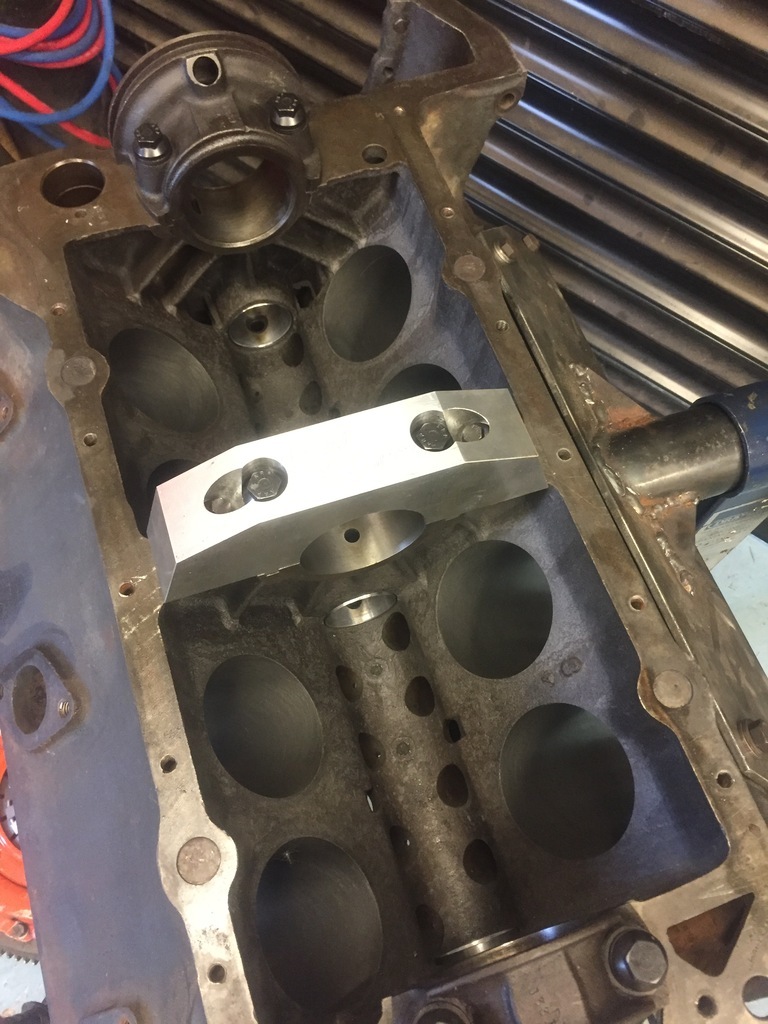

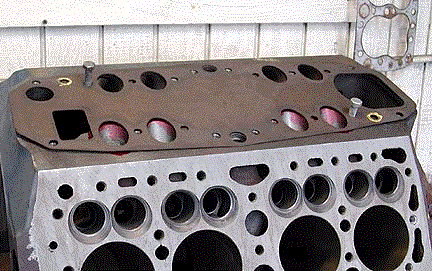

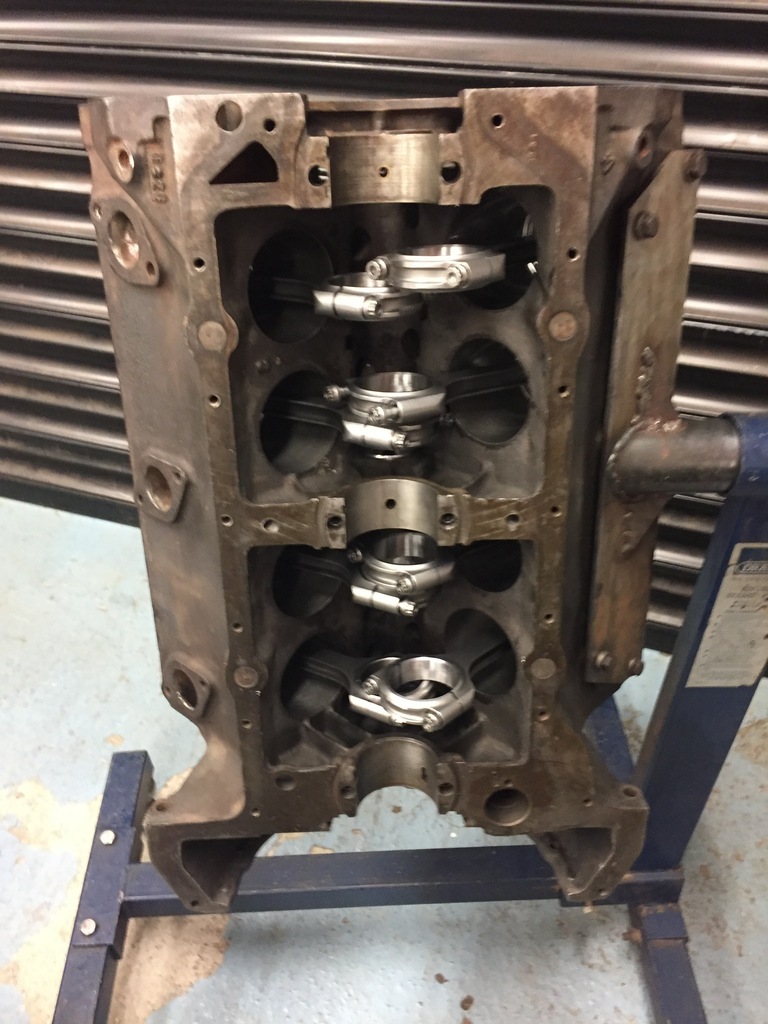

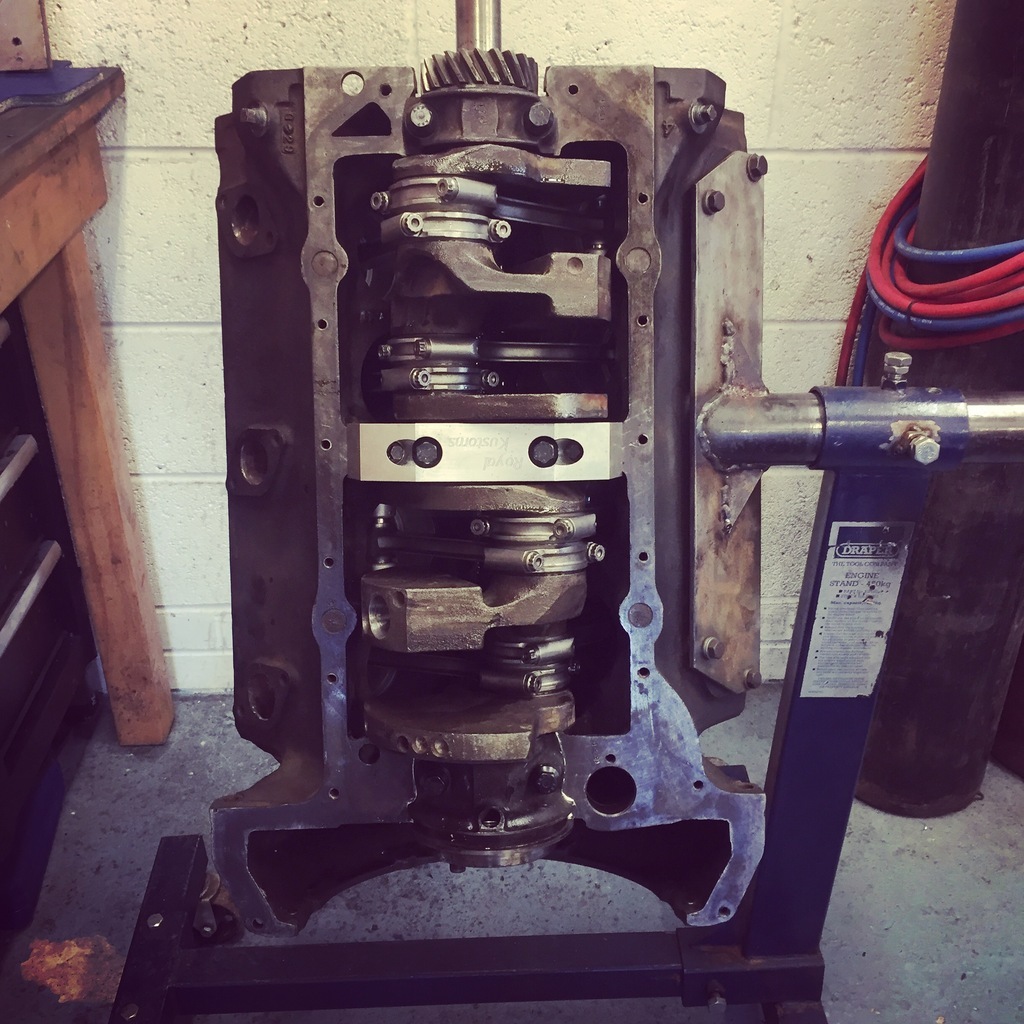

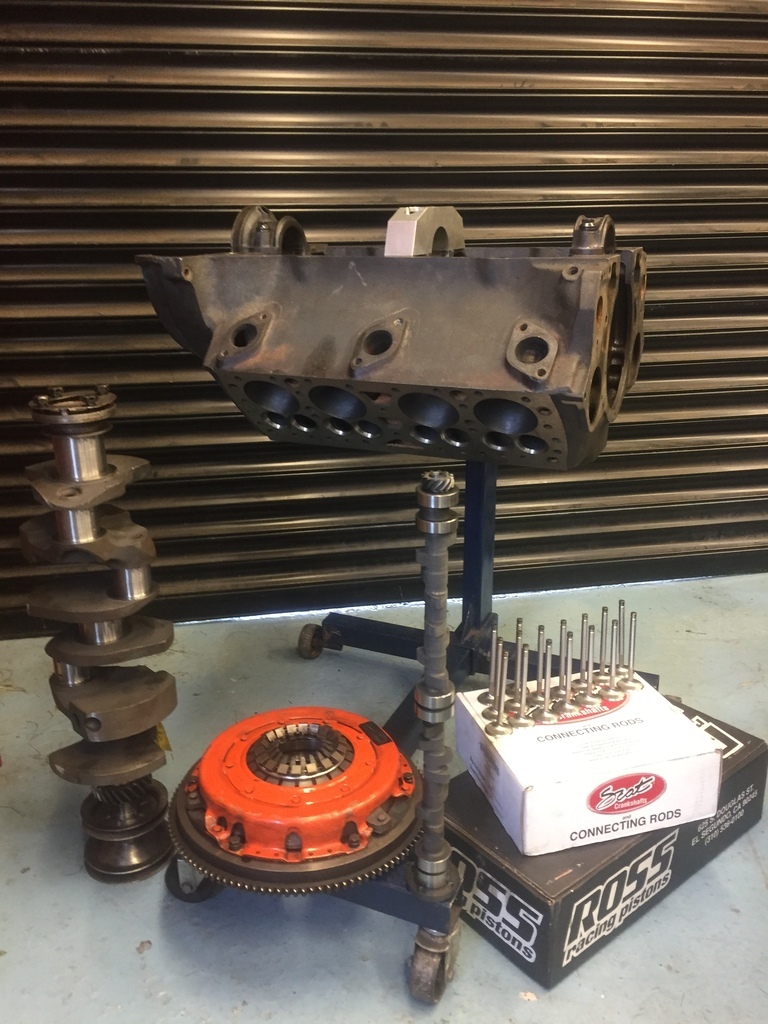

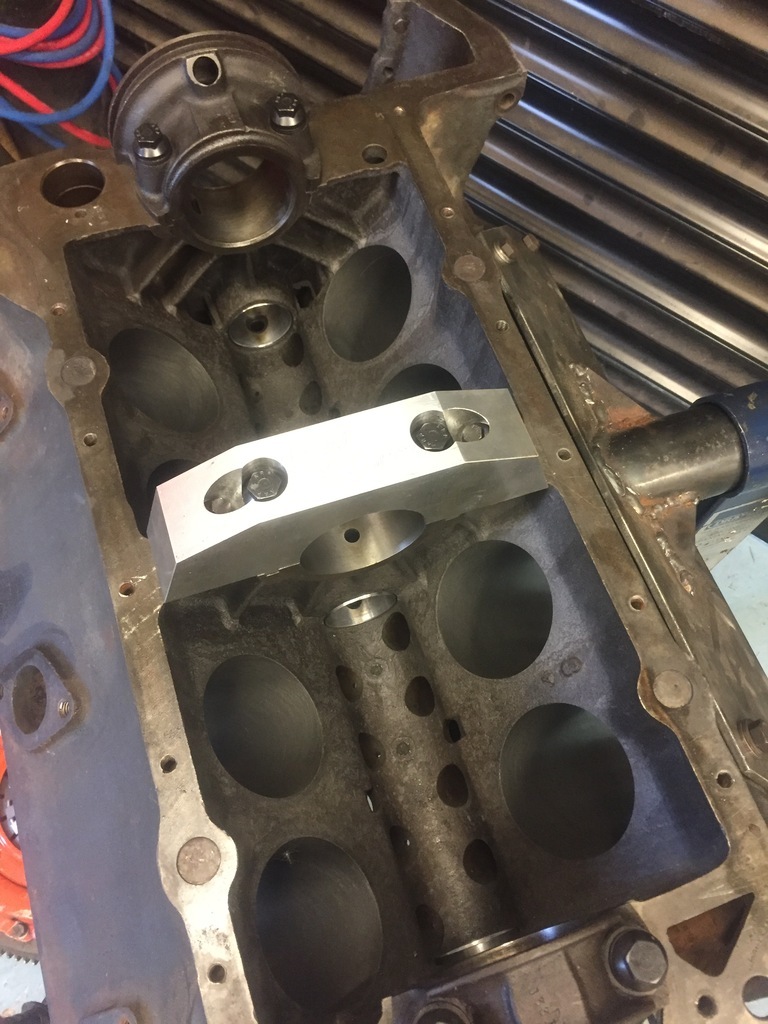

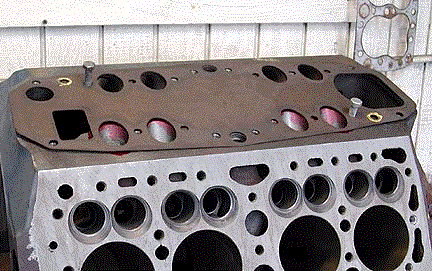

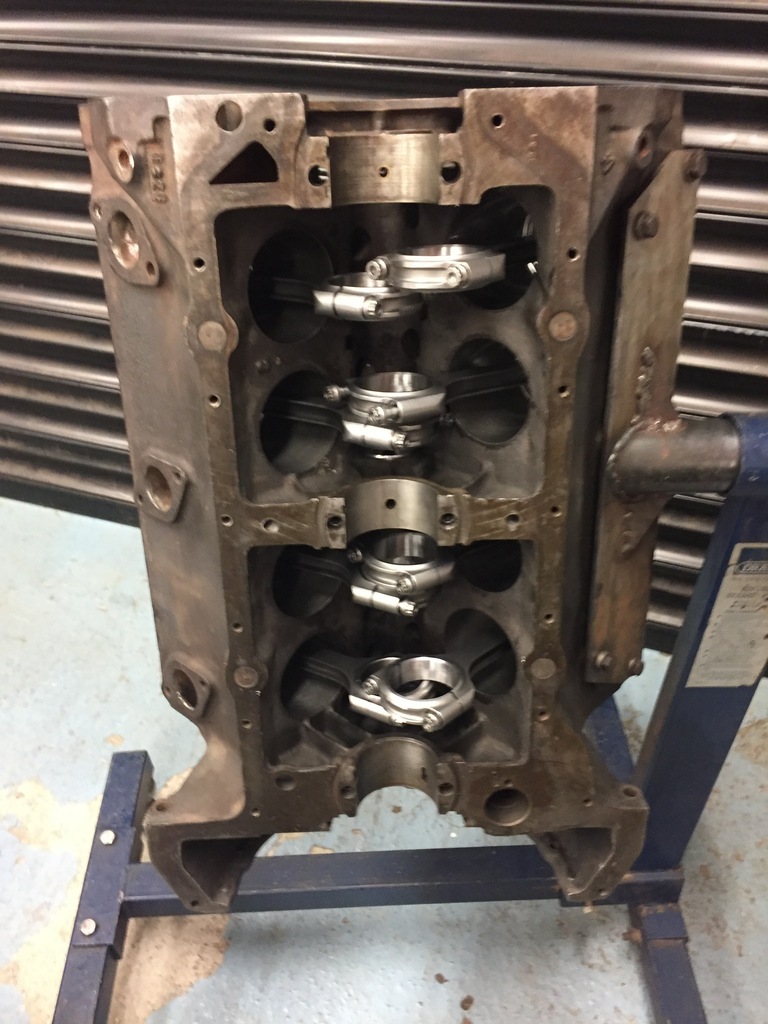

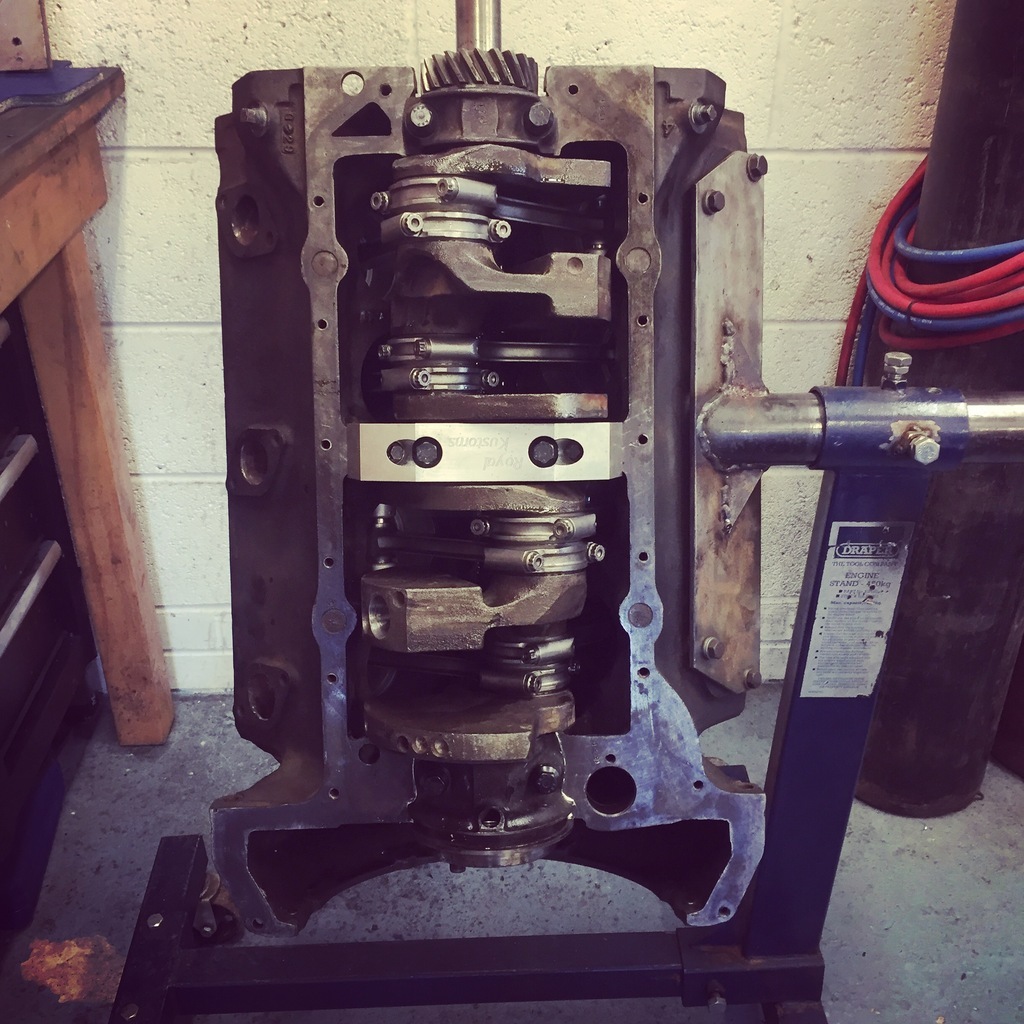

Some brief Flathead V8 history. This block is known as a 81A and it’s year range is roughly 1938-1945. It’s basically the crossover from the earlier 21 stud head 221ci(3.6L) to the later 24 stud head 239ci(3.9L). Its construction consists of the internal architecture of the early engine and the external architecture of the later motor. Fundamentally not a bad engine they aren’t particularly desirable either. With the engine being a small bore, small stroke crank my crazy plan, at this point, was to build a bullet proof, high rpm, screamer! Now “screamer” is a relative term. A stock Flatty’s peak rpm is around 3500rpm and my French Flatty peaks at 5300rpm which is pretty good going. I have now found myself with a dead V8 and no real means to store it so I did the next best thing and let someone else store it for me by handing the heavy bits over to Royal Kustoms. 😆 Even though the engine was knackered, the block which is the important bit seemed to be in excellent condition from a casual inspection. Only full crack testing would decide the fate of its future. It passed the crack testing with flying colours. Full steam ahead. A time later this is what I got back from Royal Kustoms. A rebored block taking 221ci out to 239ci. The maximum you can go on a small bore block. Reground crank, healthy Cam, larger Pro-Flo valves, aluminium flywheel, diaphragm clutch, forged rods and custom ordered forged pistons. Why custom pistons? Forged Flatty pistons are an off the shelf item but not when you’re at standard bore. Nobody is building standard bore Flattys anymore!  Some more magic was added to the block. Remember the bullet proof bottom end idea? The Flattys have 3 mains, yes 3, count ‘em. This isn’t as much of a problem that some will lead you to believe but when it does become an problem it’s usually the centre main that goes first. Royal Kustoms created this solution. A billet steel, 4-bolt main cap to replace the factory cast, 2-bolt one. Belt and braces.  |

| |

Last Edit: Feb 26, 2022 20:30:52 GMT by Enbloc

|

|

Enbloc

Part of things

Posts: 399

|

|

|

|

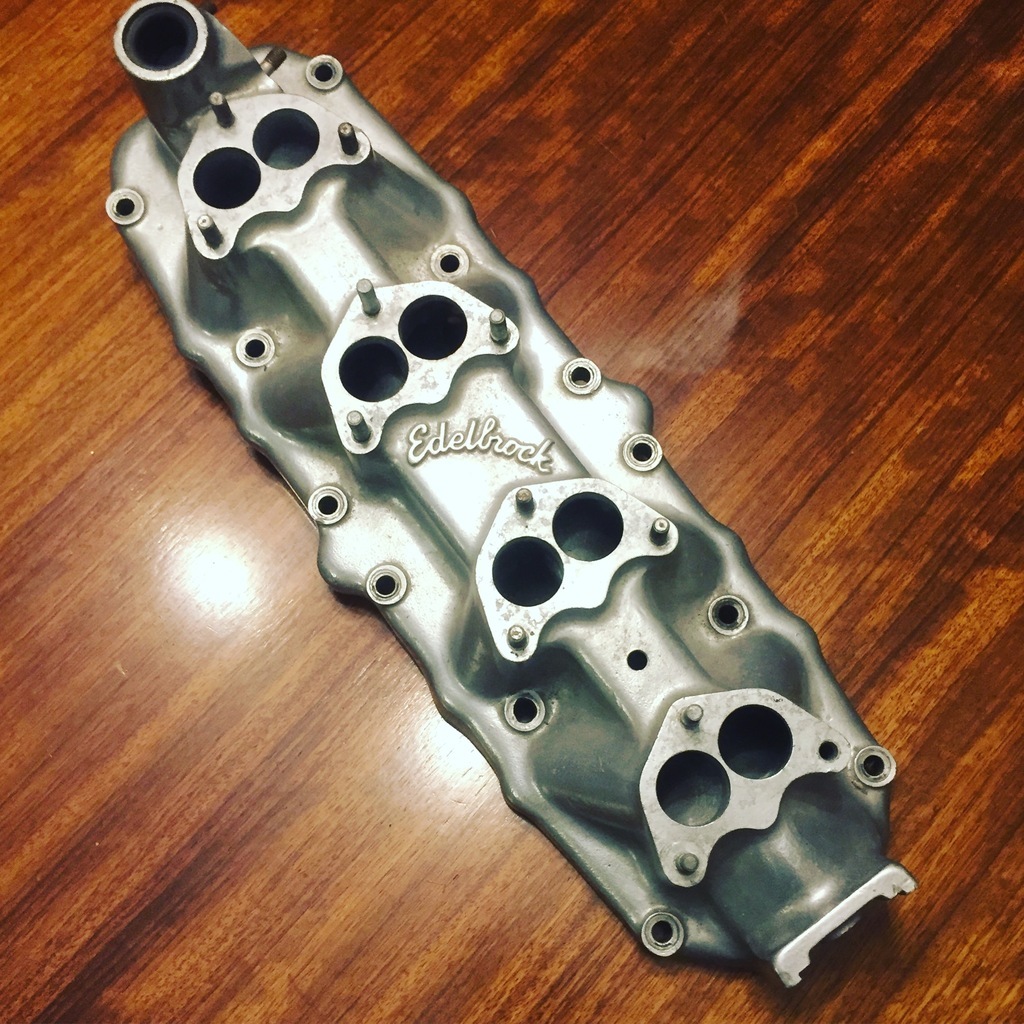

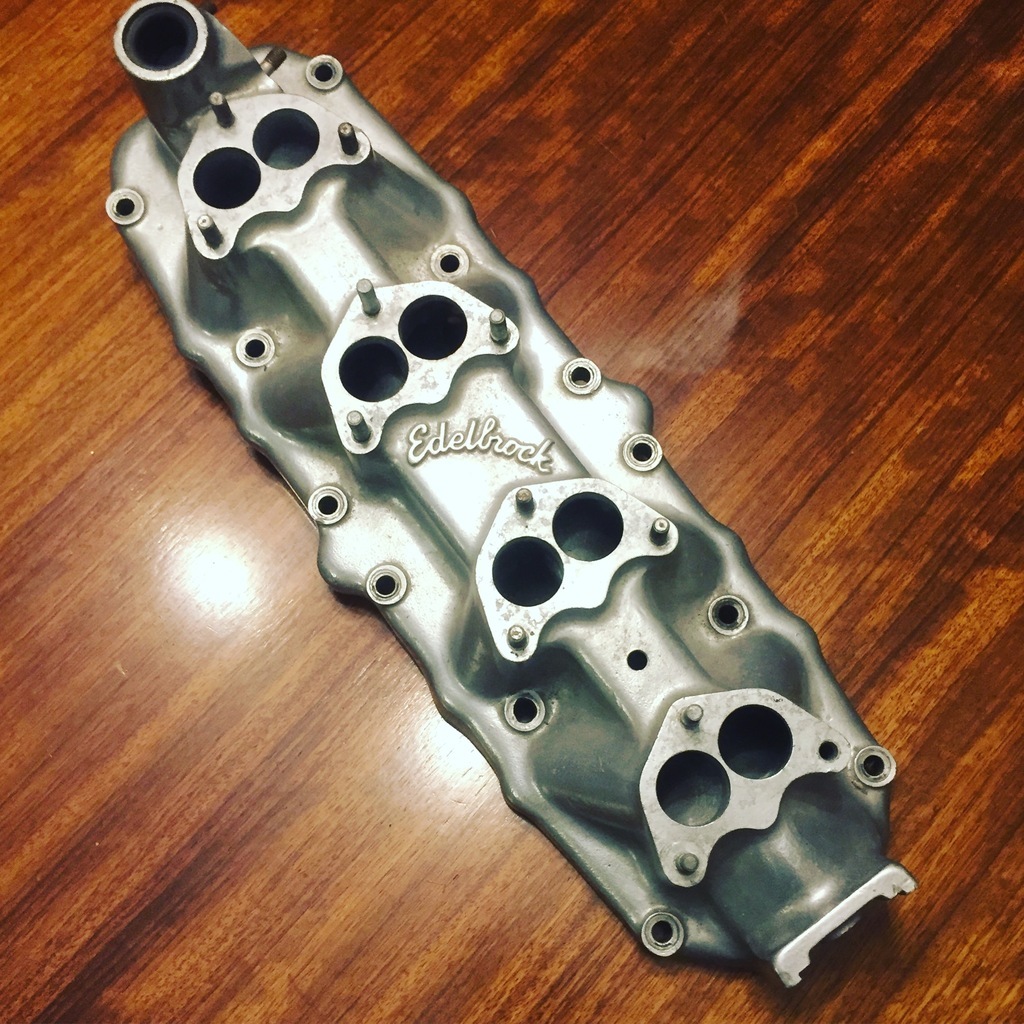

With the block back it was time to get on with more prep work. First was to relieve the deck face. The valves in a Flatty are sunk into the deck face in relation to the bore edge. What was realised in the depths of history was this ‘excess’ of material between valves and bore could be removed to create a significant increase in airflow. The same mod even went onto being incorporated into the block castings in the last generation French engines. Stock engine  Relieved block.  The relieving itself can be achieved multiple different ways and the type of relief that is best will be argued over to the end of time. I chose to do a simple full width, fixed depth relief at 0.100” thou (2.5mm). But how to do it? I had a mental note in my head of using a wood router! A router is basically a die grinder in a fixture, so with a decent carbide burr it can make quite the milling machine! Nothing like frill of sending a carbibe burr into fresh bores. 😆 I’m certainly not reinventing the wheel here as I found this picture in the Peterson Archives from I guess the sixties. Yes, I had the same expression on my face through the whole experience.  It was at this point, 2017, that I lost interest in the whole thing mainly because I’d bought this…  There was a small amount of movement in this down time when my lovely partner got me this much wanted, surprise birthday gift, 4 carb/8 throttle original Edelbrock manifold because you know, REVS!  |

| |

Last Edit: Mar 22, 2022 15:03:07 GMT by Enbloc

|

|

Enbloc

Part of things

Posts: 399

|

|

Mar 21, 2022 21:11:35 GMT

|

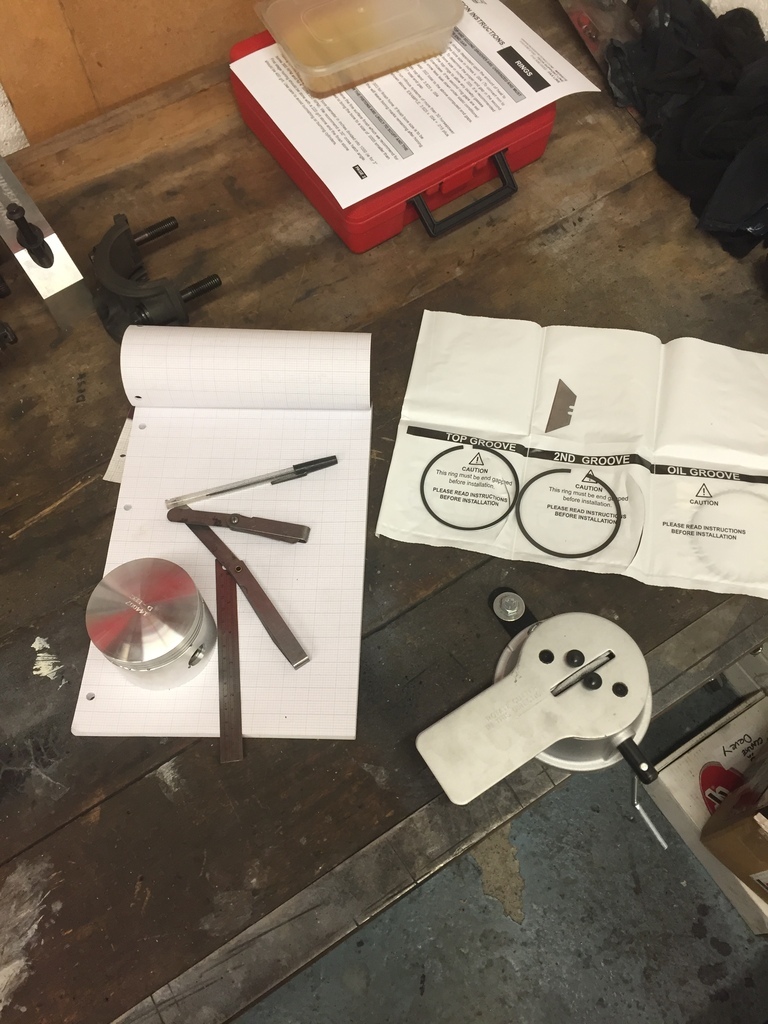

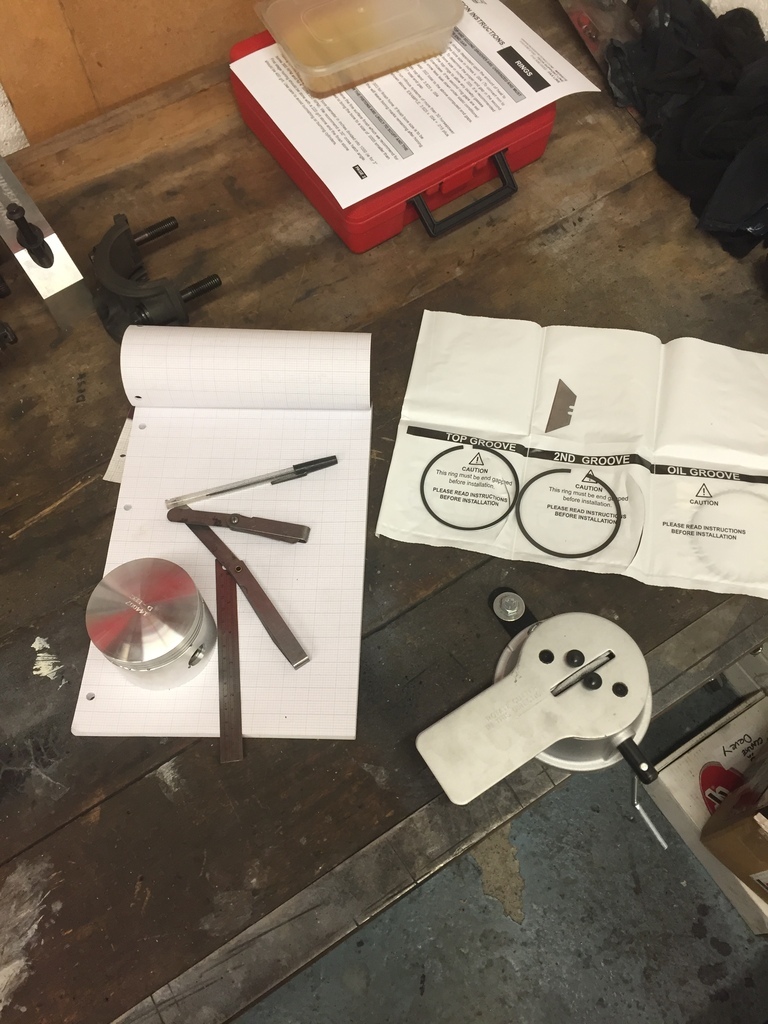

So, roll on 18 months and I finally had enough of tripping over this thing in the garage. That and seeing the start of surface rust forming on the machined surfaces spurred me on to actually put it together. First job was to get the block back on the engine stand. I decided to give it a very superficial port job. Enthusiasm was still lacking and attempting a porting job wasn’t really helping. Over that hump it was given a good clean in readiness for some assembly.  I treated myself with this engine build to a piston ring filer. Wow! What a revaluation it was compared to hand filing. It took a fraction of the time, much cleaner finish and I still had skin left on my fingers at the end. 😆  Remember the custom made standard bore pistons? This happened next… The forged rods from Scat are to big to pass down anything but an oversize bore. Where to go from here? My initial idea was to feed the piston/rod assembly in from the bottom of the bores. This was a failure in two respects. First the underside of the block isn’t flat or square to the bore like the head side so the piston compressor doesn’t sit flat and the rings pop out as the pistons get knocked in and you kink an oil control ring… like I did…. curse word. The second issue is the the pistons won’t pass the 4 bores adjacent to the centre main because of the webbing. Second idea was to disassemble the piston from the rod, push the piston down the bore as normal and push it far enough out the bottom of the bore to expose the piston pin but not so far that the rings spring out. Reconnect the piston to the rod and push the whole assembly back to the top of the bore again. Repeat X7.  Fiddly but it did work. Crank goes in as normal and pull each connecting rod up to its journal. Before the crank went in though I had another change and decided the lightened factory flywheel that I was originally going to use and had all been balanced into the rotating assembly didn’t really fit with the “rev monster” ethos. I splashed out on an super lightweight SFI spec aluminium flywheel and of course had the rotating assembly balanced… Again.   |

| |

Last Edit: Mar 21, 2022 21:15:25 GMT by Enbloc

|

|

|

|

|

|

|

You're still moving forwards, it's just along a parallel path! No backwards steps at all!  |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Mar 22, 2022 12:14:57 GMT

|

You're still moving forwards, it's just along a parallel path! No backwards steps at all!  Ha! Glass half full and all that. |

| |

|

|

|

|

|

Mar 22, 2022 13:19:36 GMT

|

|

This is an excellent, excellent post. Informative and as with all good build threads I'm looking forward to what's going to happen next.

|

| |

|

|

|

|

|

Mar 22, 2022 14:43:00 GMT

|

|

Can't wait to hear more.

I also want to be a fly on the wall when a subsequent owner tries to take the pistons out for a rebuild..... Wait..what....

|

| |

|

|

|

|

Enbloc

Part of things

Posts: 399

|

|

Mar 22, 2022 20:32:41 GMT

|

This is an excellent, excellent post. Informative and as with all good build threads I'm looking forward to what's going to happen next. Thanks. Trying my best with something that is a little obscure. Can't wait to hear more. I also want to be a fly on the wall when a subsequent owner tries to take the pistons out for a rebuild..... Wait..what.... Never thought of that! Will probably never make it a second owner. 💥😆 |

| |

Last Edit: Mar 22, 2022 20:34:28 GMT by Enbloc

|

|

Enbloc

Part of things

Posts: 399

|

|

Mar 24, 2022 17:35:03 GMT

|

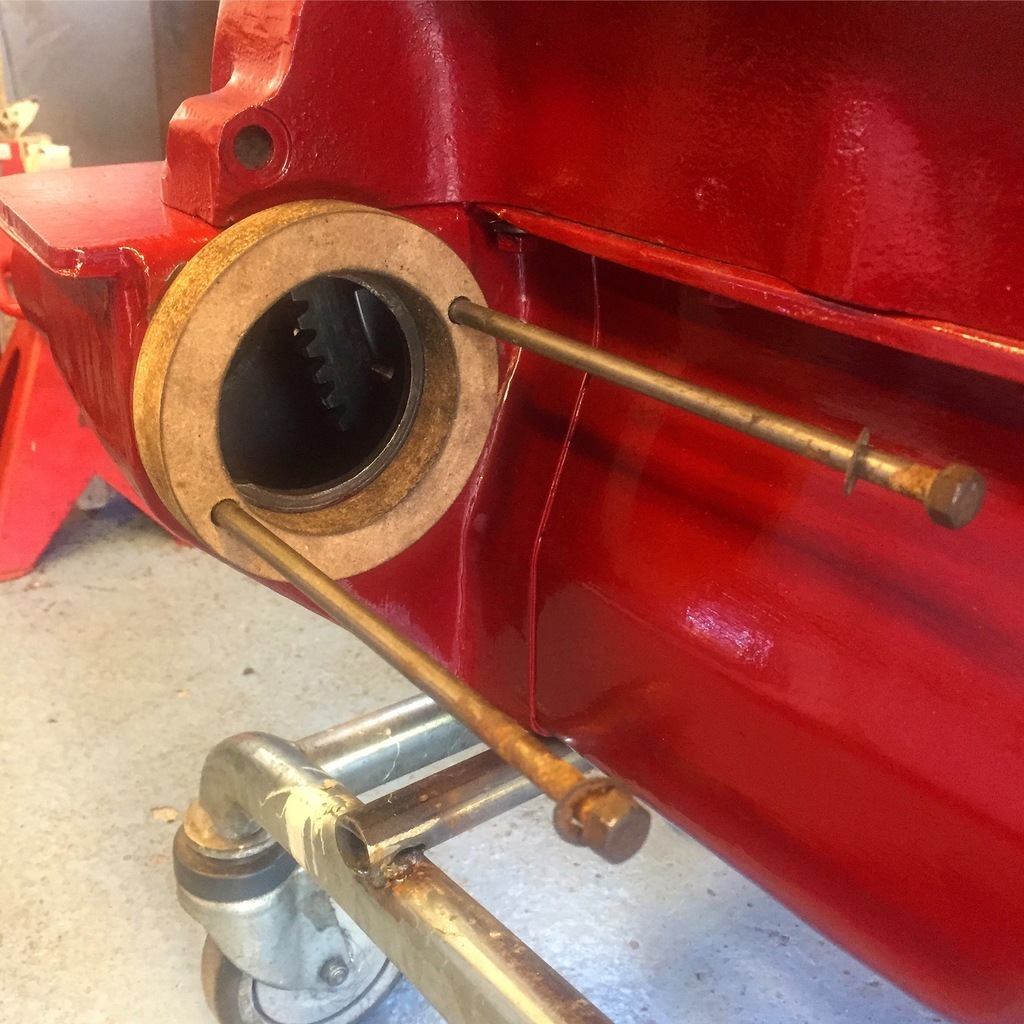

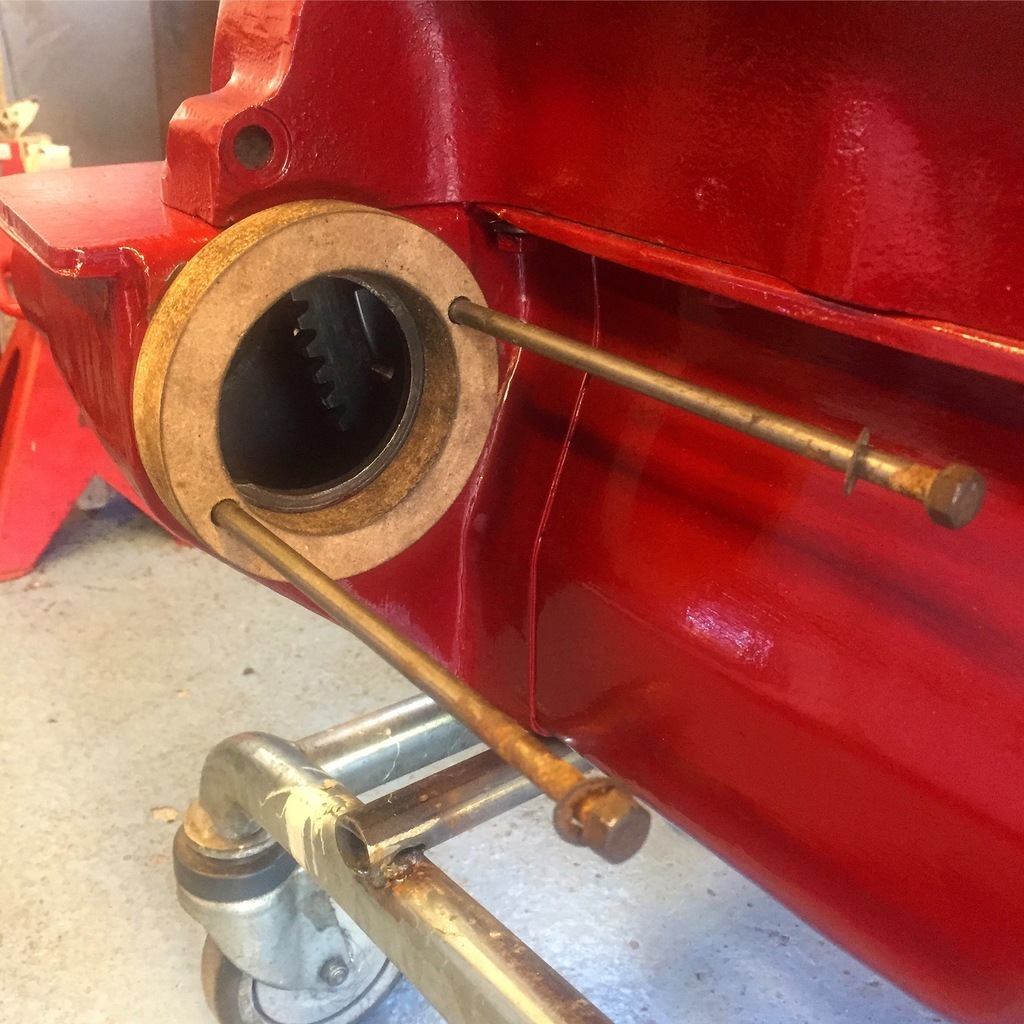

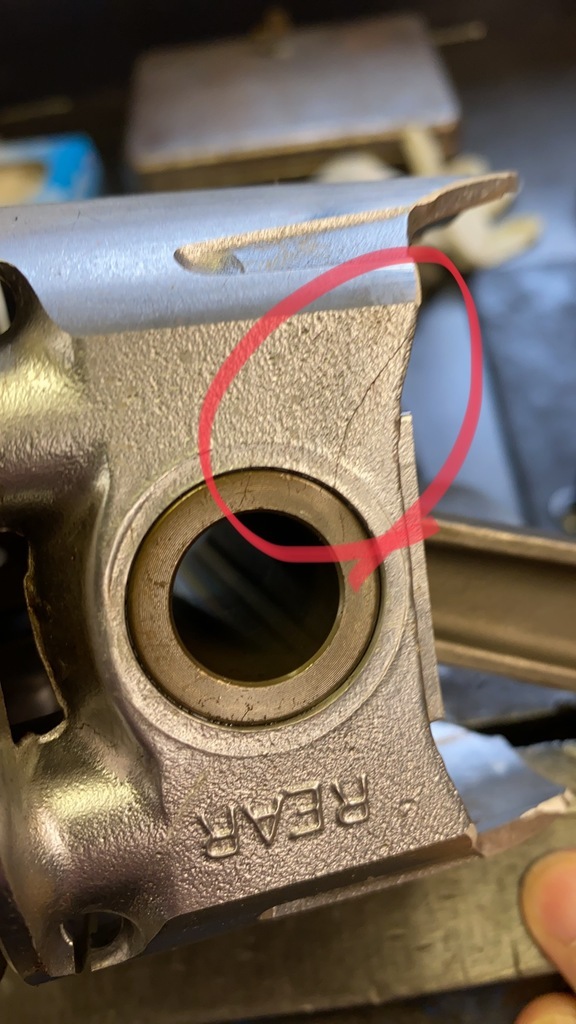

With a break in engine assembly, probably due to waiting on on a replacement piston ring pack from Ross (See above), I decided to address the sump issue. Said sump issue was basically that I’d robbed it to go on the replacement French that was now in the car. Luckily I’d had the foresight to pick up a couple of Ford Pilot style sumps from a previous visit to the Bealieu Autojumble. I dug out the best one (Read the one that needed less cleaning) and then remembered what was lurking in the bottom. What the…??  Fair play to whoever created this piece of copper pipe mastery, squeezed it into the bottom of sump, soldered the ends on and connected it all up. It was a utter pain to remove as well. It was in there tight. And the million dollar question, heater or cooler?   Apart from filling the holes from removing the pipe work the main job was to build up some baffling around the oil pump pickup. Most Flatheads came with zero baffling of any kind. Way back when I starting hillclimbing this car/engine combo the lack of oil control never sat well with me. Again, way back, I built some simple baffling as a “something is better than nothing” stop gap. Well, it worked so well as I never suffered from any oiling issues after many years of competing that I just copied the design over to the replacement sump.   As mentioned the sumps origins are 50’s British. They are identical to the US sumps bar one difference, the starter motor mount. In true British engineering tradition, you take a simple design that works and has been in production for 25 yrs and produced in its millions and you make it more complicated and not interchangeable with anything else! The US stater motor is a simple round hole with two fixings. The British version has the same fixing points but the hole is just slightly smaller and out of round. 🤷♂️ #becauselucas All is not lost as you can simply enlarge the hole to US size. I turned up this MDF template ready for when the time comes.  |

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,219

|

|

Mar 27, 2022 11:16:30 GMT

|

That is so cool  |

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

Mar 27, 2022 12:57:11 GMT

|

|

Welcome back! Been a while since I’ve had anything to do with hotrodding but this is very cool. You always did know how to put a car together, good to see you haven’t lost your touch.

|

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Mar 27, 2022 21:13:47 GMT

|

Welcome back! Been a while since I’ve had anything to do with hotrodding but this is very cool. You always did know how to put a car together, good to see you haven’t lost your touch. Hey Jonny, I'm impressed you remembered who I am! You were always my hero in your Pop.  |

| |

Last Edit: Mar 27, 2022 21:15:45 GMT by Enbloc

|

|

|

|

|

Mar 27, 2022 21:25:52 GMT

|

|

I'm trundling my way through your HAMB build thread - good read thanks!

|

| |

1968 Mini MkII, 1968 VW T1, 1967 VW T1, 1974 VW T1, 1974 VW T1 1303, 1975 Mini 1000 auto, 1979 Chevette, 1981 Cortina, 1978 Mini 1000 1981 Mini City, 1981 Mini van, 1974 Mini Clubman, 1982 Metro City, 1987 Escort, 1989 Lancia Y10, 1989 Cavalier, 1990 Sierra, 1990 Renault 19, 1993 Nova, 1990 Citroen BX, 1994 Ford Scorpio, 1990 Renault Clio, 2004 Citroen C3, 2006 Citroen C2, 2004 Citroen C4, 2013 Citroen DS5. 2017 DS3 130 Plenty of other scrappers!

|

|

Enbloc

Part of things

Posts: 399

|

|

|

|

I'm trundling my way through your HAMB build thread - good read thanks! Cool. Glad it’s of interest. |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Mar 28, 2022 11:03:05 GMT

|

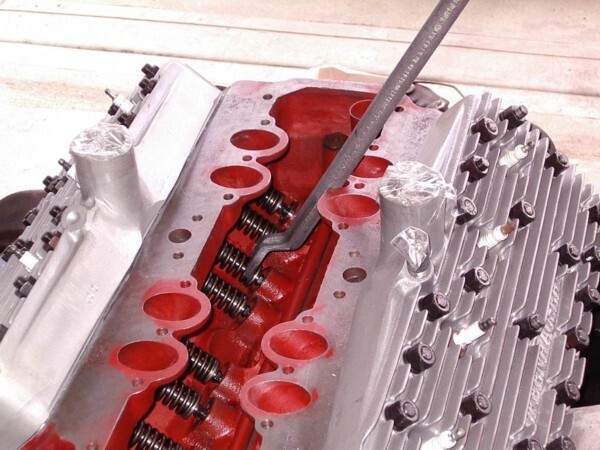

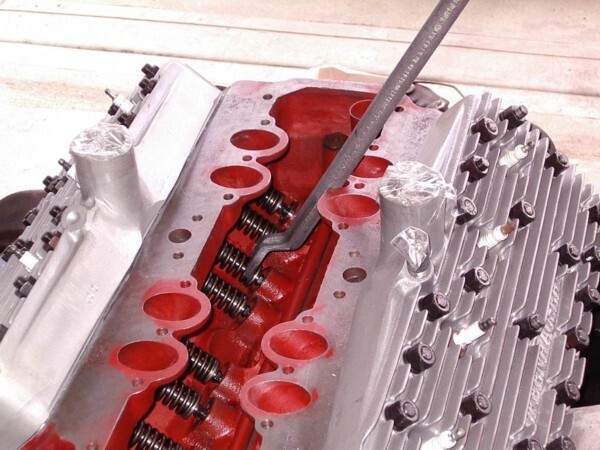

With the rotating assembly fitted it was time to move onto the valve train. Of course things aren’t quite conventional. The valve assembly is built up outside of the engine.  The complete assembly is then dropped into the valve guide bore in the block where the use of a tool affectionately called a pickling fork is needed. The forked end on the pickling fork slots into a groove in the valve guide which when levered against the opposing side of the valve chest allows you to pull the whole assembly down against the valve spring exposing another slot in the valve guide where a horse shoe clip is slid in with your fingers. Simple right? Well no. The whole process is like playing a game of Operation, upside down and without removing it from the box it came in! Add in an uprated valve spring and you’re now putting your full force on the pickling fork to hold the spring down, praying the fork doesn’t slip off and take your fingers with it.   Before all this some other jobs needed addressing first. Because of the material previously taken out the port/bowl the guides now stuck up into the port. This simply involved facing the top each guide until it was flush again.   As mentioned I had fitted aftermarket valve springs. There is now only one true performance spring available for the Flattys and that’s from Isky. It does makes spring choice somewhat easier.🙄 The Isky springs are specified to have installed heights of 1.800”, 1.900” and 2.00” depending on desired seat pressure. What I’ve never worked out , unless I’m missing something obvious, is when straight up installed these springs always measure out 0.375” (3/8”/10mm) too long. What to do? This is beyond basic valve shims and stacking valve shims wouldn’t work either as even though the guide is long enough to accommodate them after about 0.100” of shims the centre spring locator stops and the shims would just be rattling around under the spring. What I did was turn up 16 spacers that were 1/2” long that slid over the original valve guides and then had an internal step turned in the I.D at the bottom to locate them on the original spring locator step.   Each valve assembly was fitted without the spacer. The spring height measured with internal callipers and the 1/2” long spacer was turned down in height to achieve a 2” installed spring height. Repeat x15 Add the Schneider 284F (Race) cam and you get lift.  As a side note I collect licenced Pre-War Ford tools, which there are many. This is a puller that is for removing the valve assemblies from the block. As you can imagine cast iron block and cast iron guide add time and moisture and they can become quite stuck. With no real access from the backside this method is works well. The alternate is cutting wheel and BFH.   |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

|

|

With the bulk of the engine assembled enthusiasm was really starting to wane again for the whole thing. Jobs were being rushed and corners cut. The unusual situation with this engine build was that it had no home and no end goal for its intended fitment. Usually you build an engine because of the need for one, whatever that need may be, that’s your drive to get it done to get it done. Not so with this. Because I knew this engine was going to sit when finished I needed to start thinking of making attempts at sealing it up for storage. The sump dealt with the lower end, my lift plate made a great cover for the valve chest just leaving the heads to cover the bores. I dug out the stock heads and plonked them on and yeh… they just floated off the deck faces. The over sized valves and valve lift caused major interference issues. This was made more complicated by the heads themselves. Remember this is smallbore 81A engine . Because of the smaller capacity the 81A heads have scaled down combustion chambers to keep the compression consistent to the bore size. The 81A heads are sometimes referred to as “cheater heads”. In some period race classes you would have to run factory heads so the use of these gained an instant compression ratio bump. Legal or not. What to do? Rush it and cut corners of course by crudely hogging out the combustion chambers till the heads fit with the prospect of cleaning them up when the time comes. 🙄  Quick mock up for the glamour shot, take it back apart, throw a cover on and push it under the bench.  The inlet did make it into living room and only recently got removed with a change around of the furniture. 😆  |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

|

|

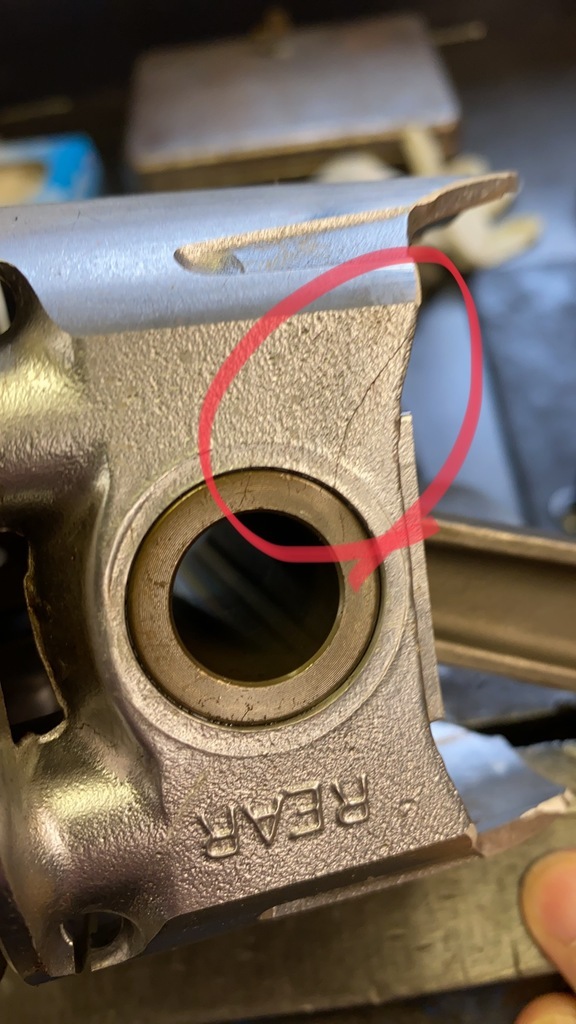

The engine went away summer ‘19 and didn’t see the light of day until end of ‘21, over 2 years in storage. Ouch! I wasn’t idle in this time. I built 2 more engines among numerous other projects. The first was the original 260ci Small Block Ford from the Falcon. It was original to the car and never been out or apart but ran like a top… Until I started sprinting in it and blew every oil seal and head gasket. 🙄 In my defence they were 55 yrs old and a little hard. 😁 A straight forward build bar the complications of being an early small bore (I see a theme here) which means that everything aftermarket SBF physically fits but doesn’t quite work. That and I got caught up with the start of the pandemic parts supply issues and ended up waiting months and months for a cam that never came and I ended up throwing in some weird Clevite Performer cam because it was the only one left in stock.  The second was my dads 1955 Cadillac 331ci in his 1948 Pontiac.  What a saga that was as I will explain, the thread title does say tangents.😁 The engine was a rebuilt take out from a Caddy that had got a SBC conversion in the States. It ran lovely for about a thousand miles and then started getting a little smokey, then a lot smokey. On pulling the heads it was found that multiple cylinders had 1” wide, 1/8” deep grooves running the full length of the bores. Why? The wrists pins had come lose in the rods and made their into the cylinders walls. The Caddy motor has push fit wrist pins. To do this properly the rods little end is heated in a special oven that expands the rod end enough that the pin drops through and when cooled the little end returns to its original size tightly gripping the pin. What cowboys do is take a gas torch to the rod, over heat it and over expand it. It then doesn’t return to its correct size when cooled. The rod is scrap, the wrist pin comes adrift and takes the block with it. The block was ‘saved’ with 8 (!) sleeves taking it back to standard bore, a replacement set of used rods from the States and a freshen up had it back running again for the next few years. Then there was a series of unfortunate events. Firs, it blew a core plug at about 90 mph on Pendine Sands without the driver realising and the engine went nuclear.  Then some spirited driving at Prescott caused a “knocking” sound which went away but didn’t as a few months later the car was recovered off the M11 with a full blown rod knock. Rebuild 2. Here’s what was found on strip down. Cracked pistons probably due to the overheating.  Cracked rocker shaft stands.  Pounded to oblivion big end shells.  Trashed crank journal.  The crank was beyond economic repair. The rod only showed fretting, possible that it was salvageable but would you want to? Pistons were scrap and the bores showed scuffing from a partial seizure. |

| |

Last Edit: Apr 2, 2022 19:35:45 GMT by Enbloc

|

|

|

|