|

|

|

|

|

So much welding! Picking up where we left off... I got that passengers inner arch finished off.  Which is a nice feeling, because the next move was starting to offer up all the new panels. It felt like a huge leap forward.  ...well it did till I saw the sort of panel gaps I was faced with on first attempt, haha.  It was like trying to do a jigsaw, knowing some of the pieces were the wrong shape, but not knowing which ones! I got the doors and bonnet on and spent many hours trying to work out some datums and work out which panels were right and which needed tweaking so things would line up. Ultimately I found that the front edge of the wings was very flexible, so was likely knocked out of shape in transport/warehouse and so I bent them to match the profile of the front panel. After much head scratching about the inner wing fitment, I decided the repairs I did to the inner arch lip was where the misalignment had originated, so some of that was cut out and repaired for the second time. I also found that my drivers door hinges were slightly bent, causing the door to sit too far backwards in the aperature. That, at least, was an easy fix with a hammer! So many hours later, things were finally starting to line up.  At this stage I'd just been clamping and screwing the panels into place with some self tappers. But now I was getting somewhere close with the alignment It was time to take the panels off and turn them into Swiss cheese, ready for the millions of plug welds I'd be doing to fix it all together properly.    Lots of work in there, much more than I thought it would be to be honest! Still, now its all together, and its looking pretty straight and kinda like a car, which is great. The welding was nearly done, but now I had quote a few small cosmetic jobs to finish off before I could actually pack the welder away for good. First up was the top of the front wings. The previous repair job had involved hammering this area in and covering it thick filler, so months ago I'd just cut it out and decided to deal with it later, unfortunately later had now arrived!   I also had the nasty extra holes that had been drilled into the car for the radio areal and for extra dashboard switches to deal with.    And small areas of rot in the bottom corners of both doors.   But finally, after 9 months of hard work, I could remove the bracing from inside the shell, and step back and admire my rust free Fiat!  That's a nice feeling indeed! I've got heaps of tidying up to do now, lots of underseal still to scrap from the inside (why would you do that previous owner...) and engine bay, then on to paint prep  As with so many of the builds on here, I have little of value to contribute, except extreme admiration and adding to what’s been said before. You guys are champions. |

| |

|

|

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Jul 14, 2022 21:02:04 GMT

|

Cheers darrenh and grizz  Small update, another one of the grim jobs has been ticked off the list in the past few days. One of the previous owners of this car decided that the best way to preserve the new floor pans that had been welded it was to waxoyl them... inside the car??! Nice sticky black goo all over the inside metal work, that ~30 years later is not really doing a great job of stopping the rust either.  I wasn't happy to just ignore it, so like the underside it all needed stripping off. This is a time consuming dirty job, and one I hope to not have to repeat any time soon! I used a mixture of sharp chisel and white spirit with a scouring pad. Slowly but surely I was able to remove it all. The end result looked arguably worse than when I started! But with the addition of some primer things looked much better!  Now to repeat the same task in the engine bay...    |

| |

|

|

|

|

|

Jul 14, 2022 21:11:13 GMT

|

Great to see this car being saved. Very cool...  |

| |

|

|

|

|

|

Jul 14, 2022 21:27:58 GMT

|

|

I found when stripping underseal that a paint stripping gun heated it up to the point where it was a lot easier/faster to remove and then you could get most of the residue off with either petrol or thinners depending on what is based on.

I've done both methods and heating it up is usually a lot faster unless it hasn't adhered to the surface underneath.

Looking good!

|

| |

|

|

|

|

|

Jul 14, 2022 21:39:06 GMT

|

|

I’ve been getting the black stuff off the bottom of my car too that has also been covered over with stonechip . I’ve used the wire wheel on the grinder. It gets it off ok but the mess is horrendous. And like you say it’s appears to have not done much for rust protection.

Long forward to more updates.

|

| |

|

|

|

|

|

Jul 14, 2022 23:18:36 GMT

|

|

Try some acetone for removing the waxoyl.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

When it’s old and hard like this was, starting with a nice sharp wood chisel was definitely the way. Scraps the bulk of it with relative ease, especially on big flat areas.  Then yes, some form of solvent to get the remains off. The engine bay is a slightly different material, it’s original Fiat stuff. As it’s so old it’s drier. It scraped with the wood chisel ok though, so will do that and then go to knotted wire wheel I think. |

| |

|

|

|

|

|

Jul 15, 2022 18:24:32 GMT

|

|

think i may have used fired and rags in astra version 1, with varying results

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Jul 29, 2022 22:16:33 GMT

|

On with the scraping! I found that the underseal in the engine bay was so old that it had dried out to the point where I could attack it with an angle grinder with a knotted wire wheel on it, and instead of melting it just turned to dust. A rather large amount of unpleasant black dust though, which seemed to just stick to everything, especially me as It was a warm day! Anyway, it was done and so I could get a bit of primer on it and feel better about the world.  Seam sealer was the next task. I tried a different brand of seam sealer, as it came in a nice tube and would go in my calking gun, making hopefully a neater job than the usual brush on type. Sadly though, it reacted badly with the primer I'd used and cracked. So I had to dig that out and went back to the old trusty Upol seam sealer I've been using for a decade. With that dried out nicely I could mask up and prepare to get the spray gun out.  On top of the primer, I went with a rubberised stone chip, which went on fairly well. It should give me a decent level of protection in those hard wearing areas.   And now it was ready for some paint! In most of my previous builds I'd gone for black underside. I like the look when its all fresh and shiny, but the downside is that very quickly, once it's been driving out in the real world, the black seems to just look like an old car, and can give off that 'slathered in underseal 'bodge job vibe. So for this car, I decided I would go with body colour for once.  I mean its such a dark blue it'll probably just end up looking black under there anyway! haha. I do like the colour though, and I think this mix I've had made up might even look a touch more grey than what was previously on the car, which I like. It's even more understated and is a wonderfully elegant colour. I'm pleased with how the paint went on, it feels like a fairly easy colour to work with. It always makes such a difference to see things painted. At one stage I was considering stopping the body work here for a while and focusing on getting a rolling chassis together, but having thought more about it, I'm going to push on and try to finish out the body shell before the warmth of summer leaves us. I don't know if I'll manage it, but it's gotta be worth a shot! I don't want to risk micro blistering from damp under the paint, like I've had issues with on the Daimler, so if its not ready to paint before autumn starts to really bite I'll have to wrap it up and wait till spring to paint it I think. With no clean running gear I repurposed the box tubing I'd bought to brace the shell into some stands so that I wouldn't damage the fresh underside when I roll the car the right way up.  I think a couple more cross braces would be wise, so I'll sort that I the next few days. Then it's time to get the car rolled the right way up and time to break out the sandpaper I think! |

| |

|

|

Brigsy

Part of things

Posts: 617

|

|

|

|

|

Great job on the fabrication/welding. Coming together nicely.

|

| |

|

|

|

|

|

|

|

|

|

|

100% sort the paint this summer, good job so far 👍

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

What was I saying about getting it painted before autumn?...  That has turned out to be an impossible task. I've been pushing on with all the spare time I have, but I do feel like I'm spinning plates a bit here with 4 vehicles, 3 of which are currently in bits! It was quickly apparent that I was not going to get all of the paint prep done this summer. So I focussed my efforts on getting the interior painted, along with window frames and door shuts. Painting the window frames leaves me the option to re-fit the glass and make it weather tight should I get to the point of assembling any of the interior this winter. This way, if things go well, I'm hooping to essentially complete the rest of the car over winter leaving me just to wait for a warm spring day to paint the exterior and then I can go for a drive! In the process of prepping the inside, I did discover some more rust in the drivers rear window frame, but thankfully it was only minor and was easily rectified.  Many late nights of sanding...  ... resulted in a car that was ready for painting.  Prepping the dashboard wasn't too bad, but I never want have to prep the underside of a roof for paint ever again! haha. Anyway, with it looking like the weather is due wet for a few weeks, I was just ready in time yesterday to get the paint on it.    It all went fairly smoothly, though painting the underside of a roof with dark paint looking top against the dark sky, I might as well have been painting blind! There are a couple of runs to sort, but as its a single stage flat colour that is far from a disaster.  I will still carry on with the exterior paint prep for now, who knows, if we get another dry bright spell in early October I might be able to paint the exterior then... but I'm doubtful that the stars will align so won't be rushing for that goal. |

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

|

|

|

|

If the prep's done you can jump on it when the opportunity arises i guess. I can imagine the fun of that roof: i assume no headlining in these?

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

Sort of... There's a stick on sound deadening / head lining panel but as you can see, on this random google image, there's still lots of paintwork exposed.  |

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

|

|

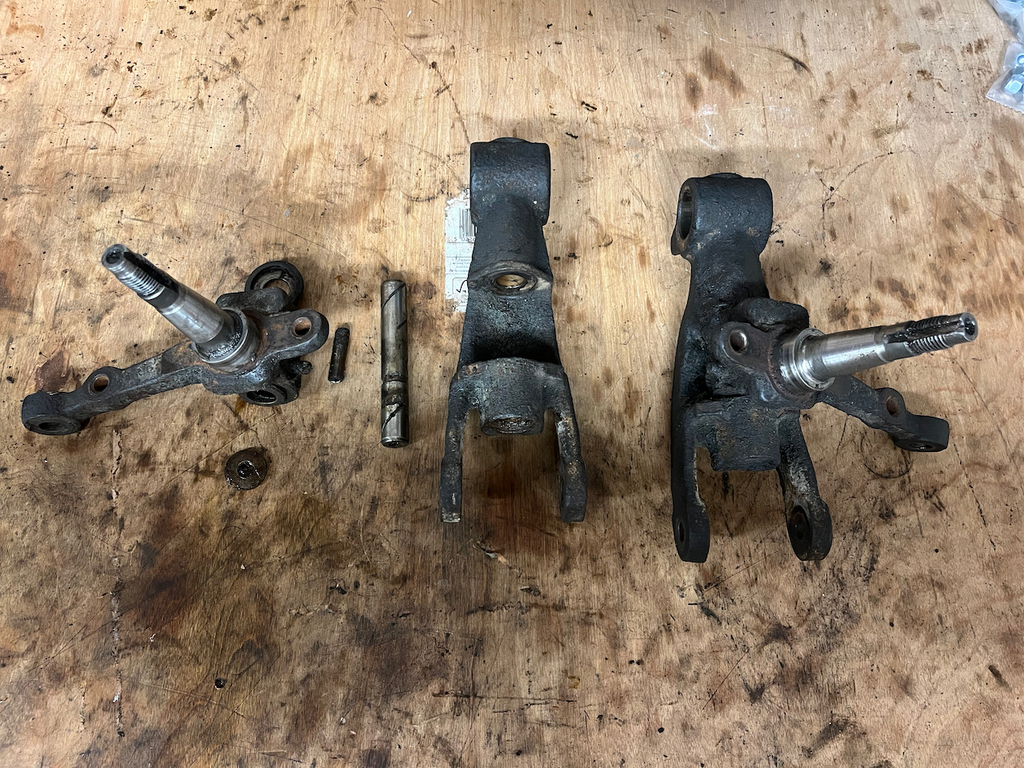

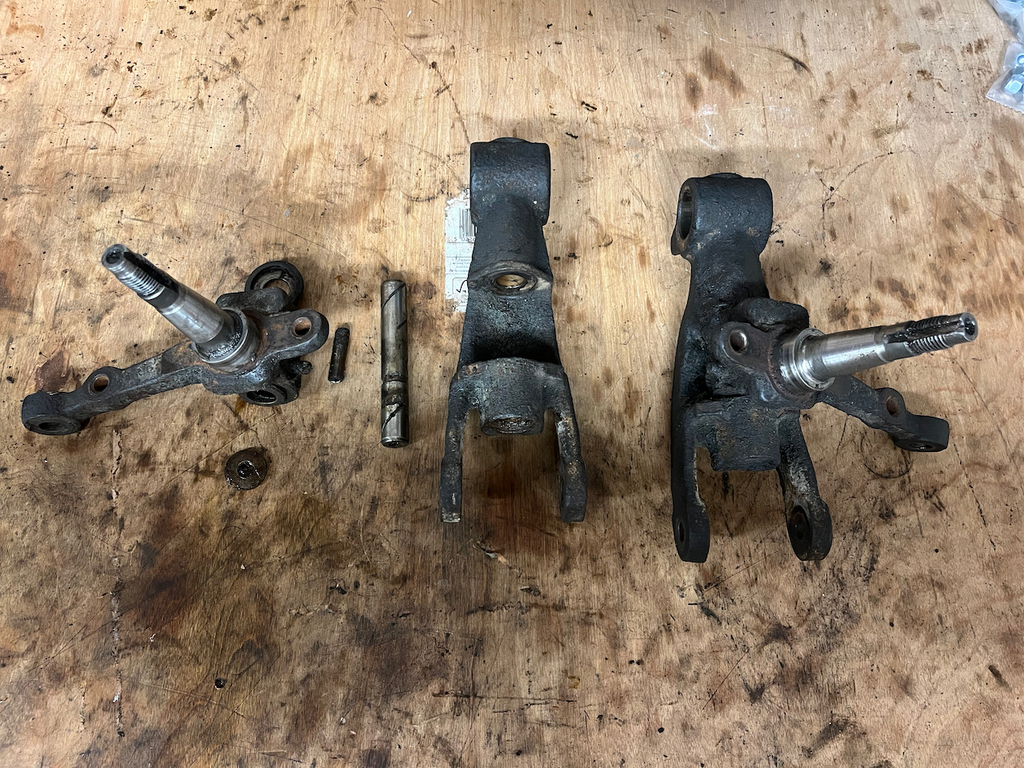

2 months since the last update, I've no idea where the time went! As usual I've been chipping away at the project, but maybe not making the leaps and bounds forward that I'd like to, haha. The enthusiasm to push on with the bodywork drained away fairly quickly as the weather started to drawn in and I realised just how many hours of paint prep were ahead of me. I've made some progress on that front though, and the left hand side of the car is mostly roughed out. Still a fair way to go on this though.  In the mean time I've retreated inside the shed and started with some of the mechanicals. Starting at the front made sense, so I rounded up all the front bits to have a look at what I had to work with.  Mmmm yeah, its all a bit rough! I worked my way through dismantling it, while making a shopping list. Corrosion seems to be a bigger issue than wear, for example the ball joints for the track rods were fine, they just needed new boots to replace the perished originals, but the threaded section to allow you to adjust the length was just rusted solid, to the point that I bent one of the arms trying to free it off.  Oh well, at least the parts are available and not overly expensive! Good job it's not too pricey as there was a rather large list of things to buy, including a new RHD steering idler as mine was seized solid and then the main casting proceeded to snap when I attempted to press the old bushes out.  Quite the haul of parts there, including all new dampers, full brake system inc drums, wheel bearings, all suspension bushes, new rear suspension arms and the list goes on... So where to start... the from uprights and kingpins made sense as I know these can be a bit tricky.  I could feel very little play in mine by hand, but I know when they are packed with old grease it can be misleading just trying to move them by hand. A full strip down and potentially rebuild was the only thing that made sense. I have a cheapo table top blasting cabinet and so the front uprights, steering arms, brake backing plates and various other small components all got treated to some compressed air and iron grit. The budget nature of the tools shows, but it got the job done eventually and got underseal and rust out from corners I'd have never managed with a wire wheel. I treated all the bare parts to some anti-corrosion primer and then a splash of paint to brighten things up. I went for a light gold / champagne kind of colour, as I thought this would contrast nicely with the dark blue body without being too stand out. Hopefully no-one but me really gets to see the underside on a regular basis anyway, but I'll know its there and feel better about it rather than it all just being a bit rusty / flat black!   The first king pin assembly went back together nicely, and with a new pin and a carefully fitted spacer there was no play. The second one was more of a fighter! The pin that came out of it was heavily corroded (on the right of the picture obviously!)  And the new pin would not go in, so I think someone had either fitted new bronze bushes and reamed them to fit the old worn pin, or possibly not reamed them at all. The bushes themselves were badly scored and the top one was loose and half slid out when I removed the pin. I was able to draw a new bush in using some threaded bar, nuts and various washers .  And eBay supplied me with the longest 19/32" hand reamer I could find (long so both bushes can be reamed in-line with each other at the same time). It still wasn't quite long enough, as the reamer doesn't get to its full size till about 1/2 the way down it's length. I went as far as I could from the one direction before swapping over and coming at it from the other.  This was obviously close enough as the new pin is now a good fit and I was able to assemble this side also. Both uprights got new bushes at the top also, where the upper suspension arm mounts.  The front spring also got stripped down, cleaned, painted and reassembled, and you can see a few other bits that have been blasted and painted in the mean time also.   I'm just waiting on some bolts and washers in there post but then hopefully the front brakes and hubs should all go together fairly quick, especially as most of it is new! |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Nov 10, 2022 10:24:32 GMT

|

|

Lovely work. reminds me of how much I enjoyed that stage of my Granada build.

|

| |

|

|

goldnrust

West Midlands

Minimalist

Posts: 1,887

|

|

Nov 10, 2022 12:02:16 GMT

|

|

Thank you. Yes, I like this bit too.

After the months / years of bodywork it’s a refreshing change to do some actual mechanics.

|

| |

|

|

|

|

|

Nov 10, 2022 12:43:12 GMT

|

|

I have a such a soft spot for these.

I was curiously looking at tuned motors, having watched the Davide Cirone videos on youtube, but wow...they price of a hot motor for one of these things is eye watering. 12K anyone?

|

| |

|

|

|

|

|

Nov 10, 2022 14:57:57 GMT

|

|

There are quite a few around with bike engines fitted probably the cheapest way to decent amounts of reasonably reliable power.

|

| |

|

|

Paul Y

Posted a lot

Posts: 1,951

|

|

Nov 10, 2022 16:24:24 GMT

|

Didn't the Wheeler Dealer lot put a 126 engine in a 500 for not a lot of money? Not sure on the HP upgrade but might be worth considering. Found it. Lovely work by the way Sir. P.  |

| |

Last Edit: Nov 10, 2022 16:26:45 GMT by Paul Y

|

|

|

|