|

|

|

|

|

20: Carbs. Original Jikov 30SSOP on original 2 plane intake.    Holley 4160 on my intake  Weber 38 DGAS  Edelbrock 650 Performer   |

| |

|

|

|

|

|

|

|

|

|

|

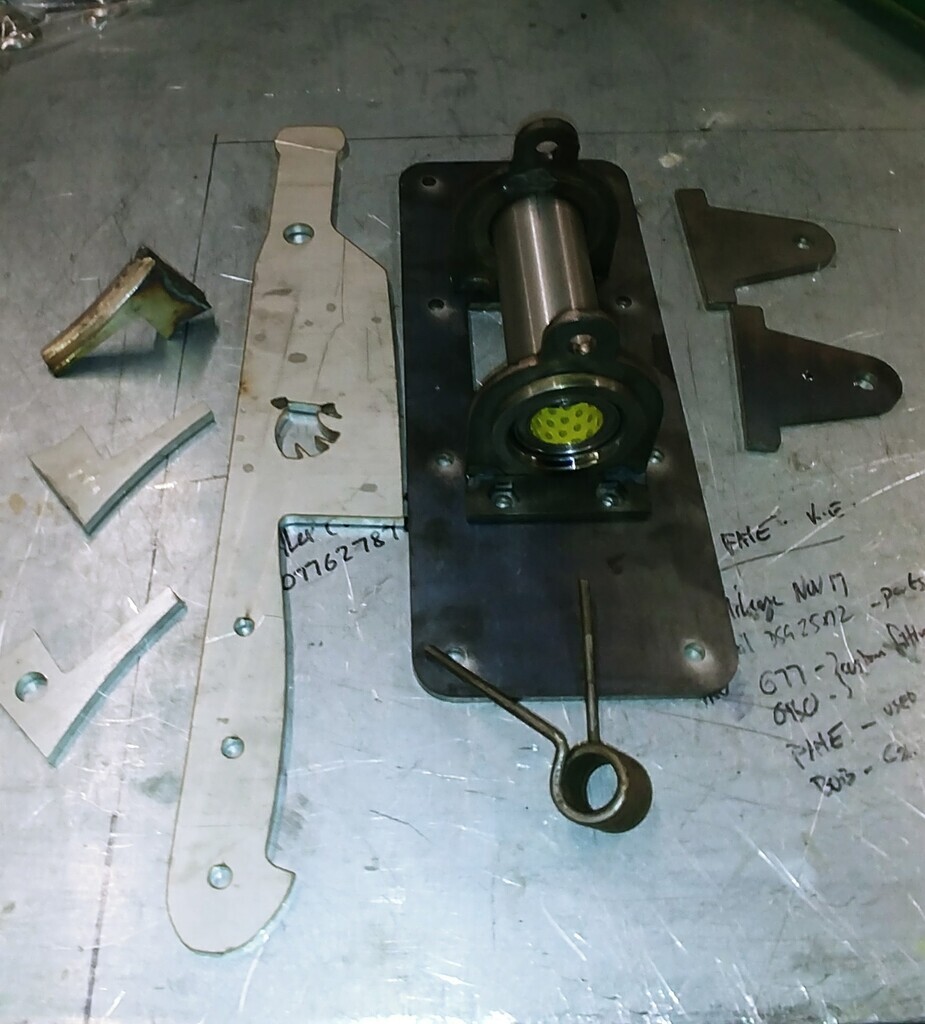

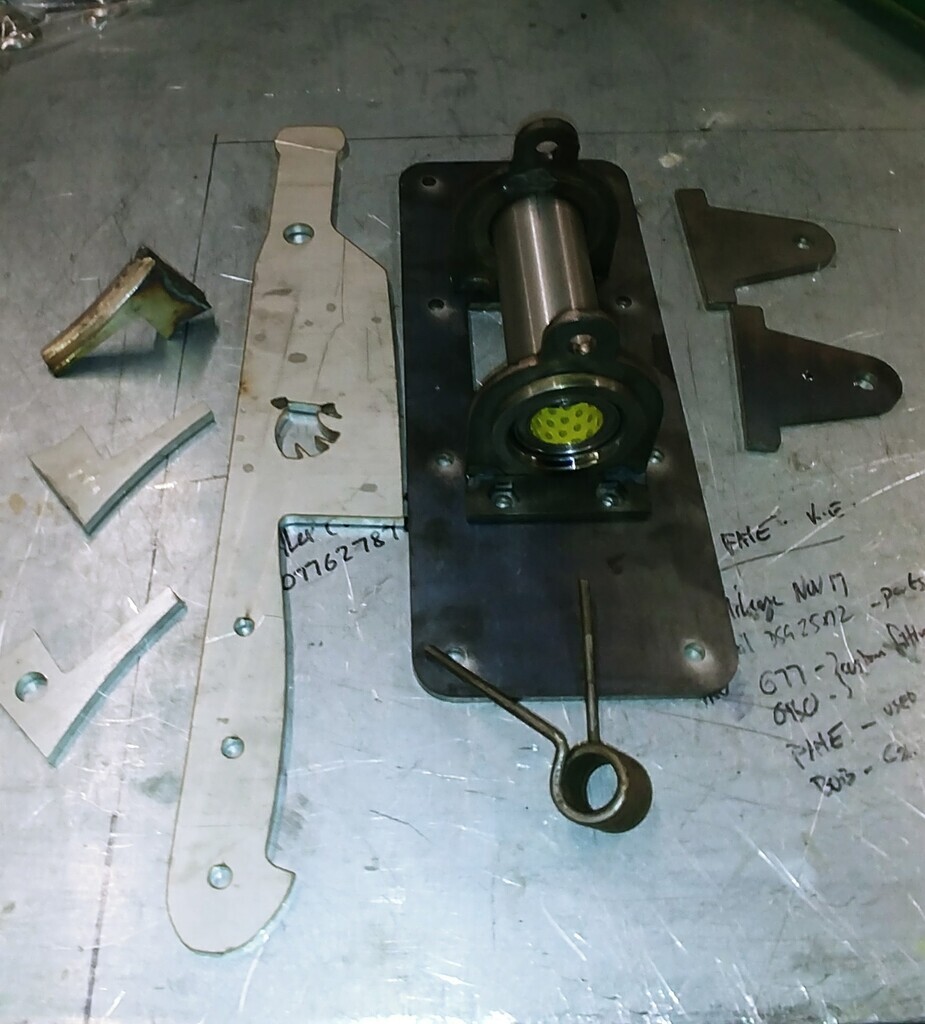

Forgot to mention the throttle box.

The carbs are all designed to be in the front operated by a cable so the mechanism is the wrong way round. Throttle box reverses the direction & also has a giant spring inside which helps the throttle pedal return to normal. Because the cable is 10 foot long don't forget.

|

| |

|

|

|

|

|

|

|

Epic. That is all. Carry on  |

| |

|

|

|

|

|

|

|

|

Great project; My wife is from Czech (Moravia) and had exactly this car (also a '68) as her first car when she was 18. She recalls it as the best car in snow.

The backgrounds of the parked car look very Czech; We lived there for a year when I worked at Skoda in Mlada Boleslav.

Bookmarked!

Daan

|

| |

|

|

|

|

|

|

|

Dobry Den Daan. I am no stranger to these Moravian beer swilling monsters & their famous fruit drinks. Stand by for an impaled kralik. 21: Gear shifting Never mind the engine for now. It will fit because it only has one mounting point on the transaxle. It just will fit & that is that. The problem here is how to change gear. The Skoda gear change wouldn't do because the Tatra car had a column change & the Skoda a floor change. Well it would work but upside down. So I made a new system. This has been one of the most difficult parts to get right. I made about 4 diferent versions. The shifter is now mounted on ball bearings left & right, sintered linear bearings in & out & 2 proper UJs. Now it hits the gears every time. But what about the dust shield? I have tried to make sure this car is not influenced by any norms & this is my favourite bit. The daggers, scary monsters, snakes, vampire bats & skellingtons etc almost got a word in here but the knife (gear stick) is a Sabatier 14" veg knife like Fanny Craddock would use to square up a turnip & if you believe in Cruella DeVille then all the pelts on display are those of hunted creatures. So there is nothing to fear here.        Perspex 2D profile was hand roughed out on an angle grinder & then wet & dry through the grades all the way to 3200 or something diamond paste. |

| |

|

|

|

|

|

|

|

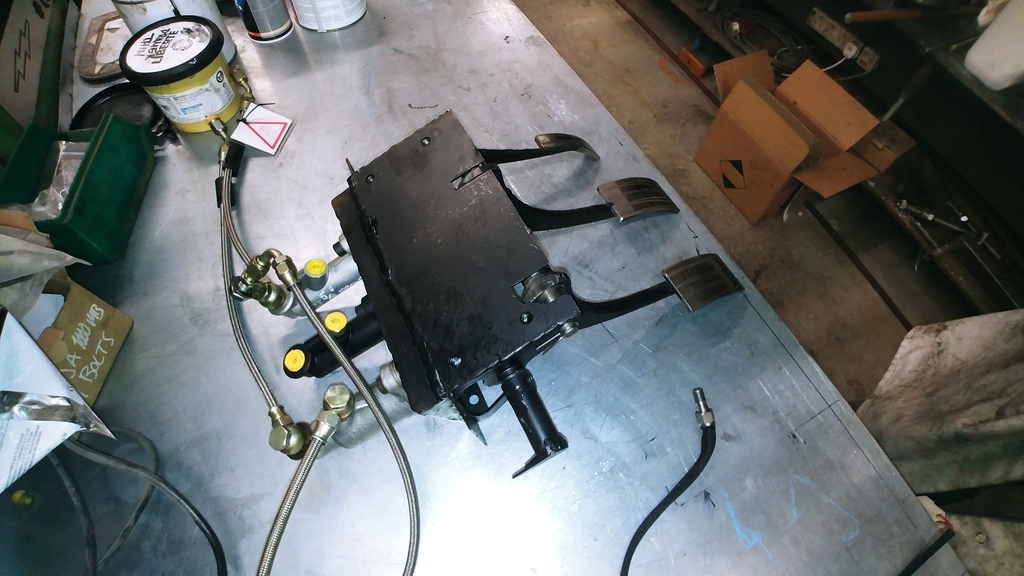

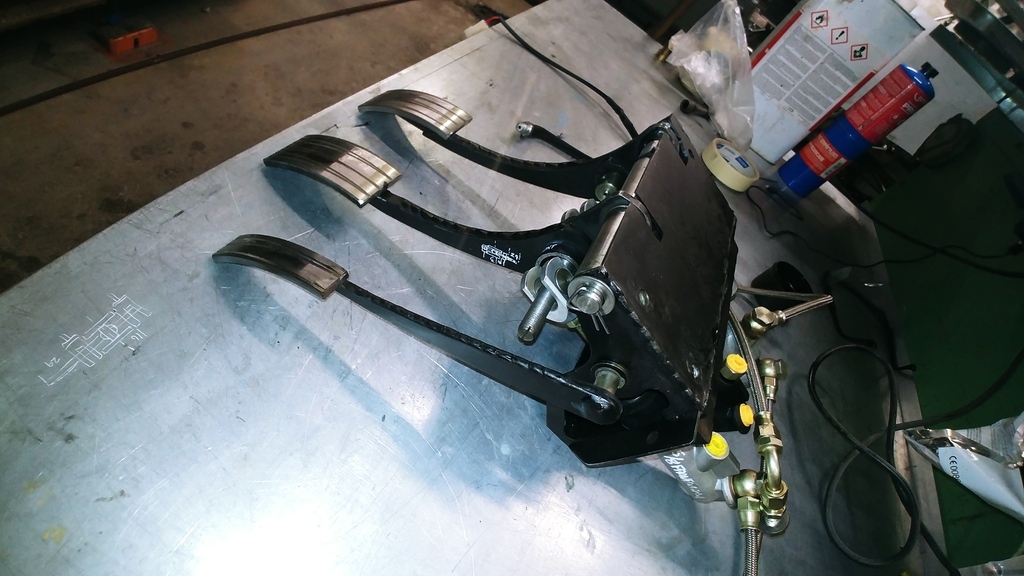

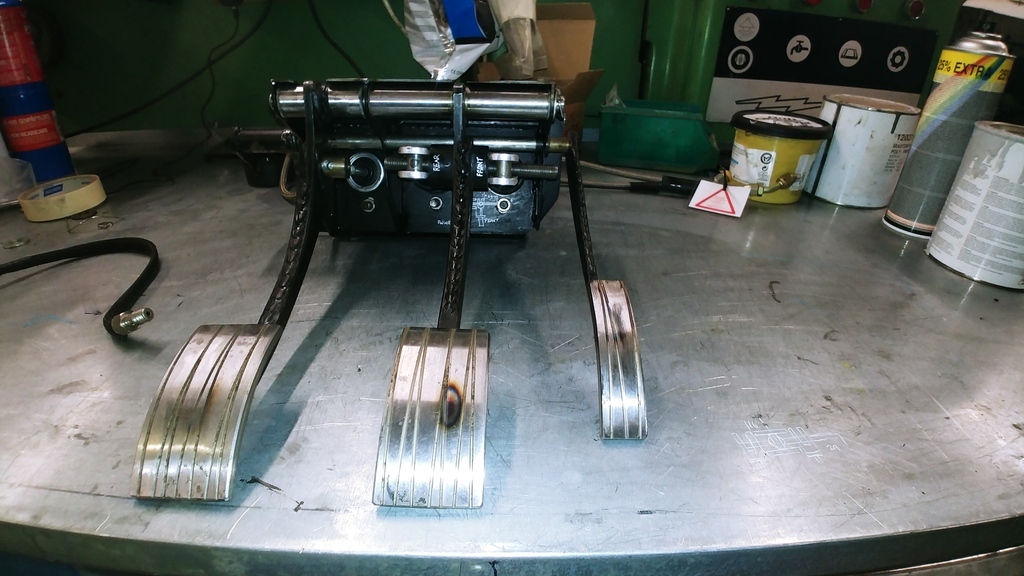

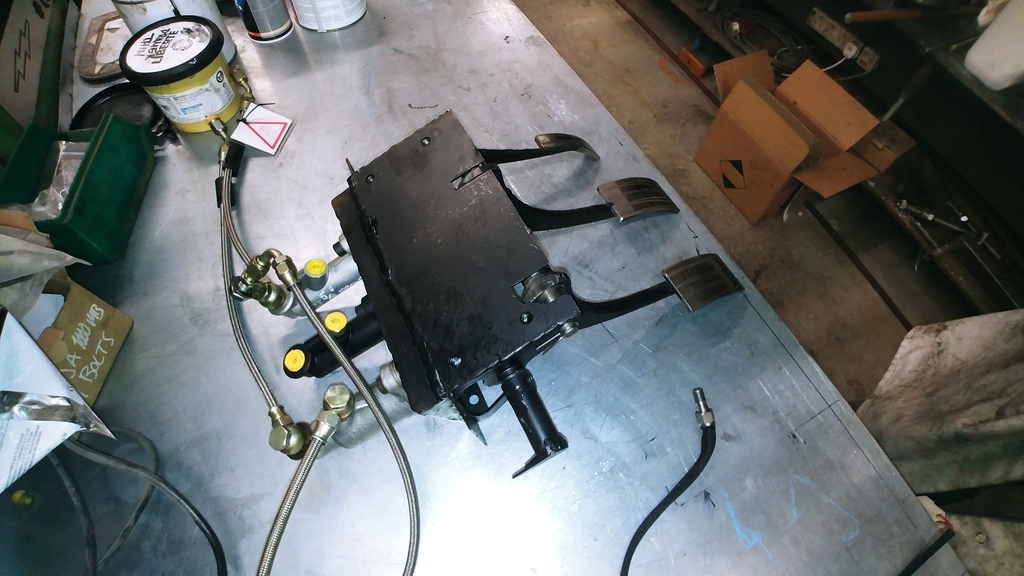

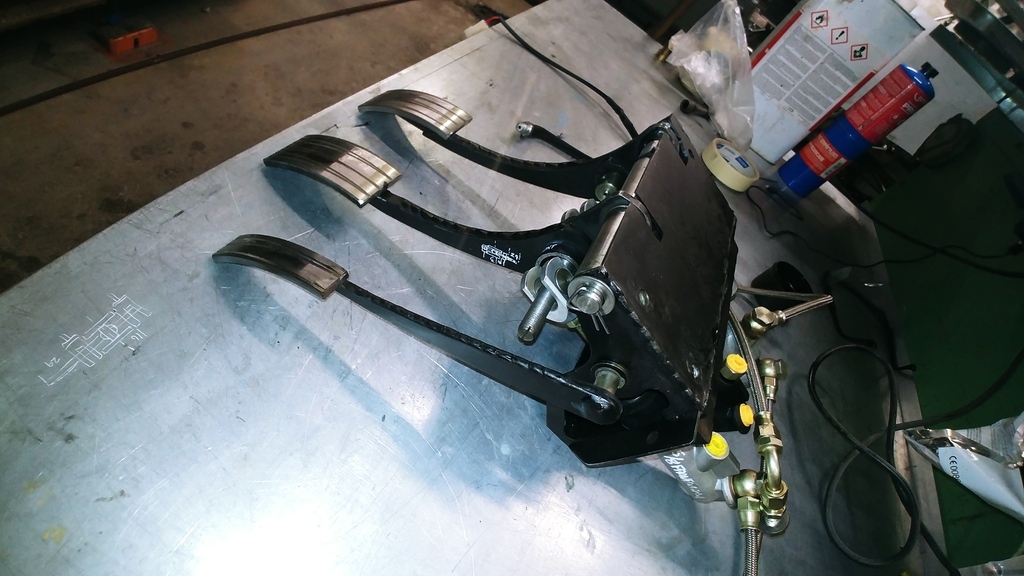

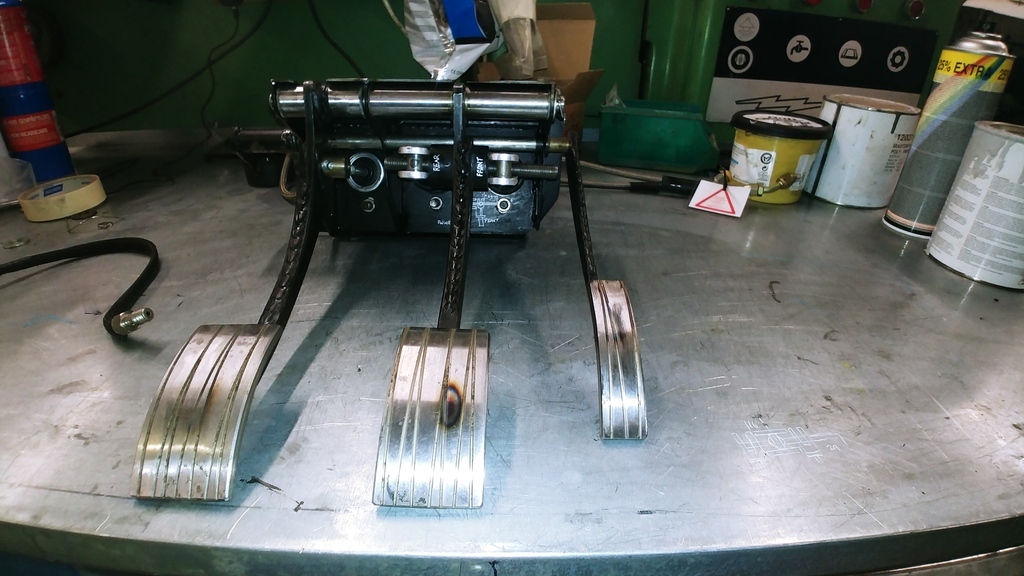

22: Pedalbox: One of the few racing parts on this car is a balance bar & a triple reservoir made by Tilton. It runs DOT5.0 fluid. Now I can BUY a pedal box for £600 from wherever. Do you think that is what I did? It is better value for money and probably faster to make one yourself than try to get one of the standard issue things in there. This one uses AP style cylinders. The original Skoda pedal box has a common reservoir for brake & clutch. I didn't dig it much.      |

| |

|

|

|

|

|

|

|

23: Ventilation. The Skoda had a heater & blower but it was based on a water cooled engine & therefore used liquid coolant. I started to make a liquid coolant stand alone unit based on an Eberspacher water heater, a Jag heater matrix & a Ford Cargo blower.     It would have worked but it turned out I had bought an obsolete heater. Eveybody told me to buy an air heater so I did & that was good because... It worked It takes up less room That means the spare wheel will go back where it belongs, under the floor. Before this revelation the spare could not be stored in its inflated state because it was too big like that. So I also carried a compressor. How Czech is THAT? This air heater is in a unit which just clips into one of the service hatches in the luggage bay. The exhaust dangles down in fresh air under the body. Fuel (Diesel) from small jerry can in the front. I kept my home made air distribution box but nothing else survived.    |

| |

|

|

|

|

|

|

|

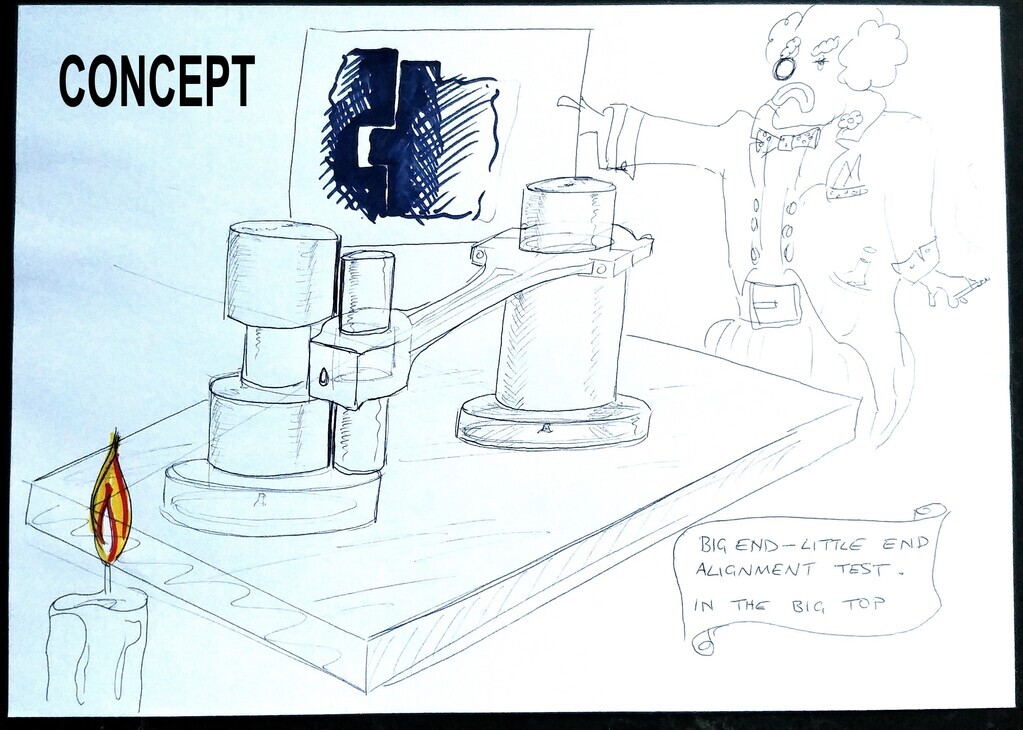

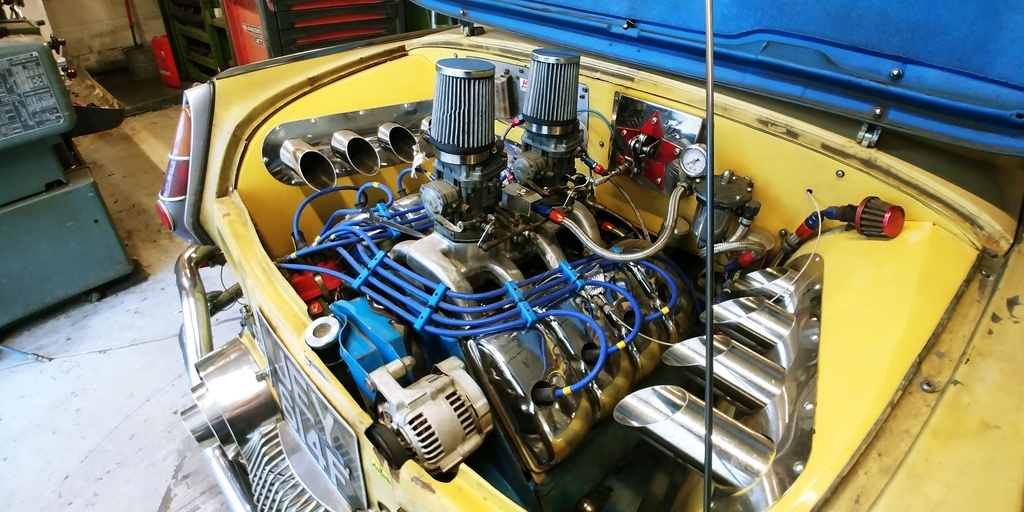

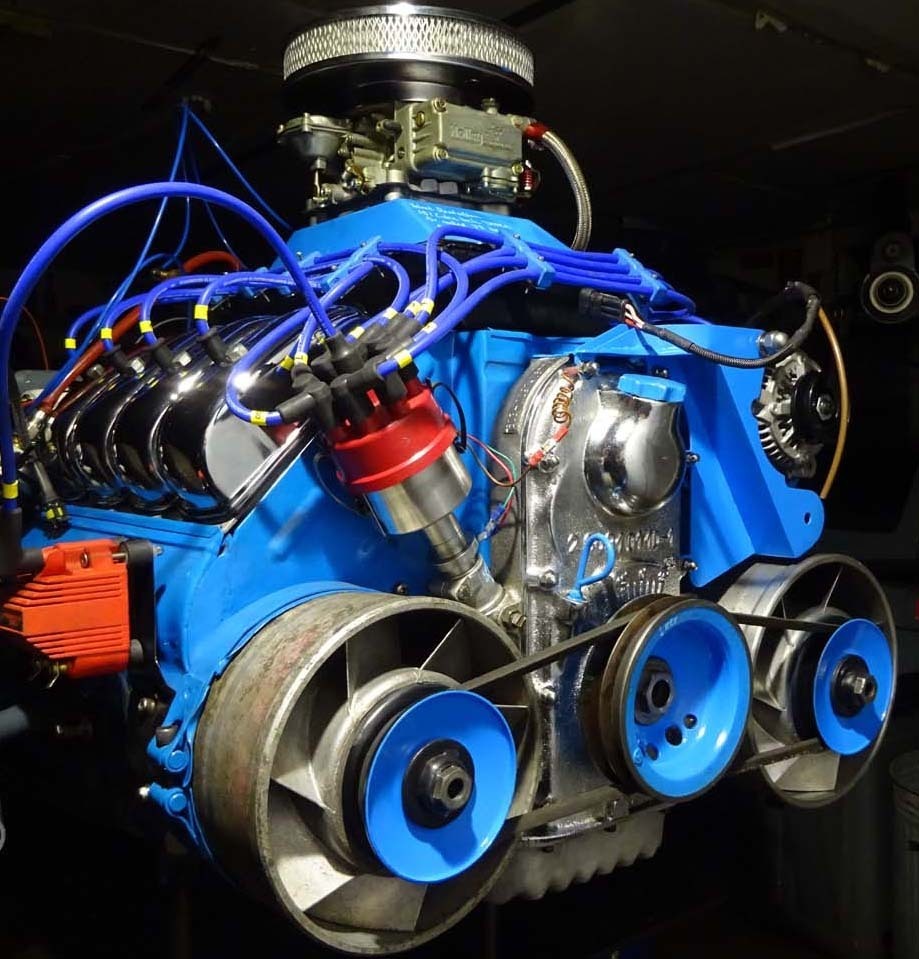

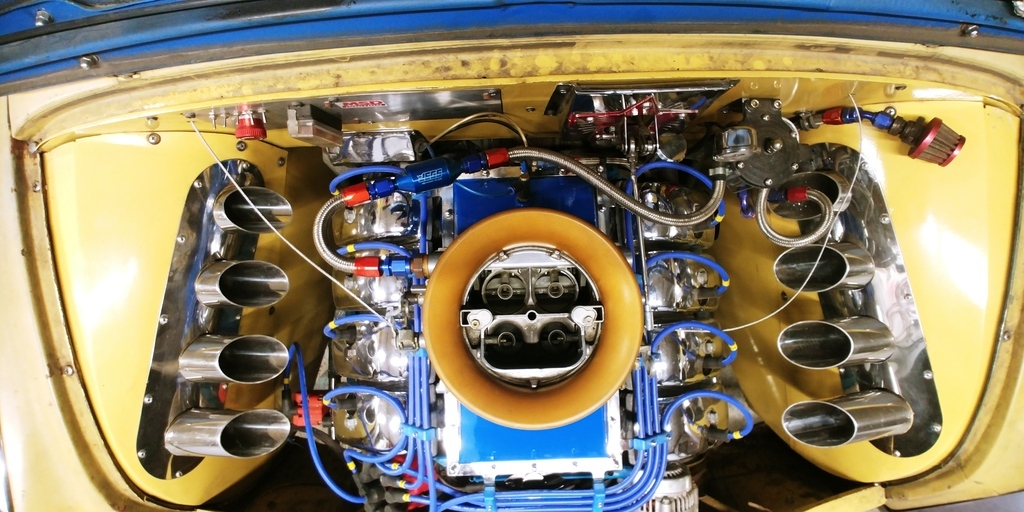

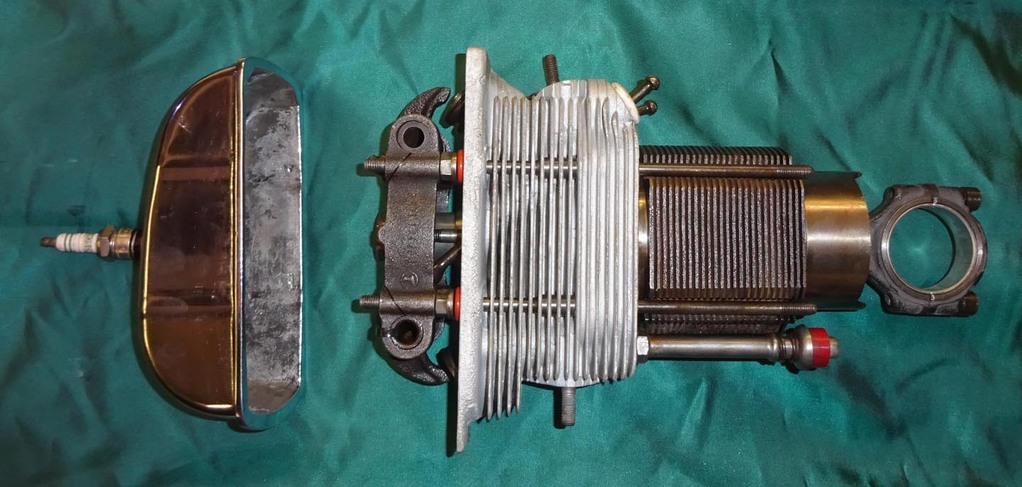

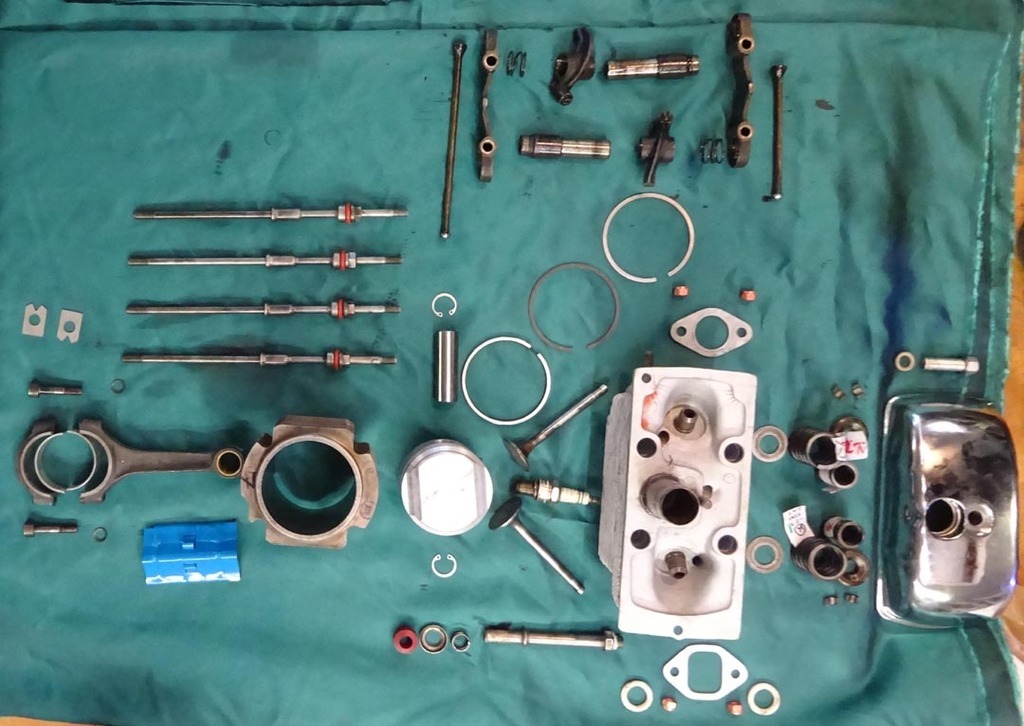

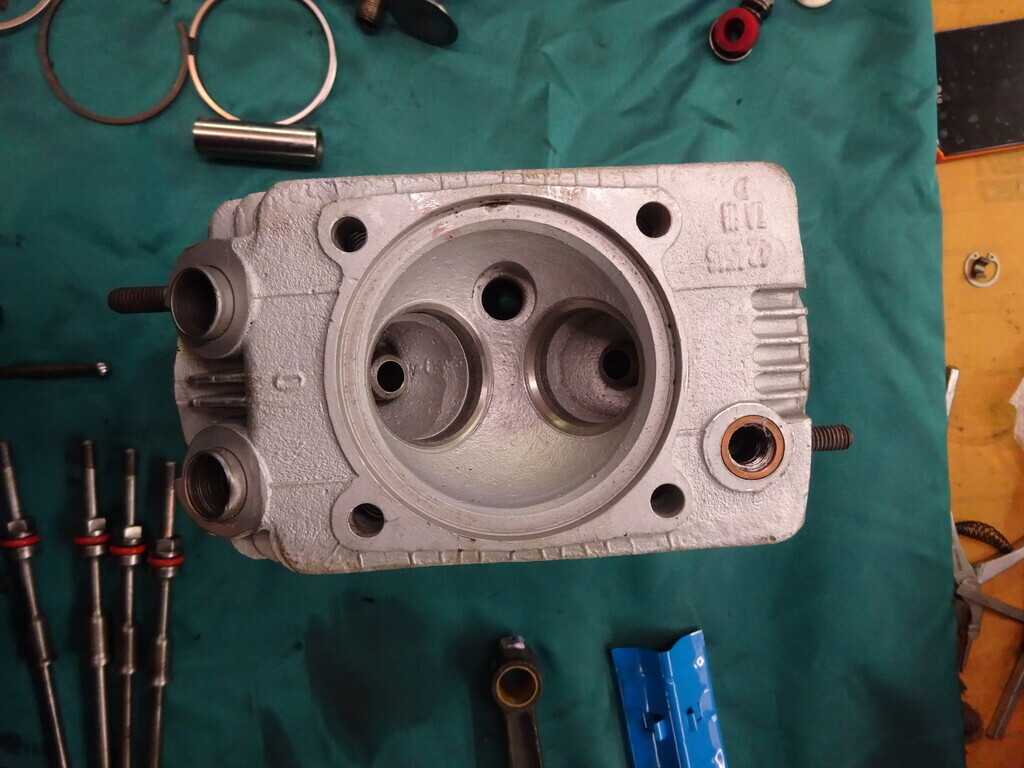

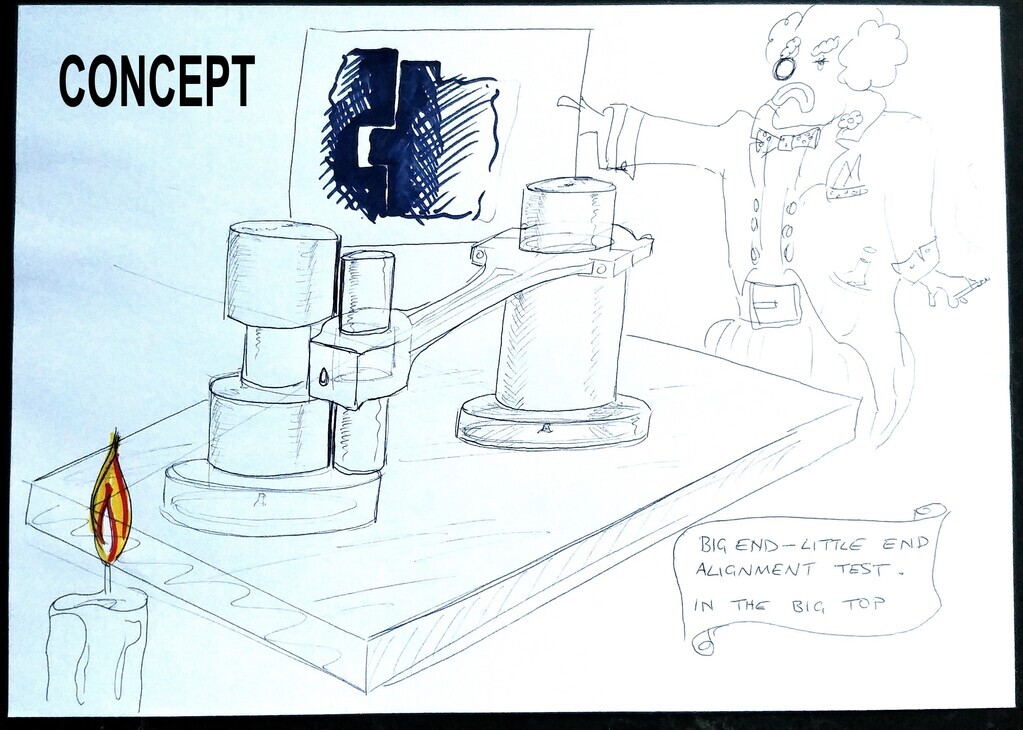

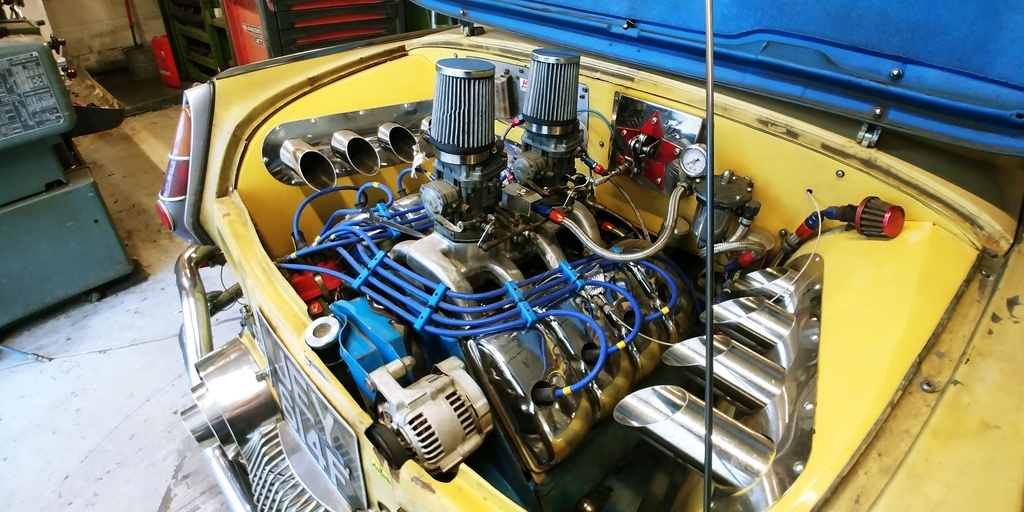

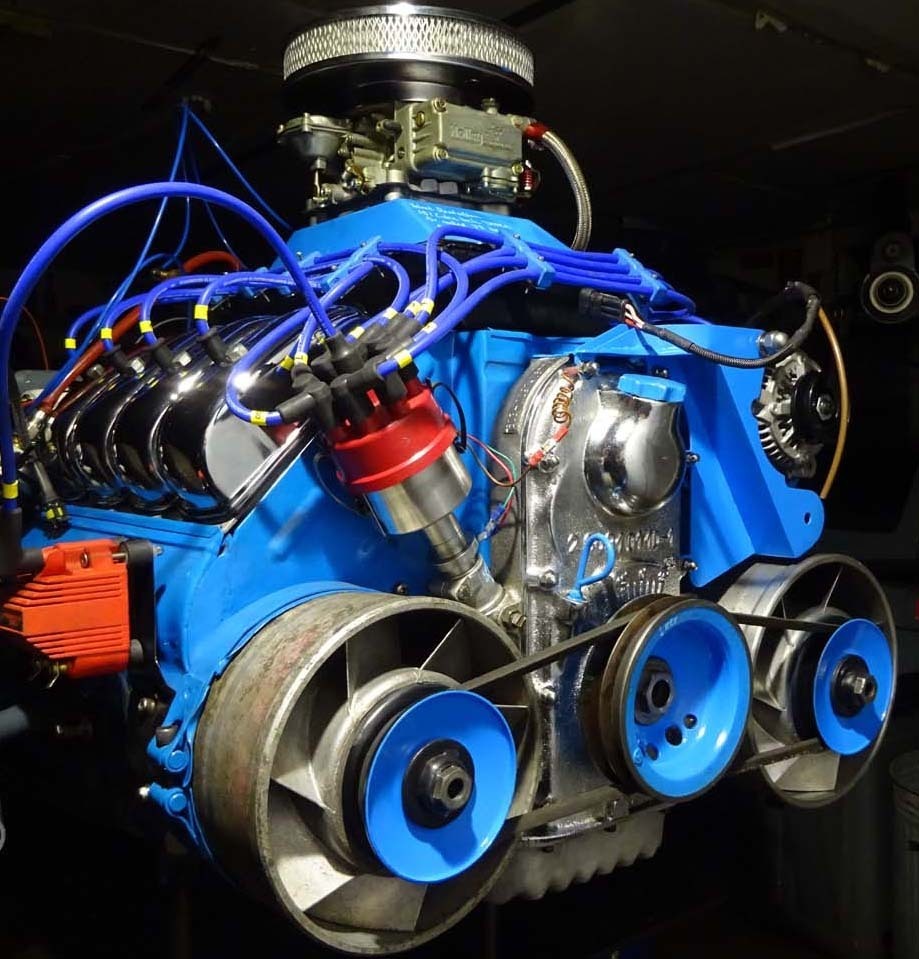

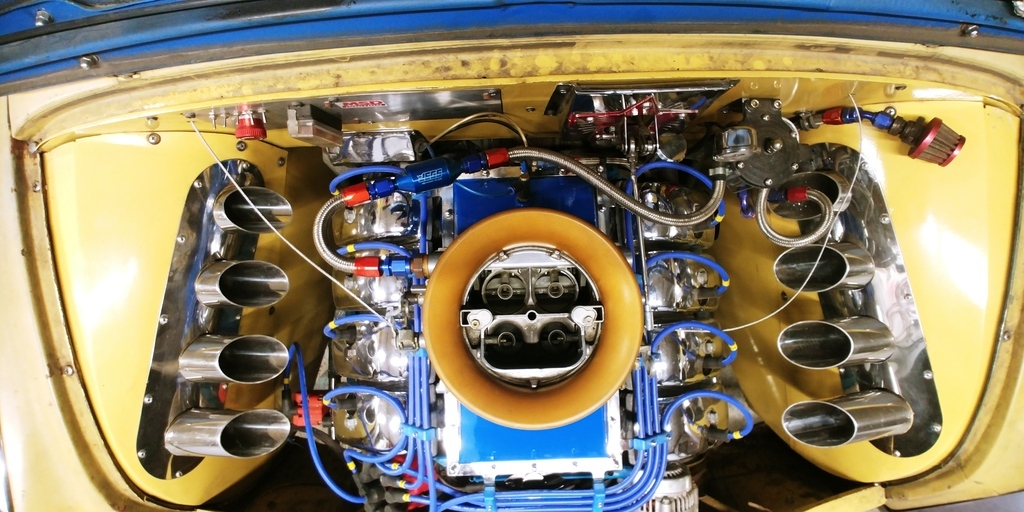

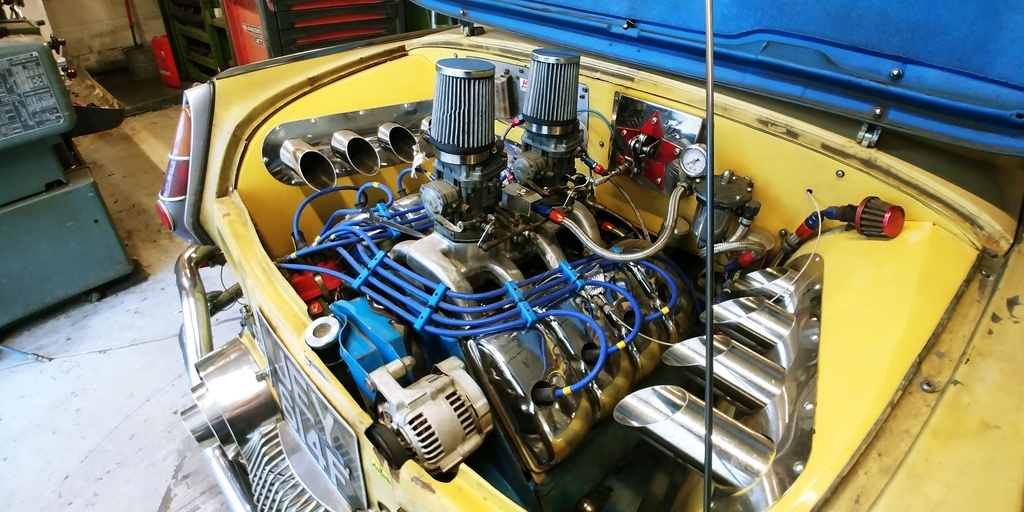

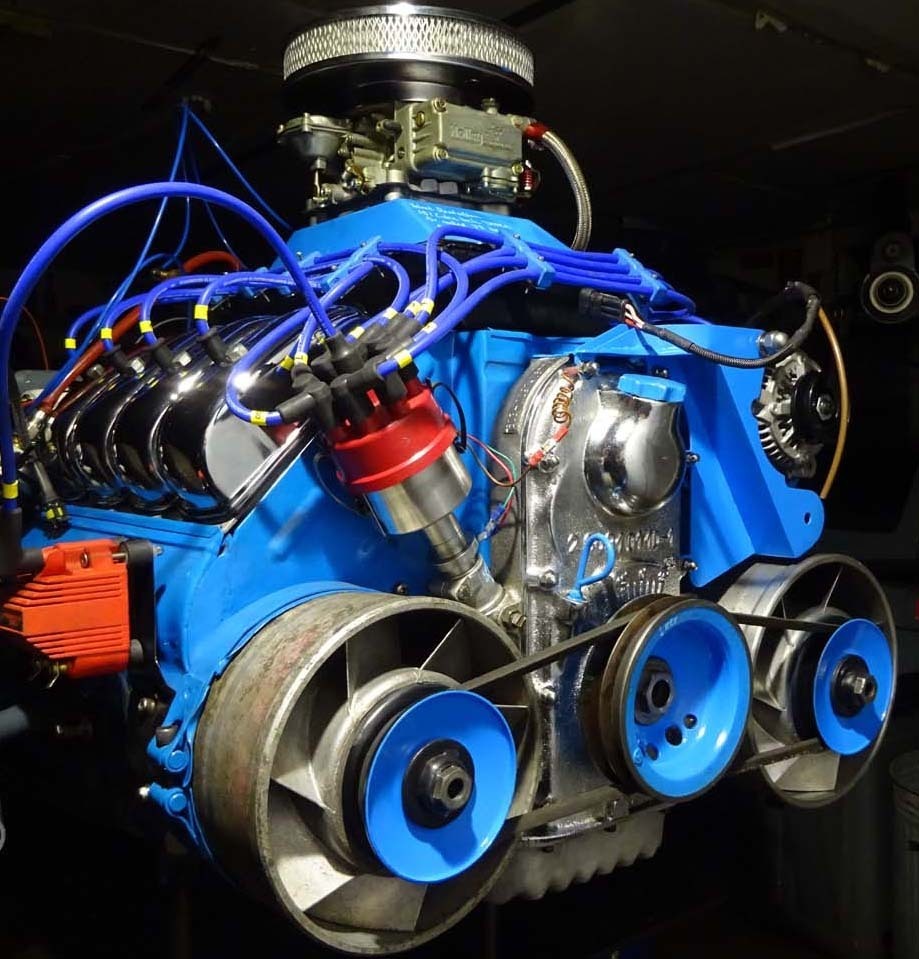

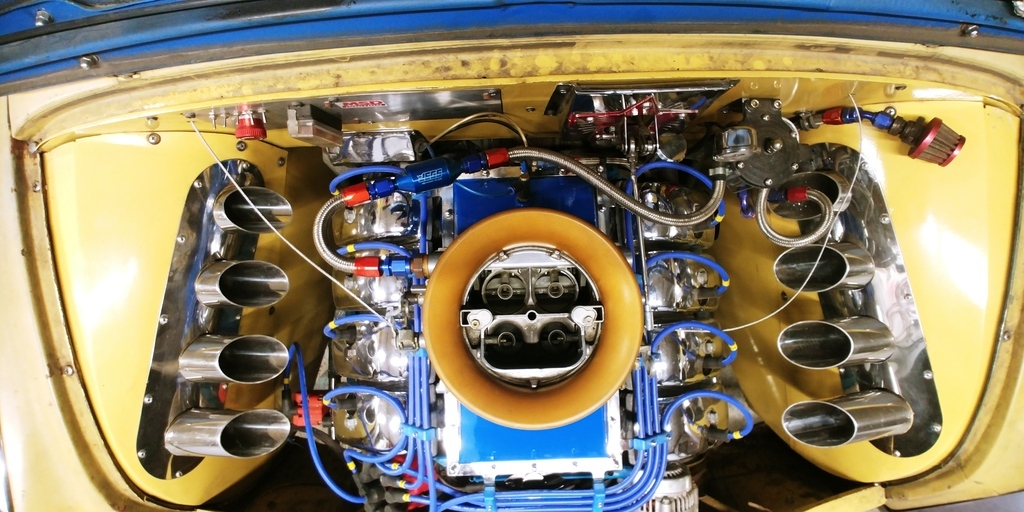

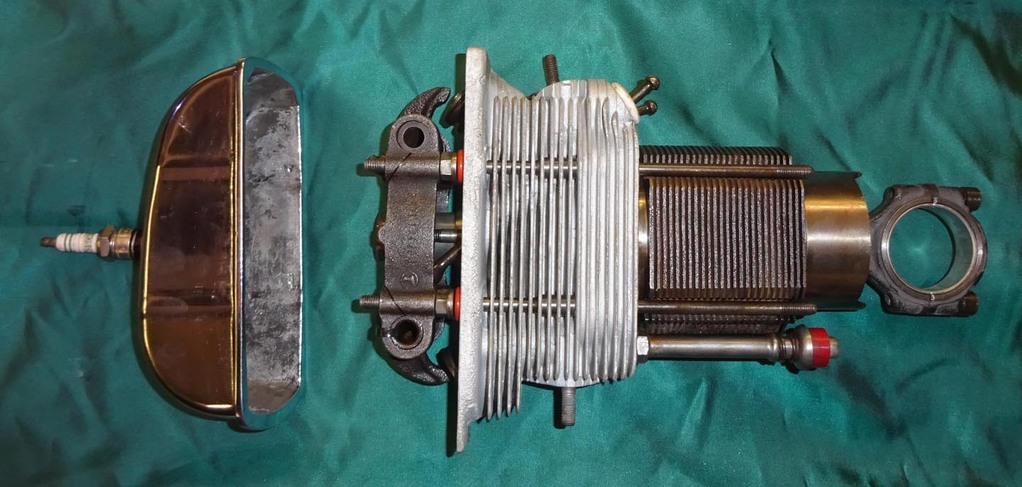

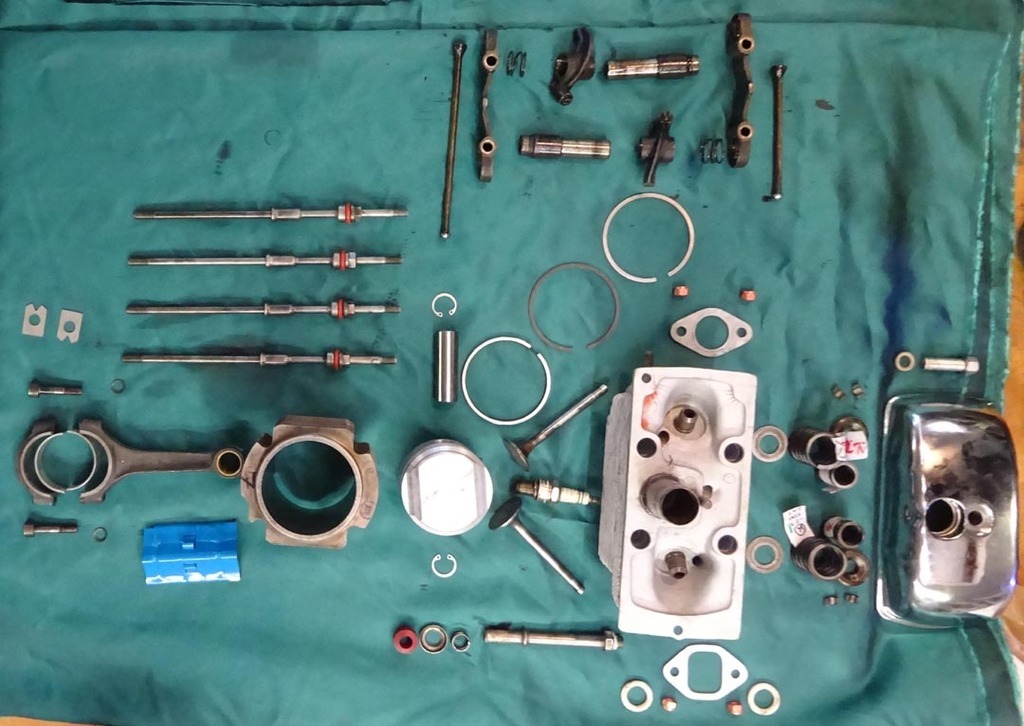

24: Engine. The first build of the engine was adequate. It got me to Prague & back & showed no signs of trouble but When I pulled it out last winter for a quick checkup I found horror due to my lack of experience & also the dimensional variations on the particular block. The trouble was with the mains delaminating & the big ends wearing unevenly. To cut a long tory hort the reason was misalignment of all the parts therein. Luckily I had some spare blocks & one measured up lovely. That got new mains, new con rods, big & little end bearings. I also modified a cam & the followers to try to pep it up a bit. So the photos show the basic architecture of it followed by how the trouble was detected & hopefully sorted out but first... The Tatra engine has the following odd things going on. It is air cooled. Split skirt pistons Individual cast iron bores in an aluminium block Hemispherical combustion chambers in individual die cast aluminium heads Single cam in the valley driven by a 3/8" TRIPLEX chain. No bearings, straight onto bores in the block 9mm diameter valve stems 8mm head bolts, 4 per cylinder. No head gaskets! Oil feed to the rockers via hollow pushrods 4 into 1 pressed steel exhaust headers like on a cement mixer Five bearing crank runs in white metal bearings which have to be line bored by experts. The lubrication filter system is plain inadequate Old fashioned rope seals in the rear end of the crank. There are two oil coolers to ensure the engine won't go above 40 degrees. All together I counted 191 ways for oil to leak out of the engine & 16 ways to leak out of the gearbox All made worse by what must be a misprint in the old service book which quotes some extremely low torque setting on the main bearing caps. The book also goes on about what to do with a plate in the intake-exhaust heat exchanger when the seasons change in Slovakia & when to change the monograde oil. The book also goes on about how to cast your own crank bearings at home & then hand scrape them over your knee. It has a recipe for the babbit metal right there! AND how to balance the rods & the crank for heaven's sake. From experience there are no two Tatra 603 conrods alike. Parallelism & perpendicularity are rare qualities in this lump. And then it has my modifications; Bad ones... S shaped exhaust with 3 mufflers a side. Intake manifold the volume of a cathedral A full flow oil filter in a canister Edelbrock carb is totally tunable, it can cope with anything but at the moment it is sitting on its hands.           |

| |

|

|

|

|

|

|

|

|

I'm just stunned, what a brilliant build thread.

|

| |

74 Mk1 Escort 1360, 1971 Vauxhall Victor SL2000 Estate.

|

|

vulgalour

Club Retro Rides Member

Posts: 7,286

Club RR Member Number: 146

|

|

|

|

|

That description makes it sound less like one large engine and more like several smaller engines working together.

|

| |

|

|

|

|

|

|

|

|

|

That description makes it sound less like one large engine and more like several smaller engines working together. I hadn't thought of it that way but you have just pre-empted a pre written paragraph...

A quick search on the web shows a stock BSA650 had 35HP at 5000rpm. I know the pistons, bore & stroke etc are almost identical to the low compression (G) version of the Tatra. So 4 Beezers have 8 cylinders & 140HP. That is 40HP more than my 8 cylinder Tatra. The goal is to make it run as well as 4 BSA 650 & then maybe I will get the secondaries open at last on that Edelbrock."

|

| |

|

|

|

|

|

|

|

OK, lets get rid of that rope seal. Had to generate out the original diameter. there isn't enough meat there for a standard seal because there is a labyrinth behind it so you have to make do with that & reduce the thickness of the circlips & also reduce the thickness of the oil seal. Then you have to machine the flinger off the crank & shring a new sleeve on & cylindruical grind it. No pictures of that sorry. Use nitrile cord in the 2 vertical seals instead of asbestos rope.       |

| |

|

|

skinnylew

Club Retro Rides Member

Posts: 5,717

Club RR Member Number: 11

|

|

|

|

|

This is utterly bonkers........and utterly awesome!!!!!

|

| |

|

|

|

|

|

|

|

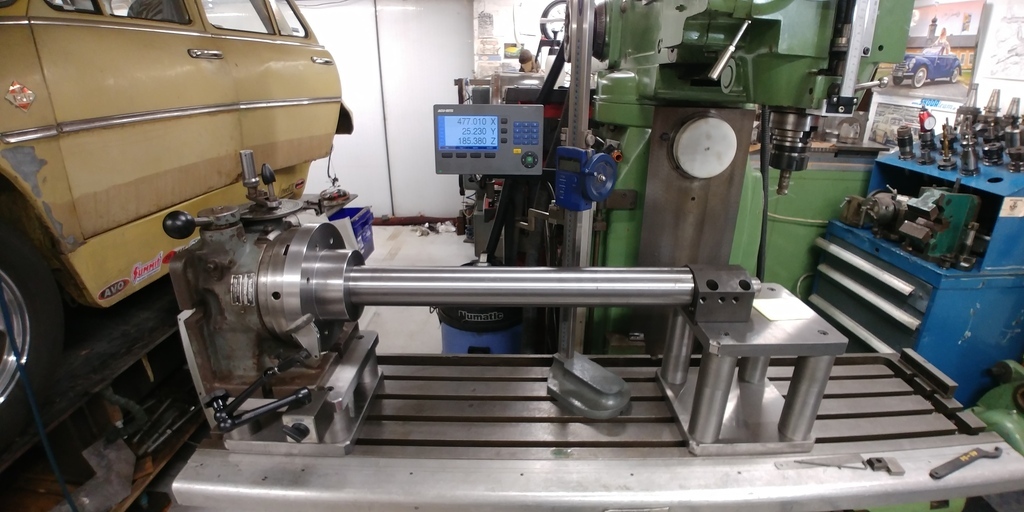

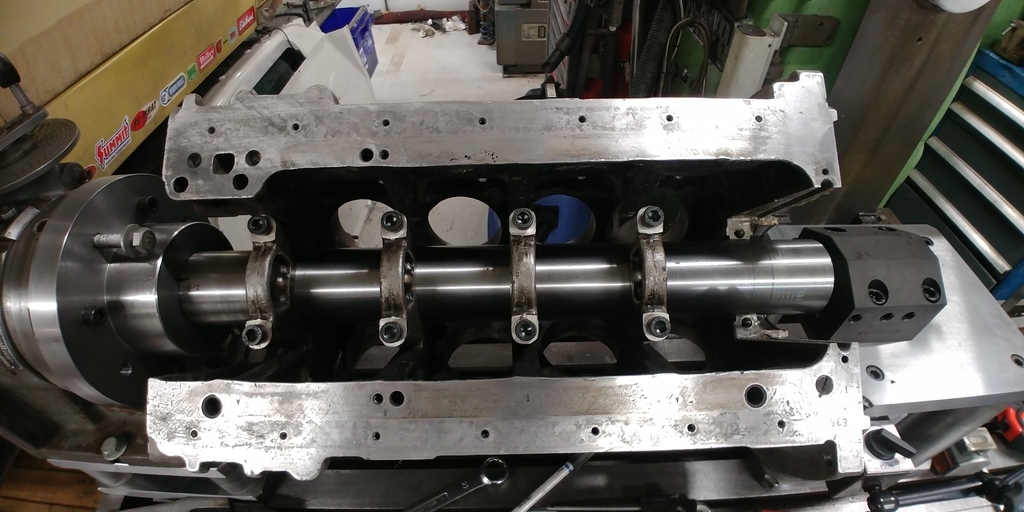

What is wrong with the rods? Here is a fixture which is the same diameter as the crank pin. It has been made in one operation so that diameter is perpendicular to its base which is bigger & therefore heavy enough to hold it down firmly onto the surface plate. The technical term is "cylindrical square" but they are way obove anything I can make. I call it a near enough square. The other square has a notch in it to admit the little end. Both diameters are equal. The gudgeon pin should touch all the way round. You can see the light pouring through from a mile away. The light source isn't needed. This is amanufacturing issue not a damage issue. No two rods alike. New rods needed.   |

| |

|

|

|

|

|

|

|

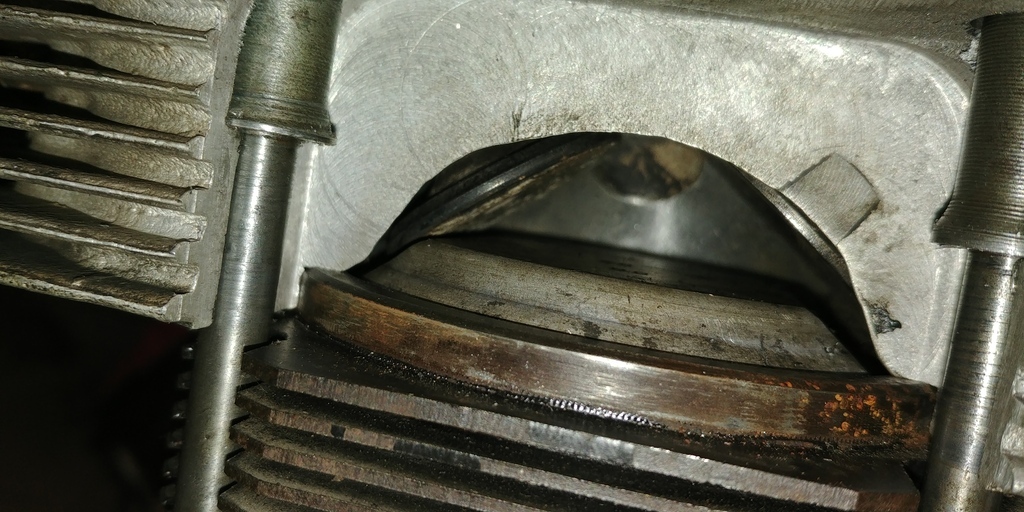

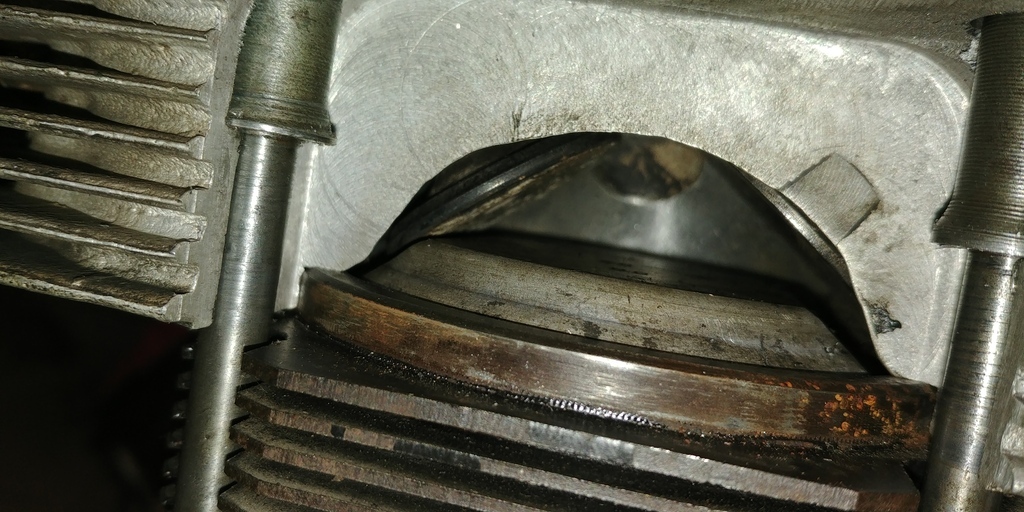

What happened to the pistons? Some worse than others. Here is a bad un.  Why? I have heard a lot of theories. Too hot, too fast, wrong oil. It was misalignment due to amongst other things... Bent rods AND  Misaligned cylinders. Look at the step where the bore has been walking about. I found a block with no step. It doesn't do hot or fast & it was the semi synthetic 15-40 motor oil which saved it. All the pistons went back in with fresh rings on. |

| |

|

|

|

|

|

|

|

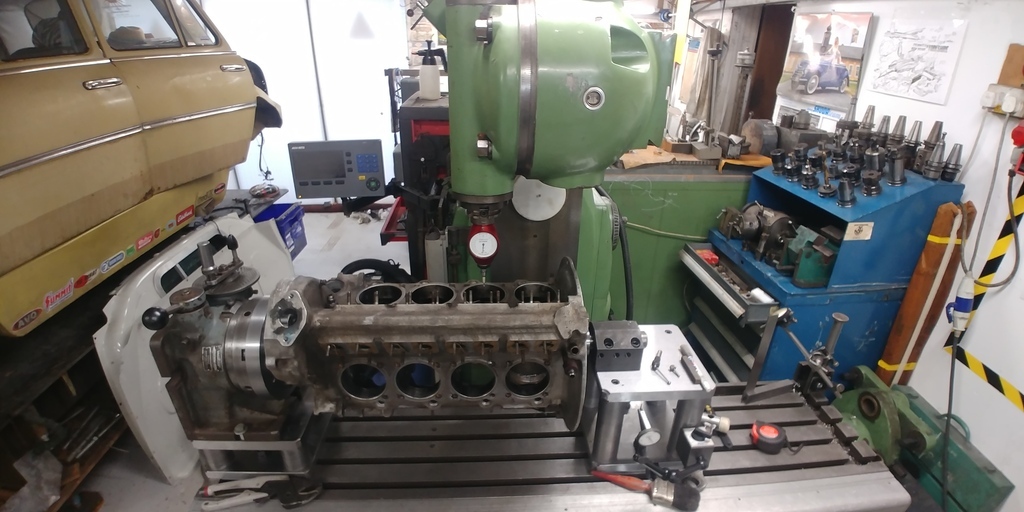

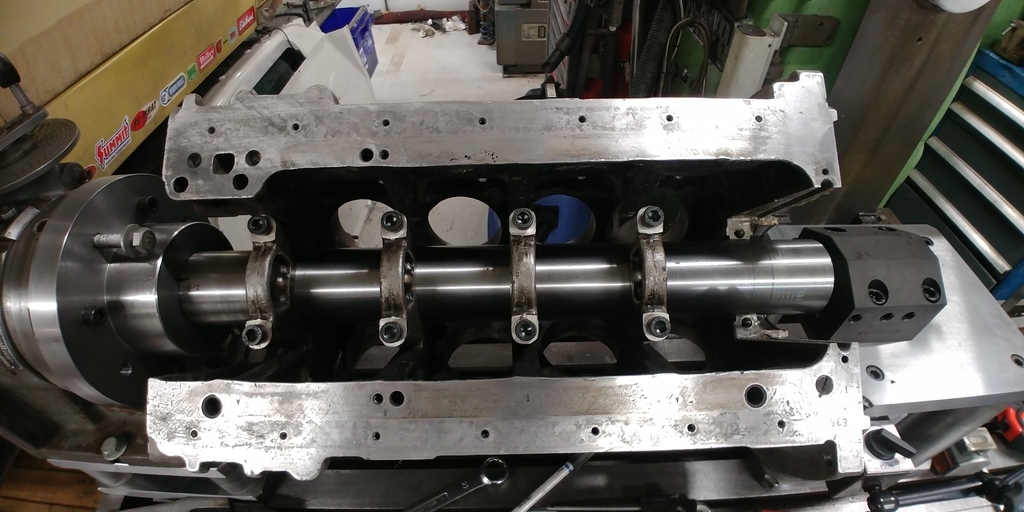

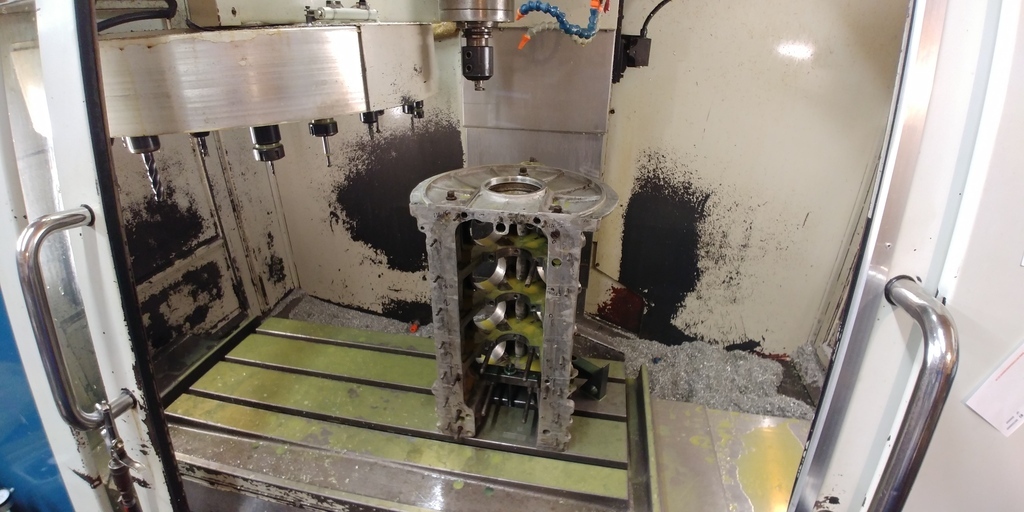

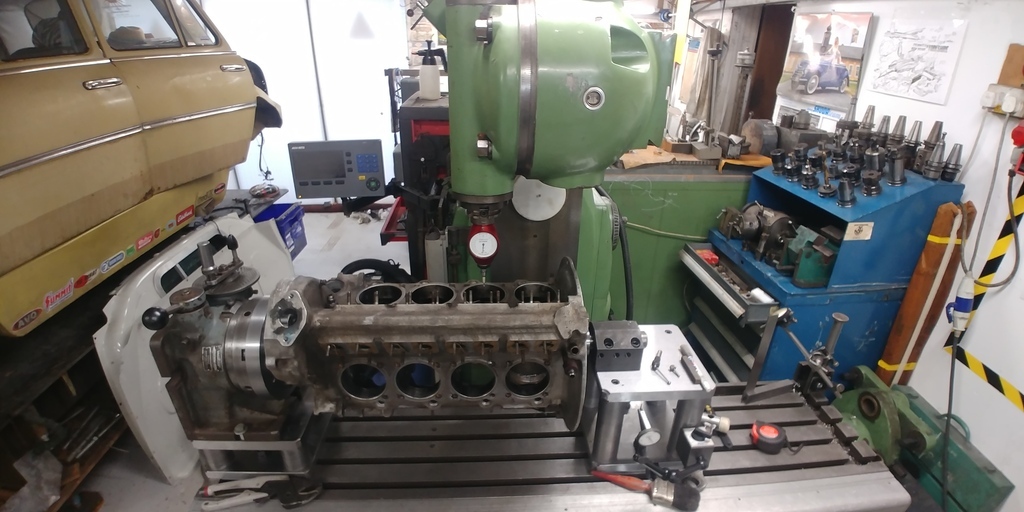

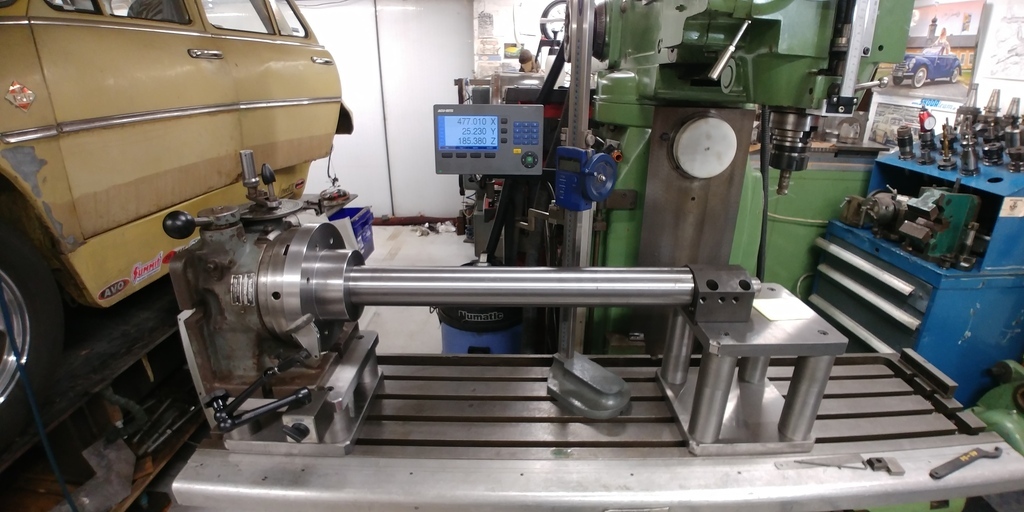

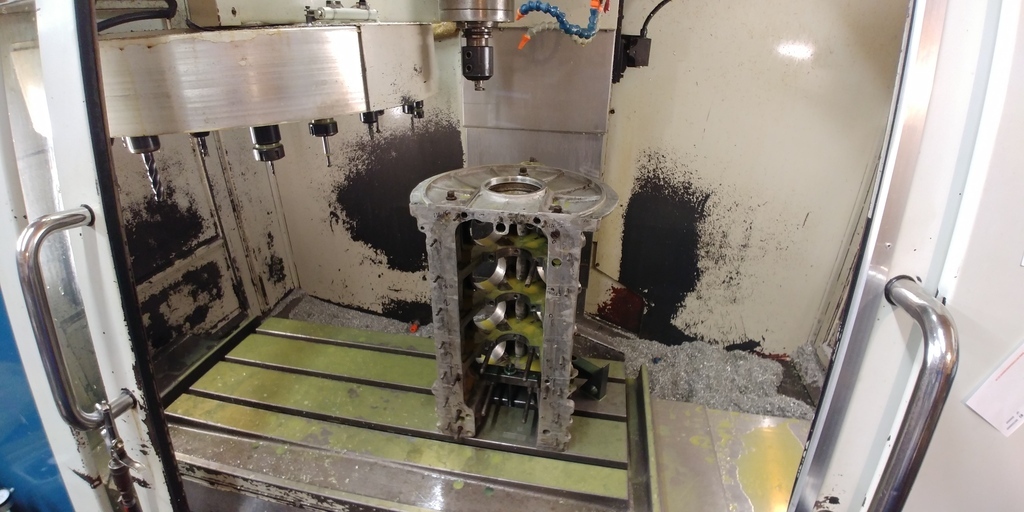

I know the crank is right and I know the line boring of the mains in the block is right. How do I know? Well I had to make another fixture which is the exact diamter as the outside of the main shells, cylindrically ground to be parallel enough not to show up on any instruments in my posession. It has full contact all over the main bearing housing bores. Clock that fixture into the miller and now you can do polar coords off the crank axis. That is how I know everything is everywhere. It is also how I will fix it but in a different machine.    |

| |

|

|

|

|

|

|

|

Engine looks a bit air cooled VW, a bit motorbike and very bonkers  |

| |

|

|

|

|

|

|

|

The main bearings were de laminating because the bearing caps had been walking about. I take responsibility but the cap faces didn't get like that in my lifetime.   When the caps were torqued down, the stress was going through the shells. The idea is to skim the cap faces in the above fixture, make new caps undersize & send them for line boring. There will be a filler piece in the block which gets glued & pinned. Then they bore to a modern bearing size. Also, the new caps get bolted through a gusset plate to hold them down a bit better. While it is in this fixture we can bore the cylinder holes in the block to take a an insert which will be of a tougher material. That allows us to raise the heads a little bit and get a bit more room for when we stroke the crank. Oh yes and while it is there we will machine out the M8 head bolt threads & place an M10 or even M12 Helicoil there. Because I suppose we're going to need something to hold a blower down one day. |

| |

|

|

|

|

|

|

|

|

excellent thread & stunning engineering work.

|

| |

Todos con Lorca

|

|

|

|

|

|

|

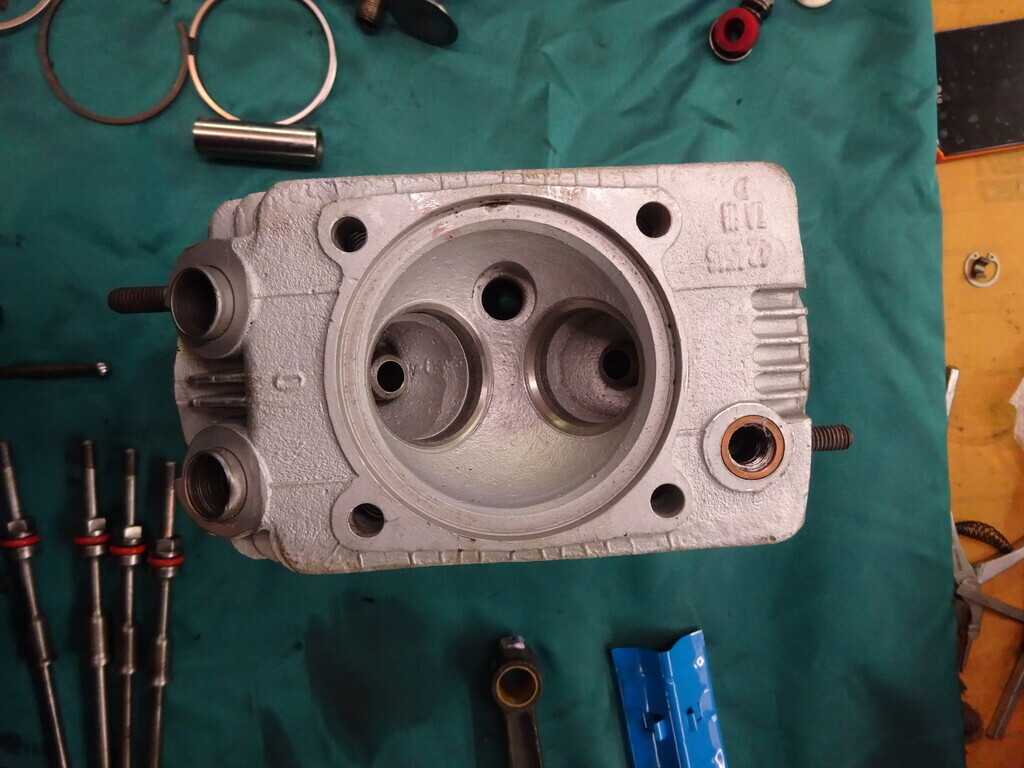

I know there is enough room for bigger bolts because I did a cutaway head whilst examining camshaft options. The camshaft is tame but if you mix and match different Tatra cams & followers in theory you get a hot cam. Done that already. It is still nothing to write home about.  |

| |

|

|

|

|

Ax GTi Turbo

Ax GTi Turbo