|

|

|

|

|

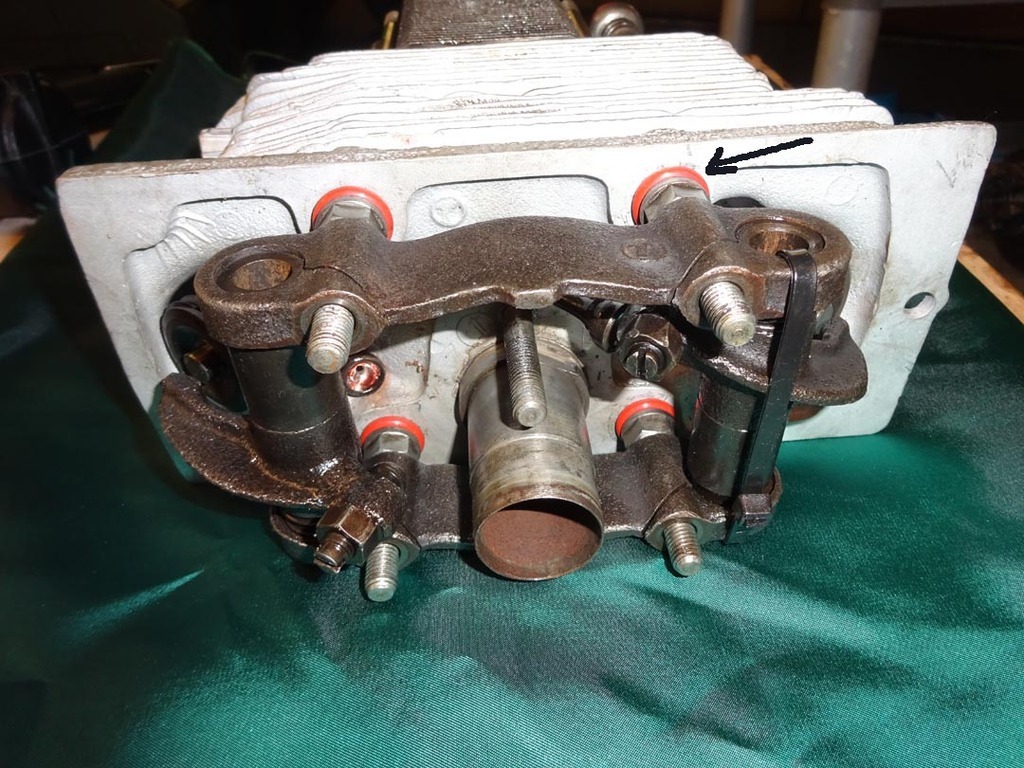

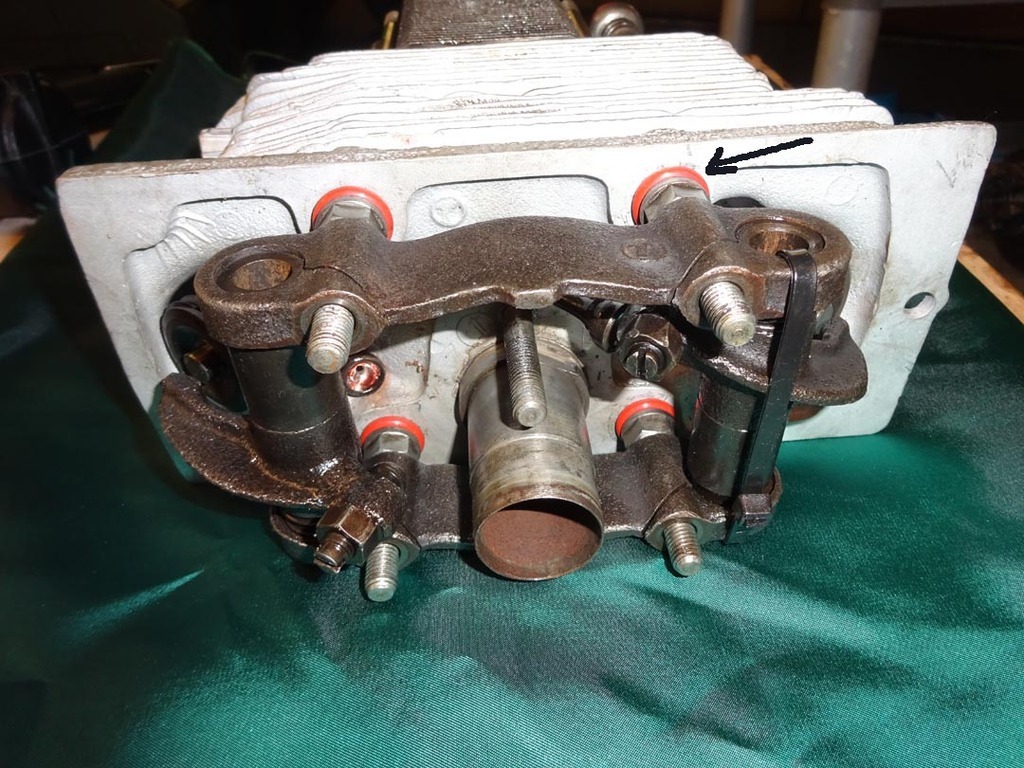

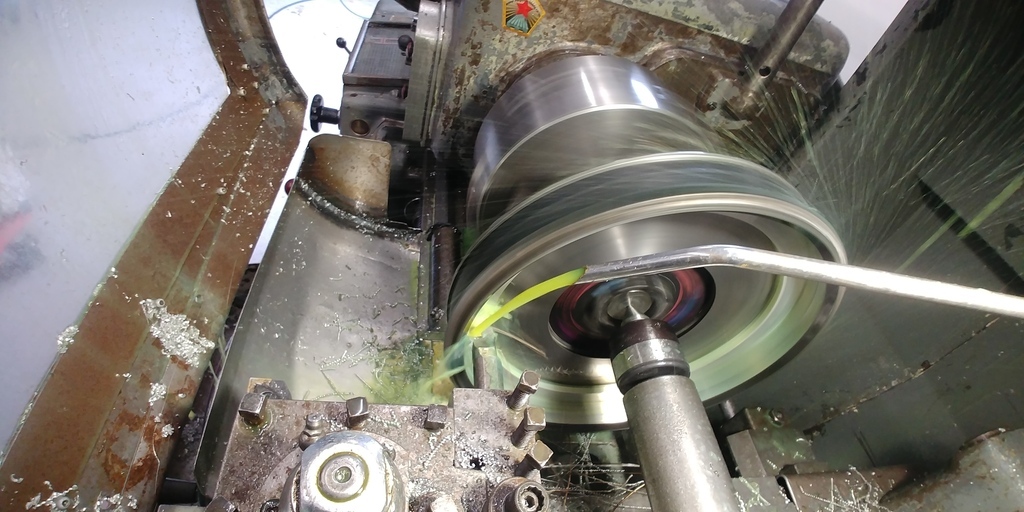

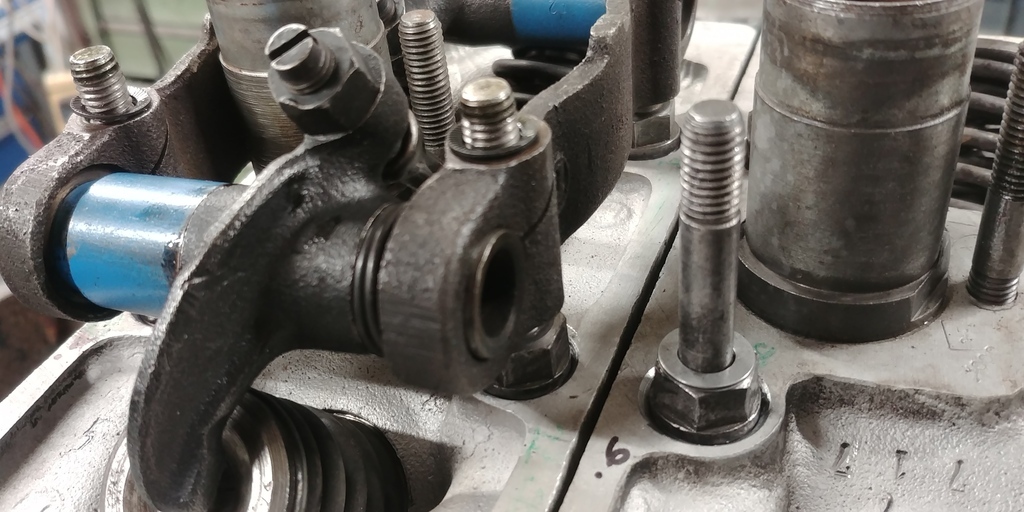

I have boxes of cylinder heads and not one is damaged. I don't think it is possible to break one. Bear in mind that the valve stems are fatter than the head bolts. I wonder if there could be any dimensional stuff going on there. Lets see...  They all appear to have been made alike so that is good. See those O rings at the top end of the bolt?  They are supposed to stop rocker oil from escaping. How can they do that if they don't even enter the bore? They don't. The dreadful things leak everywhere. That is 32 leaks you've got there, son. What happens is after a load of amateurs like me have been in & out of these engines, we get a stack of washers down the little hole. Machine them OUT!  Of course, we need another fixture for that. But that still isn't enough. The little hole has a nasty sharp edge on it which cuts the O ring & renders it useless. Knock the corner off the holes carefully with a radius cutter in a machine. Not by hand. If you go too deep you are back in the mire. And it isn't over yet. |

| |

|

|

|

|

Mike D

Club Retro Rides Member

Posts: 2,197

Club RR Member Number: 57

|

|

|

|

|

Absolutely fantastic 😃 keep up the good work 👍👍

|

| |

|

|

|

|

|

|

|

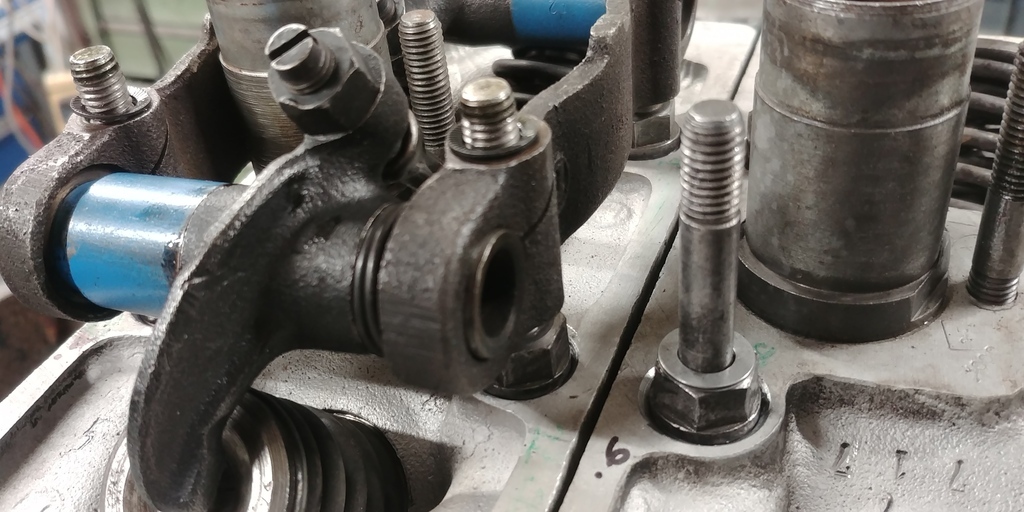

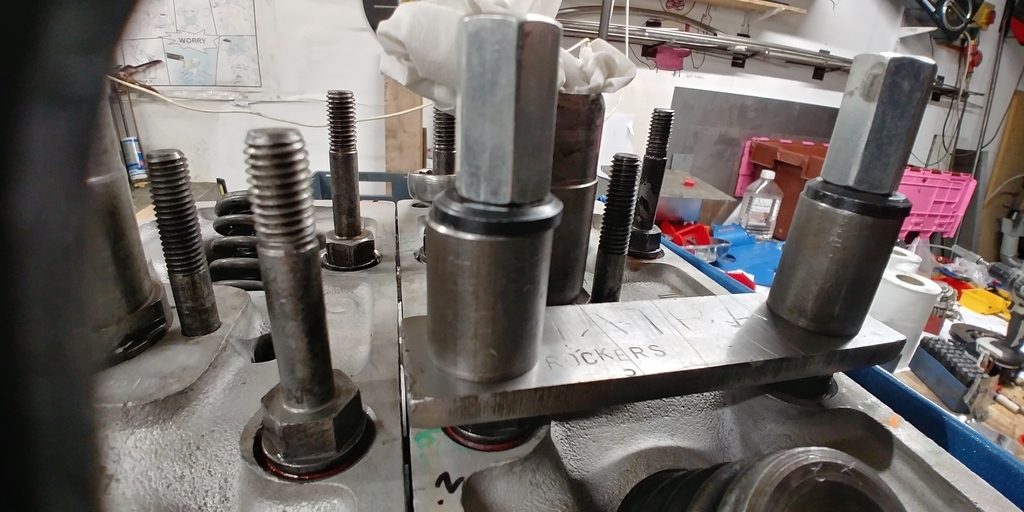

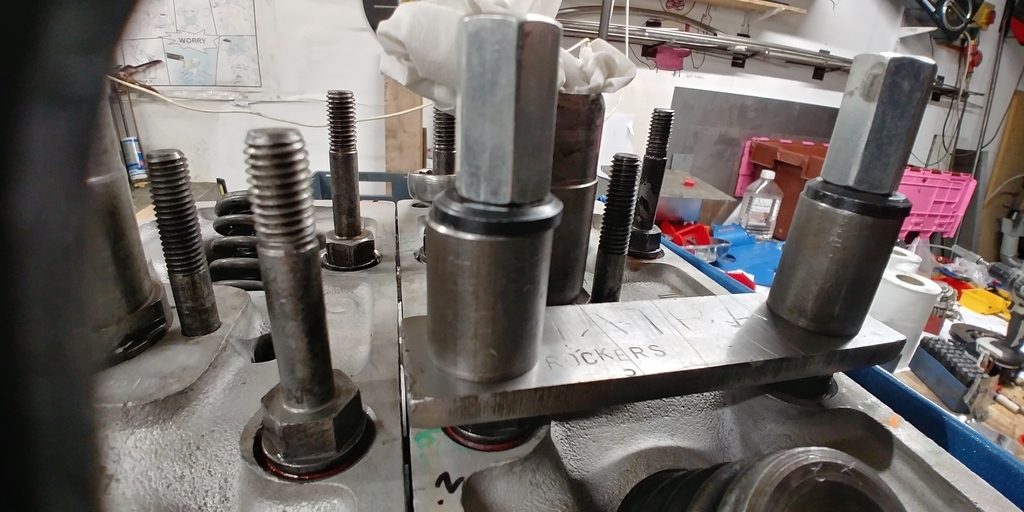

So the head bolts now go to the required depth. Are they level? What if they aren't level? The rocker shafts will have been on the wonk for 20 years & you will observe uneven wear on the shafts & the rocker faces. Never mind the uneven wear for now. Go for levelling up the rocker platforms. Torque down the heads, clamp the rocker levelling fixture in position & measure the height. Insert shim washers accordingly. They only need to be level in pairs.    I wonder if the rocker frames are right.... NO. Is there a fixture for that? yes there is! The frames are clamped in pairs in V blocks so whatever you do next will end up making the shafts level to the previous step.   If you have a pile of spares, go and get the best shafts & rockers otherwise make do & mend. How? I made a fixture to grind a new radius on the rockers so it is parallel to the shaft axis. You can be cheeky & shift the CROWN a little so you get a bit more lift. Forgot to photograph that. Sorry. So now the top end is quieter & more efficient but does it still leak? Oh yes. You could still have another 32 leaks in that area. |

| |

|

|

|

|

|

|

|

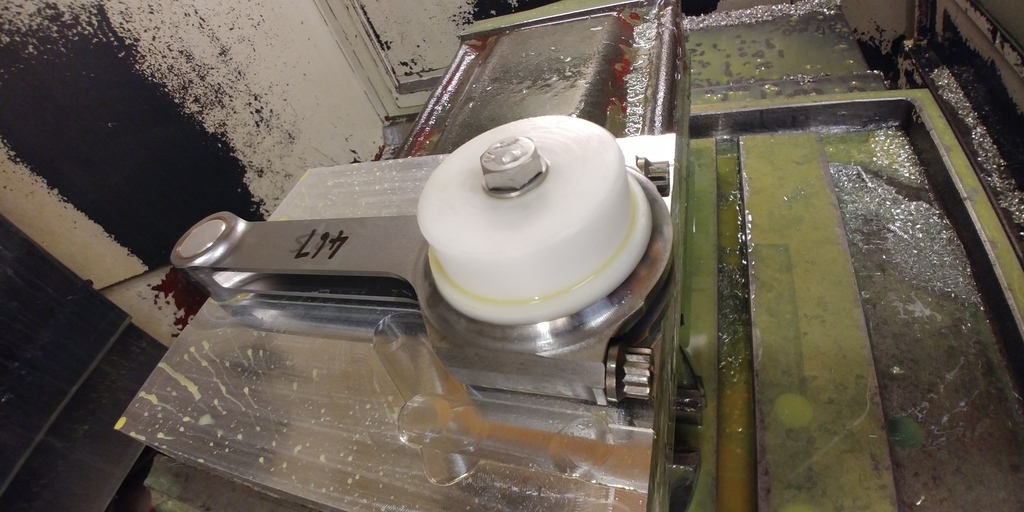

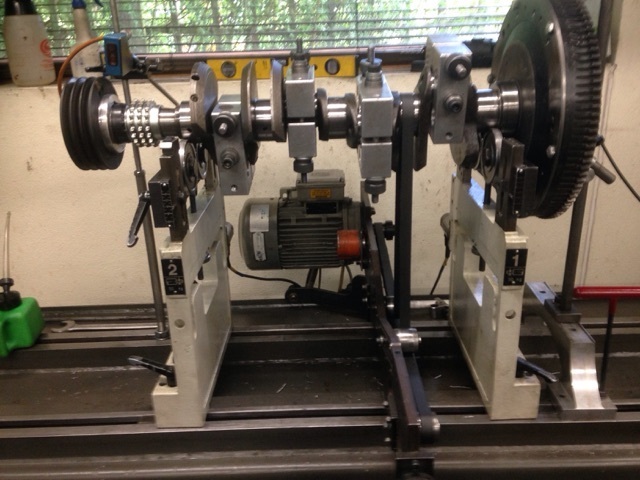

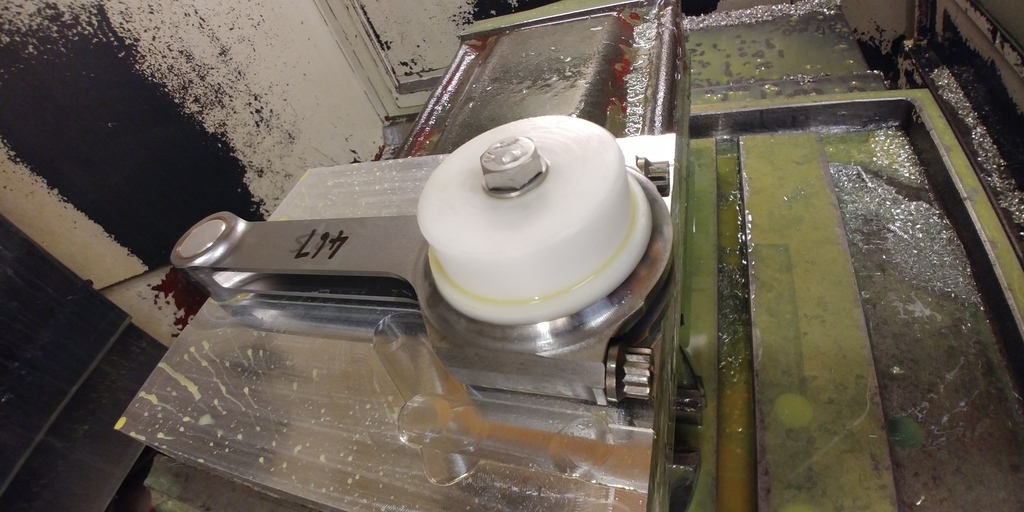

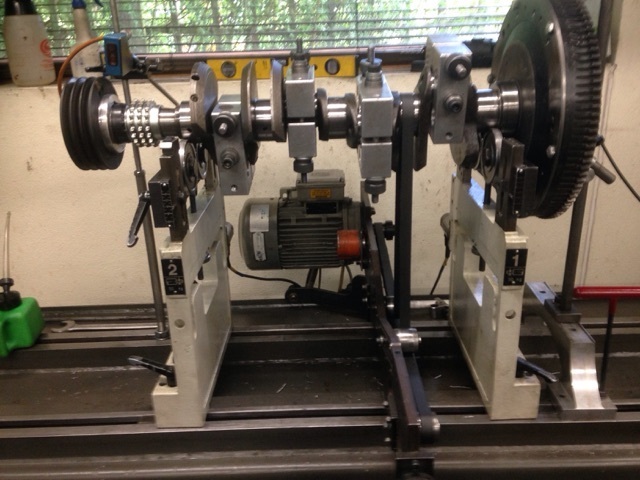

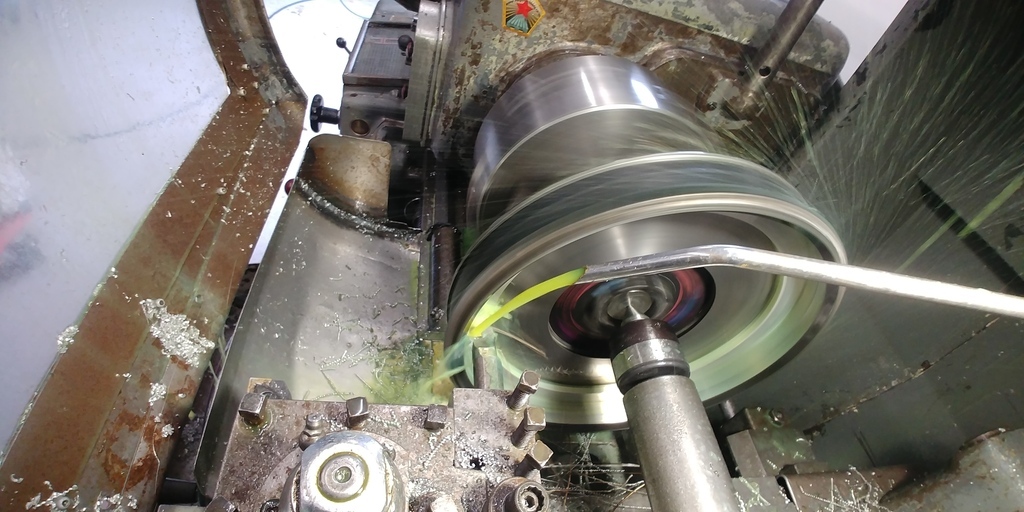

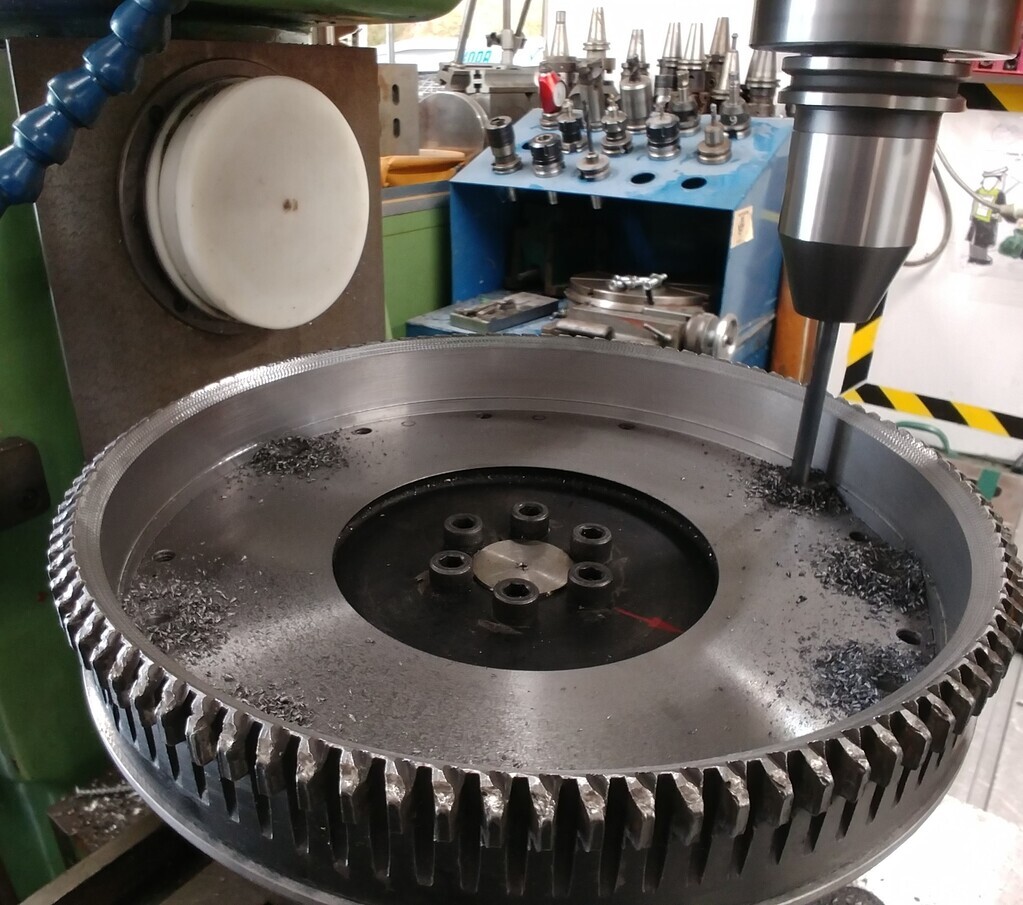

So what about these custom rods? I ordered them about 3 pages ago. Custom rods arrive & look good.  Did they measure? NO Did they weigh? NO. Words fail me but my chums higher up the pyramid of knowledge got that sorted. The rods were nice but a thou out of round. Sorted on a Sunnen hone at W Drake. They weighed 40 grams too much. Sorted on an old Hurco CNC. Of course, a fixture was required. $0 grams is about 1 1/2 sugar cubes of steel. Don't quote me on that, I don't use the stuff.     The guy at the apex of this pyramid of knowledge got the whole system into <1 gram.   |

| |

|

|

|

|

|

|

|

|

Thanks for making the time to share this.

Also you're mental, which is a good thing.

|

| |

|

|

ChrisT

Club Retro Rides Member

Posts: 1,670

Club RR Member Number: 225

|

|

|

|

Just stunned by this, what a great project, amazing attention to detail and skills involved  |

| |

|

|

|

|

|

|

|

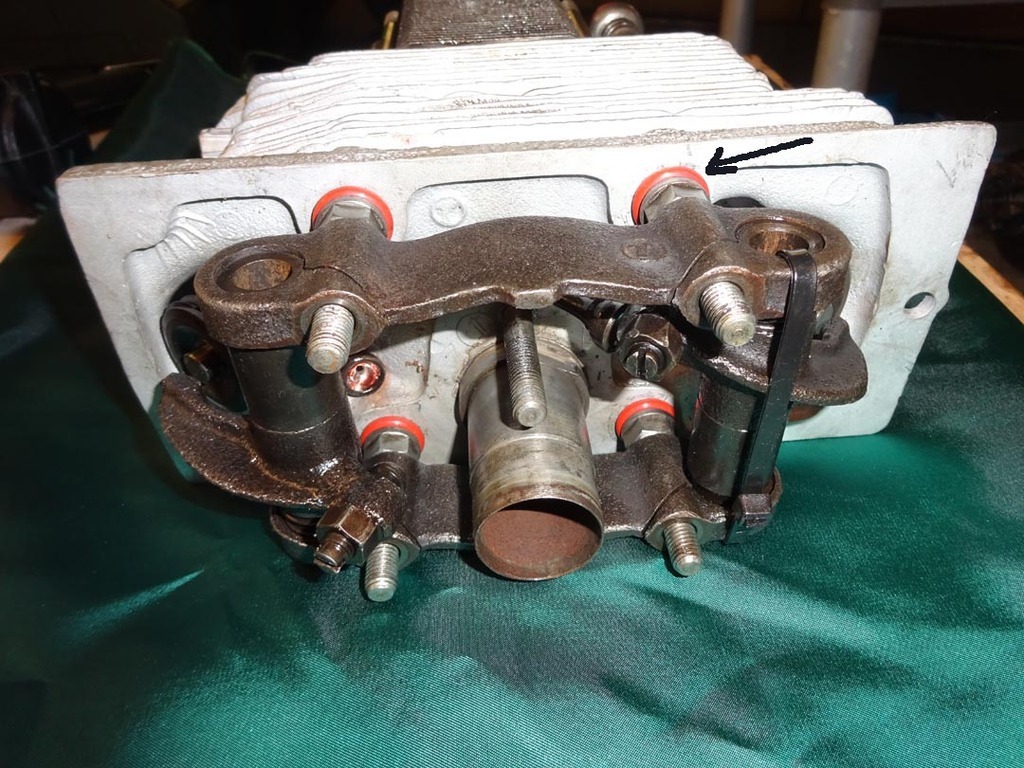

Lube: The original system was no different from any other manufacturer of that era. Bypass oil filter YUK! But SO MUCH WORSE. Really. They were only doing their best & all that entailed was keeping this avante garde rear engined torpedo running between city hall & brothel. Everybody knows this involves ascending a mountain. The climate is ridiculous ranging from minus double figures in winter to PLUS double figures in the summer. Unimaginable! Here is a flow chart Pump Relief valve ->tank 45psi Front of oil gallery (right next to the pump) -> Front bearings -> tank Oil cooler1 oil cooler2 gauze oil filter ->burst valve 15psi -> tank Rear of oil gallery 2 foot away from the pump tank So as you ascend the mountain the clean cool monogragde oil goes like butter & starves the rear bearings while the hot filthy muckment contaminates the front bearings. Its the work of a madman. So while it is in the fixture, drill a hole & connect the two feeds together & block the port near the first relief valve with a plug internally. Then make a spin on oil filter to replace the gauze & hey presto.    And they say I am spoiling it. You try and find a brothel up a mountain these days. |

| |

|

|

|

|

|

|

|

|

Ignition:

The ignition is MSD 6AL2 programmable. It is a bit old fashioned but so far reliable having clocked up about 8000 miles. You can program several ignition timing events such as nitrous, launch, burnout or something. It is all wired with switches on the dash & the launch trigger on the handbrake release button but I have no clue about how to use it. I only bought it to correct the Mallory distributor which runs backwards on that engine rendering the throw out weights worse than useless.

Instaed of being on show, it is hidden behind a shiny panel in the engine bay.

This gets its signal fron a Mallory distributor which came out of a hot Rover V8.

It has a Unilite module to distribute the spark signal.

The coil is a MSD Blaster2

HT leads Magnecor

I had a bit of fun with a car full of lads the other day at a set of lights in Manchester making fire come out of the pipes at 2000rpm. Is that what it's for?

|

| |

|

|

|

|

|

|

|

|

fantastic and bonkers i am a machinist my self making fixtures sometimes takes longer than the job you need it for

bookmarked

|

| |

|

|

|

|

|

|

|

|

|

|

|

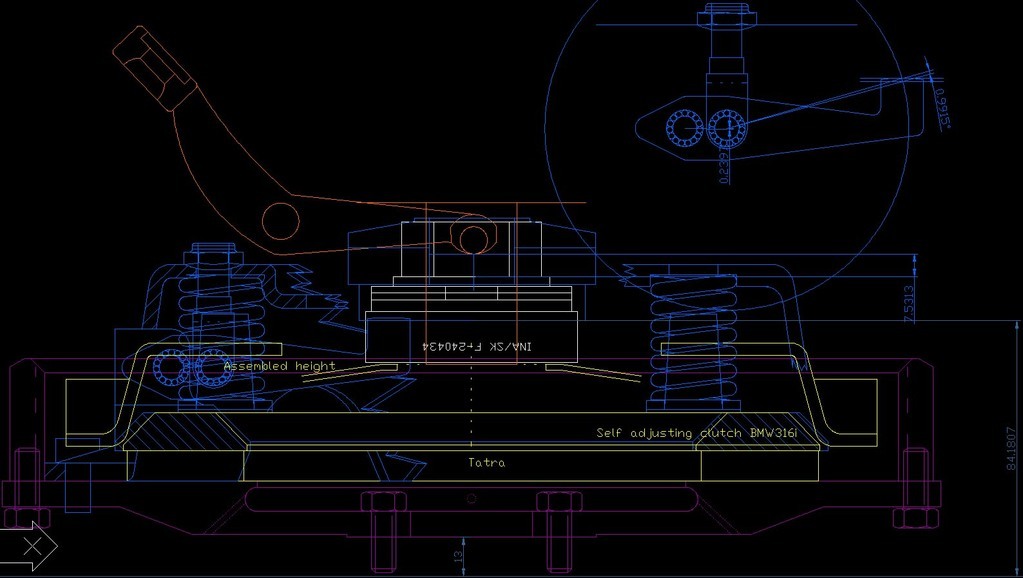

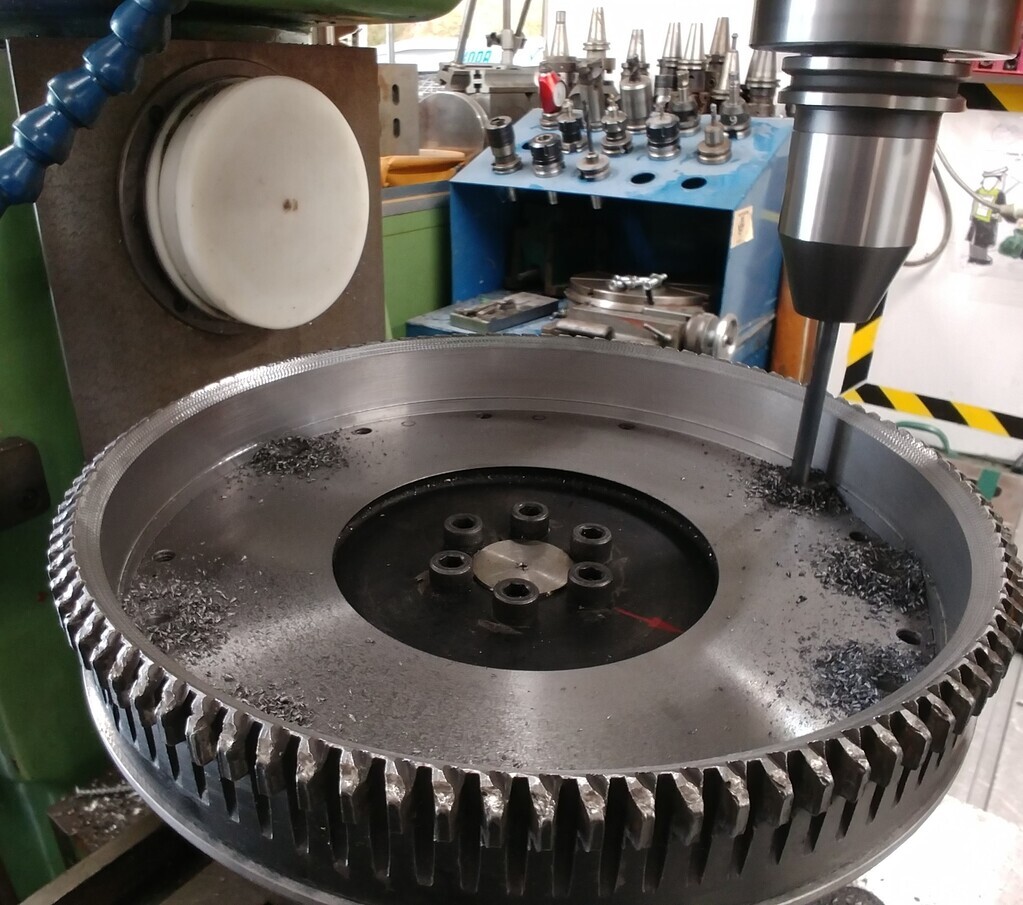

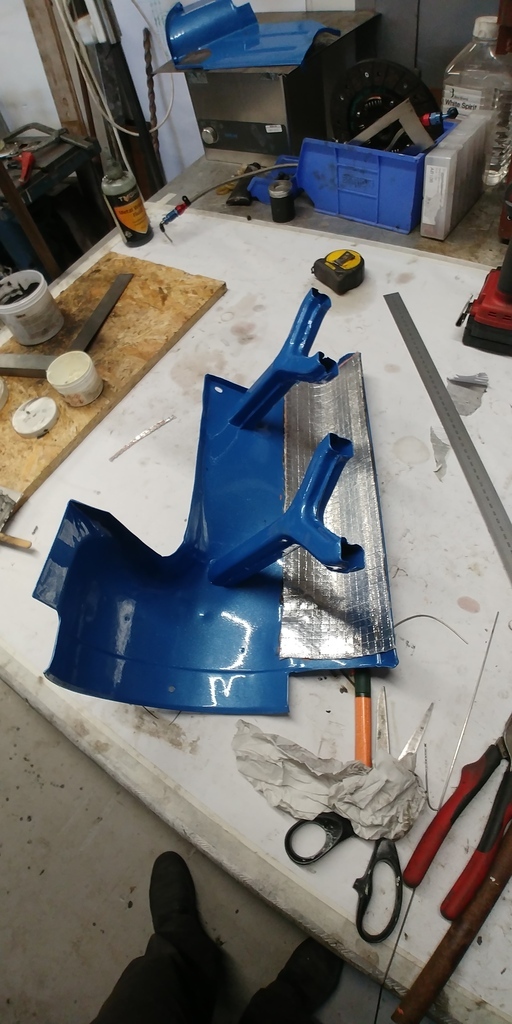

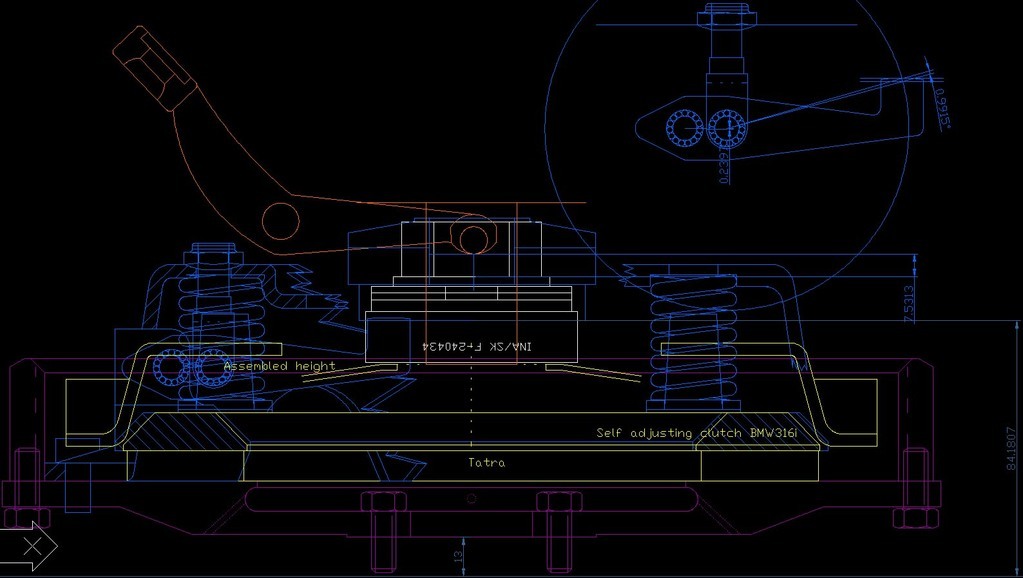

Clutch This was originally a Tatra clutch made of cast iron with 3 levers on unsealed needle roller bearings. Just remind me. Please, how much dust is allowed before that seizes up? I just decided to swap it for a BMW self adjusting clutch which weighs 3.5kg less. Can't tell any difference. Working on a concentric slave cylinder idea. I can't find a photo of the original clutch but here is a drawing showing them both together.  90 rollers, 6 pins & 6 split pins 3 pull rods 3 locknuts 3 arms 6 springs, 6 seats 1 cover 1 pressure plate 1 friction plate Thats a lot to go wrong. The modern one has almost the same assembled height, more grip, half the weight & costs less. Lets play with clutches. Yay!      |

| |

|

|

|

|

|

|

|

|

|

fantastic and bonkers i am a machinist my self making fixtures sometimes takes longer than the job you need it for bookmarked Toolmaking is nothing compared to sitting in front of this TV typewriter thing. I could have stripped & rebult the thing twice in this time. I hope everybody is enjoying it.

I'm telling you now, if I haven't said everything there is to say by tomorrow that is it. |

| |

|

|

|

|

|

|

|

|

Loving this project. What does an air cooled petrol V8 sound like on full song? I ask because a neighbour had a SAME air cooled diesel engined tractor for many years and the sound it made when working hard was totally different to any liquid cooled diesel engine we or other neighbours had.

Also wrt to your using oversized head bolts on the Tatra (mentioned on previous page) can a helicoil be trusted? Would it not be possible and far superior to tap a proper thread in the bored out hole?

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,975

Club RR Member Number: 71

|

|

|

|

Toolmaking is nothing compared to sitting in front of this TV typewriter thing. I could have stripped & rebult the thing twice in this time. I hope everybody is enjoying it. I'm telling you now, if I haven't said everything there is to say by tomorrow that is it. Thanks for sharing  |

| |

|

|

|

|

|

|

|

Toolmaking is nothing compared to sitting in front of this TV typewriter thing. I could have stripped & rebult the thing twice in this time. I hope everybody is enjoying it. I'm telling you now, if I haven't said everything there is to say by tomorrow that is it. Yes very much enjoying it, thanks for sharing |

| |

|

|

pptom

Part of things

Posts: 475

|

|

|

|

|

Absolutely amazing project and talent. Thanks for sharing.

|

| |

|

|

|

|

|

|

|

|

Really excellent work and great thread. You have me hooked.

|

| |

|

|

|

|

|

|

|

|

Absolutely stunned by the thought, quality and workmanship that's gone into this!

Looking forward to the next instalment.

|

| |

|

|

|

|

|

|

|

|

Mad as a box of frogs - and multi-talented. We are much blessed 🙂

Bringing the Tatra V8 kicking and screaming into the 21st century - fantastic!

Great thread, Great project, Great car!

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|