keyring

Part of things

Posts: 913

Club RR Member Number: 47

|

|

|

|

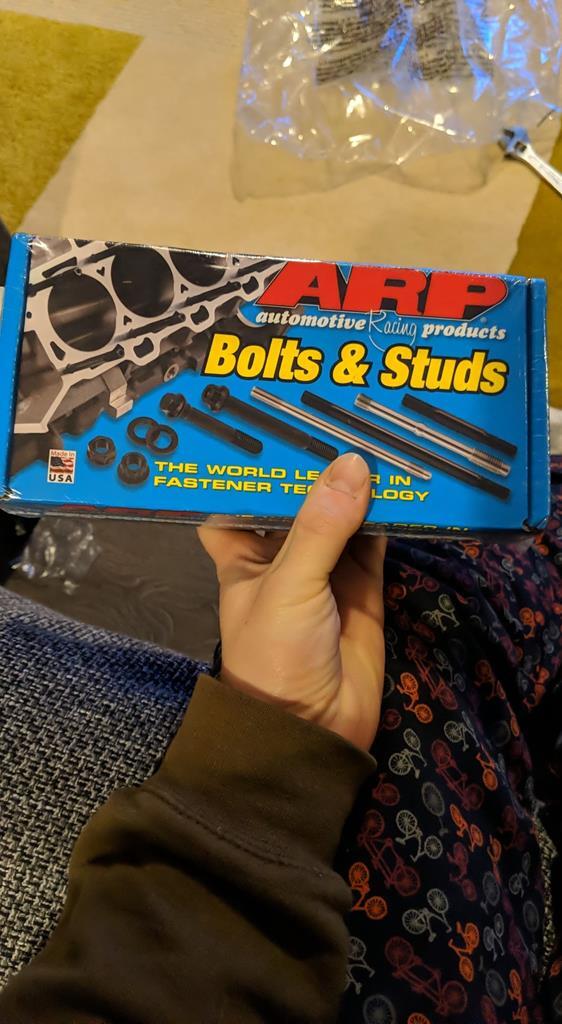

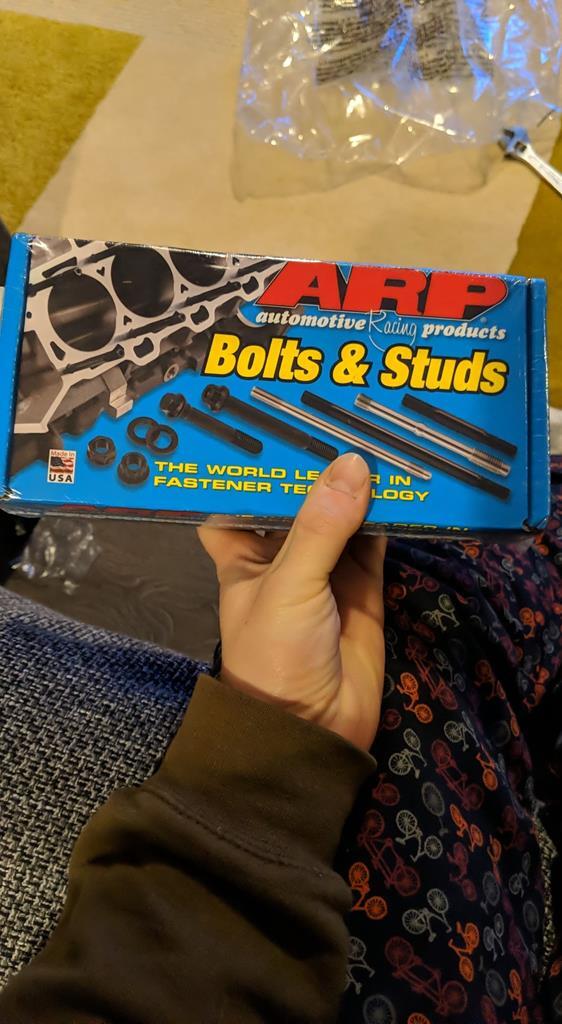

Hello again everyone... been extremely quiet on the forum for months now, I’ve been spending a lot of time doing extra shifts at work and working on the house, so I’ve not had too much time to sit on the forum unfortunately  Some of you will remember my mk2 thread, however it was pretty rusty, and after a lot of thinking, I decided it just wasn’t worth the work to make it solid again, and I was never having the time with trying to get the house work done... so I finally seen another mk2 golf for sale that looked like it fitted the bill for what I wanted, I believe a few people on here may know the car when the original owner had it... So the car in question is a mk2 driver shell, with full cage, 6 pot brakes, cut arches with mbl arches, kw v1 coilovers, smoothed bay and a mk5 r32 engine that didn’t run among other modifications (loom not made) people may remember the car from being red with a 3.1 bored out vr6 engine fitted. The car looked like this from the advert     So here i borrowed a friends trailer, hired a l200 and started to make the drive down from Edinburgh to Banbury first thing on the Saturday, made good time, got down, picked it up and got the obligatory photo for Facebook/Instagram  ( this is a few weeks ago before the whole Coronavirus situation started)  and got back to mine with it into the garage for 3am Sunday morning  So the car sat there and I went back to work, once back I treated myself to the highest axle stands I could find  I then got the engine pulled out with a friend...   Which takes me as far as I have went so far, the r32 engine is now sold and gone to a friend to go into his mk3 golf cabby. I plan to stick to the trusty 2.8 12v vr6 engine. Parts for these are cheaper when boosting them, and I had already collected a large amount of parts for going for more boost than my last set up... I have just swapped a friend my na 1.6 mx5 for his spare vr6 engine with arp rod bolts with new rings etc. These them arrived in the post...  so just need to get them fitted along with the decomp plate and start building the engine up ready to get it fitted. The shell itself, as you can see from the photos the interior needs a bit of a clean up, the floor could do with a bit of a repaint, there is some rust staining, mostly from there being some water lying in the floor from me collecting it, and 2 small bits needing a weld on the floor where the seat rails have been welded from the inside, but overall it just needs the engine and some mechanicals sorted and it’ll be out... That takes us up to the current progress, I’m awaiting a o2m 6 speed gearbox coming for it with a diesel gear set and quaife lsd fitted to it, which should make a big difference over what the standard vr6 box would Hopefully social distancing rules relax a bit once I’m home again, and I can start gathering some other bits for it and sell other parts that came with it I no longer need (hoping to pay for the bits I need, with money I get in from selling parts that came with this and from my other mk2 set up) RRG is my deadline, so let’s see how things go  |

| |

|

|

|

|

keyring

Part of things

Posts: 913

Club RR Member Number: 47

|

|

May 10, 2020 22:28:16 GMT

|

So I'd liked to have got stuck into the golf a lot more than I have done this time off, but instead I hired a skip, cleared out loads of rubbish from doing the house up, cleared loads of unneeded rubbish, and sold off a lot of the parts I no longer need from my first turbo set up (obviously posting and adhering to social distancing rules) However, with getting that all out of the road, I've managed to start doing more to the mk2. I have ordered a few bits, but I'll post them up as they arrive  So, unfortunately there is a couple of bits on the shell that need welding (Only small bits, where when the previous owner has had the bucket seat mounts welded into the car, the underseal has burned off, and then not been replaced  ) So these are the two on the passenger outer floor   So I thought it best to do one at a time, I cut the first one out (there was a tiny hole under the underseal just after it hence it looking like a much larger bit has been cut out)   I'll be honest, making the small panel with the curve/shape required I struggled with, and its not an exact copy, but once I had it tacked in a couple places, I could tap it into a better fit and shape.   So I got it welded in, from the inside of the car, and buffed the weld down with the edge of the grinder and the thin belt sander being careful not to touch the surrounding metal to prevent making it thin.   I could probably do with buffing just a couple of the welds back a little more to take the edge off of them... Finally, I checked it from the underside, and welded a couple small parts of it from the underside, and then buffed these welds back too...   The underside I wasn't as concerned about getting the welds completely flush, as once undersealed they aren't seen. I'm fully open to advice/constructive criticism, I'm going to read through the panel making thread again, but if anyone has pointers for me based on the photos that would be great, thanks! Hopefully get another couple bits done before I go! |

| |

|

|

jmsheahan

Club Retro Rides Member

Posts: 689

Club RR Member Number: 121

|

Mk2 golf vr6 turbo.... round 2jmsheahan

@jmsheahan

Club Retro Rides Member 121

|

|

|

|

Shame to hear about the other Mk2 but the new one looks like it's going to be fun! Bookmarked

|

| |

|

|

|

|

|

|

|

|

Nice, I saw this one for sale on FB MK2 group

|

| |

|

|

|

|

|

|

|

|

What! No bead roller, no folder, no shrinker - stretcher, no hydraulic press, no cnc cad cam! The sacrilege! Having spent several recent days reading a certain "build" thread I for one appreciate that you have just cracked on with no fuss and basic tools and just got on with it. Nice one, that will do.

|

| |

|

|

|

|

|

May 11, 2020 12:46:13 GMT

|

Repair is looking good, looking forward to seeing this progress  |

| |

1990 VW Polo Breadvan Berg Cup'd - Project Breadbin

1986 944 Lux

1987 944 Turbo

1971 Covin Turbo Coupe

|

|

keyring

Part of things

Posts: 913

Club RR Member Number: 47

|

|

May 11, 2020 22:49:54 GMT

|

Shame to hear about the other Mk2 but the new one looks like it's going to be fun! Bookmarked It is, but it just needs too much welding for me to find it worth keeping, a friend has bought it for a project though  Nice, I saw this one for sale on FB MK2 group Thanks, it wasn't completely as good as advertised, and the seller wasn't the greatest, but hey ho  What! No bead roller, no folder, no shrinker - stretcher, no hydraulic press, no cnc cad cam! The sacrilege! Having spent several recent days reading a certain "build" thread I for one appreciate that you have just cracked on with no fuss and basic tools and just got on with it. Nice one, that will do. Ha, I wish I had those tools and was good enough at bodywork to justify them, but it'll get there! Thanks  Repair is looking good, looking forward to seeing this progress  Thanks mate, my aim is RRG, hopefully that still goes a head! |

| |

|

|

keyring

Part of things

Posts: 913

Club RR Member Number: 47

|

|

May 11, 2020 23:36:25 GMT

|

So, today I got the next patch done, I did start late in the day, but it still feels like it takes me forever while doing this kind of work, I remade this panel 3 times before I was happy enough to fit it, and even then I think it could be better. Practise makes perfect though, so by the time I do the last one, I should be half way there with making the panels (these aren't even complicated  ) So the section to be repaired today was... I actually found a little hole under the underseal too... There are also a couple of holes that look like something has been previously fixed to them. I'll weld them up at a later point.  So I got the piece cut out and prepared    I actually ended up making the hole I had cut slightly more square, to help making the panel easier to shape So three attempts later...  Again I ended up tacking it in, and then doing the final shaping. I welded it fully and then buffed back as much as I could, again while trying to be careful not to take away too much original metal.     I won't document the rest of the patches required as much as this, these ones have purely been to get feed back from people that now a lot better then myself on how to do this kind of work and hopefully get feedback and constructive criticism. I'll get the small holes beside this patch welded up when I start doing the other patches. |

| |

|

|

keyring

Part of things

Posts: 913

Club RR Member Number: 47

|

|

|

|

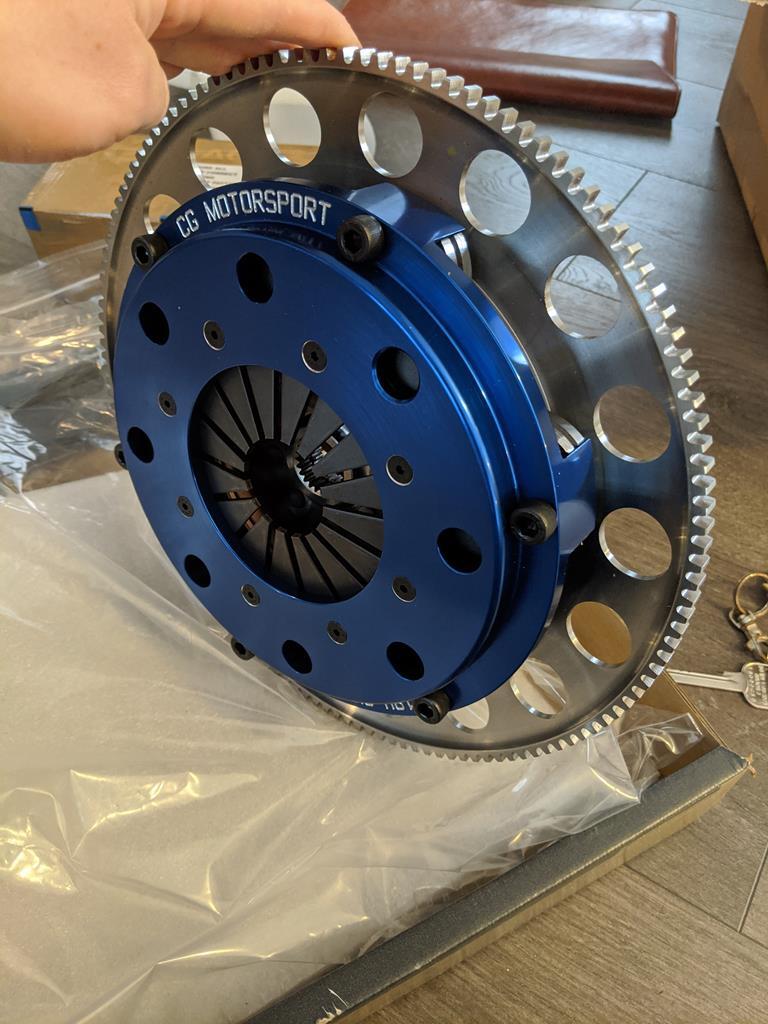

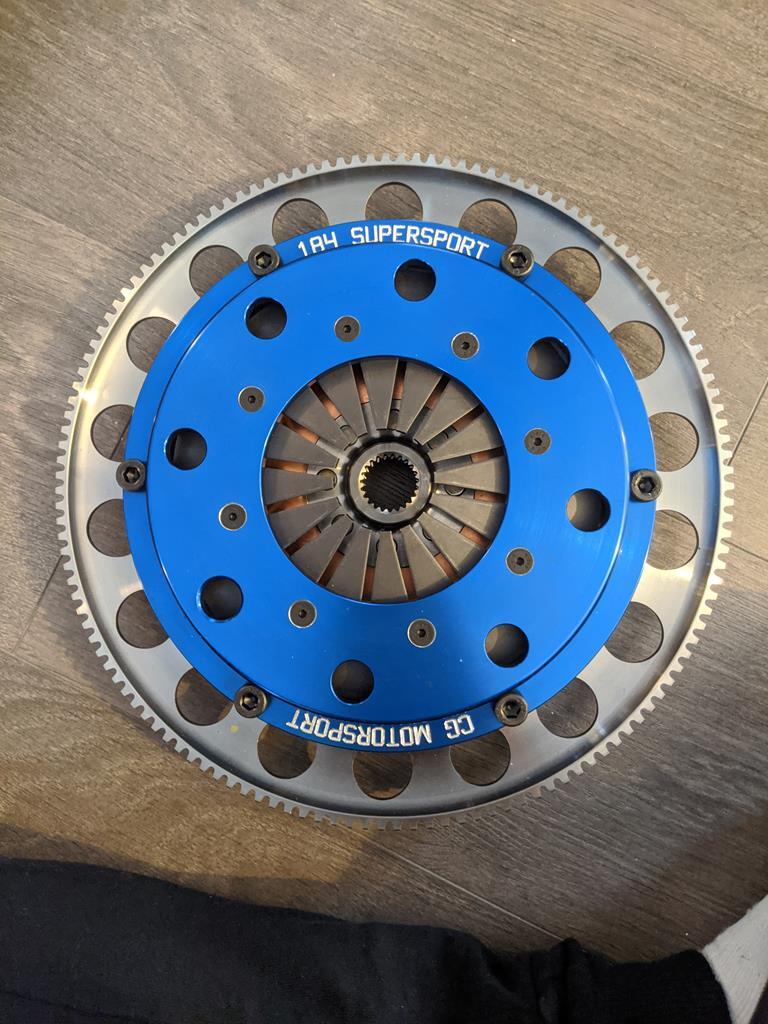

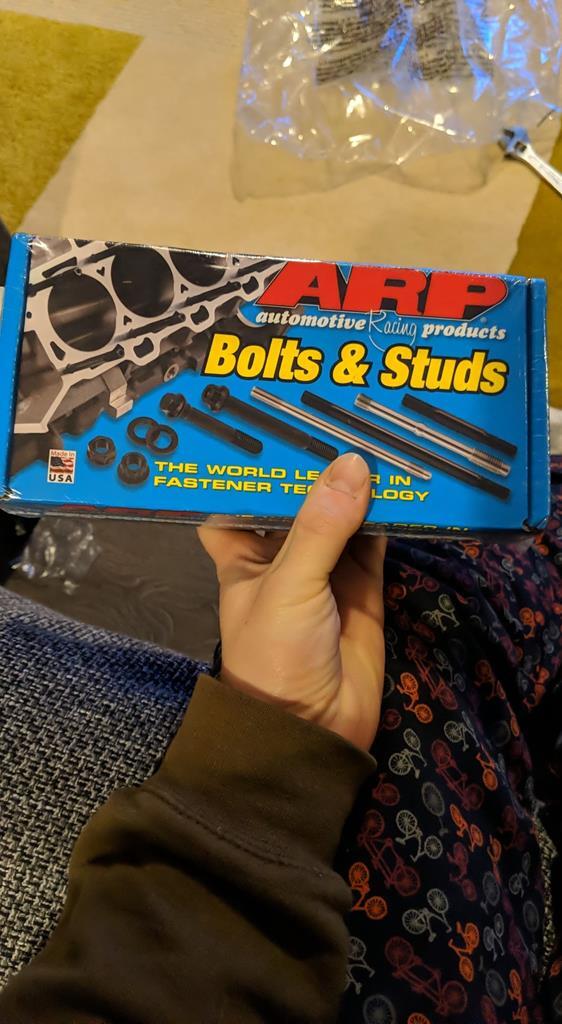

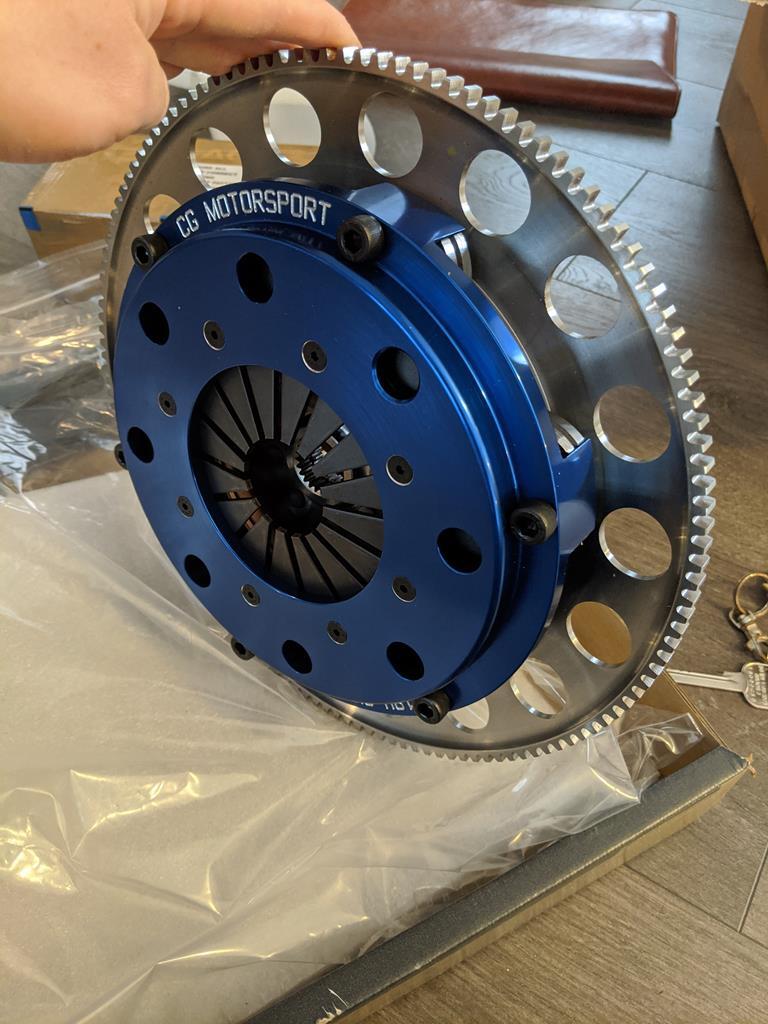

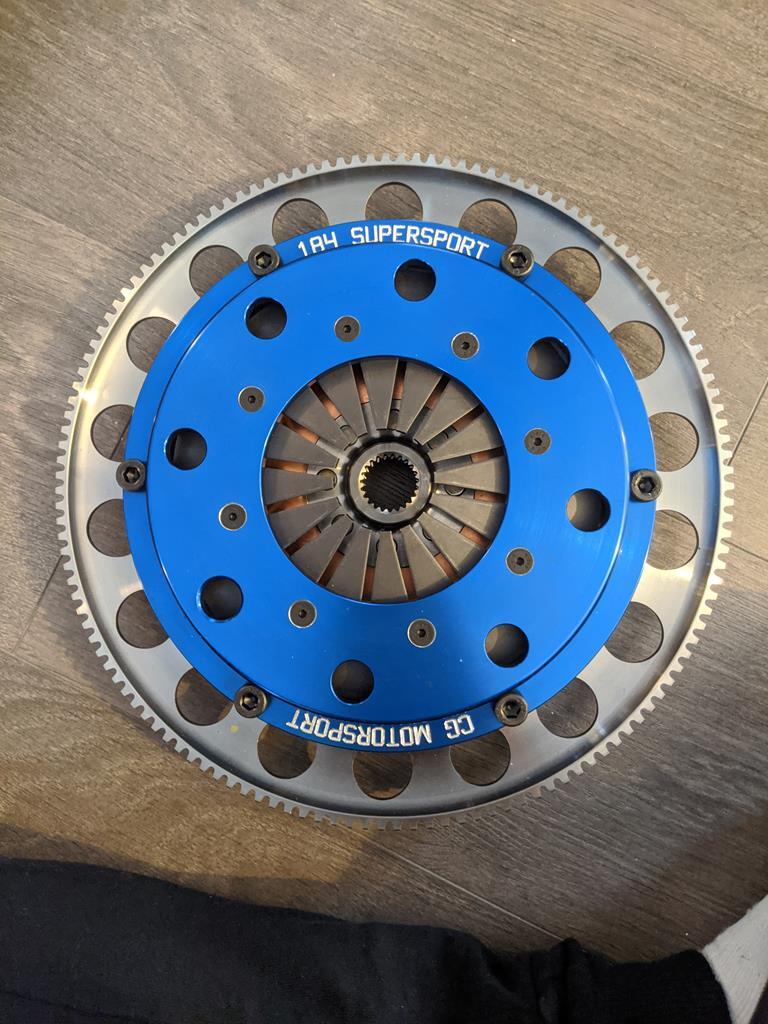

Well, i'm back at work now for 2 or 3 weeks, but managed to get my clutch delivery before I went away... After seeing it, i'm unsure whether to hang it on the wall to look at or to fit it   I went for a CG motorsport twin disc clutch from their 888-series (I've used them for all my clutches and can't recommend them enough if anyone needs a clutch)    My intercooler also arrived while I was home, i've went for a 600x300 cooler with a 3" core. I've got some trimming to do to make it fit, but it should be ok!  I have had this inlet manifold for couple of years now, but due to fitting the intercooler with the inlet and outlet at the top for space reasons, it will make it a lot tidier for the pipework and routing to have the manifold coming out on the drivers side as i'm going to run a sidewinder manifold for the turbo. There doesn't seem to be anywhere that sells manifolds coming out on the opposite side for the VR6 so this is currently away getting modified to face the other way   Next on the parts delivery I got was the bracket for fitting the O2M gearbox. In addition to this bracket, I also need to cut the gearbox mount cup off of the subframe and weld it slightly further back to allow clearance for the driveshaft. The driveshafts I also need to get ordered up as these will be a difference length and will have the 108mm cup on the inner CV and the VR6 outer CV as I run 5x100 widetrack   And then the only other thing I got while I was home, was I swapped my mk1 mx5 for another VR6 engine with a friend (following social distancing of course!) I didn't have much drive or time to work on the mx5, and he had a VR6 he had stripped and semi-built back up, it's had ARP rod bolts fitted, all new bearings, rods, chains, tensioners and guides. He decided to go down a different engine route, the engine needs the rings gapped and I've had ARP head studs sitting for my engine so i'll fit them to this engine instead since its pretty much all new!  My plan is, once i've got the the patches done on the floor of the golf, i'll get the engine stripped apart, ensure everything is clean, get the rings gapped and get everything built back up... and get rid of the green paint on the block  |

| |

|

|

OGDB

Part of things

Posts: 544

|

|

May 16, 2020 13:43:24 GMT

|

|

What an awesome car! I’ve had a 3.2 for about 7/8 years now and I love it. I have a friend with an R32 and he is equally as fond of his. They seem just a great engine. My friend has a GT500 and speaks of both engines fondly.

I have considered turboing mine for a number of years, however never pulled the trigger. Funnily enough I was looking at the 3.2 engines earlier today, however I’d want to use mine in a RWD application.

I’ll follow this with interest.

|

| |

|

|

keyring

Part of things

Posts: 913

Club RR Member Number: 47

|

|

May 17, 2020 11:59:20 GMT

|

What an awesome car! I’ve had a 3.2 for about 7/8 years now and I love it. I have a friend with an R32 and he is equally as fond of his. They seem just a great engine. My friend has a GT500 and speaks of both engines fondly. I have considered turboing mine for a number of years, however never pulled the trigger. Funnily enough I was looking at the 3.2 engines earlier today, however I’d want to use mine in a RWD application. I’ll follow this with interest. Thanks, I sold my 3.2 and stuck with the 2.8 due to having a couple of spare engines and already had all the turbo parts sitting, strength wise they are pretty much the same, so not much advantage of using the newer engines especially when going standalone management anyway! You can buy adapter plates to go from the VR6 block to a 350z gearbox, there's also one to go to an american box (I want to say TH 350 or TH 400 box - But not 100%) |

| |

|

|

( this is a few weeks ago before the whole Coronavirus situation started)

( this is a few weeks ago before the whole Coronavirus situation started)

( this is a few weeks ago before the whole Coronavirus situation started)

( this is a few weeks ago before the whole Coronavirus situation started)

)

)